A reciprocating cocoon harvesting propulsion mechanism for industrial farming

A propulsion mechanism, reciprocating technology, applied in animal husbandry and other directions, can solve the problems of inability to meet factory breeding, low efficiency, etc., and achieve the effects of simple structure, noise reduction, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

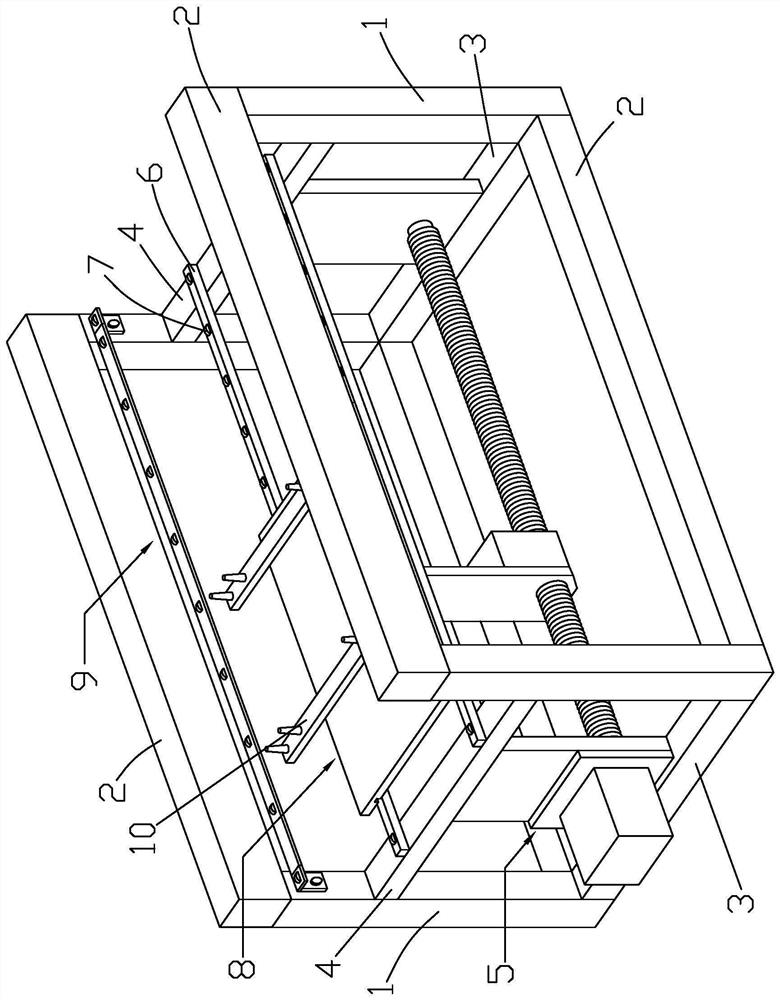

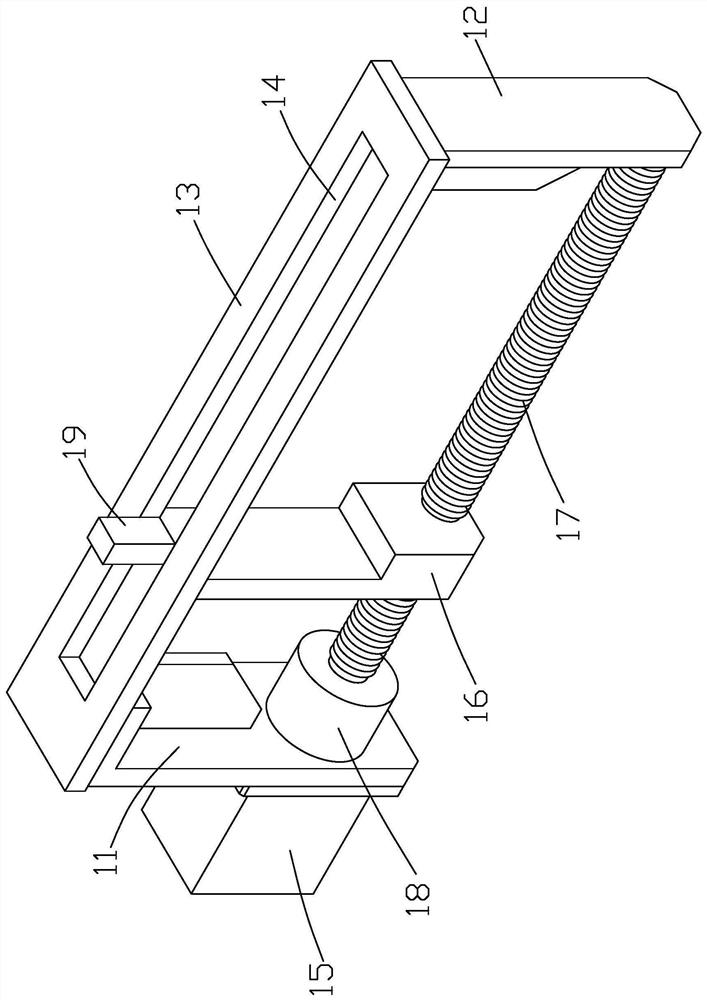

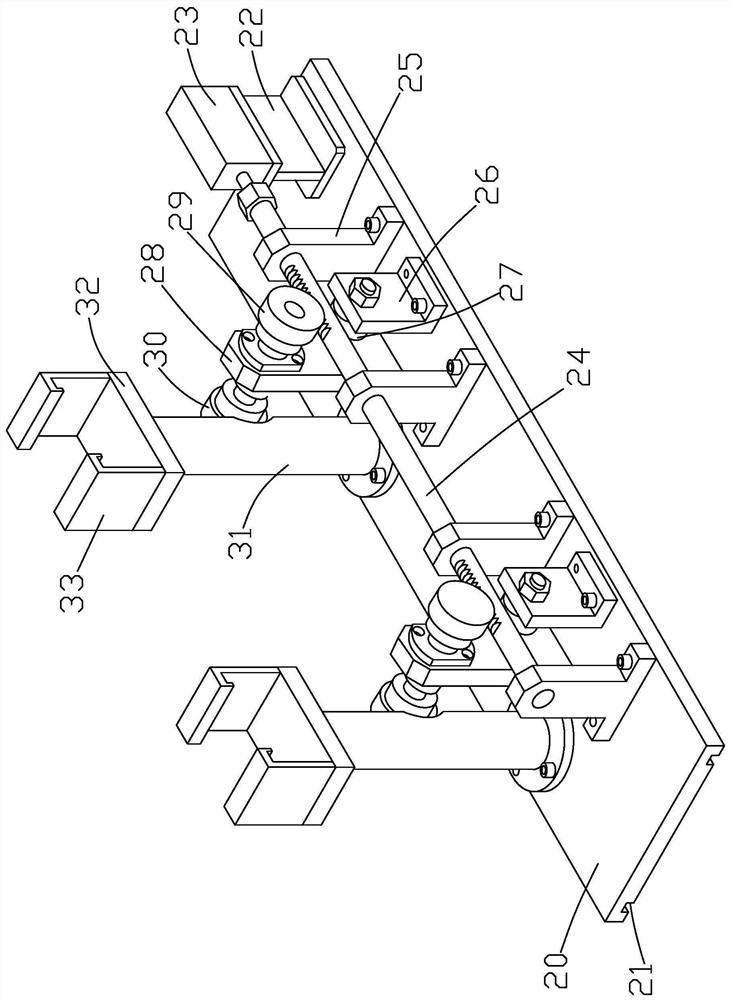

[0031] Such as Figure 1 to Figure 6As shown, it is a reciprocating cocoon harvesting propulsion mechanism for industrialized farming of the present invention, which includes a column 1, a booster mechanism 5, a jacking mechanism 8 and a cocoon cage guiding mechanism 9, and the four columns 1 are arranged in a rectangular shape parallel to each other. The top and bottom surfaces of the two columns 1 on the same side are fixedly connected by a crossbeam 2, and a lower support rod 3 and an upper support rod 4 are arranged in parallel between the two opposite columns 1, and the lower support rod 3 is located on the upper support rod 4. Below, the booster mechanism 5 is arranged between two upper support rods 4 and two lower support rods 3 parallel to each other, and the booster mechanism 5 includes a driving motor 15, a screw rod 17, a first baffle plate 11 and a second baffle plate 12. The first baffle plate 11 and the second baffle plate 12 are vertically fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com