Longitudinal mechanical flexibility compensation device for worktable of bending machine and manufacturing method of longitudinal mechanical flexibility compensation device

A compensation device and worktable technology, applied in the field of bending machines, can solve problems such as accumulated errors and inconsistencies in compensation values, and achieve the effects of enhancing wear resistance, high movement consistency, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as figure 1 Shown is a structural schematic diagram of the longitudinal mechanical deflection compensation device of the bending machine workbench in the prior art, wherein the downward slope block includes several numbers, and the defects of the compensation device are: (1) the upper slope block and the upper fixed plate and the downward slope There is a gap fit between the block and the lower carriage, and there is a cumulative error, which leads to inconsistent compensation values when the downward inclined block group moves left and right (production error caused by tool wear); (2) The carriage adopts laser Cutting and forming, there is a length error of thermal expansion and contraction; the slope of the inclined block is made by a grinder, which is inefficient.

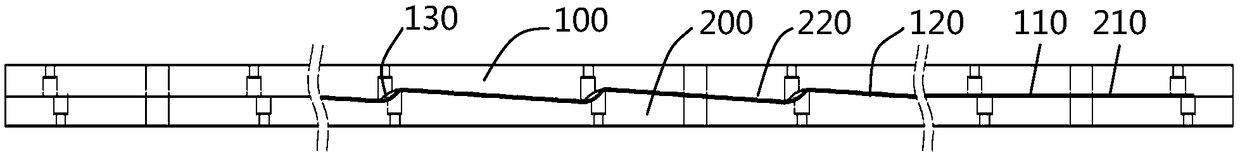

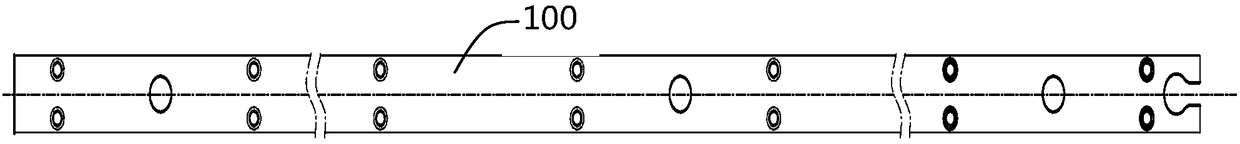

[0044] Please refer to Figure 2 to Figure 4 , The longitudinal mechanical deflection compensation device of the bending machine workbench of this embodiment includes a base 300 , a cover plate 40...

Embodiment 2

[0051] The working principle of this embodiment is: during the manufacturing process of the longitudinal mechanical deflection compensation device of the workbench, the wedge groups are evenly distributed along the rectangular groove 310, the angle of the middle wedge is the largest, and the angle decreases successively along the length direction. The wedge angle is the smallest (generally 0.08°). When the wedges are shifted equidistantly, because the middle wedge angle is large, the middle of the table can be bulged to form a corresponding deflection curve to achieve the purpose of deflection compensation.

[0052] Through the DEFORM finite element analysis software, the stamping springback of the sheet metal is simulated and analyzed, and the orthogonal test method is used to effectively deal with the influencing factors. The purpose of the orthogonal test is to observe the springback angle by changing the level of each factor. size, so as to determine the best factor level c...

Embodiment 3

[0058] The manufacturing method of the bending machine workbench longitudinal mechanical deflection compensation device in this embodiment includes the steps:

[0059] S101. Select two plates of the same high-strength steel material, 60# carbon steel chemical composition: C content 0.6%; Si content 0.2%; Mn content 0.6%; Cr content ≤ 0.25%; Ni content ≤ 0.30%; Cu Content≤0.25%, the rest is Fe;

[0060] S102. On the numerically controlled machine tool, determine one end of the upper slant plate 100 as the starting point for processing, and process the first inclined plane 120 of the upper slant plate 100 on a vertical surface, wherein the feed amount L1=[W(C) / W(Si )]*0.1=0.6 / 0.2*0.1=0.3mm; cutting speed V1=[(W(C)+W(Mn)) / W(Si)]*500=(0.6+0.6) / 0.2*500= 3000mm / min, W(C), W(Mn), and W(Si) all represent weight percentages, the slope K of the first slope 120 determines different segmental values according to the deflection curve, and the maximum value of the deflection curve is det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com