Oil refining alkali dreg waste liquid processing method

A technology for refining alkali residue and alkali residue waste liquid, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc. High content, adverse effects of sewage treatment equipment, etc., to achieve good environmental and economic benefits, reduce COD, avoid random discharge and special treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

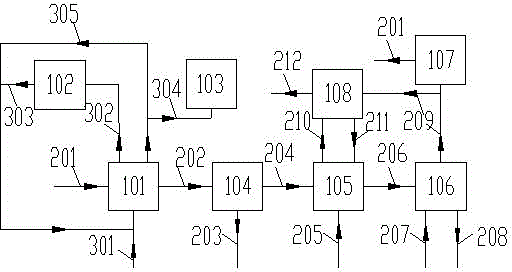

[0043] A company's catalytic gasoline alkali residue and liquid hydrocarbon alkali residue mixed alkali residue waste liquid, of which COD is 3.21×10 5 mg / L, Na 2 S (measured in S) is 1.18×10 4 mg / L, mercaptan sulfur (calculated as S) is 1.71×10 4 mg / L, the total sulfide (calculated as S) is 3.12×10 4 mg / L, volatile phenol is 8.07×10 4 mg / L. Using the present invention figure 1 The method shown is processed, first using N 2 and SO 2 Acidification treatment of alkali slag waste liquid with mixed gas to control N 2 and SO 2 The molar ratio of SO is 1:50~10:1, in order to make SO 2 Fully utilized, SO in the mixed gas 2 The concentration gradually decreases with the progress of the acidification reaction, which can be calculated according to the outlet SO of the acidification reactor 2 The concentration is adjusted and controlled, acidified until the pH of the alkali slag waste liquid drops to 2.0.

[0044] During the acidification process, before the pH drops to 10, t...

Embodiment 2

[0050] A company's catalytic gasoline alkali residue and liquid hydrocarbon alkali residue mixed alkali residue waste liquid, of which COD is 2.83×10 5 mg / L, Na 2 S (measured in S) is 1.33×10 4 mg / L, mercaptan sulfur (calculated as S) is 2.03×10 4 mg / L, the total sulfide (calculated as S) is 3.69×10 4 mg / L, volatile phenol is 5.26×10 4 mg / L. Using the present invention figure 1 The method shown is processed, first using N 2 and SO 2 Acidification treatment of alkali slag waste liquid with mixed gas to control N 2 and SO 2 The molar ratio of SO is 1:50~10:1, in order to make SO 2 Fully utilized, SO in the mixed gas 2 The concentration gradually decreases with the progress of the acidification reaction, which can be calculated according to the outlet SO of the acidification reactor 2 The concentration is adjusted and controlled until the pH of the alkali slag waste liquid drops to 4.0.

[0051]During the acidification process, before the pH drops to 9.5, the acidifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com