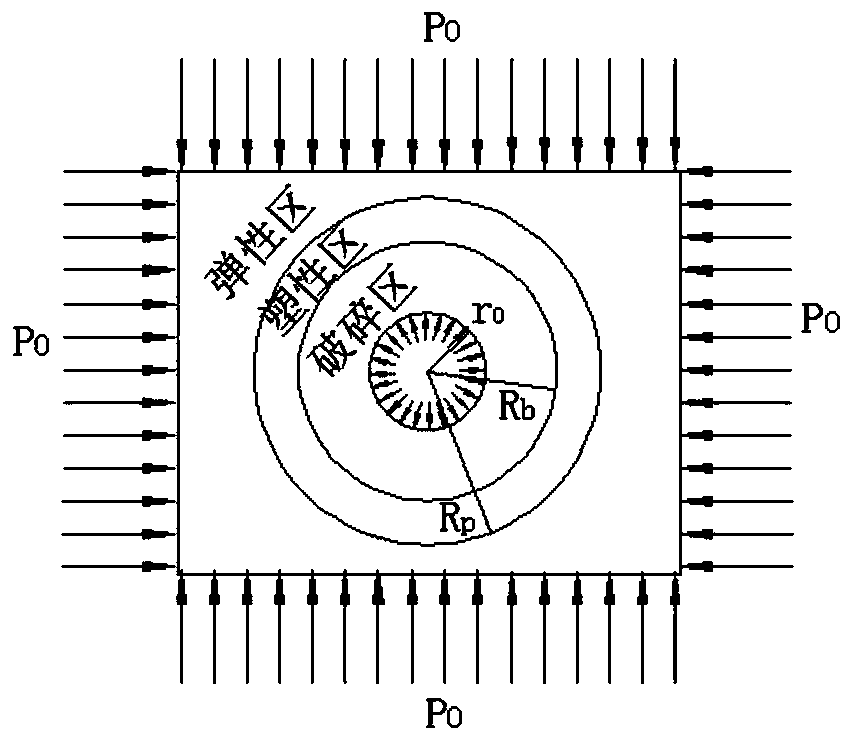

Comprehensive mechanized coal mining face withdraw channel anchor rod and anchor cable supporting determining method

A fully-mechanized mining face and retraction channel technology, which is applied to the determination field of bolt and cable support for the retracted channel of fully-mechanized mining face, can solve problems such as difficult accurate estimation, factors affecting the determination of bolt support, and lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

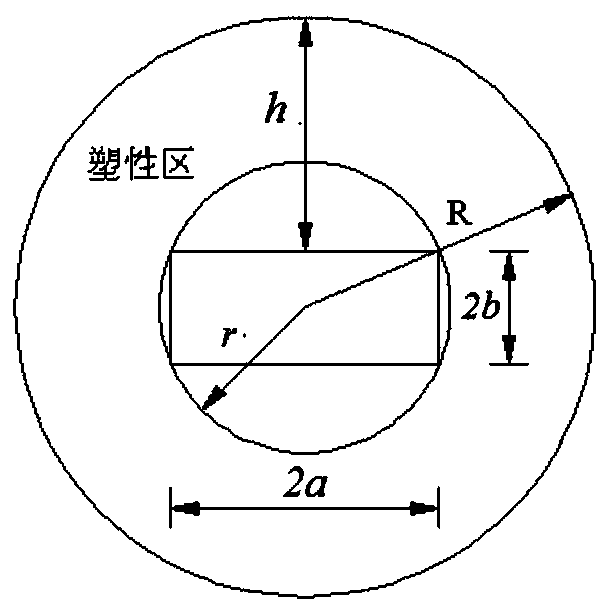

Method used

Image

Examples

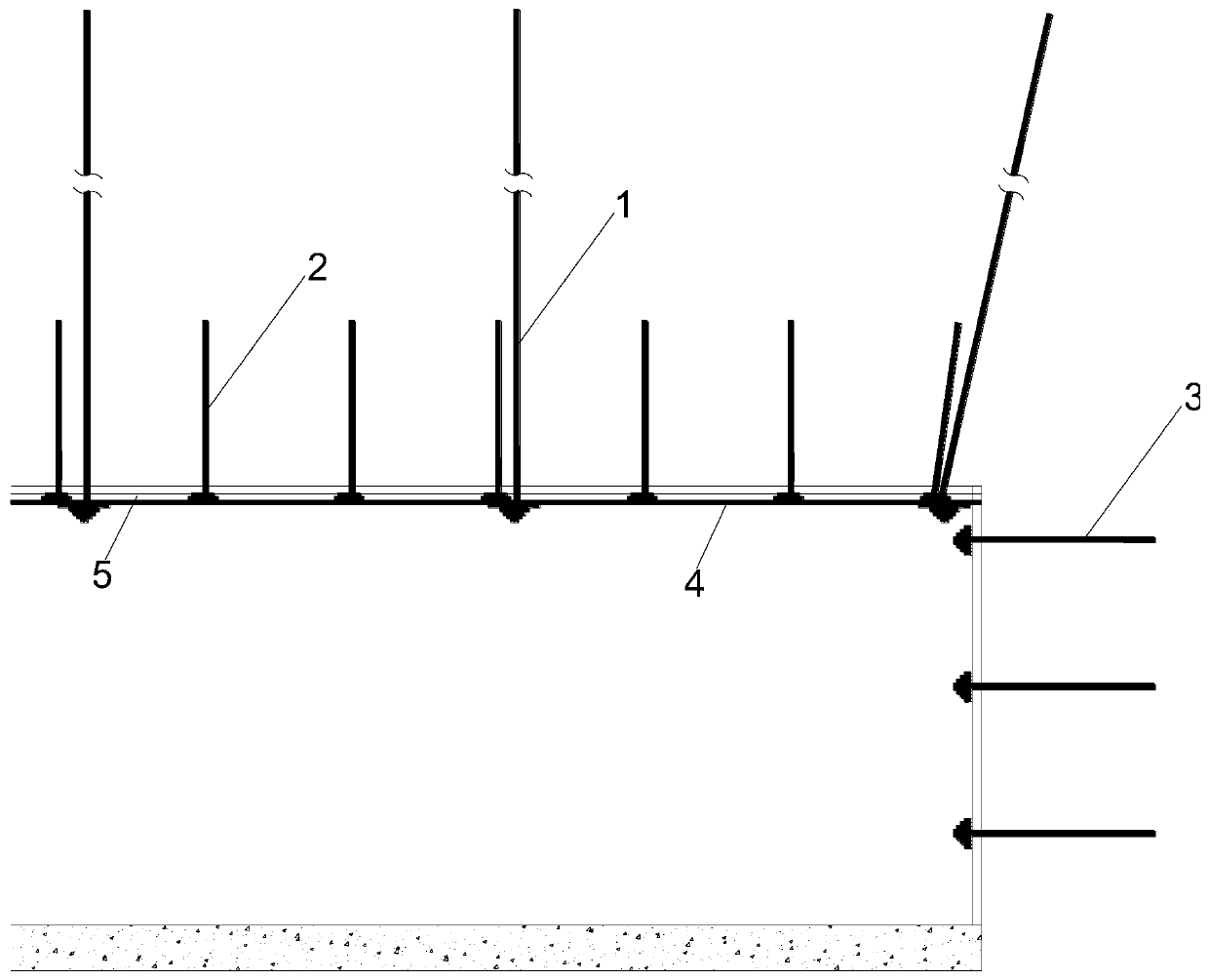

Embodiment Construction

[0121] In the method for determining the bolt and cable support of the withdrawal channel of the fully mechanized mining face in this embodiment, the fully mechanized mining face is Ningtiaota Coal Mine 1 -2 Fully mechanized coal mining face.

[0122] The safety factors mentioned below are the preset parameter values in order to prevent the consequences caused by factors such as material defects, working deviation, and sudden increase of external force during civil and mechanical engineering design. The force that engineering mechanics can bear in theory must be Greater than the force it actually bears, the safety factor is the ratio of the ultimate stress to the allowable stress.

[0123] According to the drill hole data and the underground measured data, the thickness of the coal seam within the excavation range of the N1114 working face is 0.6-1.92m, the average thickness is 1.75m, the dip angle of the coal seam is 0°41'-1°55', and the local undulation; the buried depth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com