Gas chromatography for analyzing methane and nitrous oxide in air by one sample injection

A gas chromatography and nitrous oxide technology, applied in the field of nitrous oxide and gas chromatography to analyze methane in the atmosphere with one sample injection, can solve the problems of large data accuracy error, prolong the sample measurement period, etc., and reduce the data accuracy error. , The effect of shortening the sample measurement cycle and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

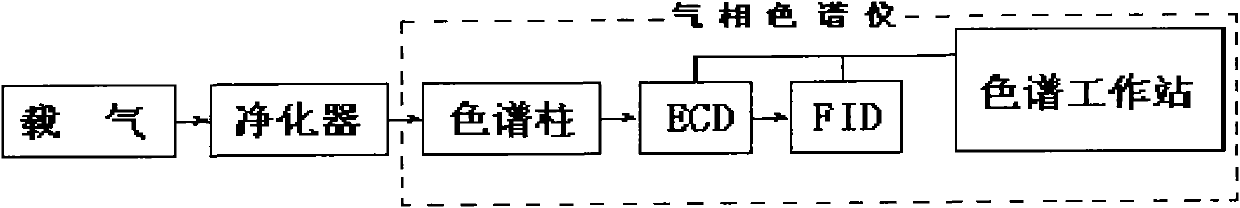

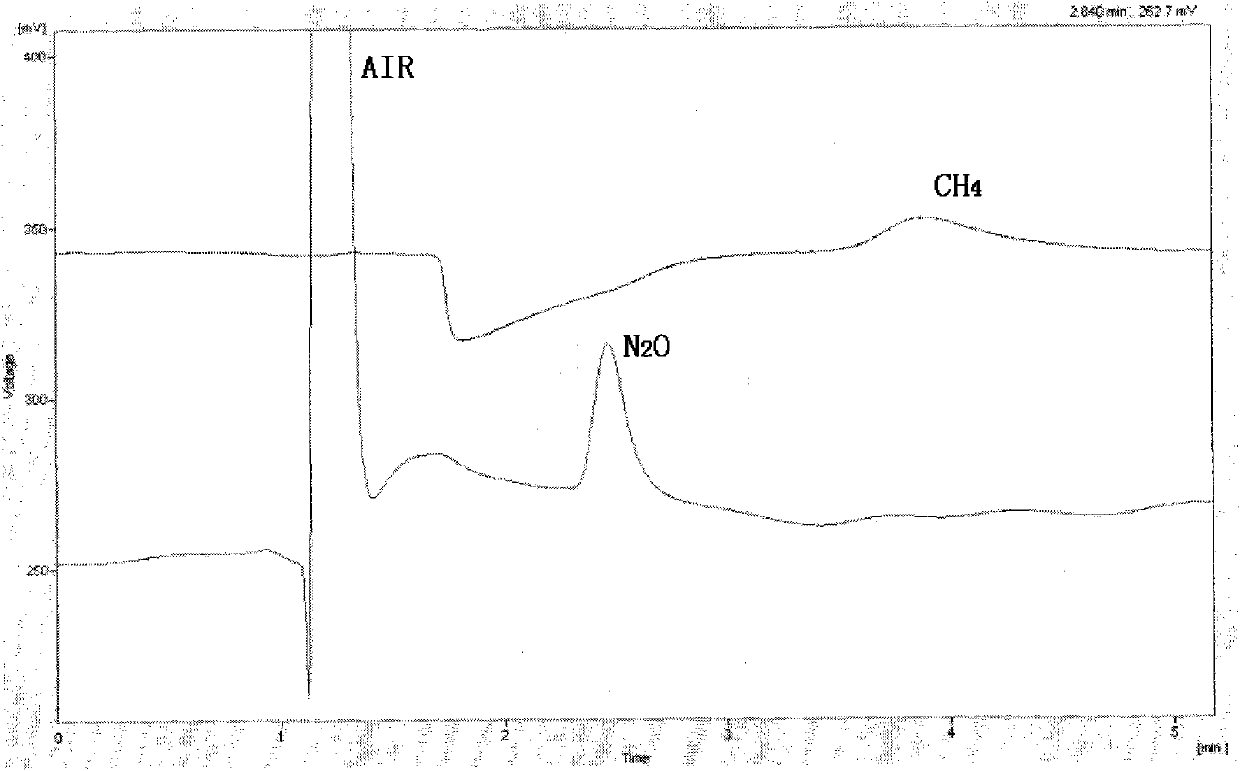

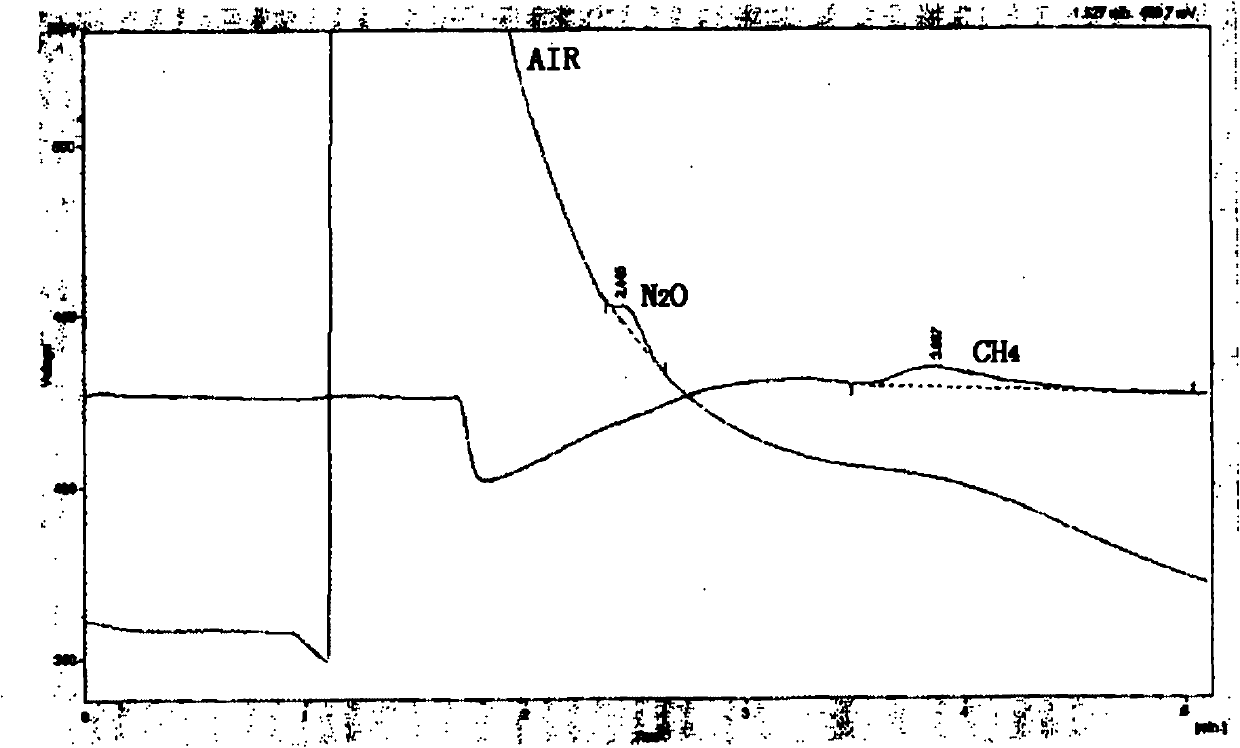

[0023] Example 1 Gas Chromatography One-time sampling analysis of methane, nitrous oxide in the atmosphere: first the purity is less than 10 -5 % carrier gas - He passes through the purifier at an output pressure of 0.20Mpa, so that the purity of the purified carrier gas is less than 10 -6 %; then pass the purified carrier gas into the chromatographic column of the gas chromatograph where the sample to be tested has been placed at a temperature of 40°C at a flow rate of 15ml / min, and after adsorption and desorption at a temperature of 90°C , the nitrous oxide and methane in the sample to be tested enter the ECD and the FID in turn, and are detected at a temperature of 110°C; finally, the data obtained by the ECD and the FID are simultaneously input to the chromatographic workstation in the gas chromatograph, and the analysis results can be obtained Chromatogram.

[0024] Among them: the chromatographic column refers to a stainless steel tube with an inner diameter of 1mm, a c...

Embodiment 2

[0026] Embodiment 2 gas chromatography single-injection analysis atmosphere methane, nitrous oxide: first the purity is less than 10 -5 % carrier gas—Ne passes through the purifier at an output pressure of 0.60Mpa, so that the purity of the purified carrier gas is less than 10 -6 %; then pass the purified carrier gas into the chromatographic column of the gas chromatograph with the flow rate of 85ml / min at a temperature of 35°C, and after adsorption and desorption at a temperature of 70°C , the nitrous oxide and methane in the sample to be tested enter the ECD and the FID in turn, and detect at a temperature of 350°C; finally, the data obtained by the ECD and the FID are simultaneously input to the chromatographic workstation in the gas chromatograph, and the analysis results can be obtained Chromatogram.

[0027] Among them: the chromatographic column refers to a stainless steel tube with an inner diameter of 5mm, a column length of 9m, and filled with Porapak, Chromosorb, G...

Embodiment 3

[0029] Embodiment 3 gas chromatographic analysis of methane, nitrous oxide in the atmosphere at one time sample injection: at first the purity is less than 10 -5 % of carrier gas——Ar passes through the purifier at an output pressure of 0.40Mpa, so that the purity of the purified carrier gas is less than 10 -6 %; then pass the purified carrier gas into the chromatographic column of the gas chromatograph where the sample to be tested has been placed at a temperature of 30°C at a flow rate of 50ml / min, and after adsorption and desorption at a temperature of 50°C , the nitrous oxide and methane in the sample to be tested enter the ECD and the FID in turn, and detect at a temperature of 230°C; finally, the data obtained by the ECD and the FID are simultaneously input to the chromatographic workstation in the gas chromatograph, and the analysis results can be obtained Chromatogram.

[0030] Among them: the chromatographic column refers to a stainless steel tube with an inner diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com