Three-degree-of-freedom micro-positioning platform based on symmetrical double compliant hinge

A technology of micro-positioning platform and compliant hinge, applied in the field of manufacturing, can solve the problems of affecting the displacement and positioning accuracy of the micro-positioning platform, the sag of the compliant hinge, and the inability to generate axial linear displacement, etc., to achieve improved displacement accuracy, large thrust, and good rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

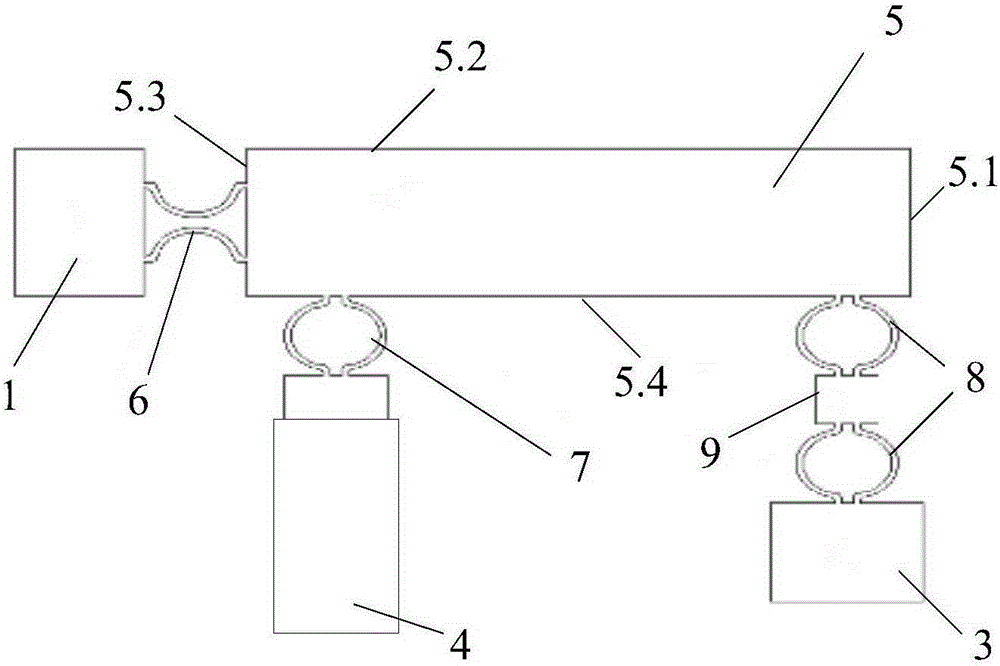

[0029] In this embodiment, the cross section of the single compliant hinge in the double compliant hinge 1, the double compliant hinge 2 and the double compliant hinge 3 is semicircular as an example to describe the following.

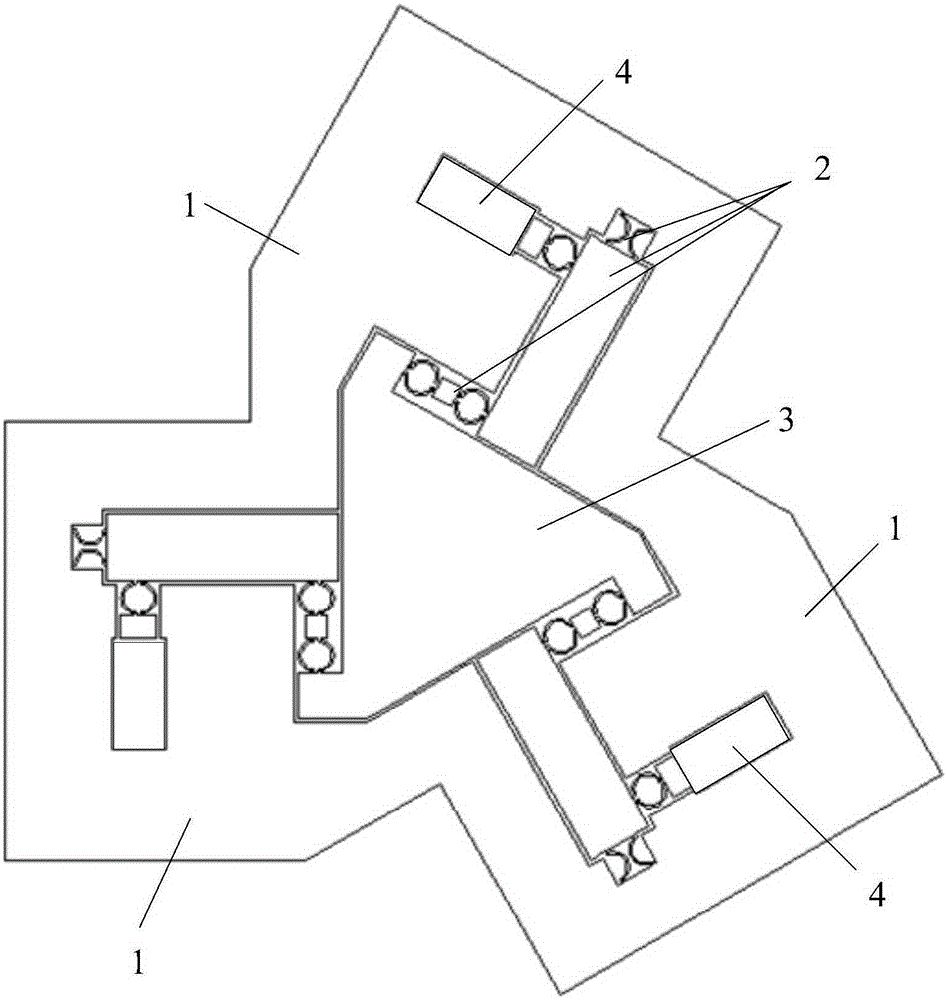

[0030] Such as figure 1 and figure 2 As shown, the three-degree-of-freedom micro-positioning platform based on symmetrical double compliant hinges of the present invention includes a fixed platform 1, a moving platform 3, a piezoelectric ceramic driver 4 arranged on the fixed platform 1, and a fixed platform 1 for connecting the fixed platform 1 and the moving platform 3. The three lever amplifying mechanisms 2; the three lever amplifying mechanisms 2 are evenly arranged on the periphery of the moving platform 3, and are respectively connected with the fixed platform 1, the moving platform 3 and the piezoelectric ceramic driver 4.

[0031] Wherein, each lever amplifying mechanism 2 includes a movable lever 5, a double compliant hinge and a guide mech...

Embodiment 2

[0038] The difference between this embodiment and the first embodiment is that the cross section of the single compliant hinge in the first double compliant hinge, the second double compliant hinge and the third double compliant hinge is arc-shaped, arc-shaped, semi-elliptical or other shapes.

[0039] Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com