An automatic centering system for wind power speed increaser test test

A technology of automatic alignment and test testing, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of long time, low production efficiency, affecting the development and growth of wind power speed-increasing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

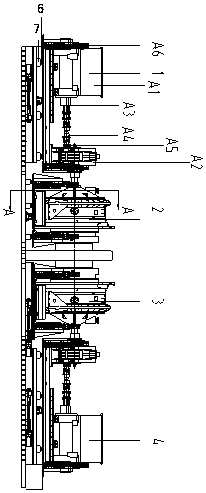

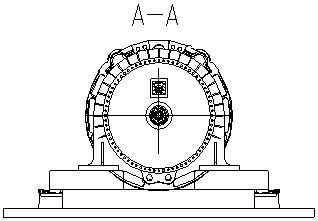

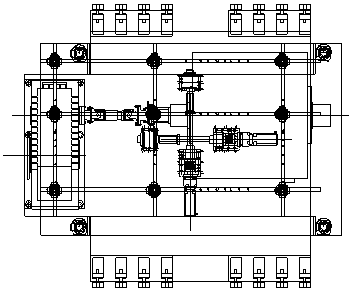

[0031] Such as Figure 1-9 As shown, this specific embodiment adopts the following technical solutions: it comprises 4 modules, respectively A module 1, B module 2, C module 3 and D module 4, A module 1, B module 2, C module 3 and D module 4 connected sequentially, the A module 1 includes the motor A1, the process gearbox A2, the torque sensor A3, the universal coupling A4 and the connecting flange A5, the torque sensor A3 is installed on the motor A1, and the front end of the torque sensor A3 is connected to the One end of the universal coupling A4 is connected, and the other end of the universal coupling A4 is connected with the connecting flange A5, and the connecting flange A5 is set on the process gearbox A2, and the relative position of the motor A1 and the torque sensor A3 is adjusted The alignment process remains the same.

[0032] As preferably, the A module 1 also includes four vertical servo structures A6 and radial adjustment bases A7, one end of the motor A1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com