The floor system and its construction method composed of grc hollow box composite slabs

A technology of combining boards and boxes, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of small span of non-secondary beam floors, poor sound insulation effect, prominent edges and corners, etc., to increase the effective use area, improve Visual effects, the effect of reducing beam height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

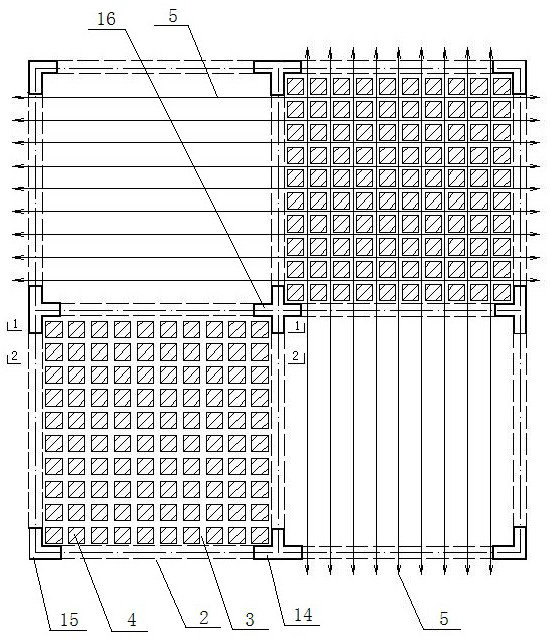

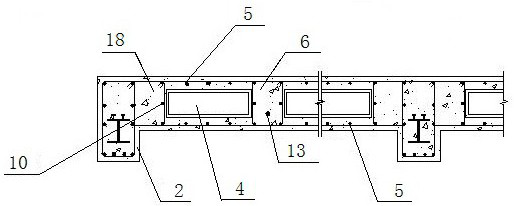

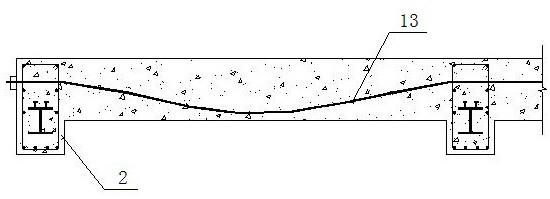

[0042] Below in conjunction with accompanying drawing, the present invention will be further described:

[0043] combine Figure 1-Figure 10 As shown, the floor system composed of GRC hollow box composite panels is composed of special-shaped composite columns 1, composite beams 2, and composite panels 3. The special-shaped composite columns 1 are special-shaped composite columns with built-in section steel 9 or FRP sections The beam 2 is a sunken section steel or FRP profile concrete composite beam, and the composite panel 3 is a composite panel with a prestressed concealed beam and a GRC hollow box. The cross-section of special-shaped composite column 1 includes T-shaped composite column 14, L-shaped composite column 15 and cross-shaped composite column 16, and the cross-section of composite beam 2 is rectangular, both of which adopt solid-web steel concrete. The shaped steel / FRP profiles in the special-shaped composite column 1 and the beam can be prefabricated in the facto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com