Garbage vertical collection system based on functions of automatically opening and closing carriage cover

A collection system and garbage technology, applied in the field of garbage vertical collection system, can solve the problems of high, continuous or intermittent opening, low frequency of use, noise pollution, etc., to avoid odor emission, fast response, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

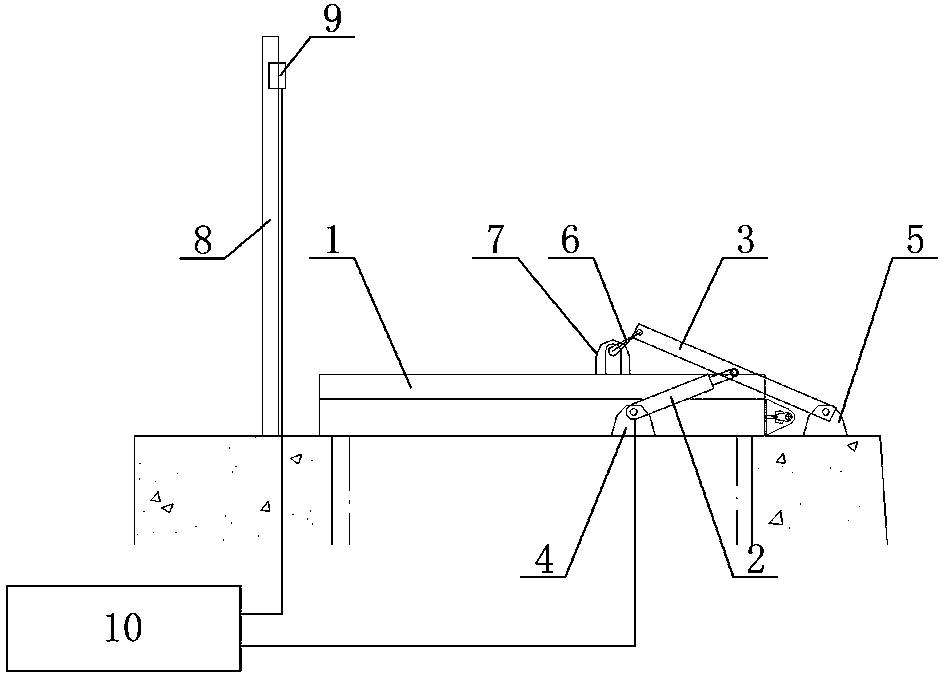

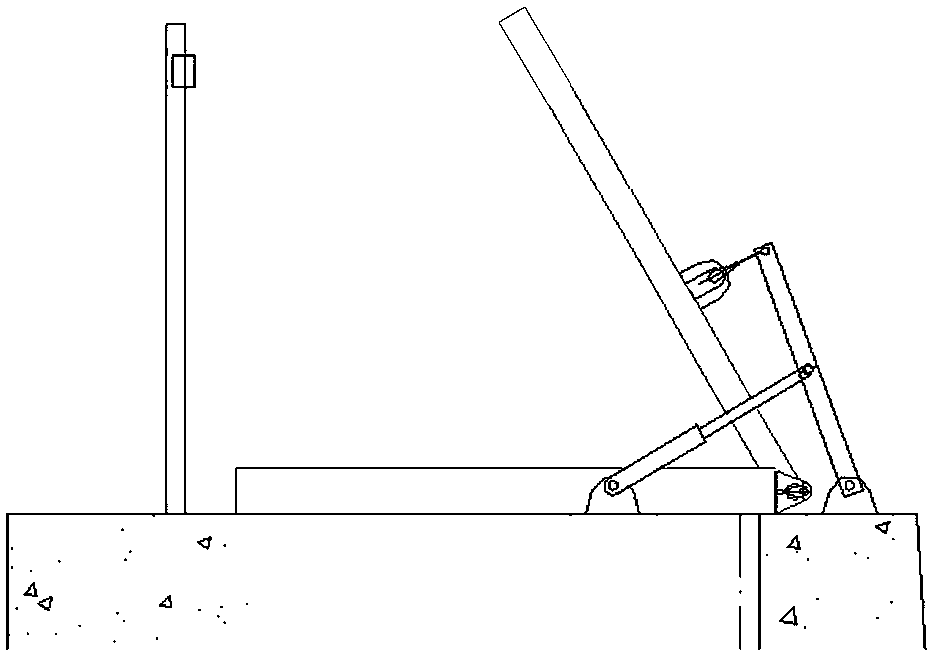

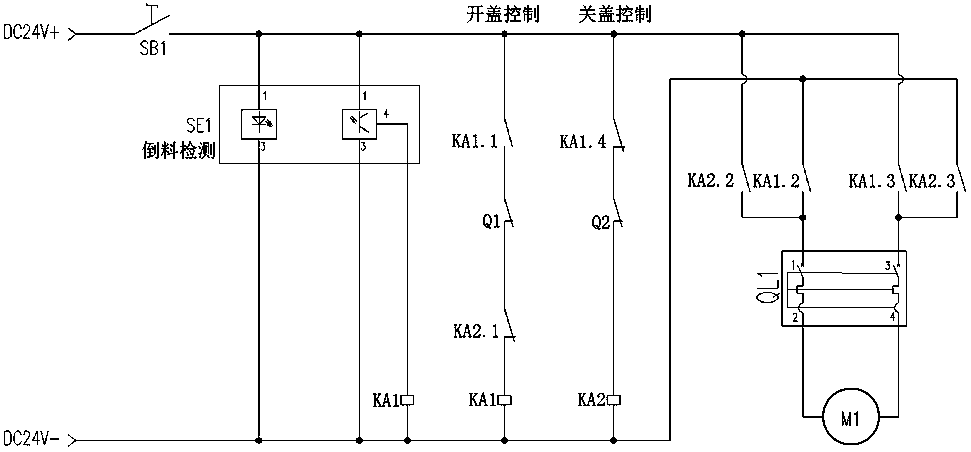

[0027] Such as Figure 1 to Figure 3 As shown, the present invention is based on the garbage vertical collection system with the function of opening and closing the trunk lid automatically, including a cover opening device, an infrared detection device and a trunk lid 1 arranged at the garbage vertical collection port, and the cover opening device includes an electric push rod 2 and a Drive connecting rod 3, one end of the electric push rod 2 is hinged with the first fixed ear 4 arranged at the garbage vertical collection port, the other end of the electric push rod 2 is hinged with the middle part of the drive connecting rod 3, the drive One end of the connecting rod 3 is hinged with the second fixed ear 5 arranged on the edge of the vertical garbage collection port, and the other end of the driving connecting rod 3 is movably provided with a hook 6;

[0028] The position close to the other end of the drive connecting rod 3 on the trunk cover 1 is also provided with an openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com