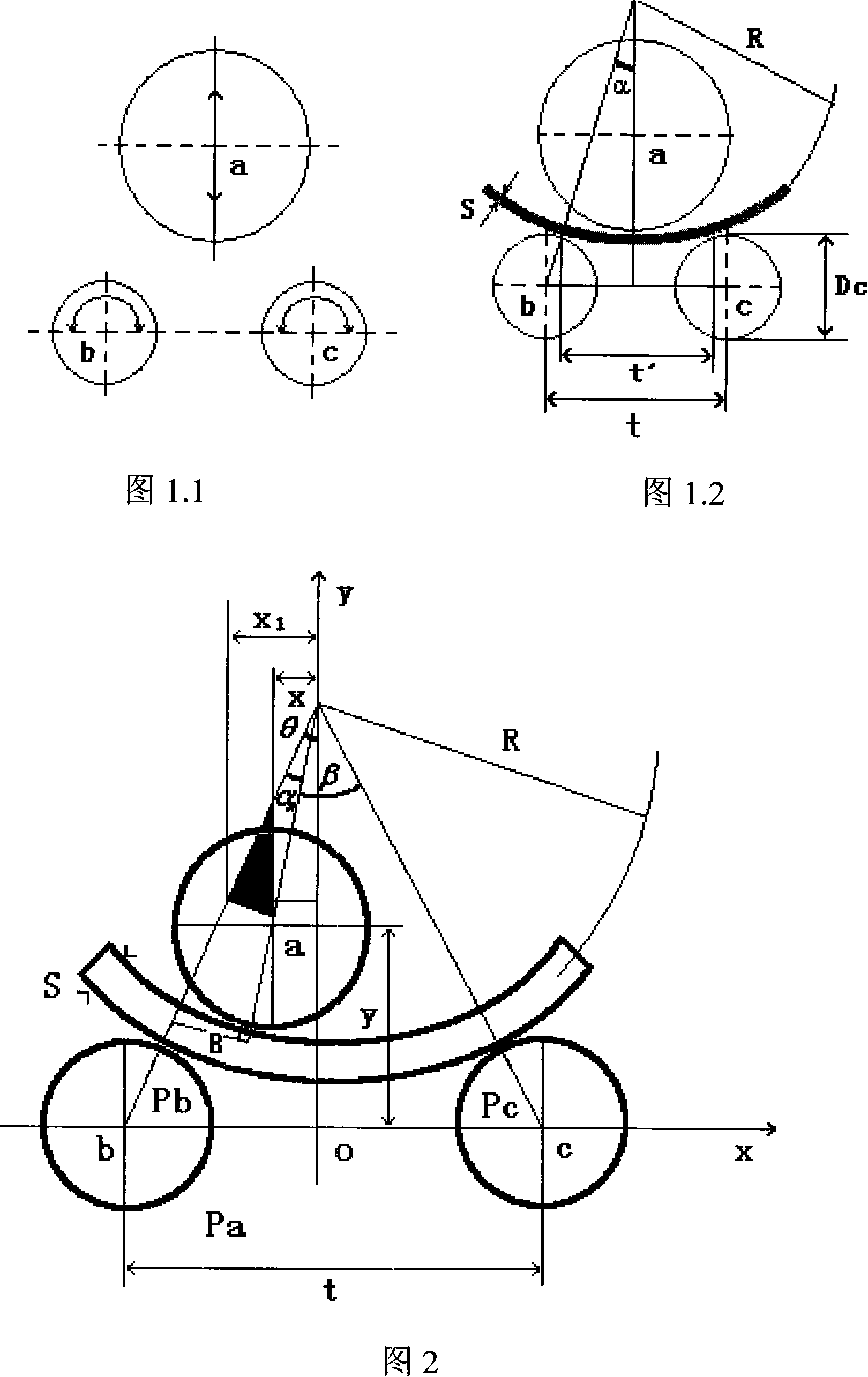

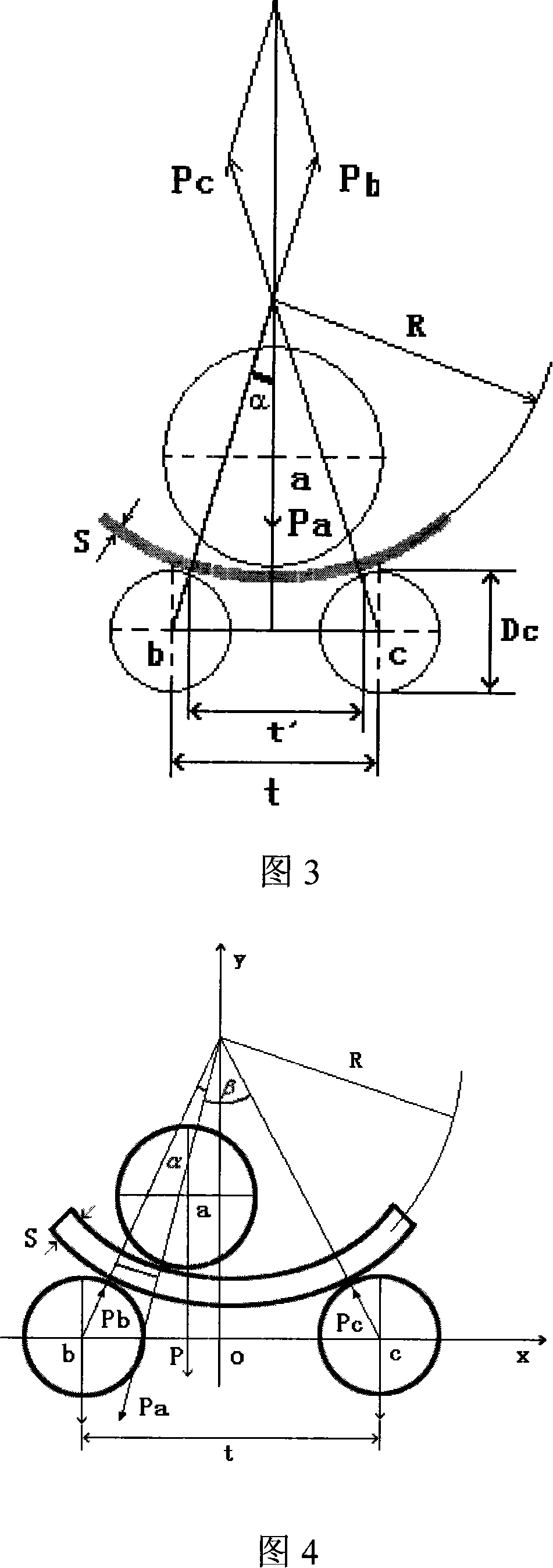

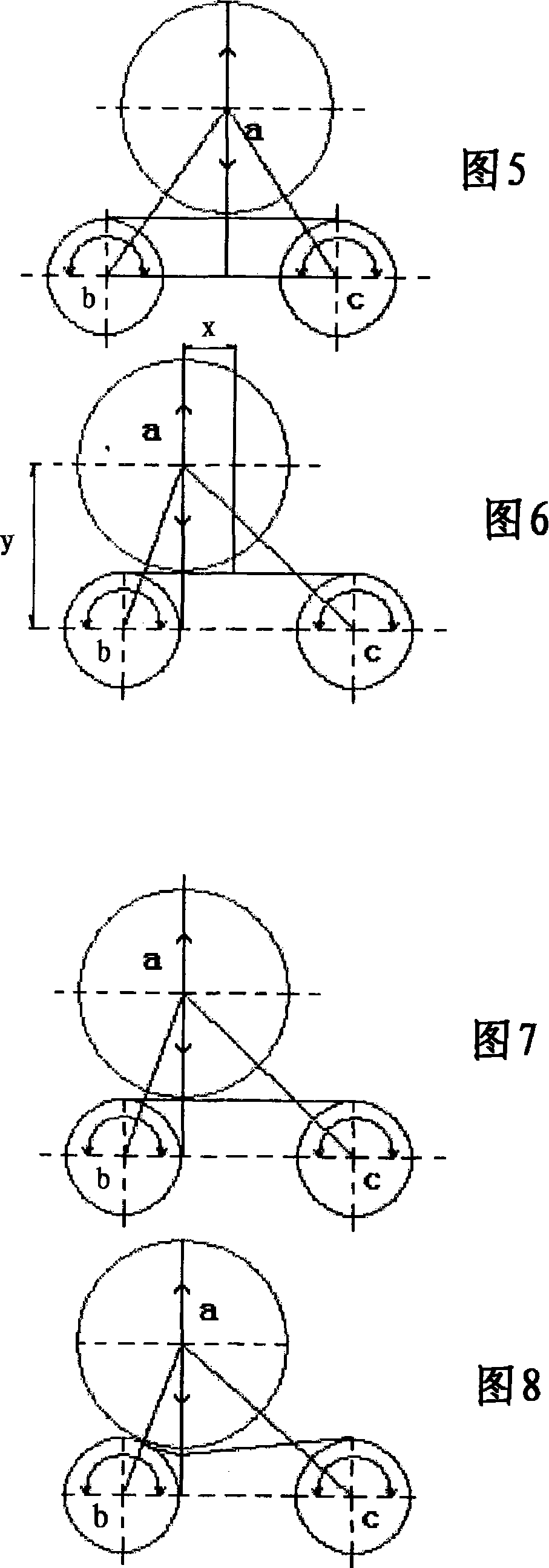

Control method for horizontal down-regulation type 3-roller lapping machine

A level down, control method technology, applied in the field of mechanical equipment control, can solve the problems of low control precision and large coiling precision error, and achieve the effect of high control precision, small coiling precision error and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] specific implementation

[0122] Next, we will use a set of specific data to carry out case calculation. The model of calculation plate rolling machine is the horizontal down-adjustment type 36×2000 produced by our company. The specific equipment parameters are:

[0123] Upper roller diameter Da=500mm

[0124] Lower roller diameter Db=260mm

[0125] Lower roller diameter Dc=260mm

[0126] Master cylinder diameter Din=320mm

[0127] Lower roller center distance t=490

[0128] Maximum coil thickness Smax=36mm

[0129] Maximum coil width bmax=2000mm

[0130] The maximum output pressure value of the master cylinder Pmax=20Mpa

[0131] Upper roller self-weight Ga=5200Kg

[0132] Upper roller span La=2145mm

[0133] Lower roller span Lb=2400mm

[0134] Horizontal maximum stroke Hmax=120mm

[0135] The user input parameters are:

[0136] Plate thickness 35mm

[0137] Plate width 2000mm

[0138] The inner radius of the roll is 1500mm

[0139] Yield limit 245

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com