Patents

Literature

31results about How to "Avoid fugitive emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic sewage constructed wetland processing and high-yield non-food energy plant cultivating technology

InactiveCN101805061AAvoid Fugitive EmissionsPromotes fast digestionWater contaminantsGas production bioreactorsConstructed wetlandNormal growth

The invention relates to an organic sewage constructed wetland processing and high-yield non-food energy plant cultivating technology, which is characterized in that the organic sewage is sent into a methane tank, an oxidation pond and a constructed wetland orderly to achieve the purpose of sewage purification, and simultaneously, the non-food energy plant is cultivated. The invention has the advantages that a buried type ABR system can be ensured to be in an intermediate-temperature fermentation state, the organic matter is digested quickly, and methane is produced with high yield; the methane is used for intensifying light, heating, increasing carbon dioxide fertilizer and enhancing photosynthesis for the system to produce the non-food energy plant with high yield; under the previous condition, plant seeds and energy plants on the oxidation pond (the stabilization pond) and the constructed wetland can grow quickly so as to obtain high yield and produce high-quality protein feed, and the normal growth and absorption of eutrophic substances in the sewage in winter can be ensured; simultaneously, purified reclaimed water is fully utilized; and the plants inside and outside the system grow quickly, a large amount of carbon dioxide is absorbed and utilized, and zero emission of sewage and methane is realized.

Owner:罗仕均

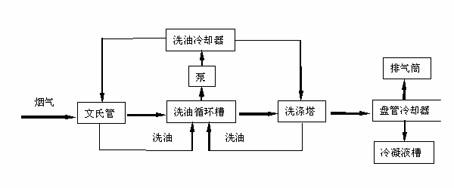

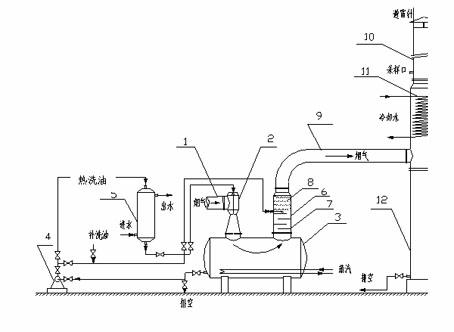

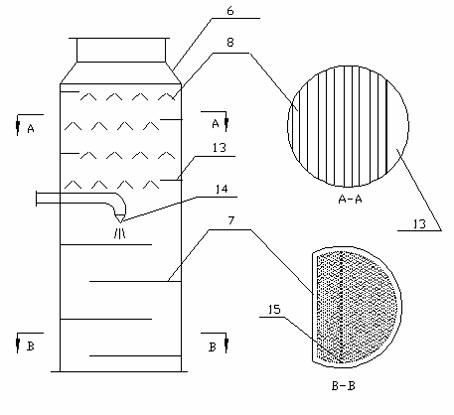

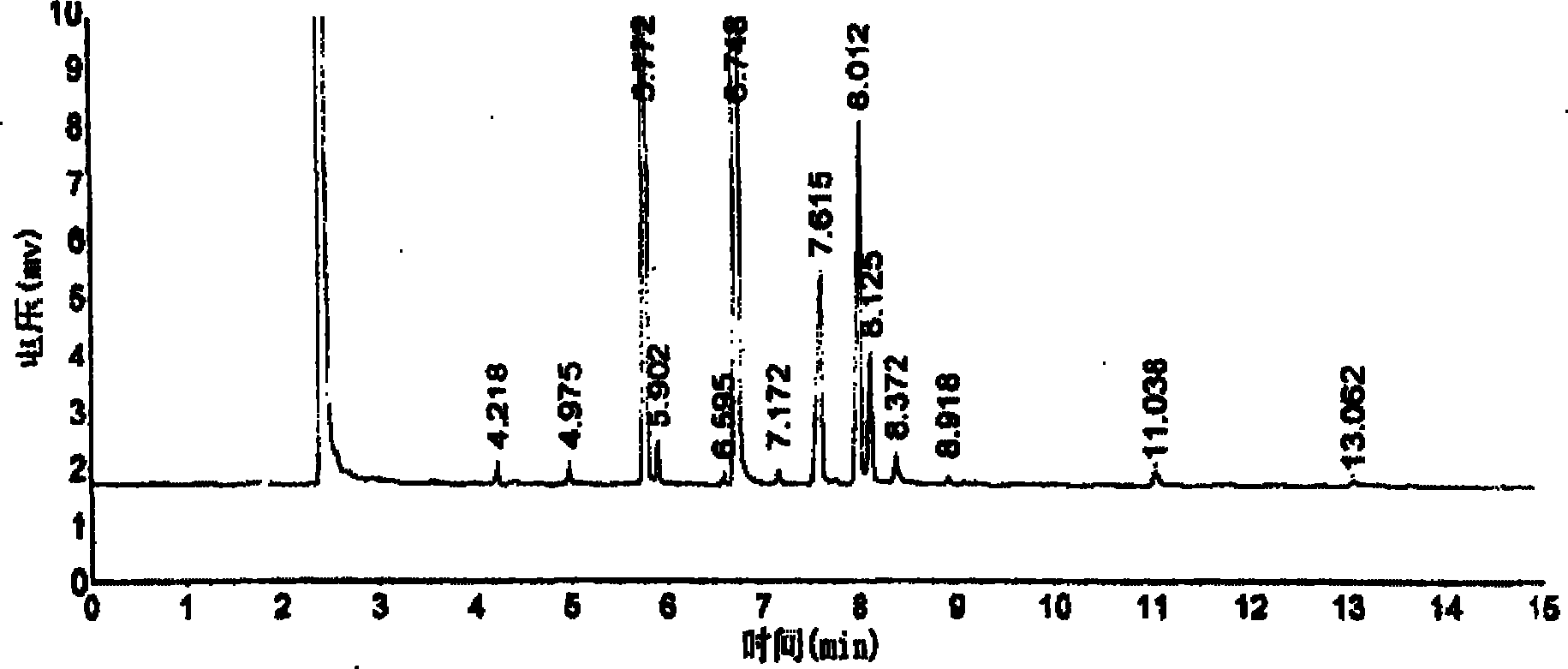

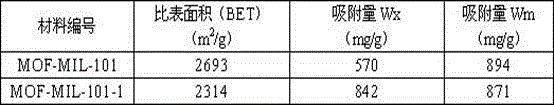

Method and apparatus for absorbing asphalt smoke

InactiveCN102463022AAvoid direct escapeAvoid Fugitive EmissionsUsing liquid separation agentVapor condensationCooling coilEmission standard

The invention relates to a method and an apparatus for absorbing asphalt smoke. An absorption process and a condensing method are applied comprehensively. Absorber oil is utilized to absorb organic matters in the smoke, and cooling water is utilized to cool the asphalt smoke indirectly; members in washing tower are improved, and a baffle plate and a herringbone strip are arranged to avoid obstruction in the tower; cycling absorber oil and a split-type structure of the chimney are simultaneously employed, and secondary washing in the washing tower and secondary condensation cooling of a cooling coil pipe are added, so as to enhance absorption effect of asphalt smoke, reduce consumption of a absorbent and realize a chimney outlet asphalt smoke concentration lower than a discharge standard. Meanwhile, as pollutants are absorbed or concentrated, reutilization of resource is realized.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

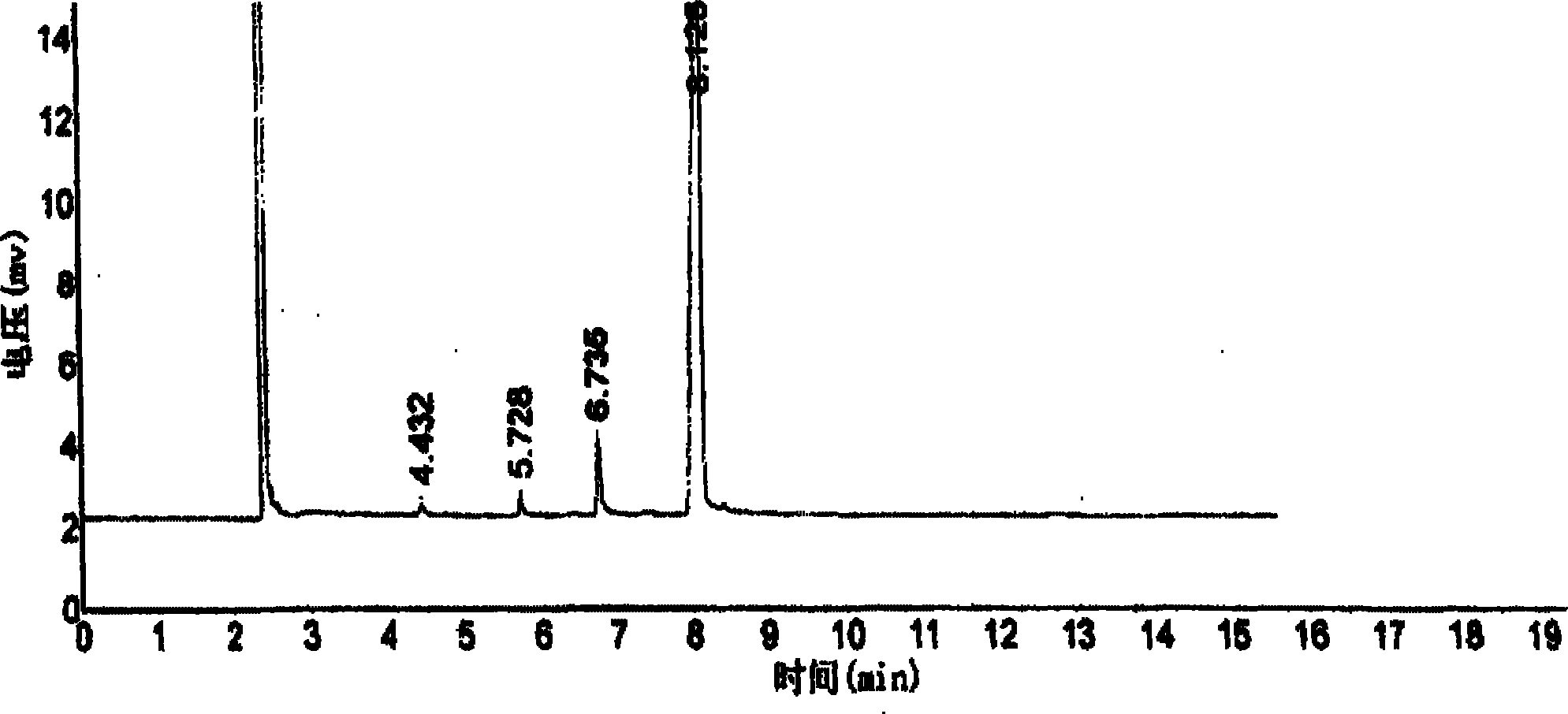

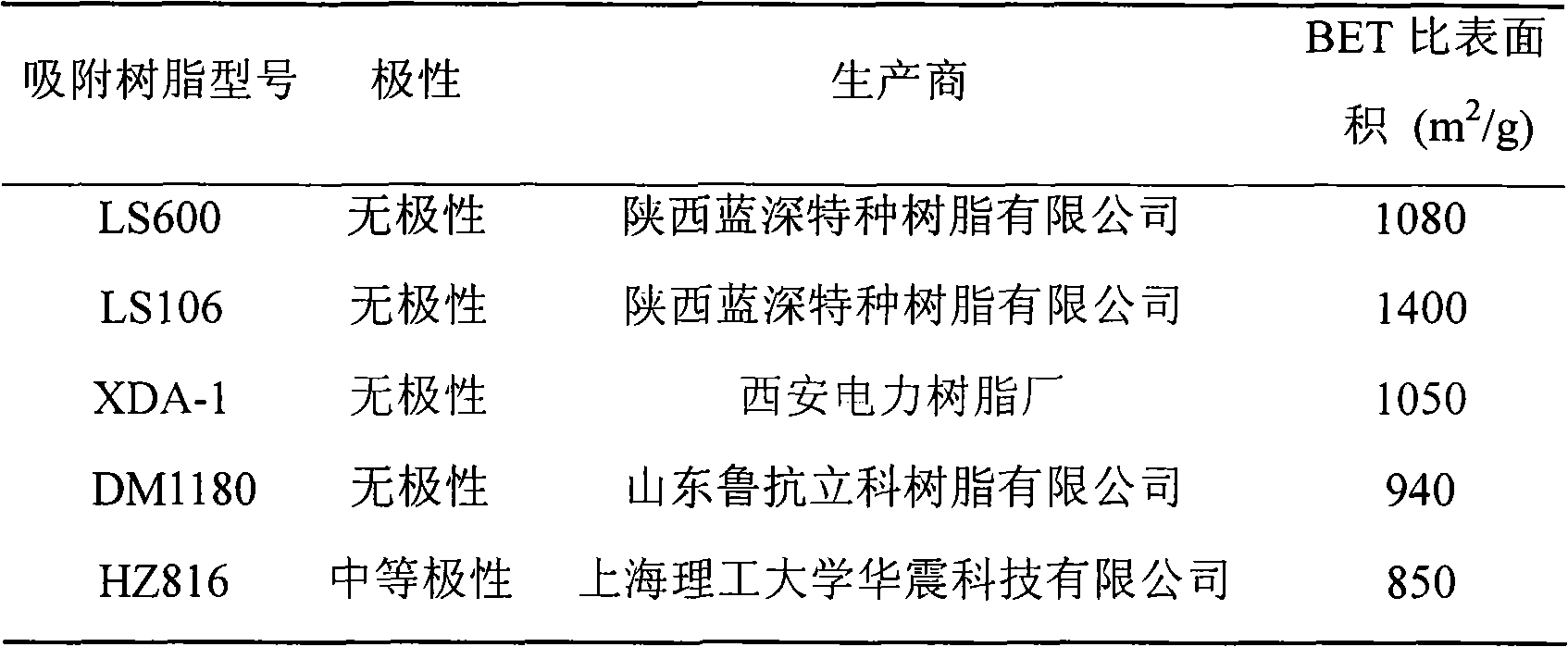

Method for treating high-concentration organic process wastewater generated in production of 2-chloro-6-fluorobenzaldehyde

ActiveCN102115274AReduce pollution loadAchieve economyWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentHigh concentrationDesorption

The invention discloses a method for treating high-concentration organic process wastewater generated in the production of 2-chloro-6-fluorobenzaldehyde. The method comprises the following steps: adding quicklime and flocculant into the wastewater and then regulating with acid; allowing the wastewater regulated with acid to pass through an adsorption tower filled with a nonpolar macroporous absorption resin I; respectively obtaining a primary saturated absorption resin and a primary eluent; performing desorption regeneration to the primary saturated absorption resin with a solvent I to obtaina solution after primary desorption; regulating the primary eluent with acid, and allowing the eluent regulated with acid to pass through an adsorption tower filled with a nonpolar macroporous absorption resin II; respectively obtaining a secondary saturated absorption resin and a secondary eluent; performing desorption regeneration to the secondary saturated absorption resin with a solvent II toobtain a solution after secondary desorption; and finally respectively recovering, purifying and separating the solution after primary desorption and the solution after second desorption to obtain 3-chloro-2-methylphenol, 2-chloro-6-fluorobenzaldehyde and 2-chloro-6-fluorobenzoicacid. The method can realize the organic combination of wastewater treatment and resource recovery.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

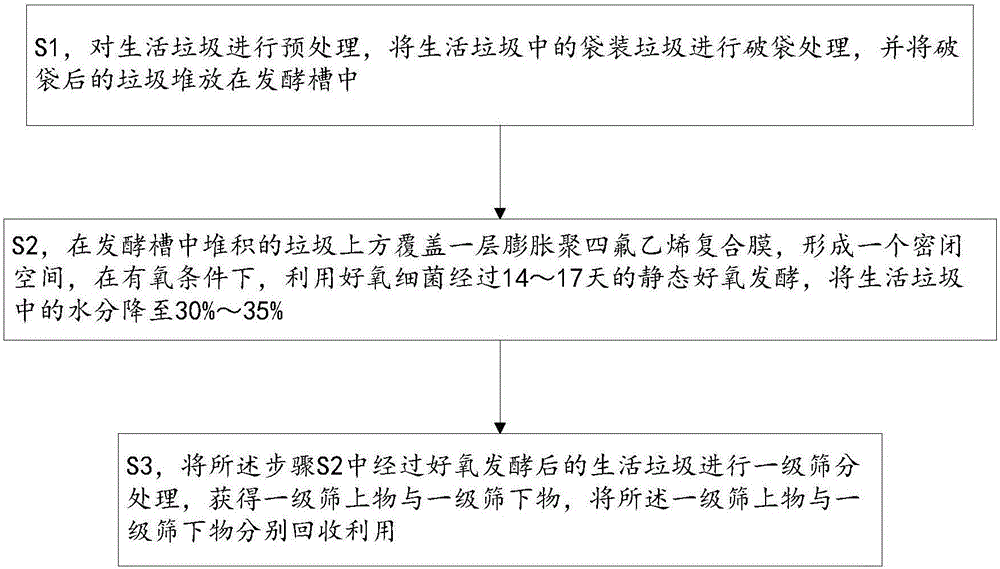

Household waste handling method

The invention discloses a domestic garbage treatment method and relates to the technical field of solid waste disposal. The domestic waste treatment method includes the following steps: S1, pretreating the domestic waste, breaking the bagged waste in the domestic waste, and stacking the broken bag in a fermentation tank; S2, fermenting The garbage accumulated in the tank is covered with a layer of expanded polytetrafluoroethylene composite film to form a closed space. Under aerobic conditions, aerobic bacteria are used for 14 to 17 days of static aerobic fermentation to reduce the moisture in domestic garbage. to 30% to 35%; S3, performing primary sieving treatment on the domestic garbage after aerobic fermentation in the step S2 to obtain the first-level sieve and the first-level sieve, and the first-level sieve The material and the undersize of the primary sieve are recycled separately. The beneficial effect of the invention is that the domestic waste can be decomposed and dried at low cost, the water content in the domestic waste can be reduced, the process is simplified, and the system investment and operation cost are reduced.

Owner:HUNAN VARY TECH

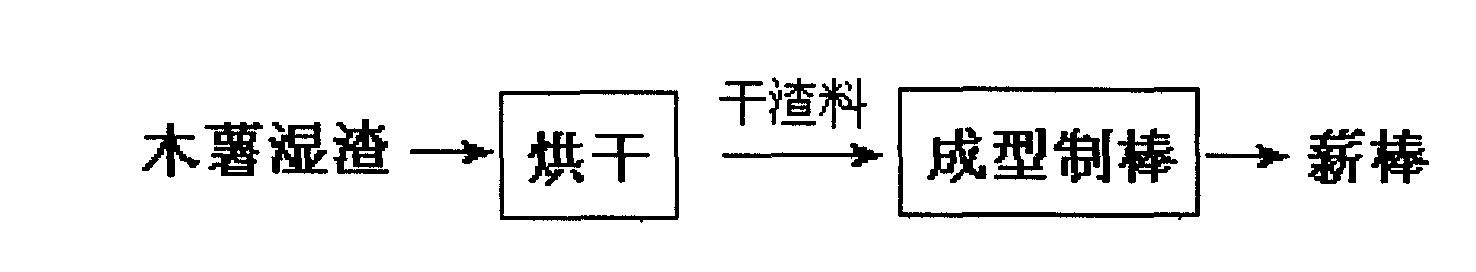

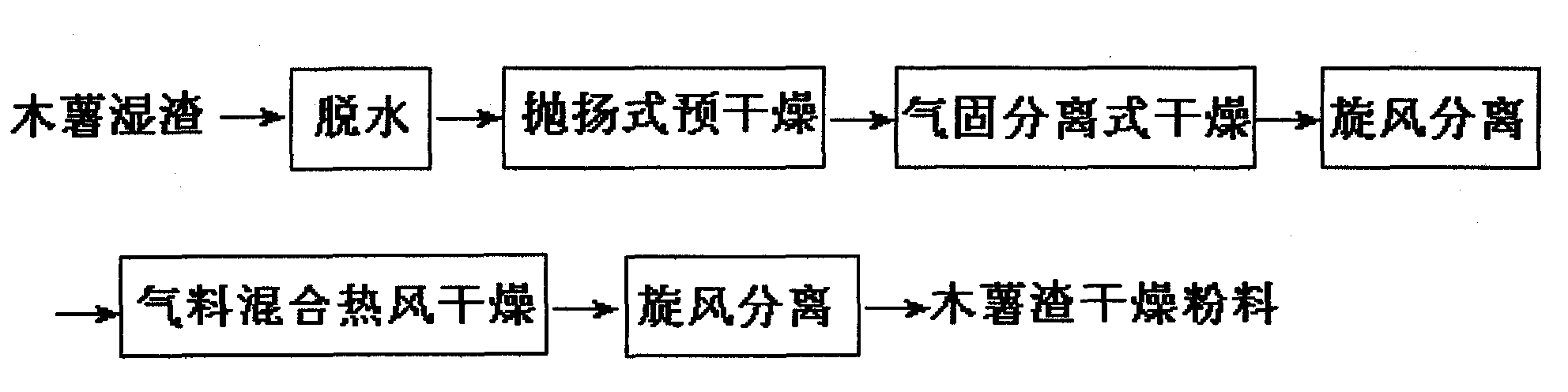

Method for preparing firewood sticks by waste cassava residues and application on charcoal preparation

InactiveCN102220178AIncrease added valueAvoid pollutionBiofuelsSolid fuelsEngineeringManihot esculenta

The invention discloses a method for preparing firewood sticks by waste cassava residues and application on charcoal preparation. The method comprises the following steps of taking the waste cassava residues produced in the production process of cassava starch as raw materials, drying the waste cassava residues to obtain dried residues, and preparing the formed firewood sticks by the dried residues, wherein after the waste cassava residues are dried, the water content rate of the dried residues is controlled to range from 10% to 15%, and the temperature of a mold for preparing the formed firewood sticks by the dried residues is controlled to be 230-280 DEG C. The firewood sticks prepared by the method are further baked into charcoal products which have the advantages of low ash content, low sulphur content, charcoal content, high heat productivity and the like, and are high-quality biomass energy. By the method, the waste cassava residues can be subject to industrial processing to form three levels of products (the dried residues, the firewood sticks and charcoal), so that circulated economic ecological chain of 'cassava-starch-cassava residues-biomass energy' can be formed, simultaneously, the risk that the waste cassava residues pollute environments can be eliminated, the direct energy-saving benefit is obvious, and the indirect emission reduction economic benefit is remarkable.

Owner:南宁市环境保护科学研究所

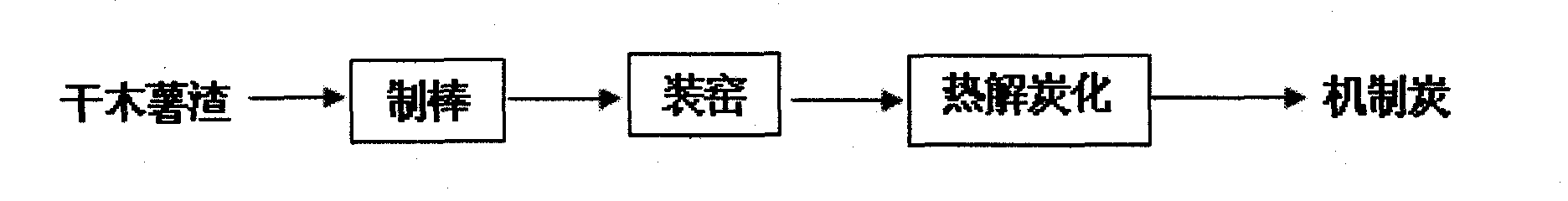

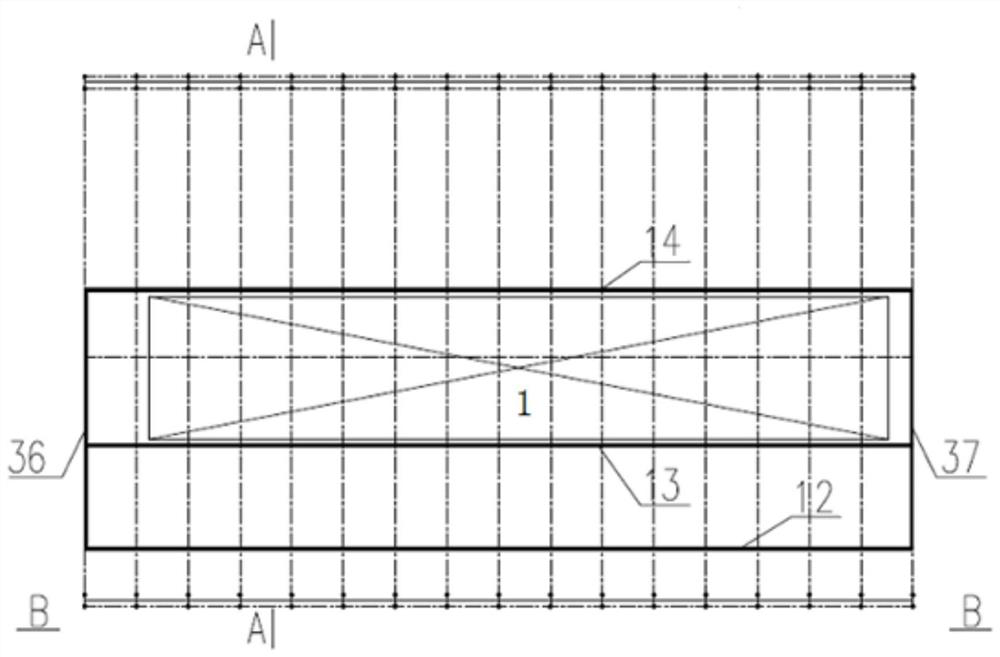

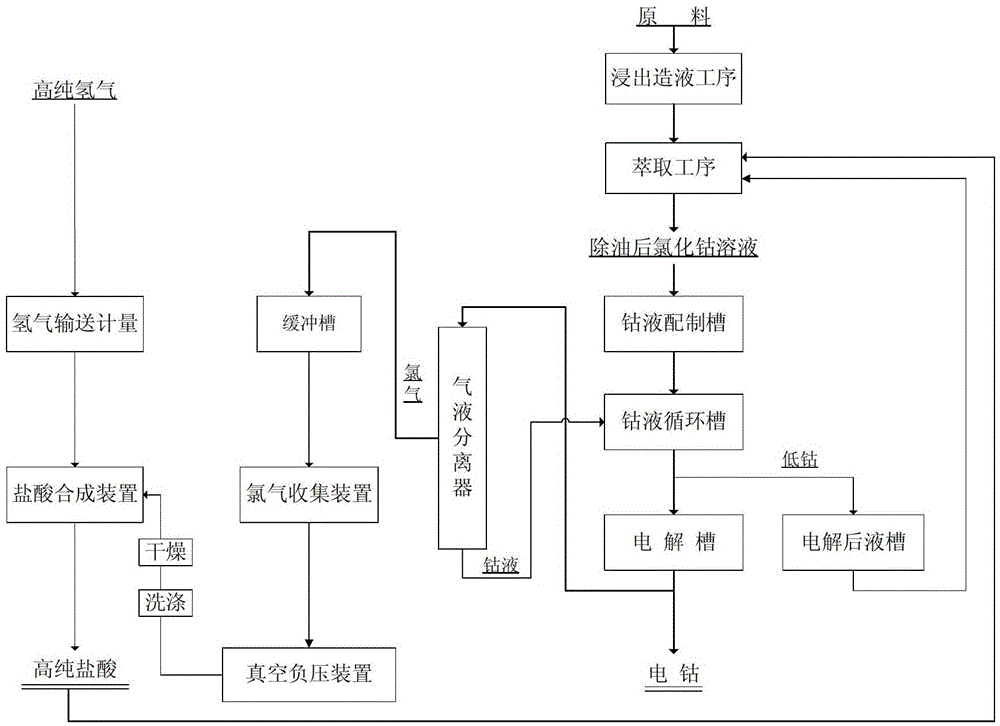

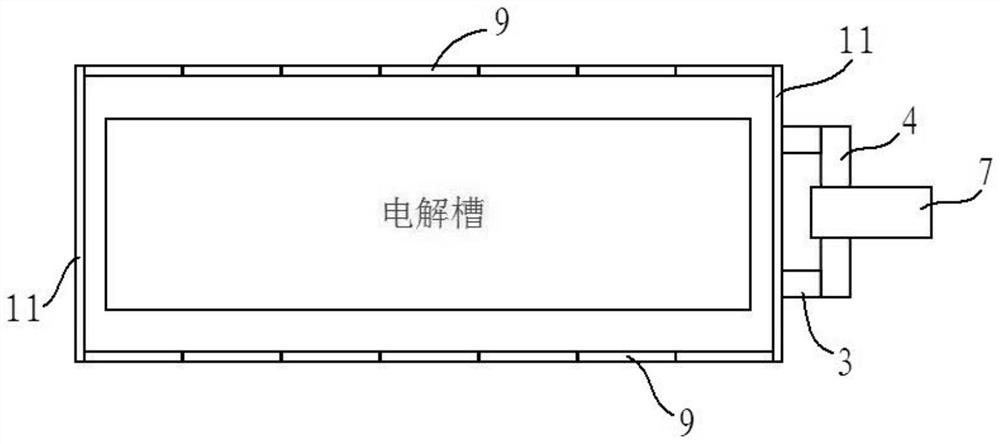

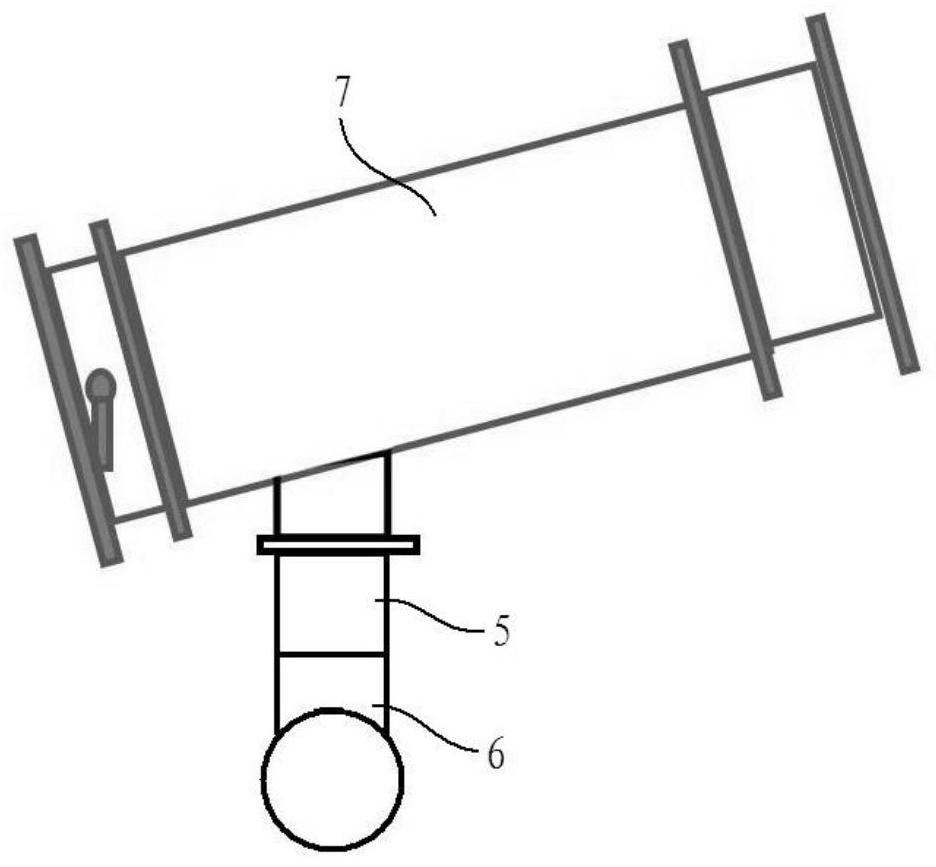

Method for preparing electrodeposited cobalt under large flow

ActiveCN103060842AImprove current efficiencyReduce cathodic polarizationPhotography auxillary processesWater chlorinationHydrometallurgy

The invention discloses a method for preparing electrodeposited cobalt under a large flow. In conventional production methods for electrodeposited cobalt, the process of processing has the disadvantages of low current efficiency and long electrodeposition time, and purity and a recovery rate of produced electrodeposited cobalt hardly reach requirements. A technical scheme employed in the invention is as follows: a deoiled cobalt chloride solution produced in wet metallurgy is used as a raw material and is diluted with pure water so as to allow the concentration of Co<2+> in the cobalt chloride solution to be 30 to 100 g / L, and the diluted cobalt chloride solution is used as electrodeposition pre-liquid; and electrodeposition is carried out on the electrodeposition pre-liquid in an enclosed electrodeposition apparatus under the conditions of a large flow of 5 to 15 m<3> / h.m<2> and a negative pressure. According to the invention, the large flow is employed in the process of preparation of electrodeposited cobalt, so cathodic polarization is reduced, high current efficiency as high as more than 95% is obtained, and direct current consumption is low; utilization of the large flow enables chlorine and oxygen generated by an anode to be taken away in time, and oxidation of the cathode cobalt by chlorine and oxygen is prevented, thereby guaranteeing product quality.

Owner:ZHEJIANG HUAYOU COBALT +1

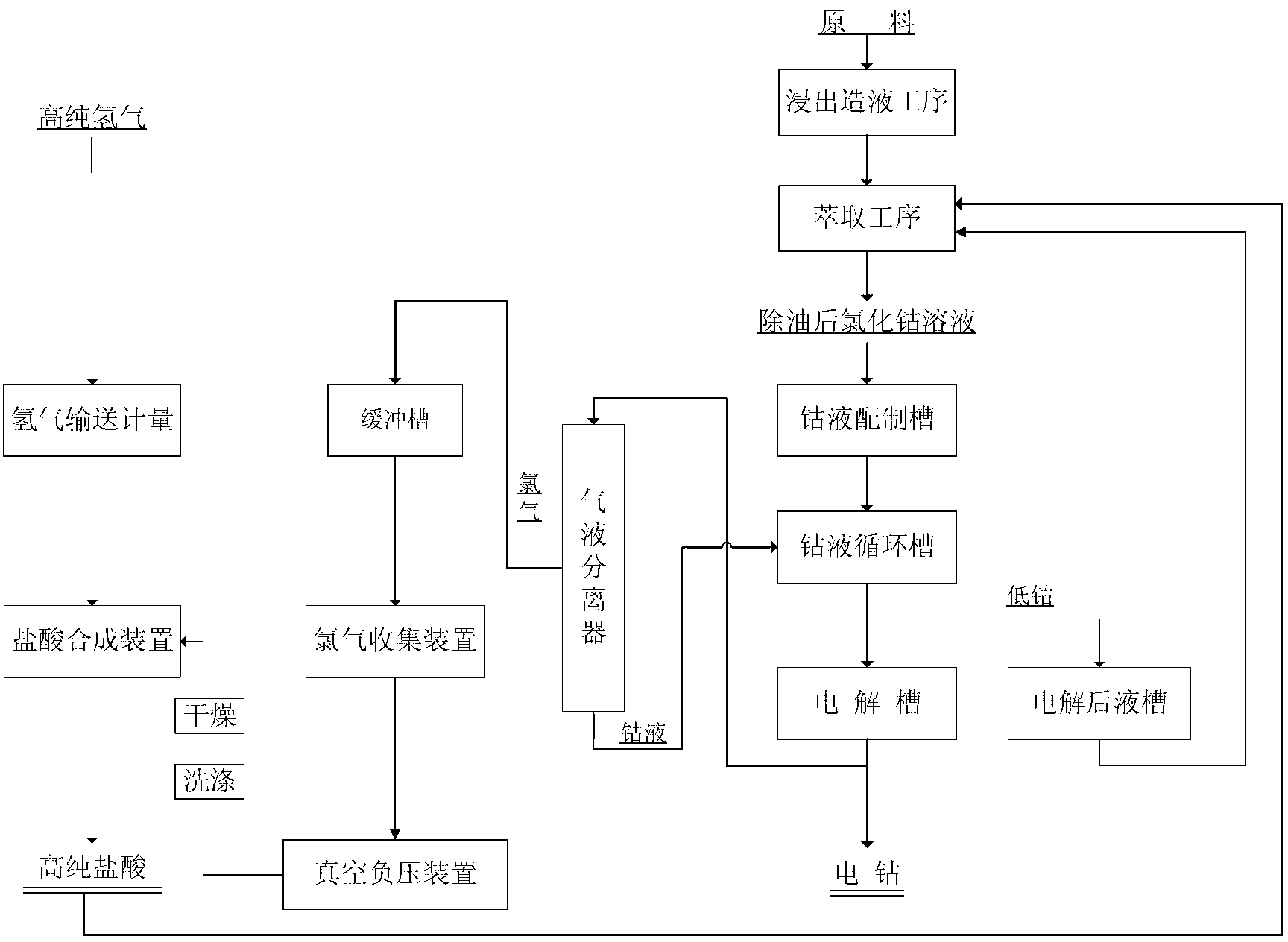

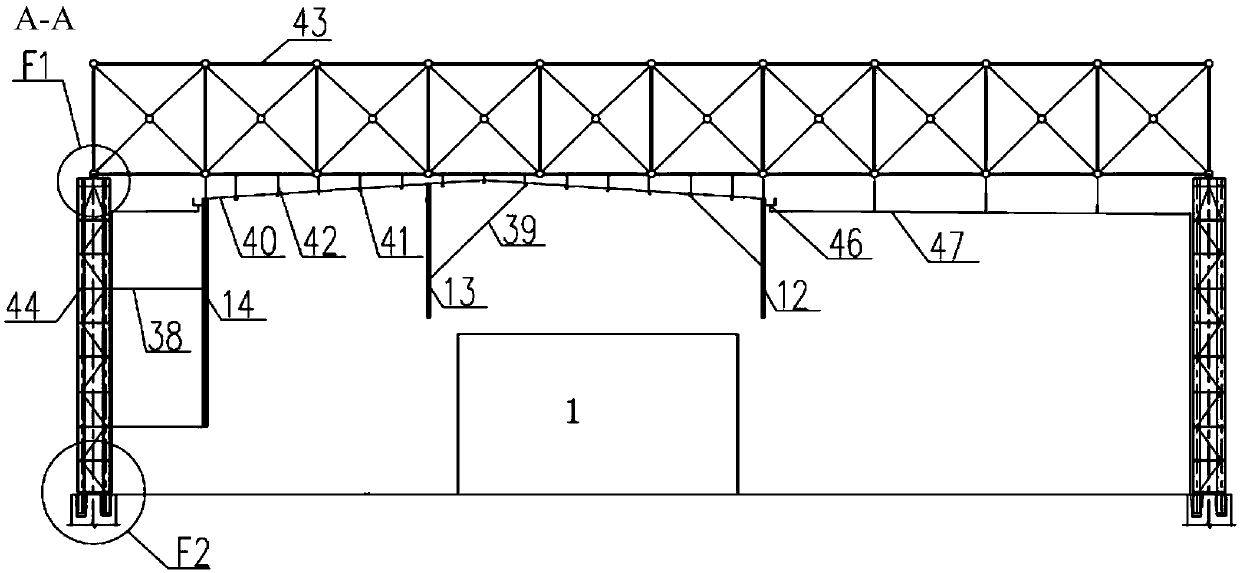

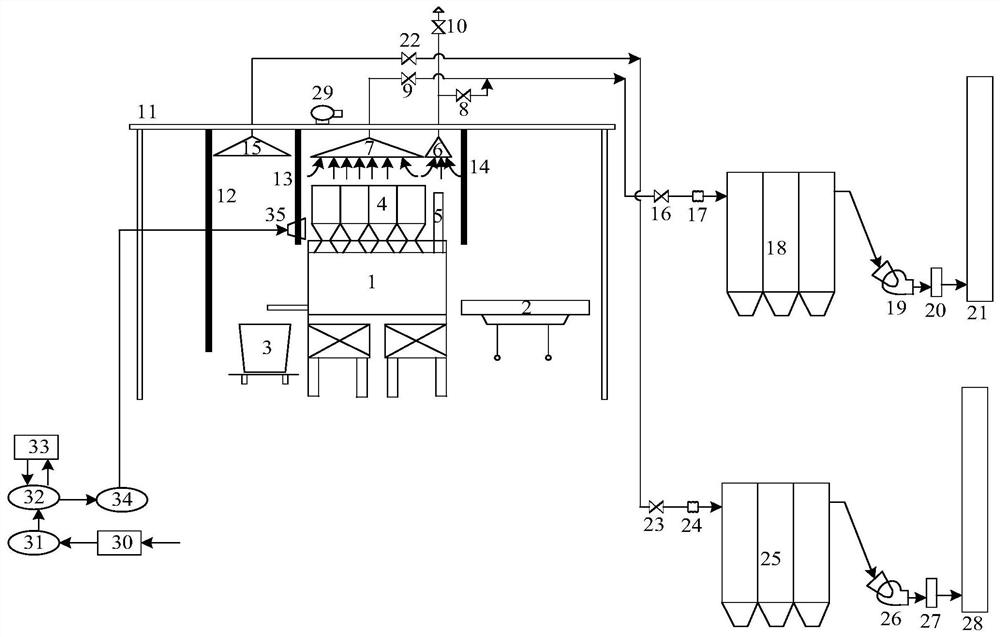

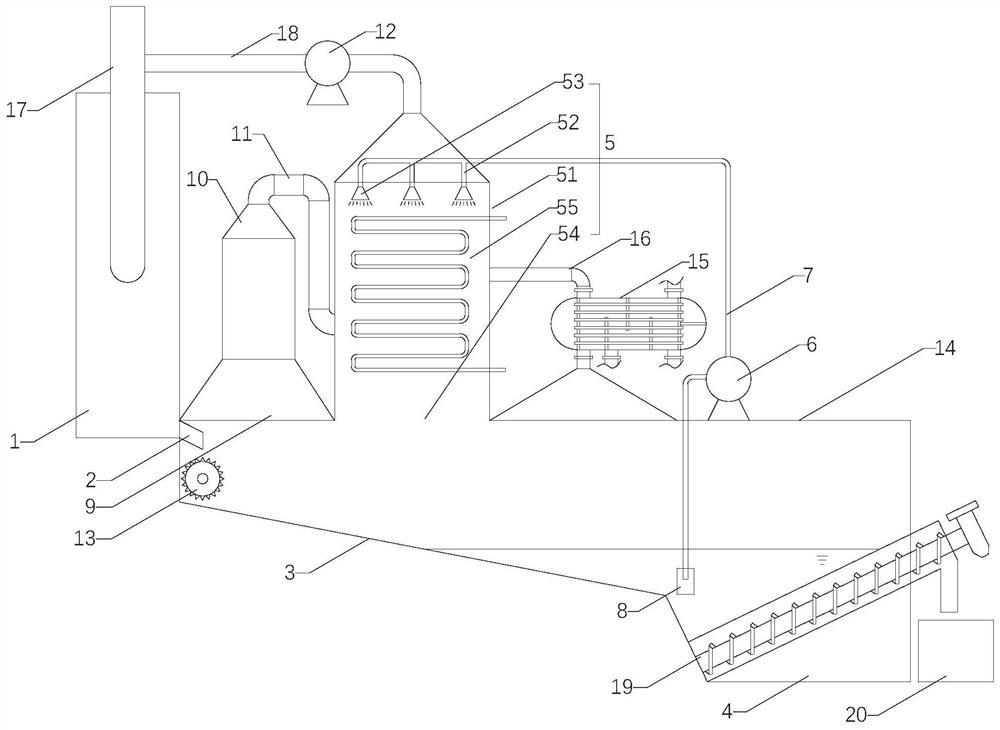

Sealing and ventilation dust removal device and method of coke oven

ActiveCN109666487AAvoid Fugitive EmissionsMeet the protection requirementsOven incrustations prevention/removalSurface coolingCoke oven

The invention provides a sealing and ventilation dust removal device and method of a coke oven. The sealing and ventilation dust removal device comprises a closed workshop formed by hanging walls, parallel string-net racks, pressure bars, corner braces, a roof, purlines, drawing bars, workshop columns, inter-column braces and the like; dust removal equipment such as an electric valve, a pneumaticvalve, a coke-side smoke exhaust cover, a rising pipe smoke exhaust cover, a furnace top smoke exhaust cover, a compensator, a draught fan, a pulse bag-type dust collector, a chimney and the like; andventilation equipment such as a fresh air pipeline, a primary effect filter, a surface cooler, a refrigerator unit, an air supplier and the like. The method comprises the following steps: 1, sealing;2, ventilating; 3, collecting dust; 4, accident diffusing; 5, smoke conveying pipeline; and 6, treating and discharging the smoke. The sealing and ventilation dust removal device and method have theadvantages that all coke oven smoke released from the top of a coal loader, a rising pipe and a coke extinguishing tank can be collected in a closed space; and by virtue of the ventilation system andaccident treatment system, the labor environment of the operation workers can be improved, the adverse influence of the environment pollution for the operation workers can be reduced, the coke oven smoke can be discharged by reaching standard after the dust removal treatment, and the discharging concentration is less than or equal to 10 mg / Nm3.

Owner:北京中冶设备研究设计总院有限公司

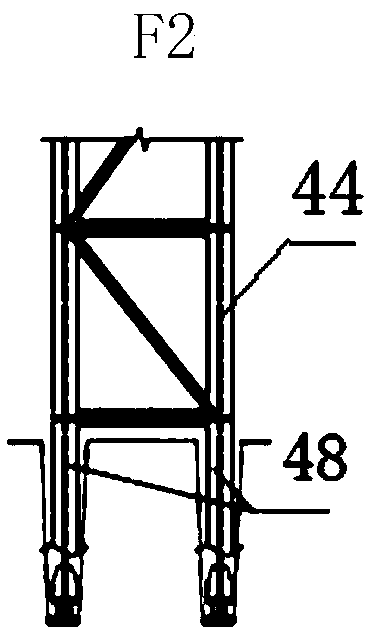

Technology for cleanly and efficiently processing lead-bearing waste residues

PendingCN108950236AGuaranteed temperatureSecurity atmosphereProcess efficiency improvementLead smeltingSmelting process

Disclosed is a technology for cleanly and efficiently processing lead-bearing waste residues. The lead-bearing waste residues produced by lead smelting and lime are matched according to the mass ratioof 1:0.03-0.07 and are then pressed into blocky lead-bearing residue blocks, and after natural drying, by mass, 7%-15% of coke, 9%-11% of silica and 74%-84% of the lead-bearing residue blocks are matched. Materials are sequentially added into a five-section integrated type smelting furnace, ignition blowing-in is conducted for oxygen-enriched intensified smelting, materials added from a smeltingfurnace feeding section (1) pass through a preheating section (2), a sintering section (3), a half-melting section (4), a smelting section (5) and a layering section (6), and the smelting process of the materials is completed. Through the technology, material preheating, sintering, smelting and clarification laying are integrated, heavy metal, valuable metal, gangue and the like are selectively separated well, dangerous waste is processed cleanly and efficiently, and the technology has the advantages that the process is short, operation is simple and convenient, and investment is small.

Owner:个旧市沙甸永和冶炼厂

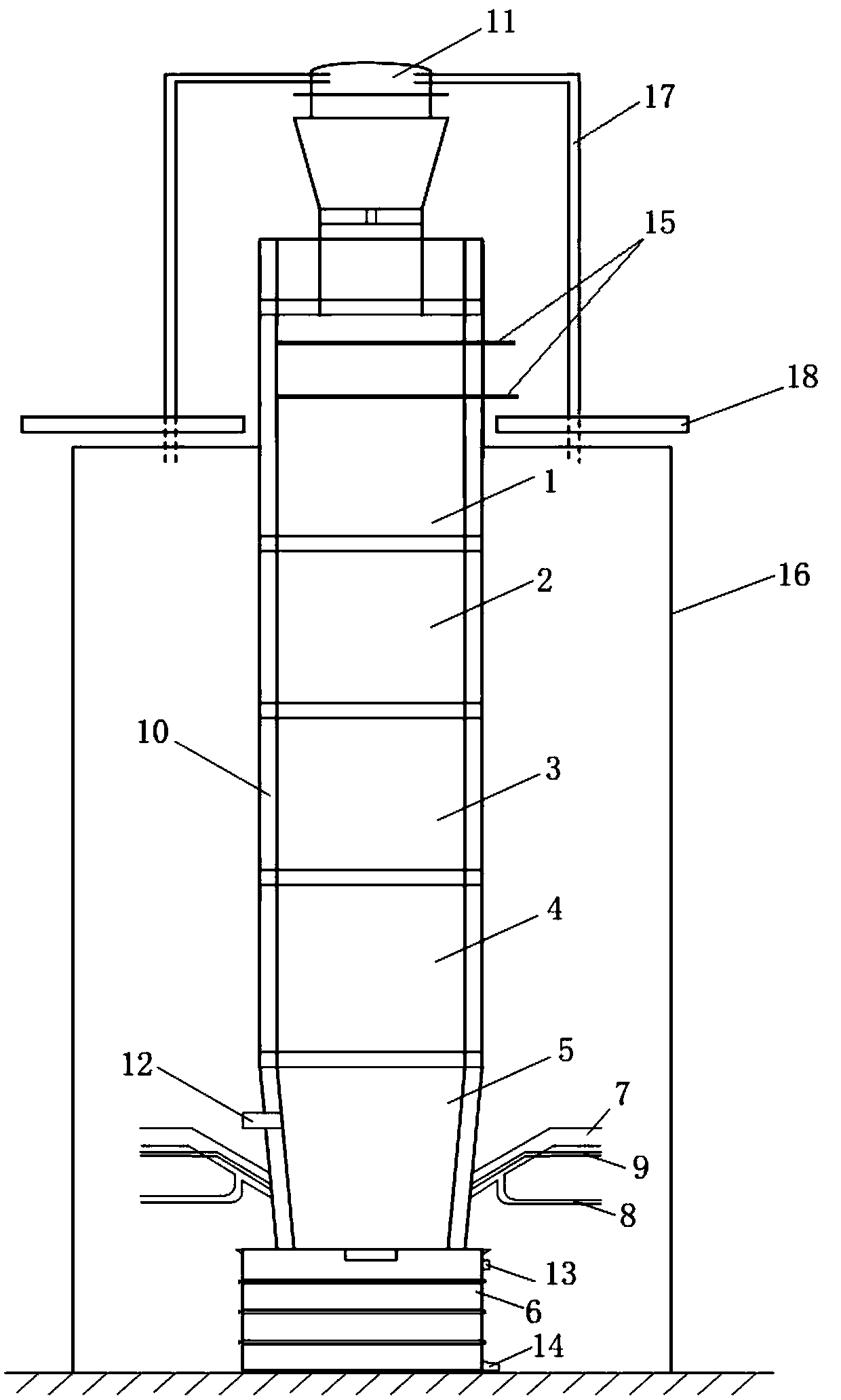

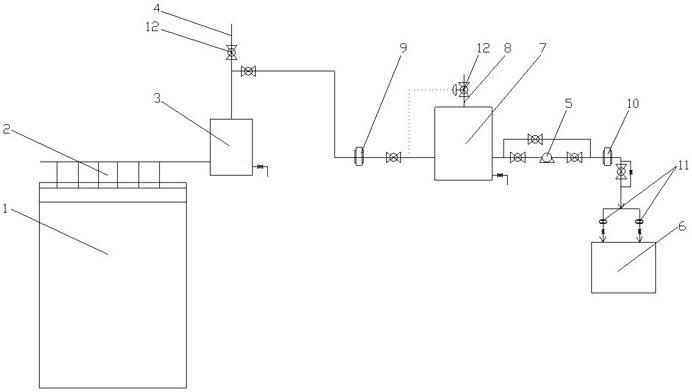

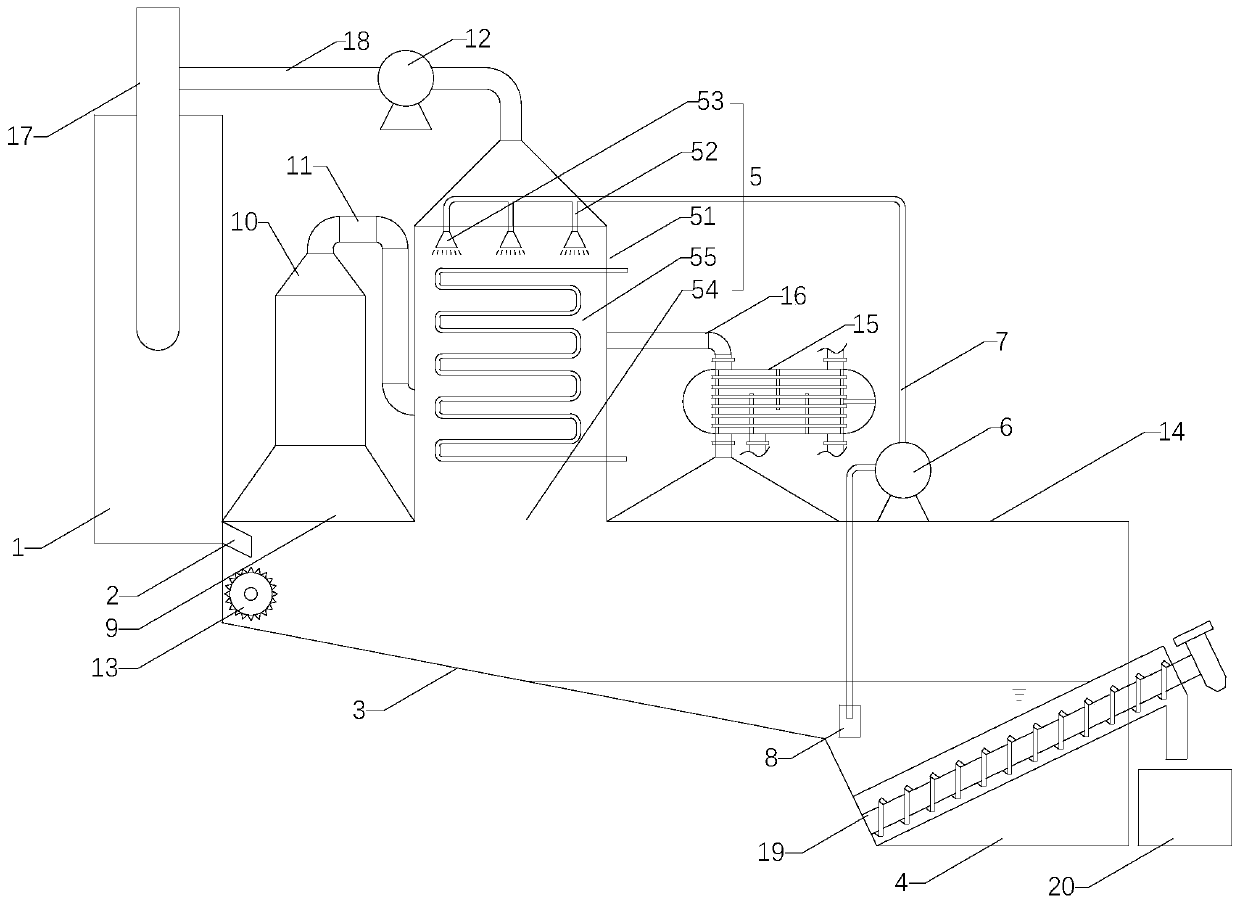

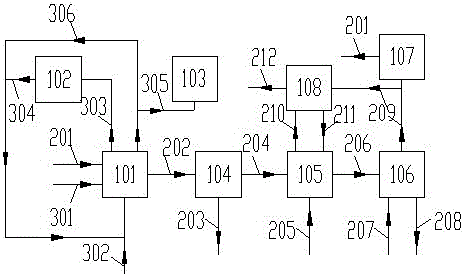

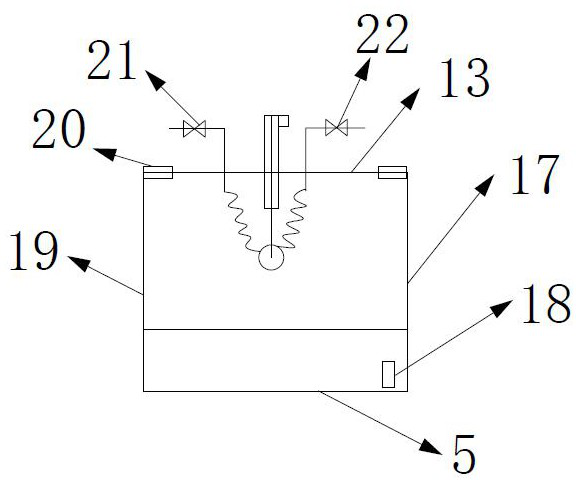

Methane gas recovering system for anaerobic reactor

InactiveCN102328997AAvoid Fugitive EmissionsEffective protectionWaste based fuelTreatment with anaerobic digestion processesProcess engineeringThree-phase

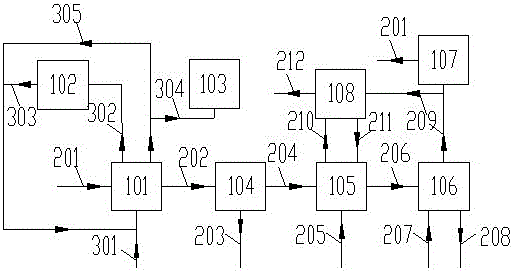

The invention relates to a waste gas recovering device for an anaerobic reactor, in particular to a methane gas recovering system for the anaerobic reactor. The invention aims at mainly solving the technical problems that the anaerobic reactor exhausts methane gas in work time so as to damage the environment to a certain degree and the like in the prior art. The waste gas recovering device comprises an anaerobic reactor (1) and is characterized in that the anaerobic reactor (1) is connected with a first water sealing tank (3) through a three-phase separator (2); the first water sealing tank is provided with a blow-down pipe (4) and is connected with a pipeline fan (5) through a pipeline; and the pipeline fan is connected with a thermo-oil boiler (6).

Owner:ZHEJIANG HENGYI POLYMER

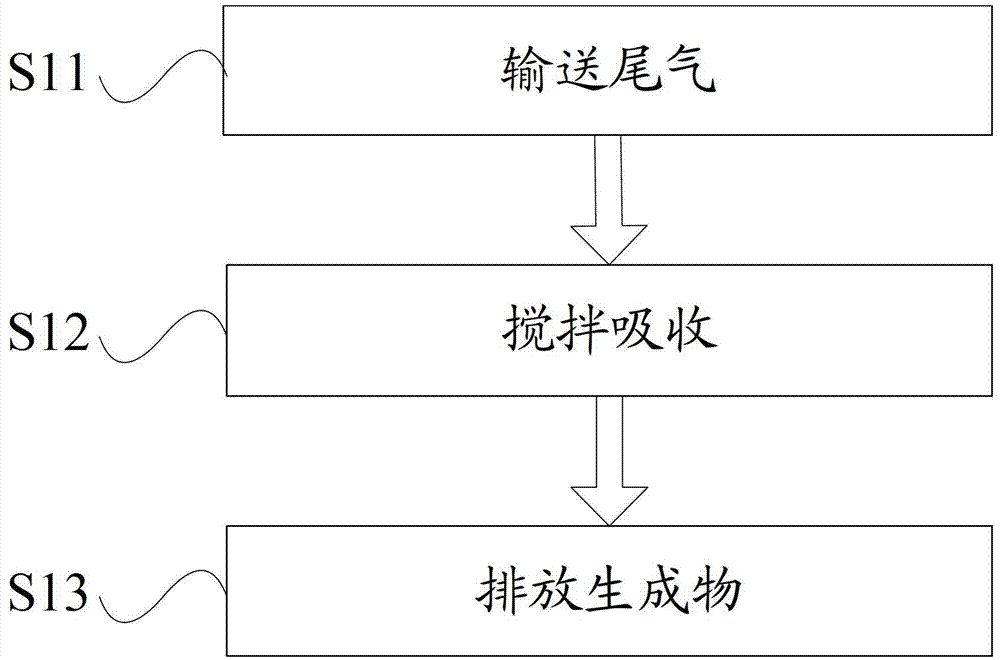

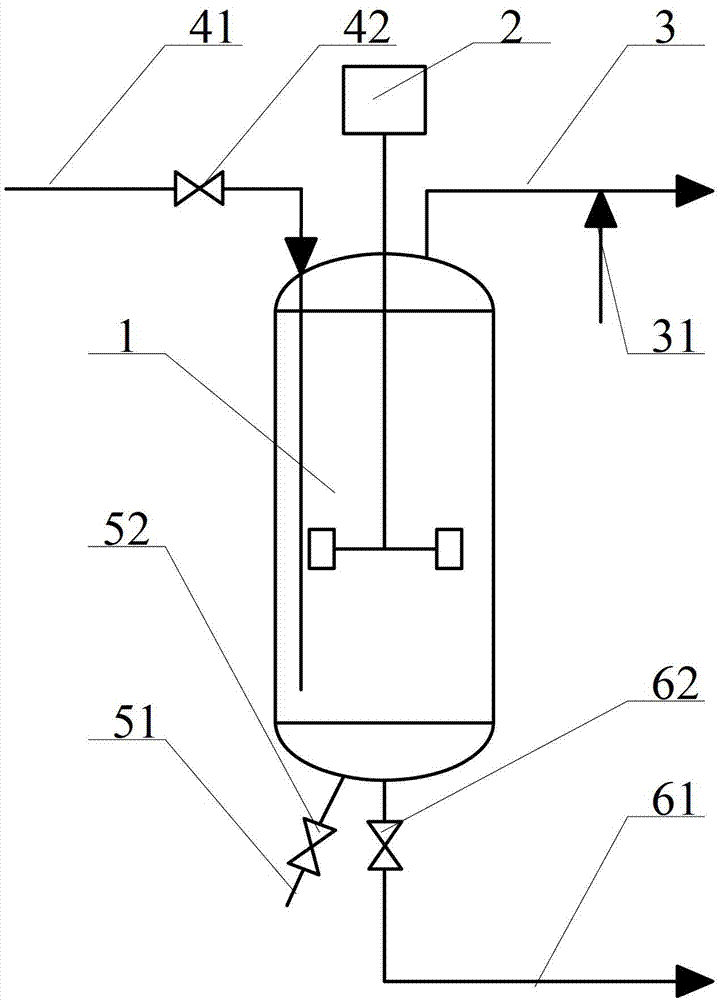

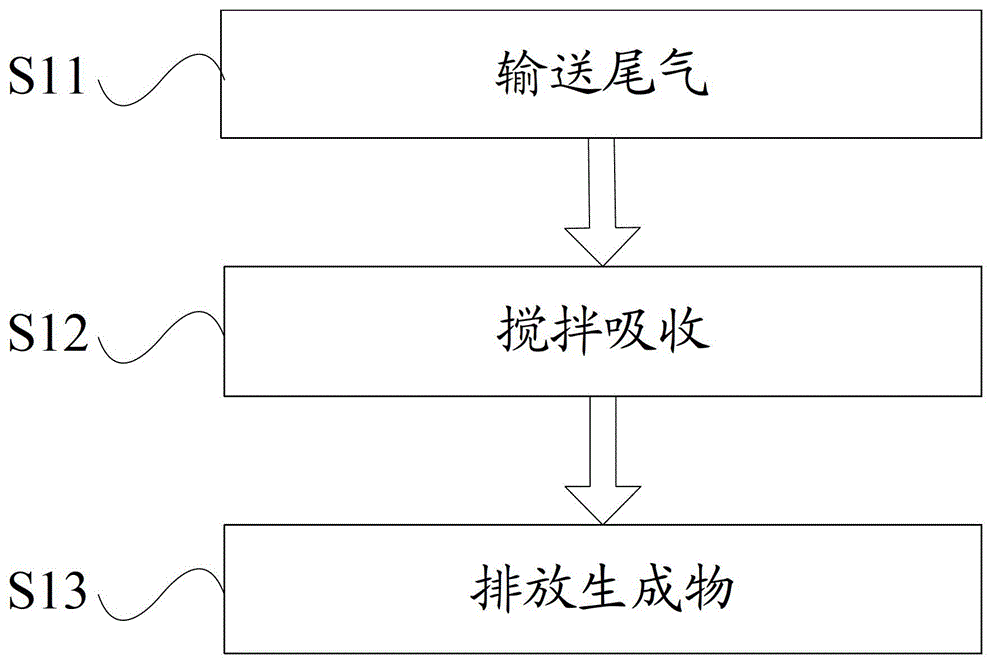

Treatment method and device for tail gas of silane purifying process

ActiveCN103041684AImprove securityPromote environmental protectionDispersed particle separationEngineeringPollution

The invention discloses a treatment method for tail gas of a silane purifying process. The treatment method comprises the following steps of: 11), passing the tail gas of the silane purifying process through a process pipeline, and conveying the tail gas to a first absorbing device, wherein an alkali absorption liquid with concentration of 20%-45% is filled in the first absorbing device; 12), sufficiently absorbing the tail gas of the silane purifying process by the alkali absorption liquid through the stirring of a stirrer in the first absorbing device; and 13), discharging the resultants obtained by the reaction of the tail gas of the silane purifying process and the alkali absorption liquid. According to the treatment method for the tail gas of the silane purifying process disclosed by the invention, the silane in the process tail gas generated in the silane purifying process is absorbed by the alkali solution, so that the tail gas of the silane purifying process is treated in a safe pollution-free manner; and the safety and environment friendliness of a silane rectification process are improved.

Owner:YINGLI ENERGY CHINA

Oil refining alkali dreg waste liquid processing method

ActiveCN104609590AAchieving zero emissionsReduce CODMultistage water/sewage treatmentWater/sewage treatment by neutralisationLiquid wasteSulfur

The invention provides an oil refining alkali dreg waste liquid processing method including the following steps: (1) N2 and SO2 gas mixture is used for acidification of alkali dreg waste liquid; before pH is decreased to 11-9.5, acidified tail gas produced by acidification is discharged into a condensing device, gas discharged by the condensing device is returned to an acidification device to be used as a carrier gas; acidification is continued to be performed until the pH value is dropped to 7-8, acidified tail gas produced by the acidification section is discharged into a sulfur recovery plant for the production of sulfur; acidified tail gas produced after the acidification section is totally returned to the acidification device to be used as the carrier gas for circulation; (2) when the alkali dreg waste liquid pH value is dropped to 2-7, acidification is stopped, and oil phase is separated; (3) the waste liquid with the oil phase recovered is extracted; (4) after extraction, acidic water is added with lime milk for causticizing regeneration, precipitate is isolated to obtain a regenerated alkali liquor, and the regenerated alkali liquor can be reused regeneration of an extracting agent in the step (3) and oil product caustic washing refining. The oil refining alkali dreg waste liquid processing method can effectively recover sulfur resources, sodium resources and phenols in alkali dreg waste liquid, reduces COD of the waste liquid without production of high salt content and high COD waste liquid, and avoids impact to the sewage treatment field; meanwhile recovered lye can be reused for oil product alkali washing refining and extractant regeneration, and the zero discharge of the alkali dreg waste liquid can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

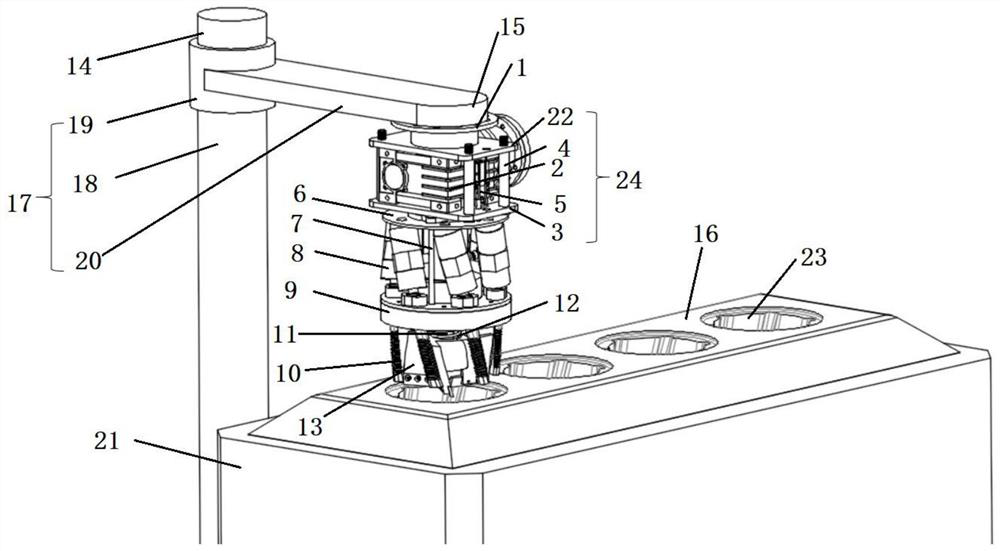

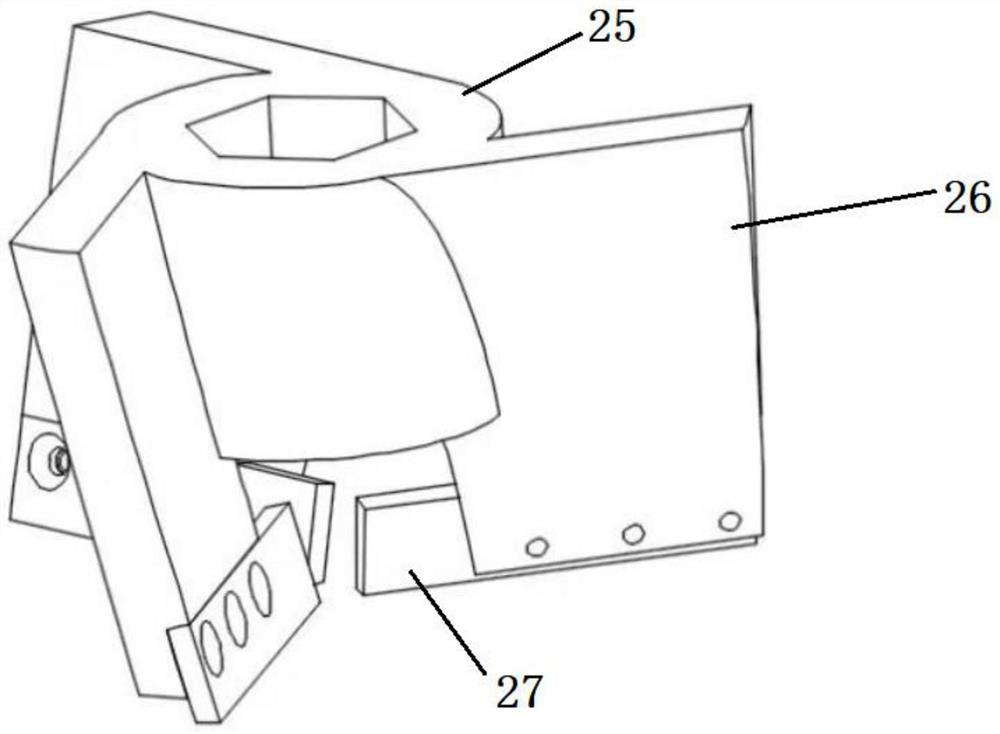

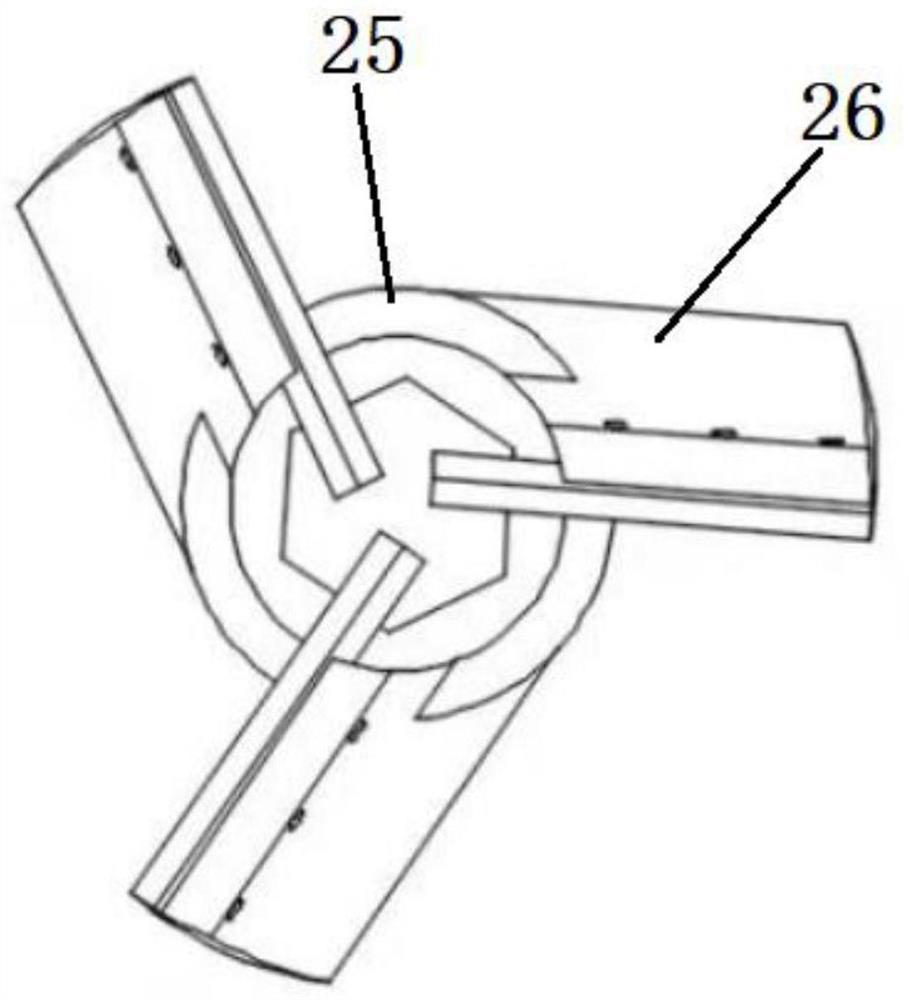

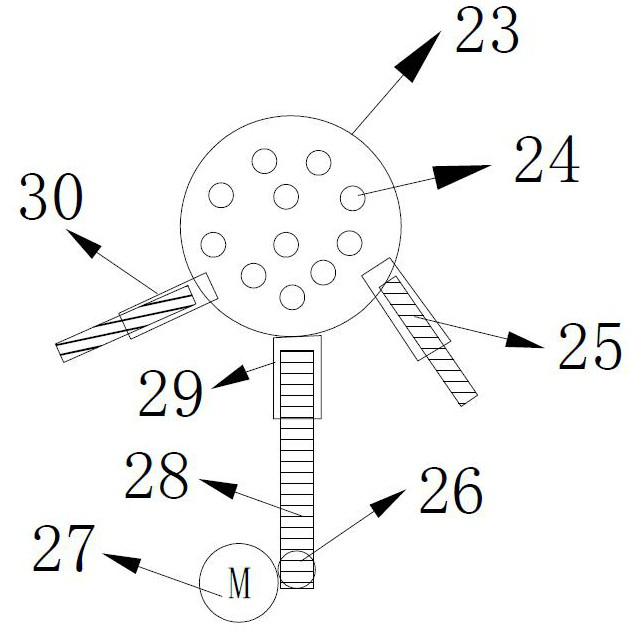

Aluminum anode carbon bowl cleaning cutter and cleaning method

PendingCN112981464AImplement automatic cleanupImprove cleaning efficiencyAluminum anodeMechanical engineering

The invention belongs to the technical field of carbon electrode cleaning equipment, and particularly relates to an aluminum anode carbon bowl cleaning cutter. The cutter comprises a support (17), a flange connecting plate (1), an air cylinder assembly (24), a longitudinal driving device (14), a bidirectional driving device (15) and a cleaning device. The support (17) comprises a cylindrical rod (18), a shaft sleeve (19) and an extension arm (20); the cylindrical rod (18) is fixed to one side of a carbon electrode platform (21), the shaft sleeve (19) sleeves the cylindrical rod (18), the extension arm (20) extends in the radial direction of the shaft sleeve (19), and the shaft sleeve (19) and the extension arm (20) are fixedly connected together; the longitudinal driving device (14) is arranged at the top end of the cylindrical rod (18); the bidirectional driving device (15) is arranged at one end part of the extension arm (20), and a structural connecting piece (1) is arranged below the bidirectional driving device (15); and the cleaning device is arranged below the structural connecting piece (1), and the air cylinder assembly (24) is arranged between the structure connecting piece (1) and the cleaning device.

Owner:BEIJING INSPECT TECH

Yellow phosphorus slag water quenching waste heat recovery device

ActiveCN110926217AImprove production efficiencyImprove waste heat recovery efficiencyCharge manipulationIncreasing energy efficiencyThermal engineeringSlag

The invention relates to the technical field of thermal engineering, and discloses a yellow phosphorus slag water quenching waste heat recovery device. The yellow phosphorus slag water quenching wasteheat recovery device comprises an electric furnace, a slag discharge port, a chute positioned below the slag discharge port, and a water quenching pool connected with the bottom end of the chute, wherein a yellow phosphorus combustion device and a spray type heat exchanger connected with the water quenching pool through a return pipe and a return pump are arranged at the joint of the slag discharge port and the chute; and the spray type heat exchanger is provided with an induced draft fan used for introducing gas in the combustion device into the spray type heat exchanger. The yellow phosphorus slag water quenching waste heat recovery device has the following advantages and effects that slag is firstly subjected to cold water spray cooling, a large amount of steam is collected through a gas collecting hood and then subjected to waste heat recovery in a steam heat exchanger, and the waste heat recovery efficiency is high; and the spray type heat exchanger can recover heat of hot waterin the water quenching pool, P2O5 can be absorbed while the spray type heat exchanger conducts heat exchange, and the effects of energy conservation and consumption reduction are achieved while pollution control is achieved.

Owner:HUBEI YAOZHIHE CHEM

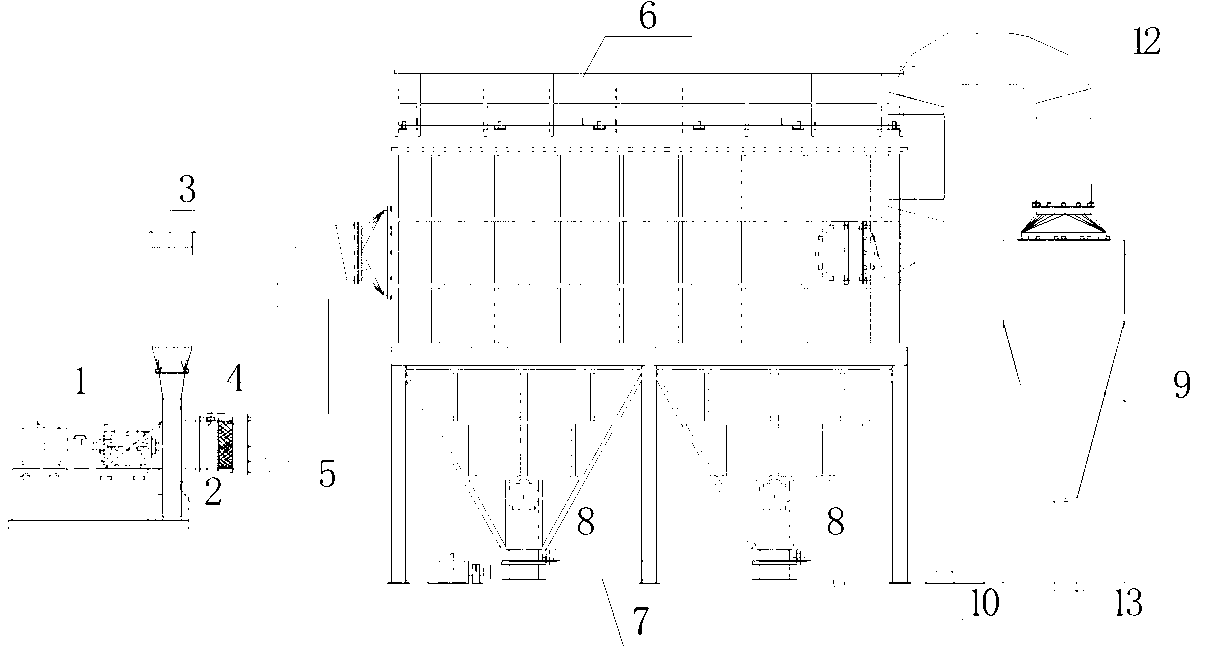

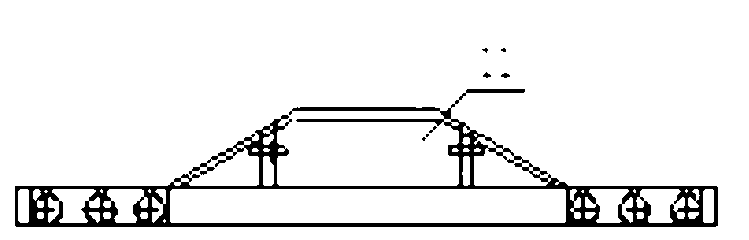

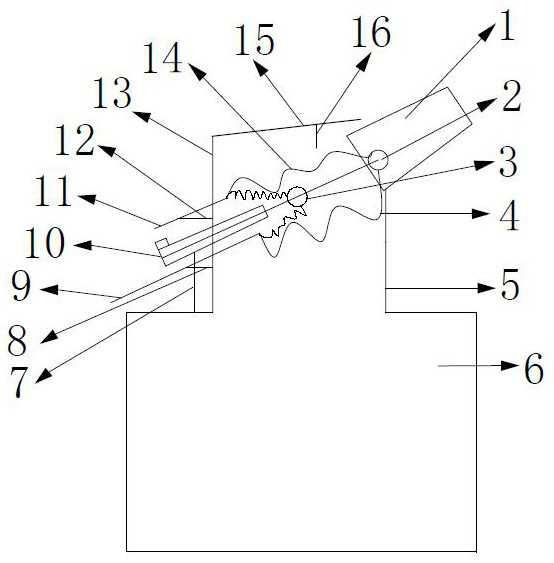

Matching vehicle-mounted movable coal-charging, coke-pushing and dust-removing apparatus of clean heat recovery coke oven

InactiveCN103074091AReduce pollutionAchieve the effect of mobile dust removalHuman health protectionCombination devicesEngineeringCoke oven

The invention provides a matching vehicle-mounted movable coal-charging, coke-pushing and dust-removing apparatus of a clean heat recovery coke oven. According to the invention, a motor (1) is connected with an induced draught fan (2), a chimney (3) is arranged above the induced draught fan (2), the induced draught fan (2) is connected with a bag filter (6) through a first connection pipeline (5), a first dust discharging valve (8) is arranged below the bag filter (6), a screw conveyer (7) is arranged below the first dust discharging valve (8), a cyclone dust collector (9) is connected with the bag filter (6) through a second connection pipeline (12), a second dust discharging valve (13) is arranged below the cyclone dust collector (9), an air compressor (10) is arranged between the first dust discharging valve (8) and the second dust discharging valve (13), and a movable dust cage (11) is arranged below the second dust discharging valve (13). The apparatus provided by the invention overcomes the problem that coke dust and raw coke oven gas escape from a coke chamber of a clean heat recovery stamping coke oven in the processes of coal charging and coke pushing and reduces environmental pollution.

Owner:山西沁新能源集团股份有限公司

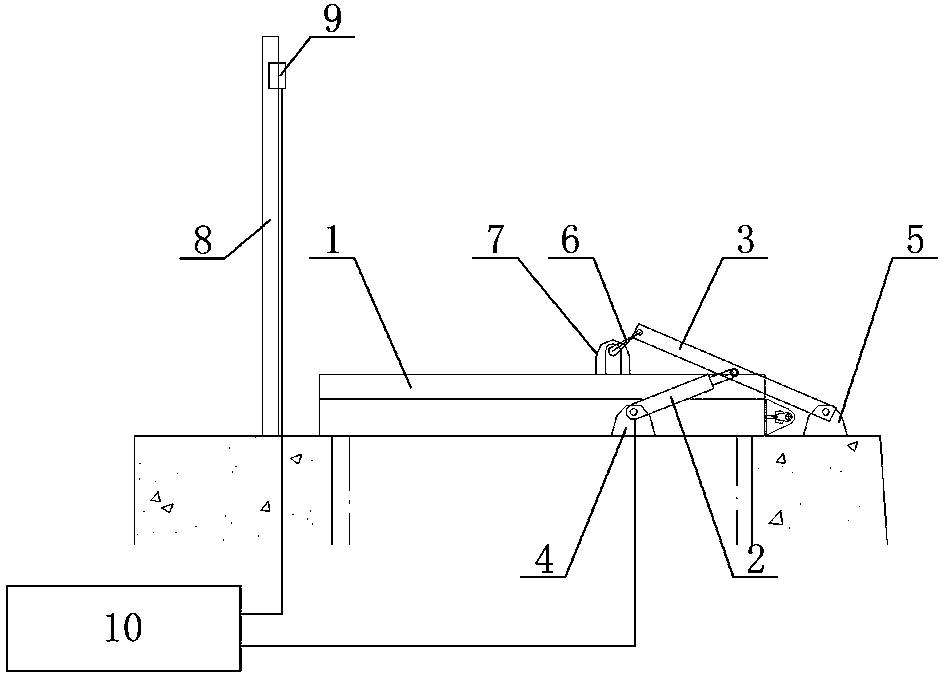

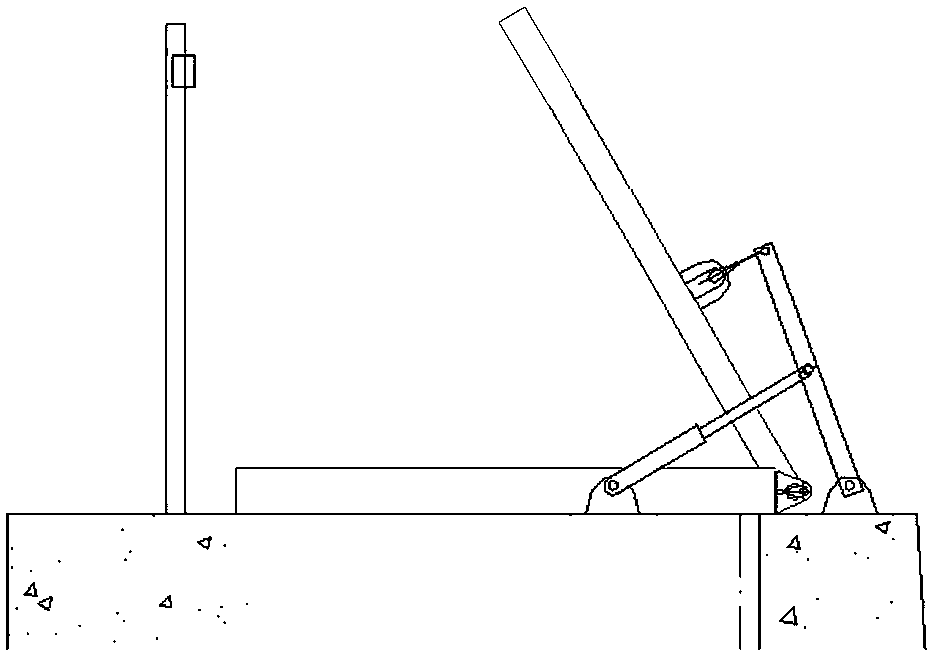

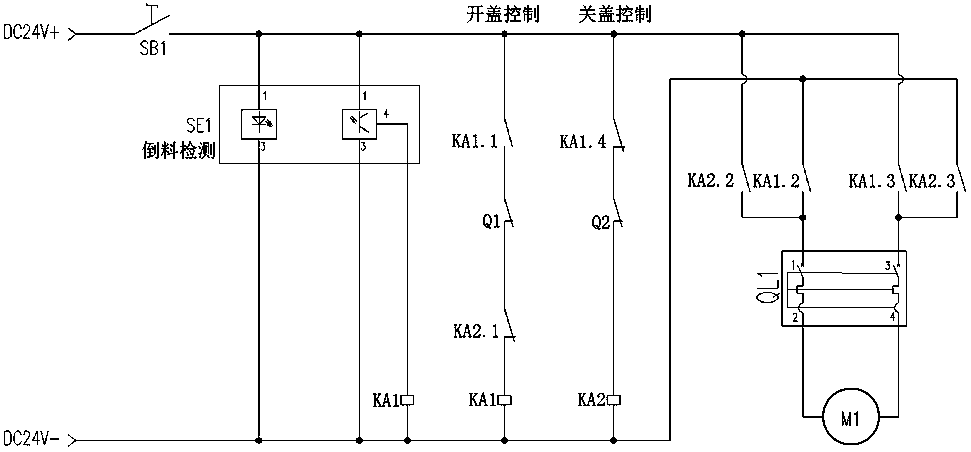

Garbage vertical collection system based on functions of automatically opening and closing carriage cover

PendingCN110877794ALow powerReduce noiseRefuse vehiclesWaste collection and transferGarbage collectionCollection system

The invention relates to a garbage vertical collection system based on the functions of automatically opening and closing a carriage cover, and belongs to the technical field of garbage collection systems. The garbage vertical collection system aims to solve the technical problem of improvement in the structure of the garbage vertical collection system with the functions of automatically opening and closing the carriage cover. According to the technical scheme, the garbage vertical collection system comprises a cover opening device, an infrared detection device and a carriage cover which are arranged at a garbage vertical collection opening; the cover opening device includes an electric push rod and a driving connecting rod; one end of the electric push rod is hinged to a first fixing lugarranged at the garbage vertical collection opening, and the other end of the electric push rod is hinged to the middle part of the driving connecting rod; one end of the driving connecting rod is hinged to a second fixing lug arranged at the edge of the garbage vertical collection opening, and a hook is movably arranged at the other end of the driving connecting rod; and a cover opening hanging lug is further arranged at the position, close to the other end of the driving connecting rod, on the carriage cover, and the hook is connected and fixed to the cover opening hanging lug in a hanging mode. The garbage vertical collection system is applied to the garbage collection systems.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

A method and device for treating tail gas in a silane purification and purification process

ActiveCN103041684BImprove securityPromote environmental protectionDispersed particle separationPurification methodsSilanes

The invention discloses a treatment method for tail gas of a silane purifying process. The treatment method comprises the following steps of: 11), passing the tail gas of the silane purifying process through a process pipeline, and conveying the tail gas to a first absorbing device, wherein an alkali absorption liquid with concentration of 20%-45% is filled in the first absorbing device; 12), sufficiently absorbing the tail gas of the silane purifying process by the alkali absorption liquid through the stirring of a stirrer in the first absorbing device; and 13), discharging the resultants obtained by the reaction of the tail gas of the silane purifying process and the alkali absorption liquid. According to the treatment method for the tail gas of the silane purifying process disclosed by the invention, the silane in the process tail gas generated in the silane purifying process is absorbed by the alkali solution, so that the tail gas of the silane purifying process is treated in a safe pollution-free manner; and the safety and environment friendliness of a silane rectification process are improved.

Owner:YINGLI ENERGY CHINA

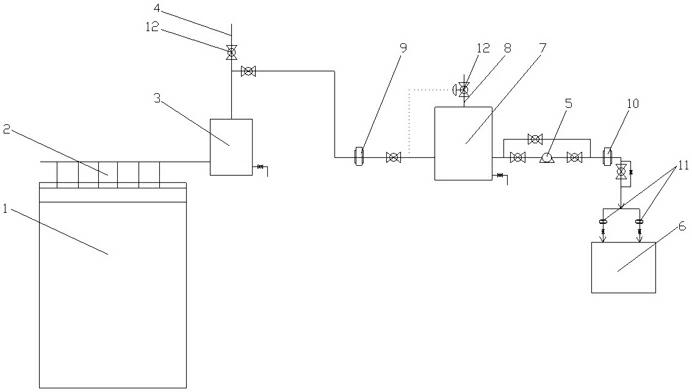

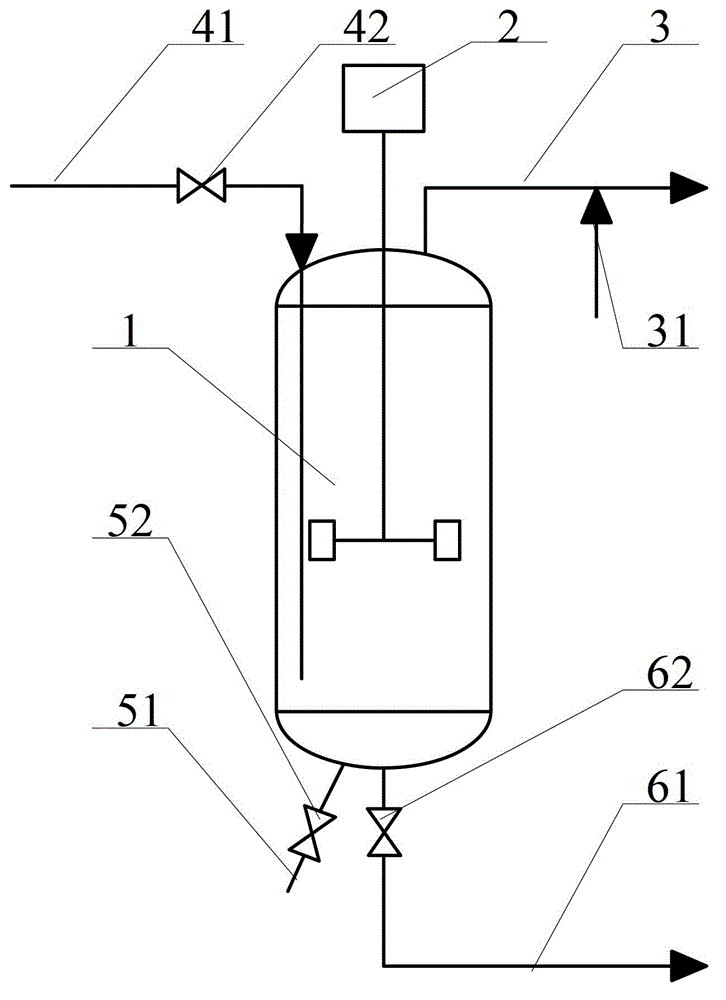

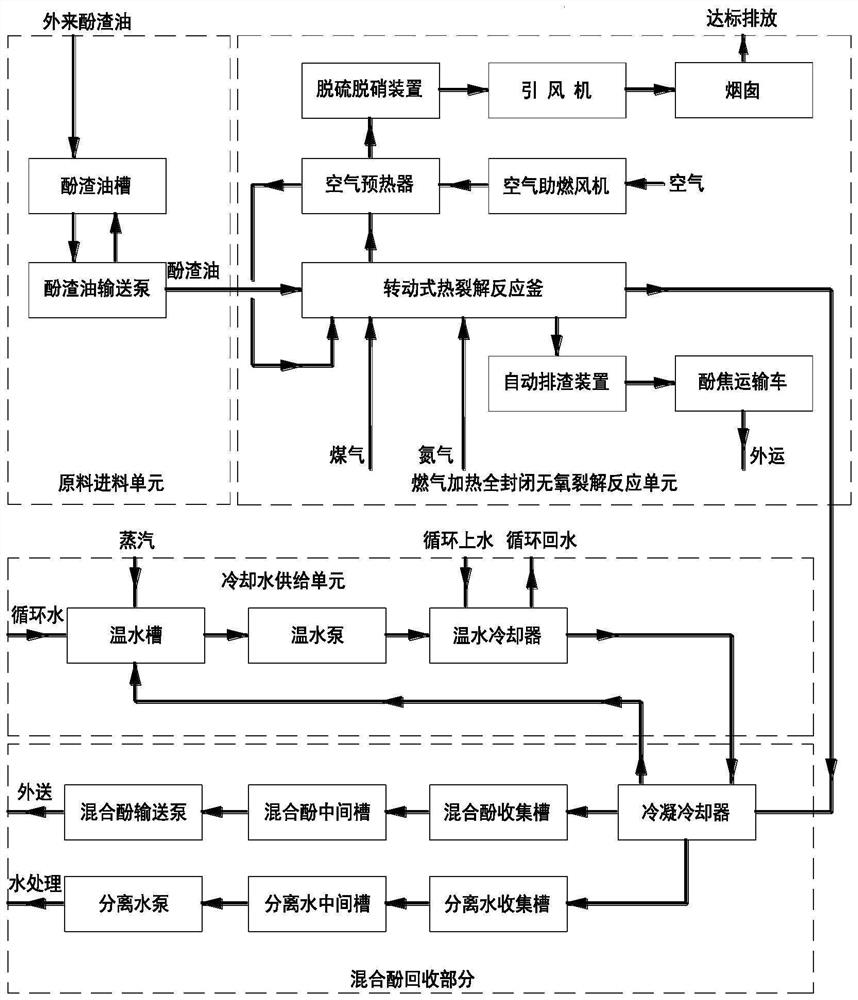

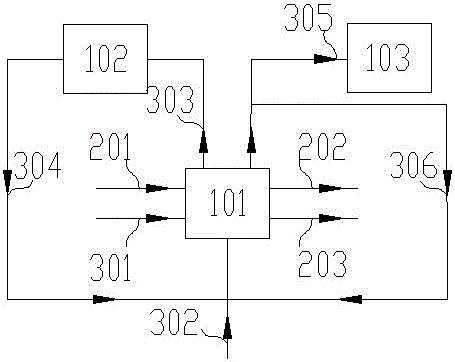

System and method for recovering mixed phenol in phenol residual oil

PendingCN114106861AAvoid Fugitive EmissionsHigh recovery rateOrganic chemistryOrganic compound preparationProcess engineeringGas heating

The invention relates to a system and a method for recovering mixed phenol in phenol residual oil, the system comprises a raw material feeding unit, a gas heating totally-closed anaerobic cracking reaction unit, a mixed phenol recovery unit and a cooling water supply unit, the raw material feeding unit stores and conveys raw materials to the gas heating totally-closed anaerobic cracking reaction unit; mixed phenol gas produced by the gas heating totally-closed anaerobic cracking reaction unit is introduced into the mixed phenol recovery unit, and the cooling water supply unit provides condensed circulating water for the mixed phenol recovery unit. According to the invention, the phenol residue oil can be treated, phenolic substances in the phenol residue are recovered while environmental protection is met, the recovered mixed phenol is fed into the raw material tank for refining the crude phenol, and then subsequent processing is carried out along with the crude phenol raw material, so that the product recovery rates of phenol, o-cresol, m-cresol, p-cresol and xylenol are increased, the yield of corresponding products is increased, and the production cost is reduced. And certain economic benefits are increased for enterprises, and both environmental protection and economy are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

A kind of treatment method of oil refining alkali residue waste liquid

ActiveCN104609590BEfficient reuseReduce CODMultistage water/sewage treatmentWater/sewage treatment by neutralisationLiquid wasteSulfur

The invention provides an oil refining alkali dreg waste liquid processing method including the following steps: (1) N2 and SO2 gas mixture is used for acidification of alkali dreg waste liquid; before pH is decreased to 11-9.5, acidified tail gas produced by acidification is discharged into a condensing device, gas discharged by the condensing device is returned to an acidification device to be used as a carrier gas; acidification is continued to be performed until the pH value is dropped to 7-8, acidified tail gas produced by the acidification section is discharged into a sulfur recovery plant for the production of sulfur; acidified tail gas produced after the acidification section is totally returned to the acidification device to be used as the carrier gas for circulation; (2) when the alkali dreg waste liquid pH value is dropped to 2-7, acidification is stopped, and oil phase is separated; (3) the waste liquid with the oil phase recovered is extracted; (4) after extraction, acidic water is added with lime milk for causticizing regeneration, precipitate is isolated to obtain a regenerated alkali liquor, and the regenerated alkali liquor can be reused regeneration of an extracting agent in the step (3) and oil product caustic washing refining. The oil refining alkali dreg waste liquid processing method can effectively recover sulfur resources, sodium resources and phenols in alkali dreg waste liquid, reduces COD of the waste liquid without production of high salt content and high COD waste liquid, and avoids impact to the sewage treatment field; meanwhile recovered lye can be reused for oil product alkali washing refining and extractant regeneration, and the zero discharge of the alkali dreg waste liquid can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

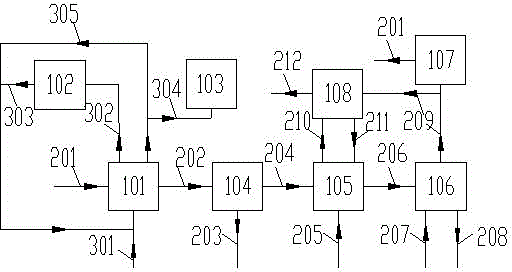

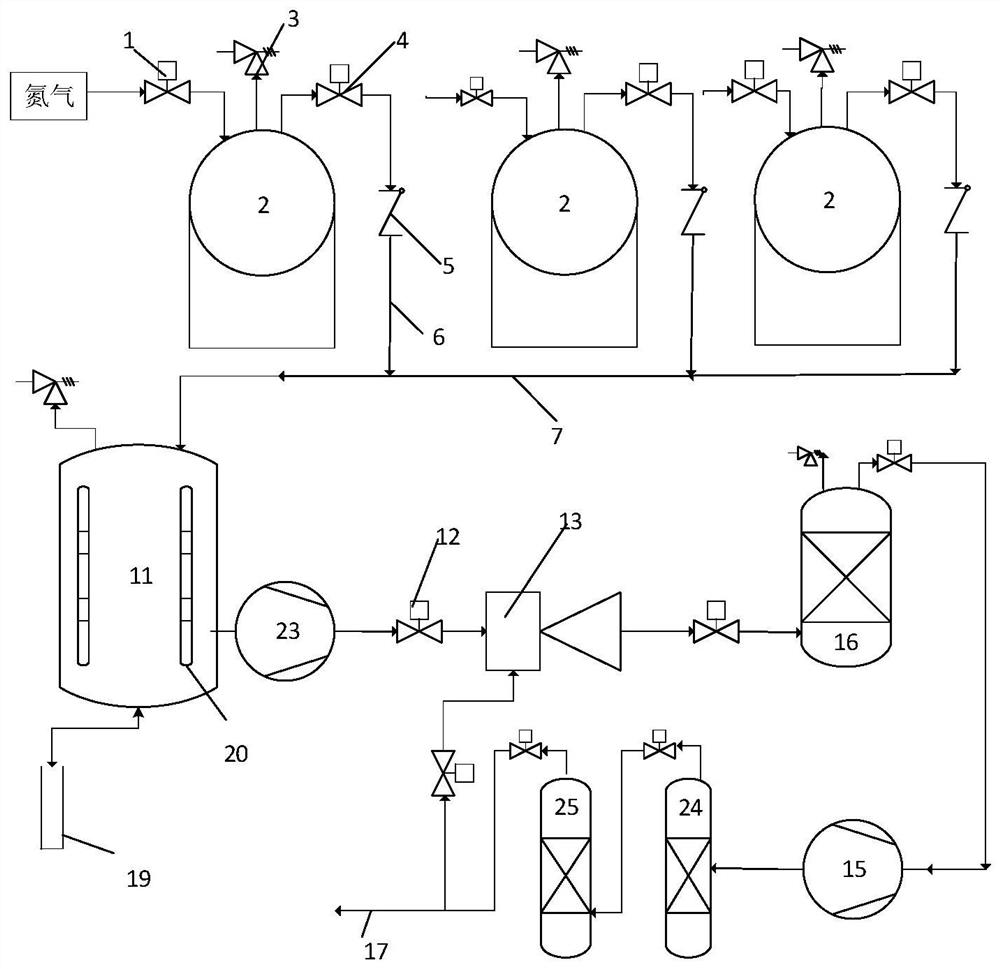

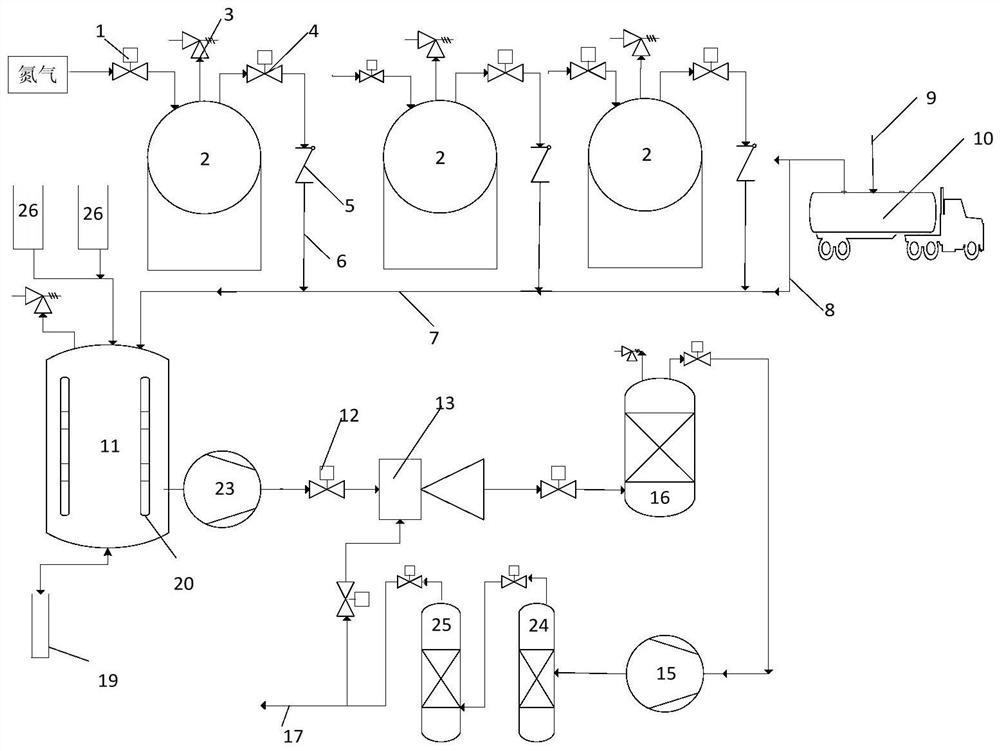

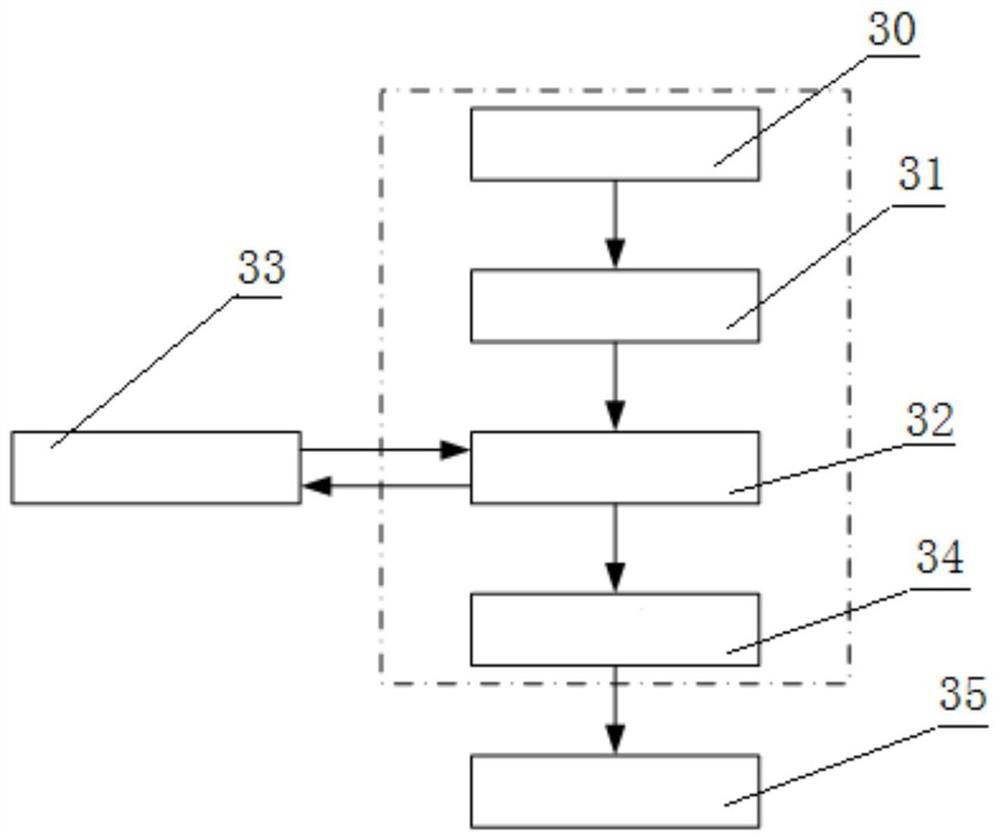

A method and device for treating coking tail gas

ActiveCN109609219BRealize closed collectionAvoid fugitive emissionsGaseous fuelsDispersed particle separationBuffer tankCoking plant

The invention discloses a coking tail gas treating method and device. The method includes the following steps that storage tanks storing coking tail gas are closed or sealed through nitrogen filling;the coking tail gas of the storage tanks is charged into a buffering tank for carrying out gas-liquid separation on the coking tail gas, and is cooled and subjected to primary dewatering, naphthaleneremoving and tar removing in the buffering tank; the coking tail gas is sucked into a venture mixer for removing impurities of the coking tail gas from the buffering tank, and a hydrogenation source is introduced into the venture mixer; gas after being mixed in the venture mixer is discharged into a deoxidizing tank and subjected to catalytic hydrogenation deoxidizing; qualified coking tail gas after detection is discharged into a main gas pipe of a coking-plant gas purification system, or is discharged into a later tail gas treatment system. According to the coking tail gas treating method, the collected high-oxygen-content coking tail gas is subjected to hydrogenation deoxidizing, the oxygen content in the coking tail gas is reduced accordingly, the oxygen content in the coking tail gascan be reduced to 0.5% or below, and the coking tail gas can be directly fed into the coking-plant gas purification system and is further purified.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

A coke oven sealing and ventilation dust removal device and method

ActiveCN109666487BAvoid fugitive emissionsMeet the protection requirementsOven incrustations prevention/removalDust controlFresh air

The invention provides a sealing and ventilation dust removal device and method of a coke oven. The sealing and ventilation dust removal device comprises a closed workshop formed by hanging walls, parallel string-net racks, pressure bars, corner braces, a roof, purlines, drawing bars, workshop columns, inter-column braces and the like; dust removal equipment such as an electric valve, a pneumaticvalve, a coke-side smoke exhaust cover, a rising pipe smoke exhaust cover, a furnace top smoke exhaust cover, a compensator, a draught fan, a pulse bag-type dust collector, a chimney and the like; andventilation equipment such as a fresh air pipeline, a primary effect filter, a surface cooler, a refrigerator unit, an air supplier and the like. The method comprises the following steps: 1, sealing;2, ventilating; 3, collecting dust; 4, accident diffusing; 5, smoke conveying pipeline; and 6, treating and discharging the smoke. The sealing and ventilation dust removal device and method have theadvantages that all coke oven smoke released from the top of a coal loader, a rising pipe and a coke extinguishing tank can be collected in a closed space; and by virtue of the ventilation system andaccident treatment system, the labor environment of the operation workers can be improved, the adverse influence of the environment pollution for the operation workers can be reduced, the coke oven smoke can be discharged by reaching standard after the dust removal treatment, and the discharging concentration is less than or equal to 10 mg / Nm3.

Owner:北京中冶设备研究设计总院有限公司

Treatment method of oil refining alkali slag waste liquid

ActiveCN104611003BEfficient reuseReduce CODMultistage water/sewage treatmentHydrocarbon oils refiningOil phaseWater processing

The invention provides an oil refining alkali dreg waste liquid processing method including the following steps: (1) sulfuric acid is used for acidification of alkali dreg waste liquid, and nitrogen is introduced; before pH is decreased to 11-9.5, acidified tail gas produced by acidification is discharged into a condensing device, gas discharged by the condensing device is returned to an acidification device to be used as a carrier gas; acidification is continued to be performed until the pH value is dropped to 7-8, acidified tail gas produced by the acidification section is discharged into a sulfur recovery plant for the production of sulfur; acidified tail gas produced after the acidification section is totally returned to the acidification device to be used as the carrier gas; (2) when the alkali dreg waste liquid pH value is dropped to 2-7, acidification is stopped, and oil phase is separated; (3) the waste water with the oil phase recovered is extracted; (4) after extraction, acidic liquid is processed with sodium hydroxide, the sodium hydroxide is added according to the final concentration of alkali of 20wt%-50wt%, and precipitate is isolated to obtain an alkali liquor capable of being reused. The oil refining alkali dreg waste water processing method can effectively recover sulfur resources, sodium resources and phenols in alkali dreg waste water, reduces COD of the waste liquid without production of high salt content and high COD waste liquid, and avoids impact to the sewage treatment field; meanwhile recovered lye can be reused for oil product alkali washing refining and extractant regeneration, and the zero discharge of the alkali dreg waste water can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for preparing electro-deposited cobalt under a large flow rate

ActiveCN103060842BImprove current efficiencyReduce cathodic polarizationPhotography auxillary processesOxygenCathodic polarization

The invention discloses a method for preparing electrodeposited cobalt under a large flow. In conventional production methods for electrodeposited cobalt, the process of processing has the disadvantages of low current efficiency and long electrodeposition time, and purity and a recovery rate of produced electrodeposited cobalt hardly reach requirements. A technical scheme employed in the invention is as follows: a deoiled cobalt chloride solution produced in wet metallurgy is used as a raw material and is diluted with pure water so as to allow the concentration of Co<2+> in the cobalt chloride solution to be 30 to 100 g / L, and the diluted cobalt chloride solution is used as electrodeposition pre-liquid; and electrodeposition is carried out on the electrodeposition pre-liquid in an enclosed electrodeposition apparatus under the conditions of a large flow of 5 to 15 m<3> / h.m<2> and a negative pressure. According to the invention, the large flow is employed in the process of preparation of electrodeposited cobalt, so cathodic polarization is reduced, high current efficiency as high as more than 95% is obtained, and direct current consumption is low; utilization of the large flow enables chlorine and oxygen generated by an anode to be taken away in time, and oxidation of the cathode cobalt by chlorine and oxygen is prevented, thereby guaranteeing product quality.

Owner:ZHEJIANG HUAYOU COBALT +1

Organic sewage constructed wetland processing and high-yield non-food energy plant cultivating technology

InactiveCN101805061BAvoid fugitive emissionsPromotes fast digestionWater contaminantsGas production bioreactorsConstructed wetlandPlanting seed

The invention relates to an organic sewage constructed wetland processing and high-yield non-food energy plant cultivating technology, which is characterized in that the organic sewage is sent into a methane tank, an oxidation pond and a constructed wetland orderly to achieve the purpose of sewage purification, and simultaneously, the non-food energy plant is cultivated. The invention has the advantages that a buried type ABR system can be ensured to be in an intermediate-temperature fermentation state, the organic matter is digested quickly, and methane is produced with high yield; the methane is used for intensifying light, heating, increasing carbon dioxide fertilizer and enhancing photosynthesis for the system to produce the non-food energy plant with high yield; under the previous condition, plant seeds and energy plants on the oxidation pond (the stabilization pond) and the constructed wetland can grow quickly so as to obtain high yield and produce high-quality protein feed, andthe normal growth and absorption of eutrophic substances in the sewage in winter can be ensured; simultaneously, purified reclaimed water is fully utilized; and the plants inside and outside the system grow quickly, a large amount of carbon dioxide is absorbed and utilized, and zero emission of sewage and methane is realized.

Owner:罗仕均

Multifunctional feeding device of kitchen garbage treatment equipment

PendingCN112357395AAvoid fugitive emissionsTimely supplementRefuse receptaclesFresh airEnvironmental engineering

The invention discloses a multifunctional feeding device of kitchen garbage treatment equipment. The multifunctional feeding device of the kitchen garbage treatment equipment mainly comprises a frontsealing plate, a rear sealing plate, a right sealing plate, a left sealing plate, a cover plate, a baffle plate, a telescopic spraying device, a water inlet pipe and a compressed air inlet pipe, wherein the telescopic spraying device comprises a telescopic spraying device support, an electric linear push rod and a spraying ball; the end of the electric linear push rod is in threaded connection with the spraying ball; small spraying holes are formed in the surface of the spraying ball; the spraying ball is in threaded connection with a water inlet pipe and connected with the compressed air inlet pipe through a quick connector; the water inlet pipe comprises a water inlet hard pipe, a water inlet hose and a water inlet pipe support; and the compressed air inlet pipe comprises a compressed air hard pipe, a compressed air hose and a compressed air pipe support. The multifunctional feeding device of the kitchen garbage equipment is closed, so that waste gas is prevented from being discharged disorderly; and the telescopic spraying device can clean a kitchen garbage can in time and supplement fresh air and water in time, so that the oxygen content and the humidity of a feeding bin are controlled.

Owner:龚娟

Acidification treatment method of oil refining alkali residue waste liquid

ActiveCN104609591BEfficient removalEfficient recyclingSulfur preparation/purificationMultistage water/sewage treatmentOrganic sulfide compoundOil phase

The invention provides an oil refining alkali dreg waste water acidizing processing method including the following steps: (1) acidification processing of oil refining alkali dreg waste water is performed, and nitrogen is introduced; (2) before pH is decreased to 11-9.5, acidified tail gas produced by acidification is discharged into a condensing device, gas discharged by the condensing device is returned to the step (1) to be used as a carrier gas; (3) along with the acidification, the pH value is continued to decrease, and when the pH value is dropped to 7-8, acidified tail gas produced by the acidification section is discharged into a sulfur recovery plant for the production of sulfur; (4) after the acidification is continued to perform until the pH value is dropped to lower than 7, the acidified tail gas is totally returned to the step (1) to be used as the carrier gas; and (5) when the alkali dreg waste water pH value is dropped to 2-7, the acidification is stopped, and oil phase is separated. The oil refining alkali dreg waste water processing method can effectively remove sulfides in alkali dreg waste water, organic sulfide and hydrogen sulfide in the acidified tail gas can be respectively recovered, and recycled, and efficient economic acidification process can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

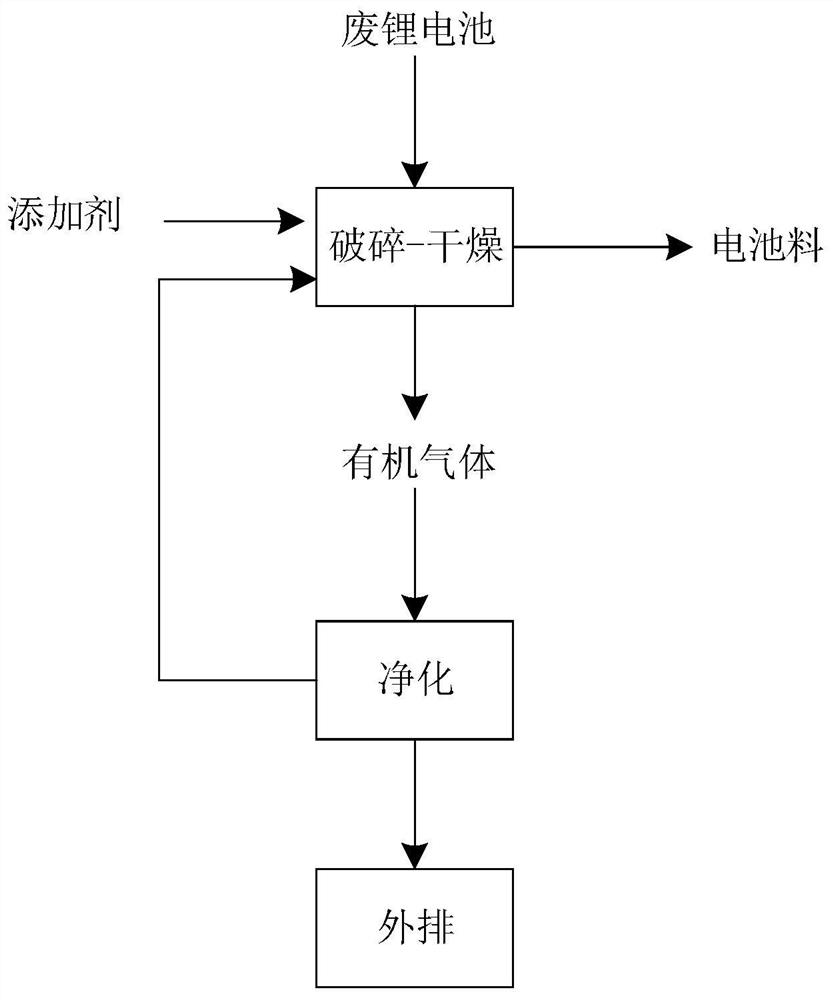

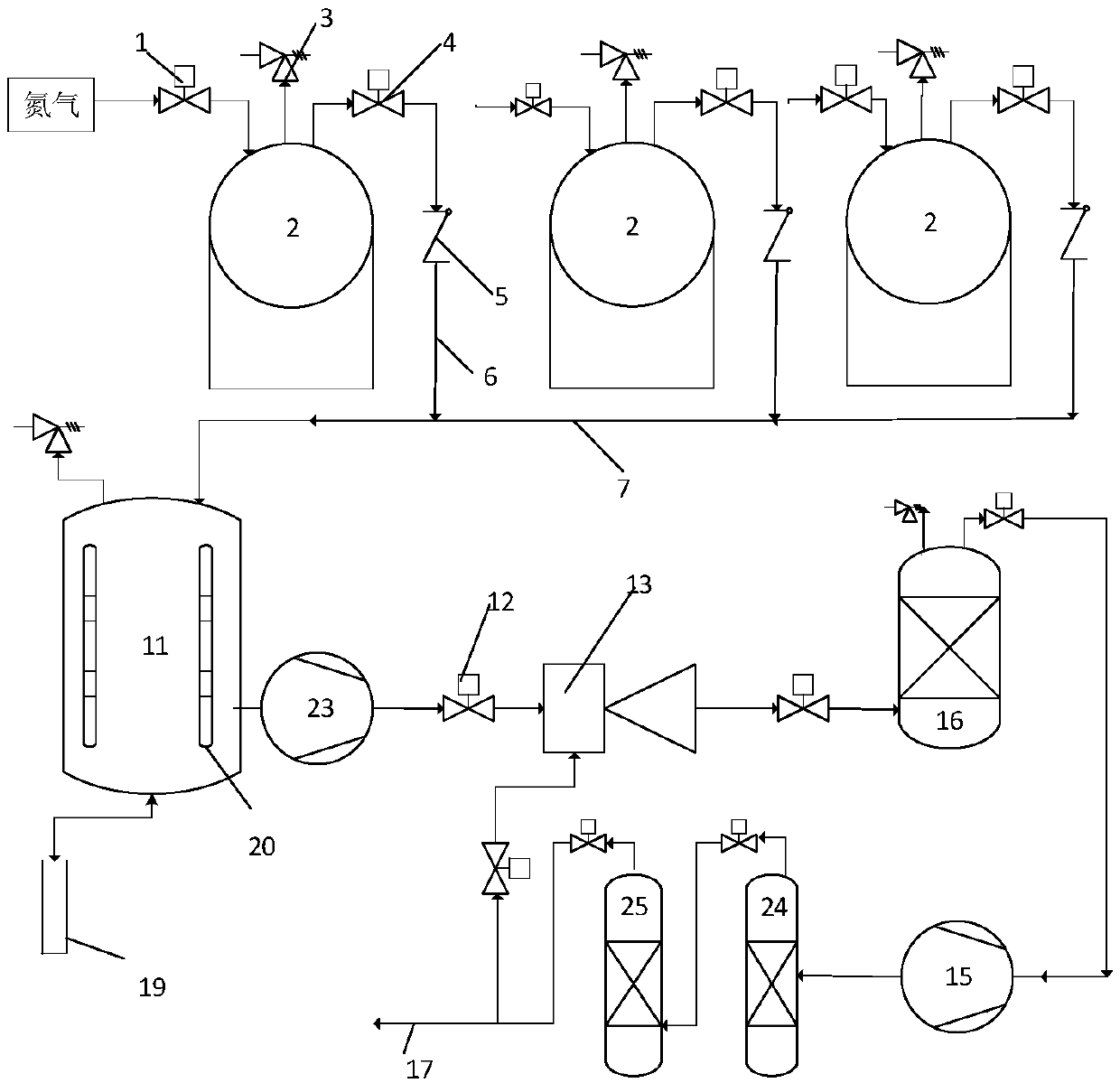

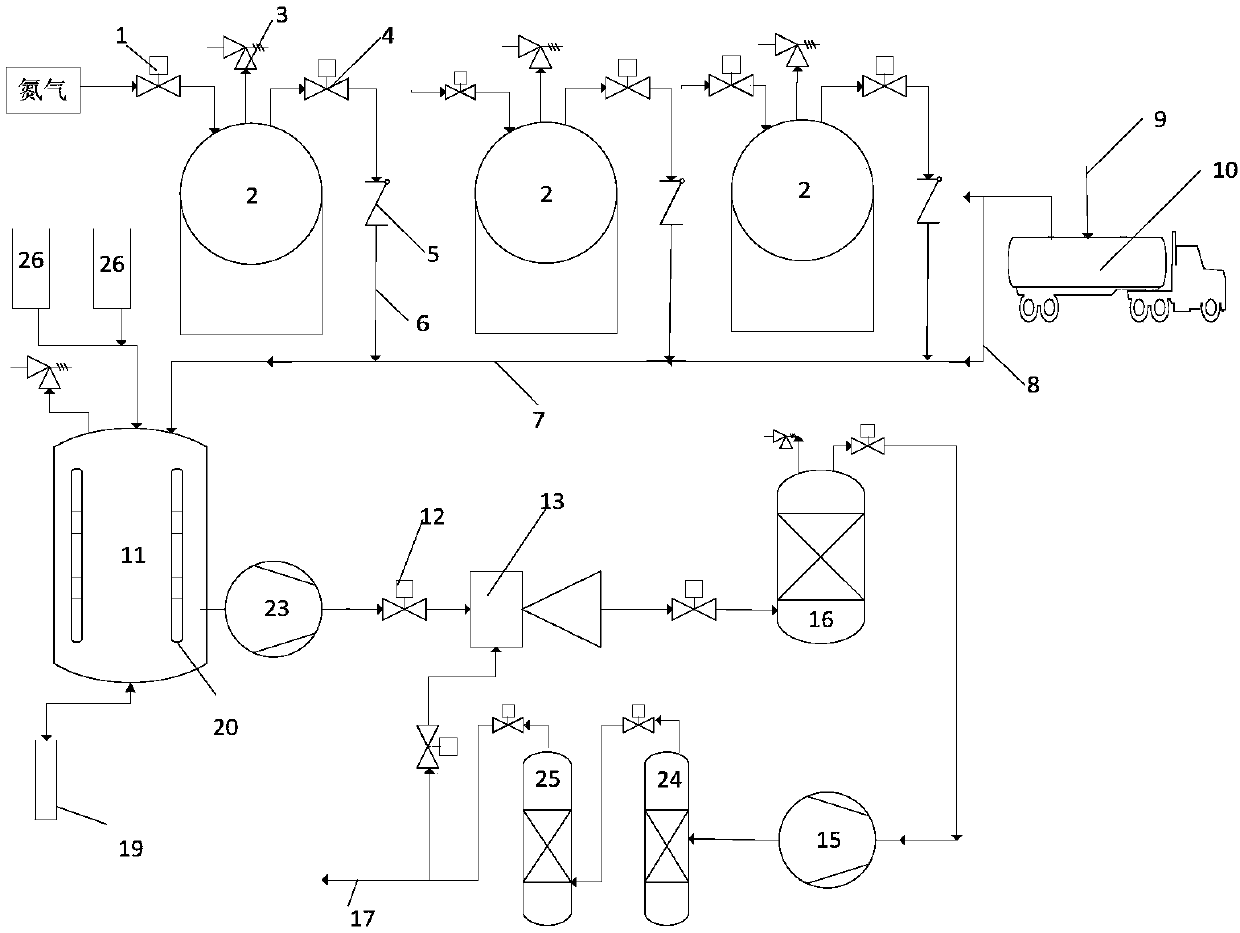

Harmless treatment method for waste lithium battery electrolyte

ActiveCN112820970AHarmlessAvoid reflowWaste accumulators reclaimingBattery recyclingElectrolytic agentEngineering

The invention provides a harmless treatment method for a waste lithium battery electrolyte, which comprises the following steps: crushing and drying a discharged waste lithium battery in sequence to obtain a battery material without the electrolyte and an organic gas; after the organic gas is subjected to purification treatment, recycling part of the organic gas for drying treatment, and discharging the residual gas; and monitoring the oxygen concentration, the organic gas concentration, the fluoride concentration, the chloride concentration and the system temperature in the crushing treatment and drying treatment process, and when any numerical value exceeds a set value, introducing an additive for adjustment. By means of the treatment method, harmlessness of the waste battery electrolyte can be achieved, diaphragm soft melting and unorganized emission of organic waste gas are avoided, meanwhile, purified gas is recycled, waste heat is fully utilized, and meanwhile the waste gas emission amount is greatly reduced; meanwhile, by monitoring the gas concentration, safety accidents of equipment in the production process are effectively avoided, and the requirements of safe production and clean production are met.

Owner:中科南京绿色制造产业创新研究院 +1

Coking tail gas treating method and device

ActiveCN109609219AAvoid Fugitive EmissionsSolve the problem of high oxygen content in gasDispersed particle separationGaseous fuelsTarExhaust gas

The invention discloses a coking tail gas treating method and device. The method includes the following steps that storage tanks storing coking tail gas are closed or sealed through nitrogen filling;the coking tail gas of the storage tanks is charged into a buffering tank for carrying out gas-liquid separation on the coking tail gas, and is cooled and subjected to primary dewatering, naphthaleneremoving and tar removing in the buffering tank; the coking tail gas is sucked into a venture mixer for removing impurities of the coking tail gas from the buffering tank, and a hydrogenation source is introduced into the venture mixer; gas after being mixed in the venture mixer is discharged into a deoxidizing tank and subjected to catalytic hydrogenation deoxidizing; qualified coking tail gas after detection is discharged into a main gas pipe of a coking-plant gas purification system, or is discharged into a later tail gas treatment system. According to the coking tail gas treating method, the collected high-oxygen-content coking tail gas is subjected to hydrogenation deoxidizing, the oxygen content in the coking tail gas is reduced accordingly, the oxygen content in the coking tail gascan be reduced to 0.5% or below, and the coking tail gas can be directly fed into the coking-plant gas purification system and is further purified.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

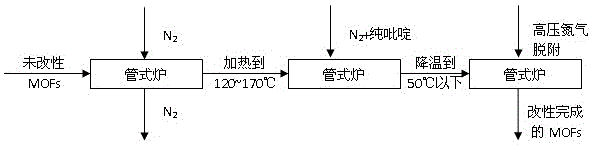

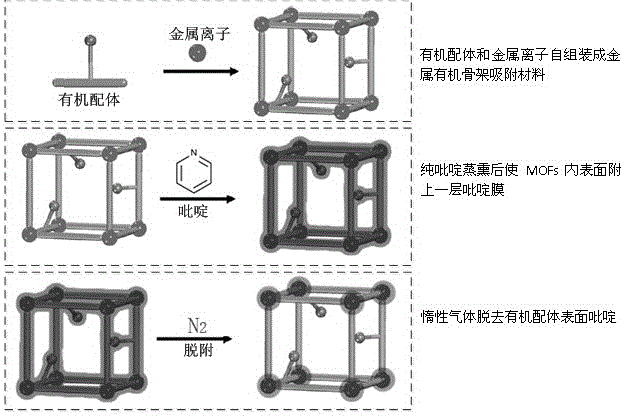

A method for surface modification of metal-organic framework adsorption materials

InactiveCN104549185BFew stepsEasy to operateOther chemical processesDispersed particle separationChemical treatmentDesorption

The invention relates to a surface modification method of a metal-organic framework adsorbing materials. Metal-organic framework porous adsorbing materials (MOFs) are subjected to chemical treatment in a plurality of steps, so that the adsorptive property on non-polar organic gas molecules in presence of water molecules can be improved. The preparation method of the materials comprises the following steps: firstly, putting to-be-modified MOFs into a tube furnace, and introducing nitrogen to ensure no residual air inside; introducing a certain amount of pure pyridine (C5H5N) into the tube furnace together with the N2, and reacting at certain temperature; cooling a reaction tube containing the MOFs to below 50 DEG C, and introducing N2 to the tube furnace; and after desorption is ended taking out and encapsulating the modified MOFs for later use. The metal-organic framework porous adsorbing materials are simple in modification process and high in operability; and the problems of adsorptive property degradation and internal structure damage of the non-polar organic gas molecules caused by hydrophilia of metallic clusters in MOFs porous materials can be solved by the MOFs prepared by the method.

Owner:TONGJI UNIV

A waste heat recovery device for yellow phosphorus slag water quenching

ActiveCN110926217BImprove production efficiencyImprove waste heat recovery efficiencyCharge manipulationIncreasing energy efficiencyThermal engineeringSlag

Owner:HUBEI YAOZHIHE CHEM

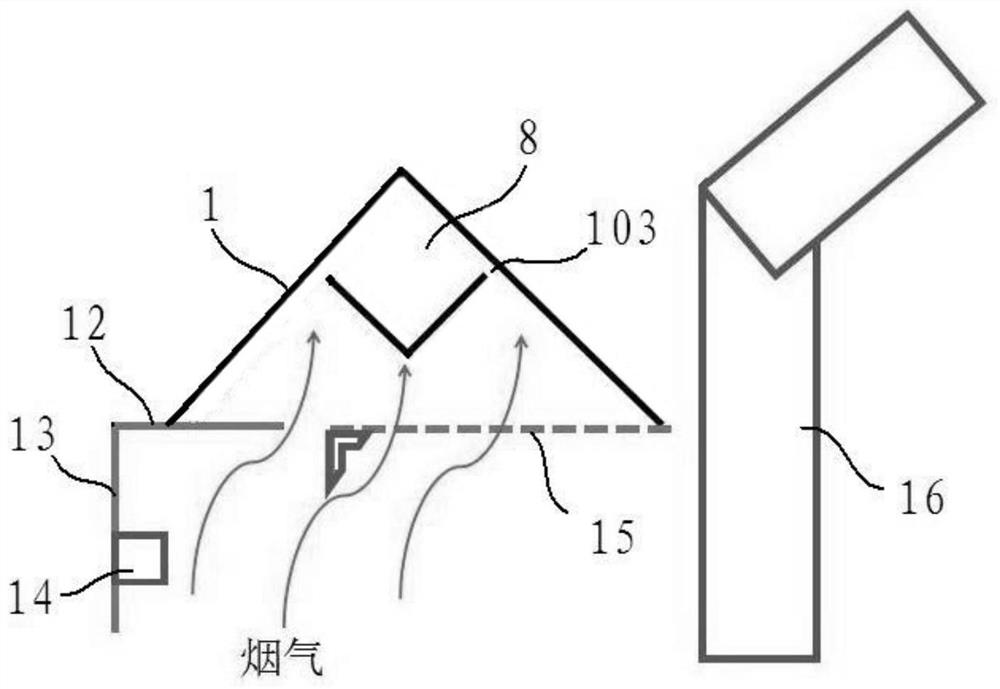

Collecting device for cathode square steel head smoke during roasting of aluminum electrolysis cell

A collecting device for cathode square steel head smoke during roasting of an aluminum electrolysis cell is composed of an air collecting cover body, baffles, a transition pipe, a branch soft connecting pipe, a header soft connecting pipe, a header three-way pipe and a branch smoke pipe. The air collecting cover body is formed by tightly connecting a plurality of air collecting covers. Each air collecting cover is composed of an outer angle plate, an inner angle plate and an air hole. The baffles are arranged at the two ends of the air collecting cover body, so that the air collecting cover body and the two baffles form a closed space, and a negative pressure cavity is formed in the air collecting cover body. The transition pipe penetrates through the baffle arranged at one end of the aircollecting cover body and communicates with the negative pressure cavity. The other end of the transition pipe communicates with the branch soft connecting pipe. The branch soft connecting pipe communicates with the header soft connecting pipe through the header three-way pipe. The header three-way pipe is connected to the smoke pipe. The collecting device for cathode square steel head smoke during roasting of the aluminum electrolysis cell is used for centralized recovery of smoke through the negative pressure cavities formed between the outer angle plates and the inner angle plates of the air collecting covers in combination with a subsequent collecting pipeline, and avoids unorganized emission of smoke in the production process.

Owner:鹤庆溢鑫铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com