Patents

Literature

218 results about "Sewage farm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sewage farms use sewage for irrigation and fertilizing agricultural land. The practice is common in warm, arid climates where irrigation is valuable while sources of fresh water are scarce. Suspended solids may be converted to humus by microbes and bacteria in order to supply nitrogen, phosphorus and other plant nutrients for crop growth.

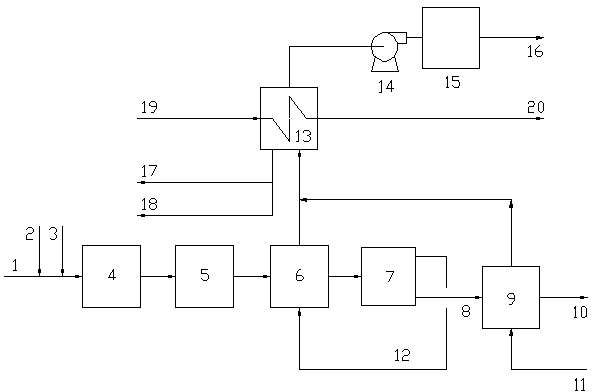

A high-temperature wet oxidation method for treating waste caustic soda

InactiveCN102285729ANo impactNo secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by oxidationHigh concentrationGas phase

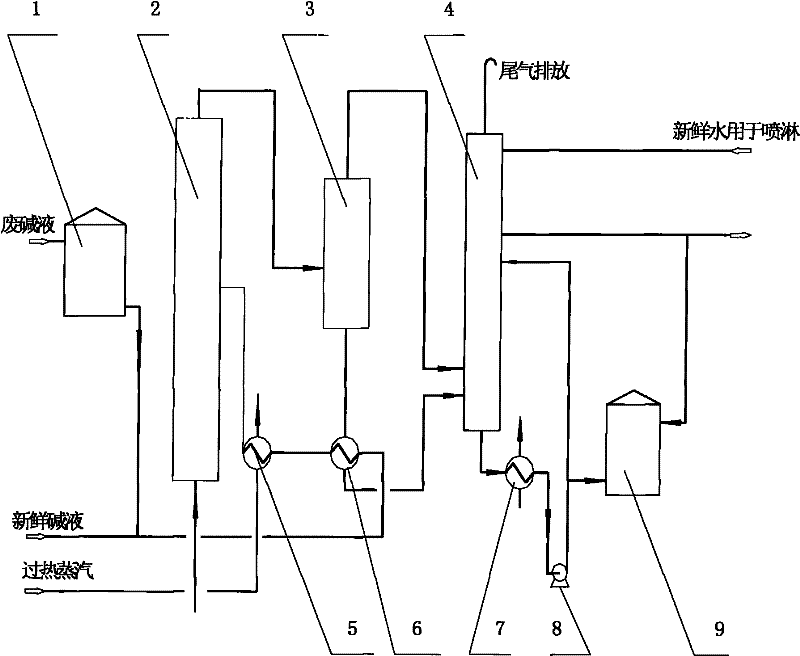

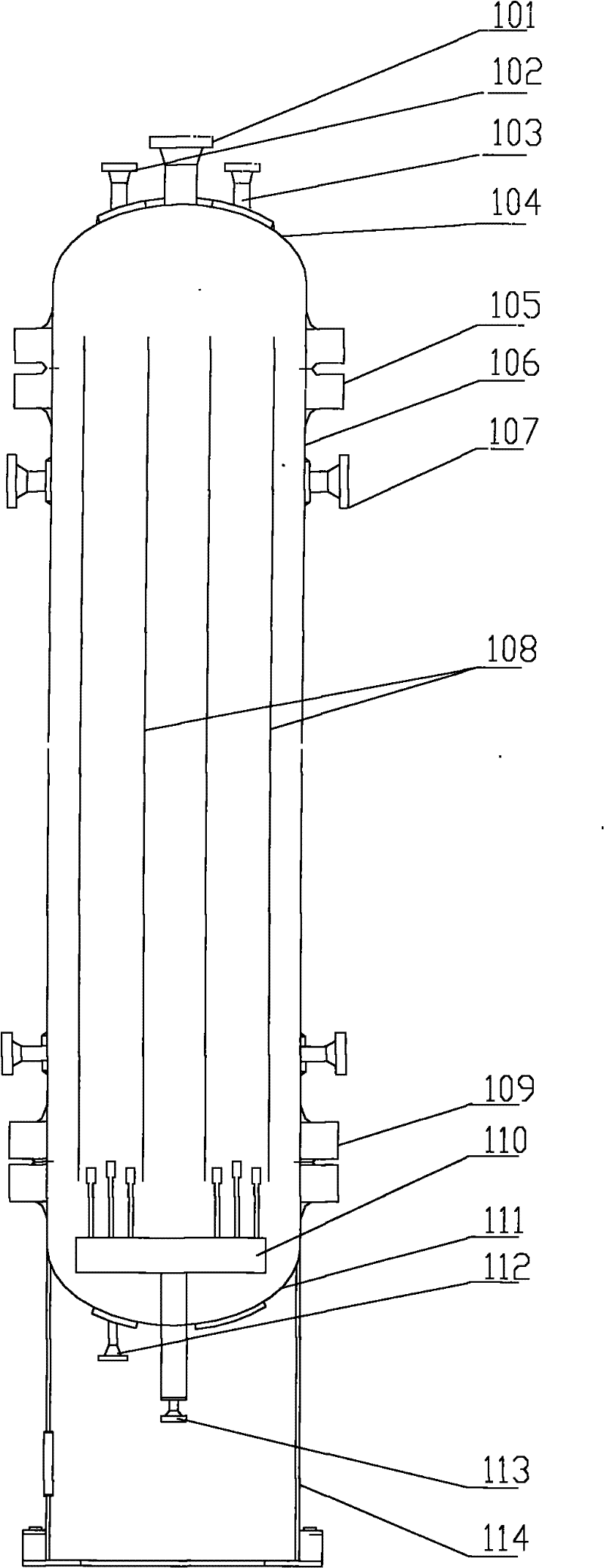

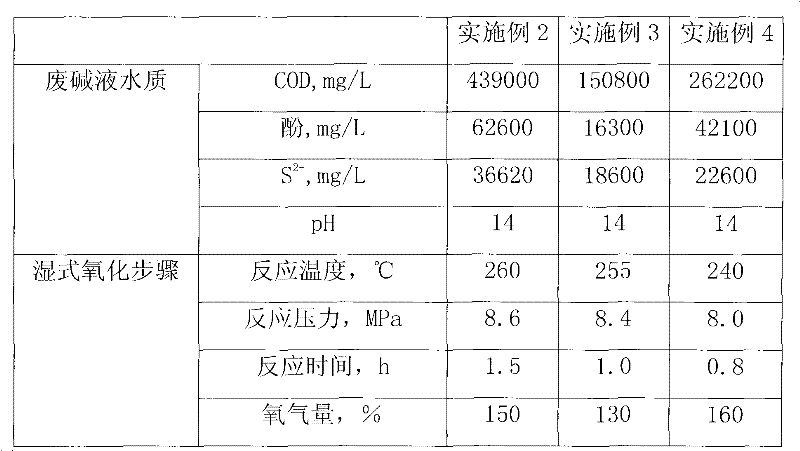

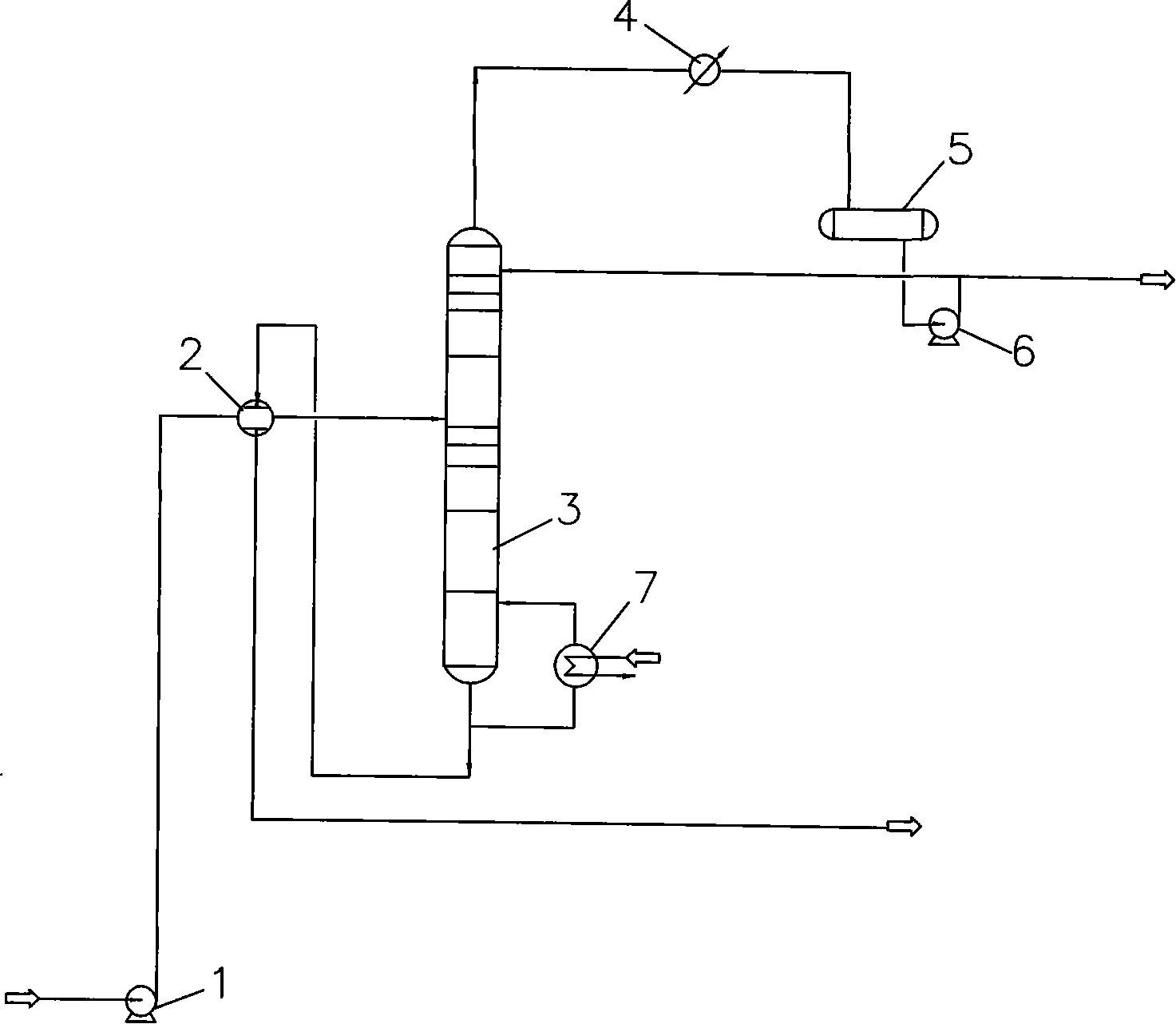

The invention discloses a method for treating waste lye by high-temperature wet oxidation. At 220°C to 260°C and under the pressure of keeping the waste lye in liquid phase, the waste lye is contacted with air exceeding the theoretical oxygen demand, and the waste lye is used The oxygen in the air oxidizes the inorganic sulfide and organic matter in the waste caustic so that the sulfur in it is converted into sulfate, and the organic matter is oxidized and decomposed into water and carbon dioxide; the reacted material discharged from the wet liquid phase oxidation reactor enters the high-pressure gas-liquid separator , The oxidized spent lye after gas-liquid separation and the waste lye feed are exchanged for heat, and the oxidized spent lye after heat exchange and the gas phase separated from gas and liquid enter the cooling and washing tower. Compared with the prior art, the method of the present invention has low energy consumption, the removal rate of S2- can reach 100%, the removal rate of COD can reach 75%-85%, and the waste lye after treatment can be directly discharged into the sewage treatment system, effectively alleviating the The pressure brought by the high concentration of wastewater in sewage treatment plants.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and apparatus for treating oil refining sewerage

ActiveCN101434443AReduce shockFacilitate deep processing and reuseWater/sewage treatmentMultistage water/sewage treatmentHigh concentrationActivated sludge

The invention relates to a treatment method and a device for refinery sewage. The refinery sewage is sent into an electrolytic catalysis oxidation reactor which is provided with an anode, a cathode and solid catalyst particles, wherein, the lower part of the reactor is provided with an oxygenation aeration device, the solid catalyst particles are filled between the anode and the cathode, and the solid catalyst particles adopts particle activated carbon loaded with metals having catalytic and oxidation function. The effluent of the electrolytic catalysis oxidation can be further treated by adopting an activated sludge process. The method is used for treating high-concentration salt-containing mixed wastewater such as the draining water of a refinery electrical desalting unit, the alkali washing waste alkali liquid of oils, liquefied petroleum gas and dry gas, and cutting water in an oils tank farm, and the like, the wastewater after treatment satisfies the requirement of direct discharging, thus alleviating impact on a wastewater treatment plant. The method put forward by the invention has the advantages that high-concentration wastewater can reach disposable treatment standard and does not need any dilution biochemical treatment, treatment effluent is not polluted secondarily by metal ions, and investment and running cost are lower, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

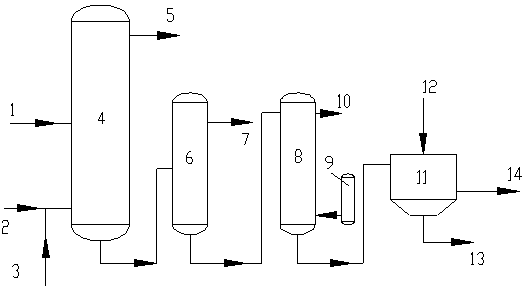

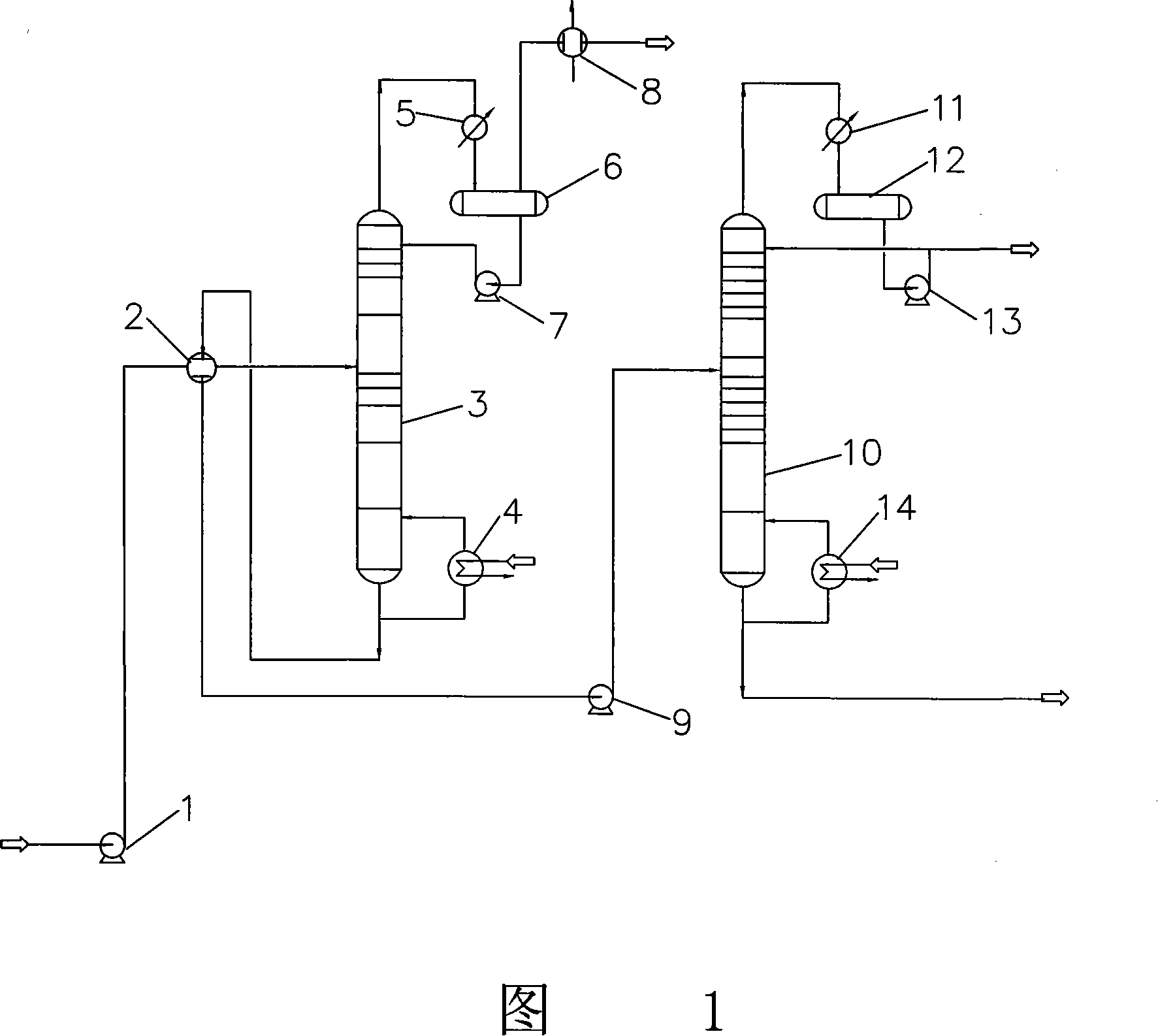

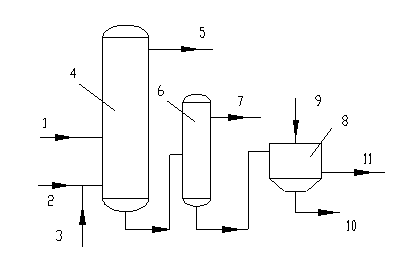

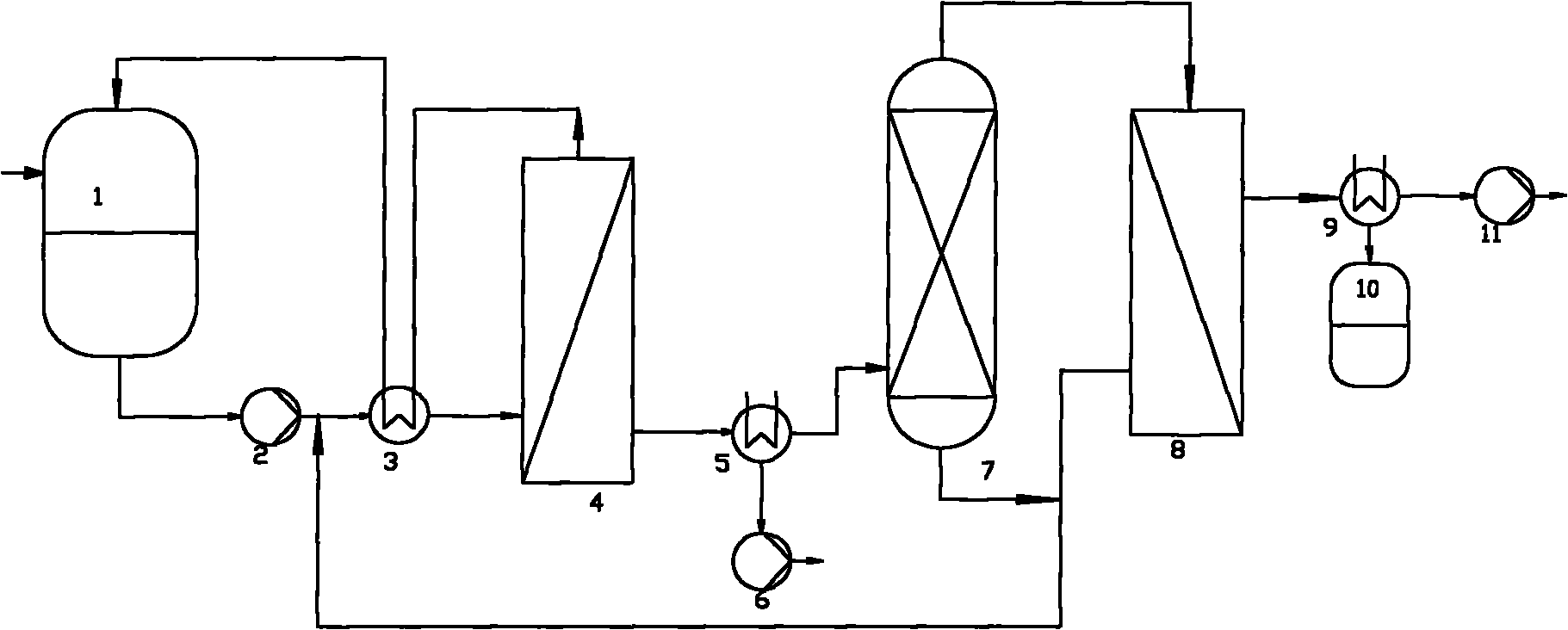

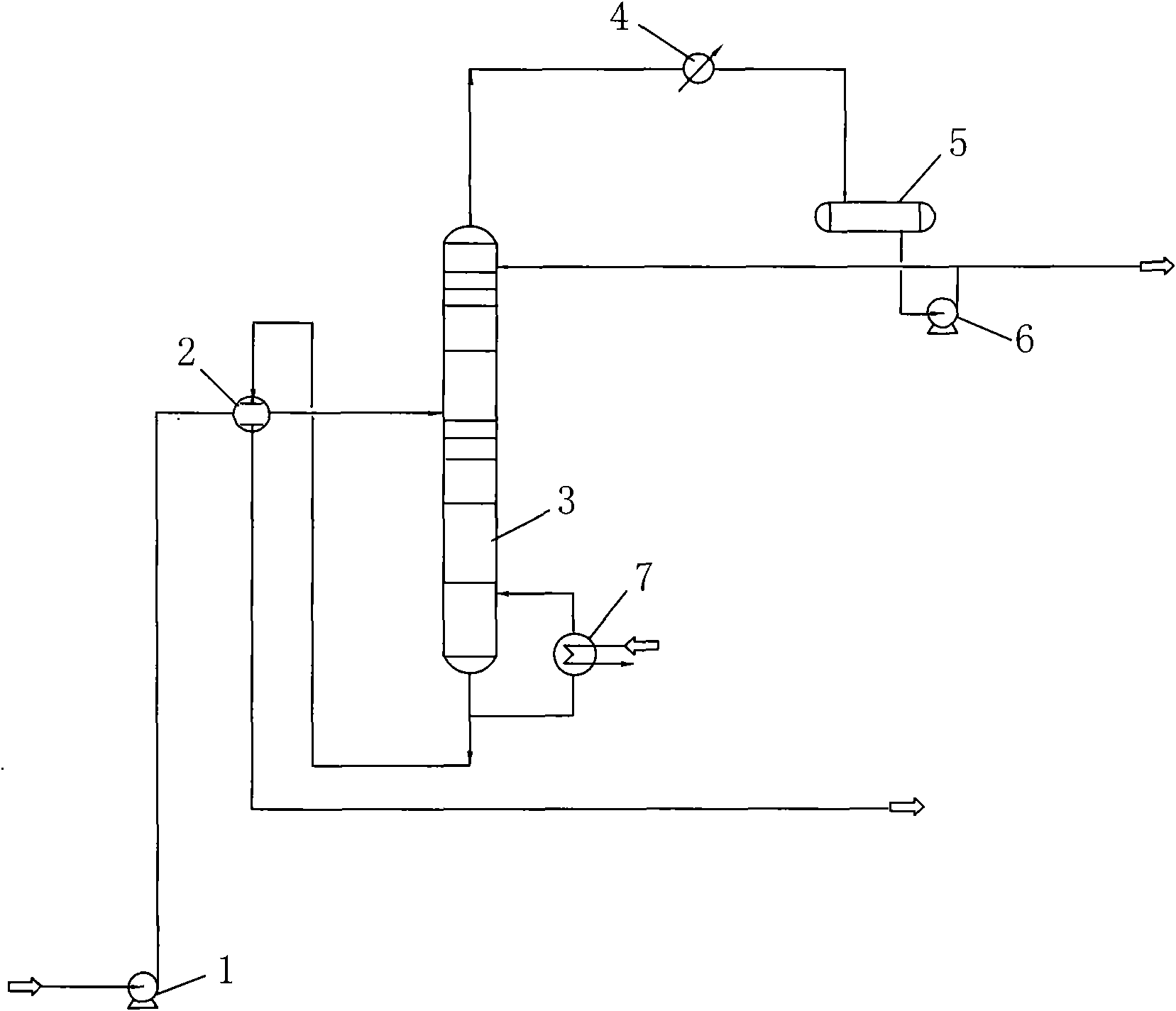

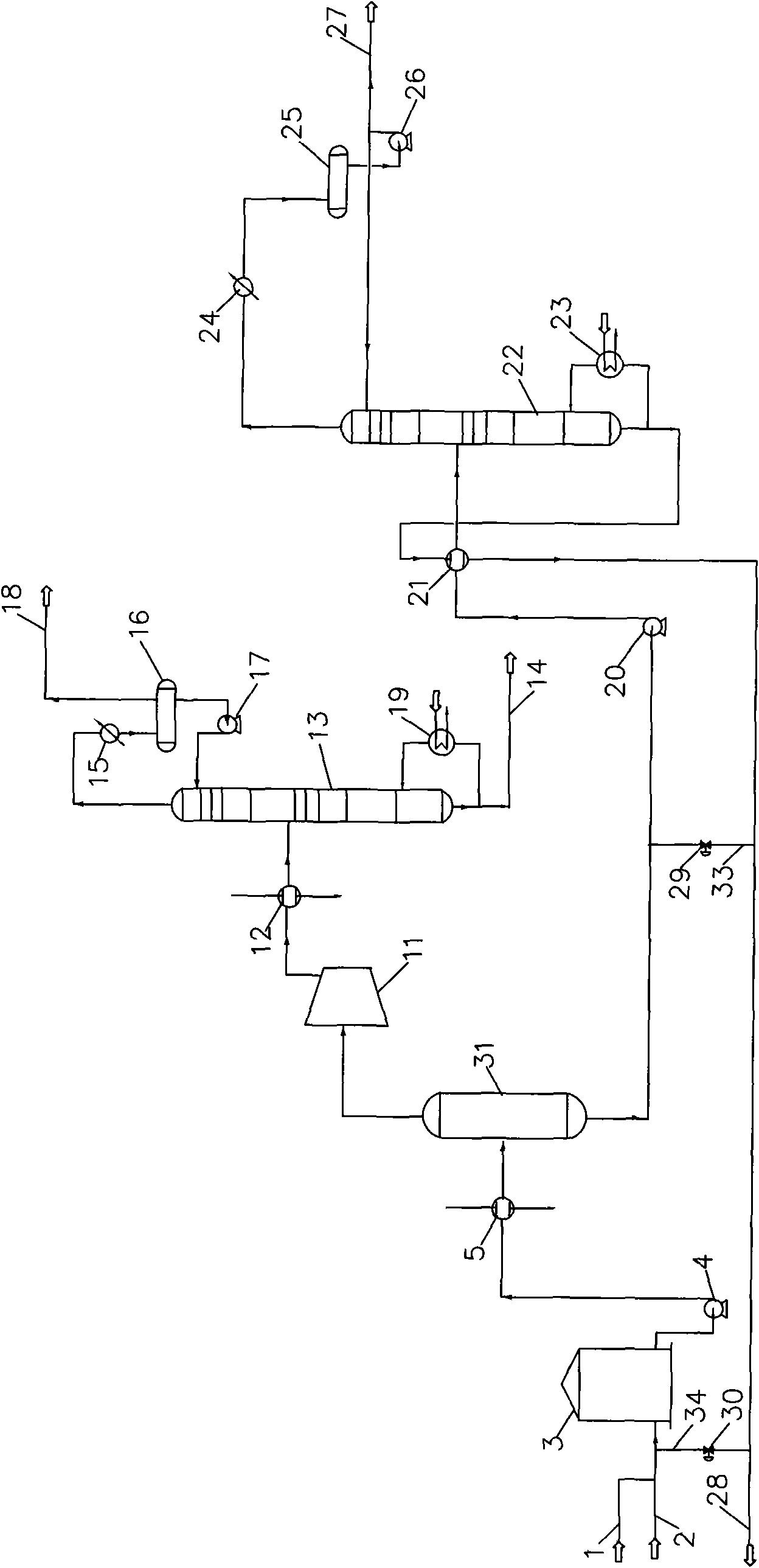

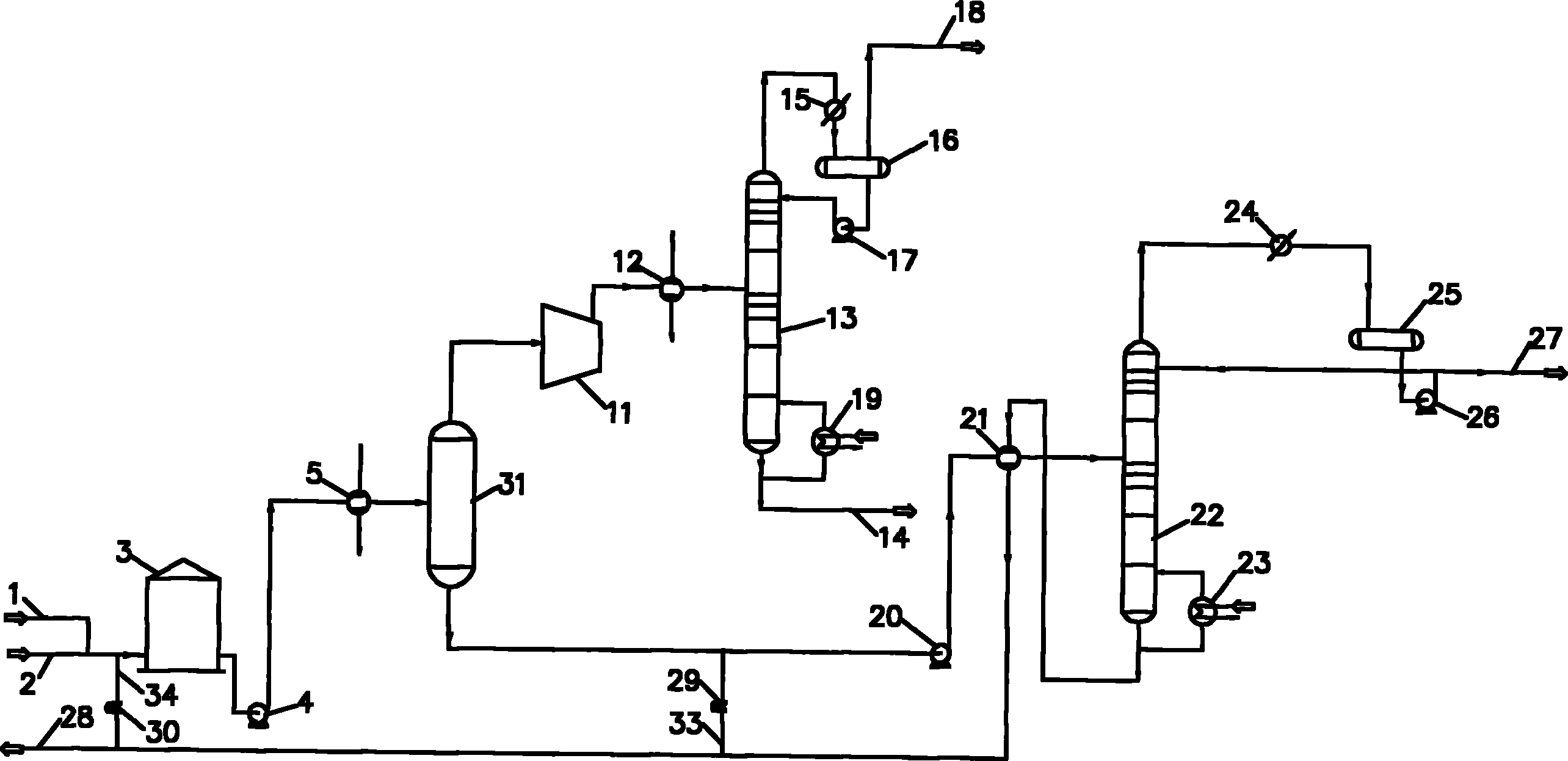

Technique for processing wastewater containing methanol and dimethyl ether

ActiveCN101139118ASimple processLess investmentWater contaminantsWater/sewage treatment by heatingRefluxWastewater

The present invention discloses a wastewater treatment technics containing methanol and dimethyl ether and solves the problem that the wastewater produced by MTO device can not meet the need of the water inlet quality of wastewater treatment plant. The technics of the present invention includes that the wastewater containing methanol and dimethyl ether exchanges heat with the purified water in the bottom of a stripping tower after pressuring and enters the stripping tower. The gas mixture of methanol, etc., generated at the top of the stripping enters into a reflux drum after heat exchange. Part of the methanol gas return to the top of the stripping tower as reflux and the other part is sent to the outside of the device or as the material of MTO device. The bottom of the methanol stripping tower generates purified water and is sent to the outside of the device after exchanging heat with the wastewater containing methanol and dimethyl ether. The total content of methanol and dimethyl ether in the purified water acquired after treated by the technics of the present invention is less than or equal to 100ppm and the purified water can meet the need of the water inlet quality of wastewater treatment plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

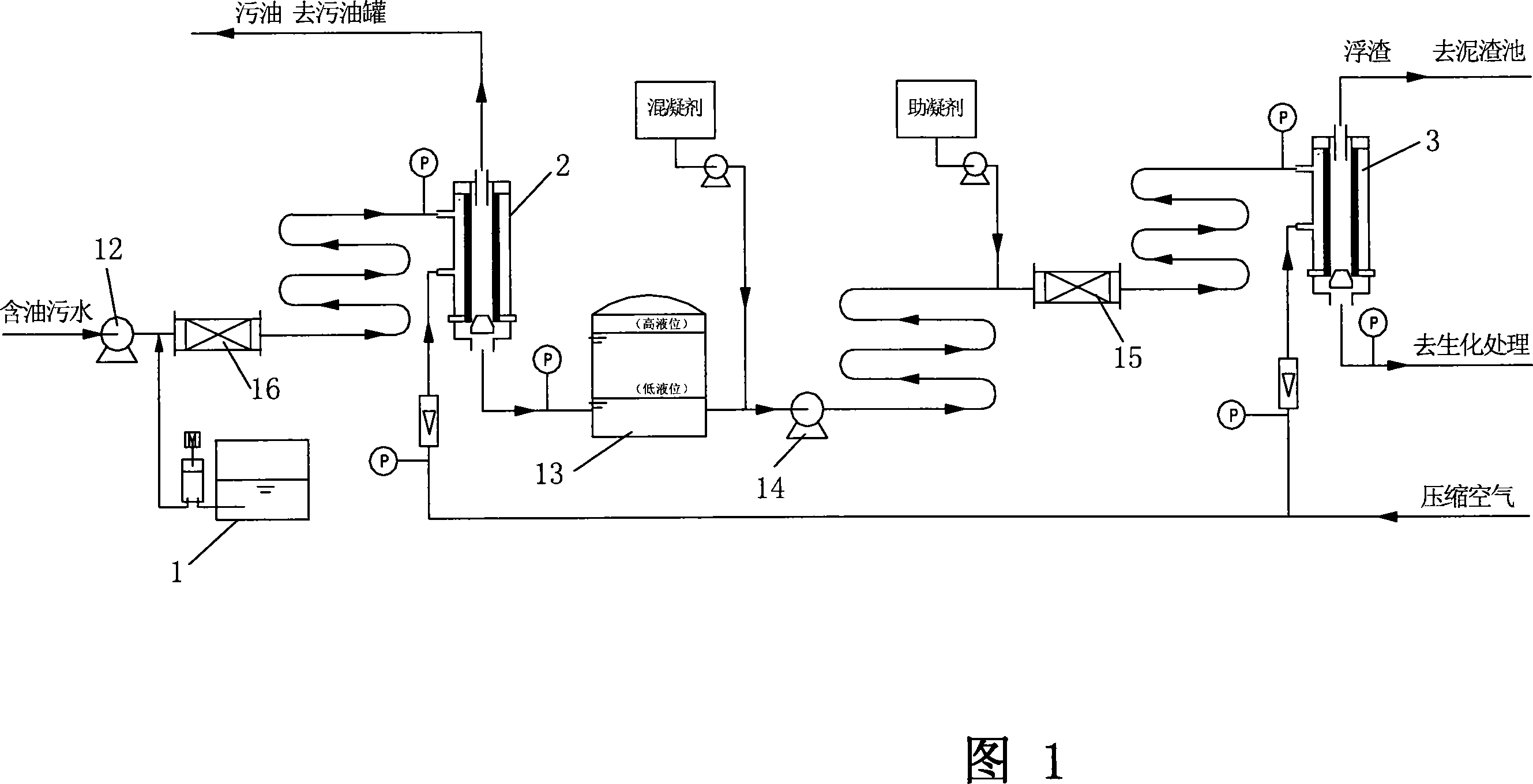

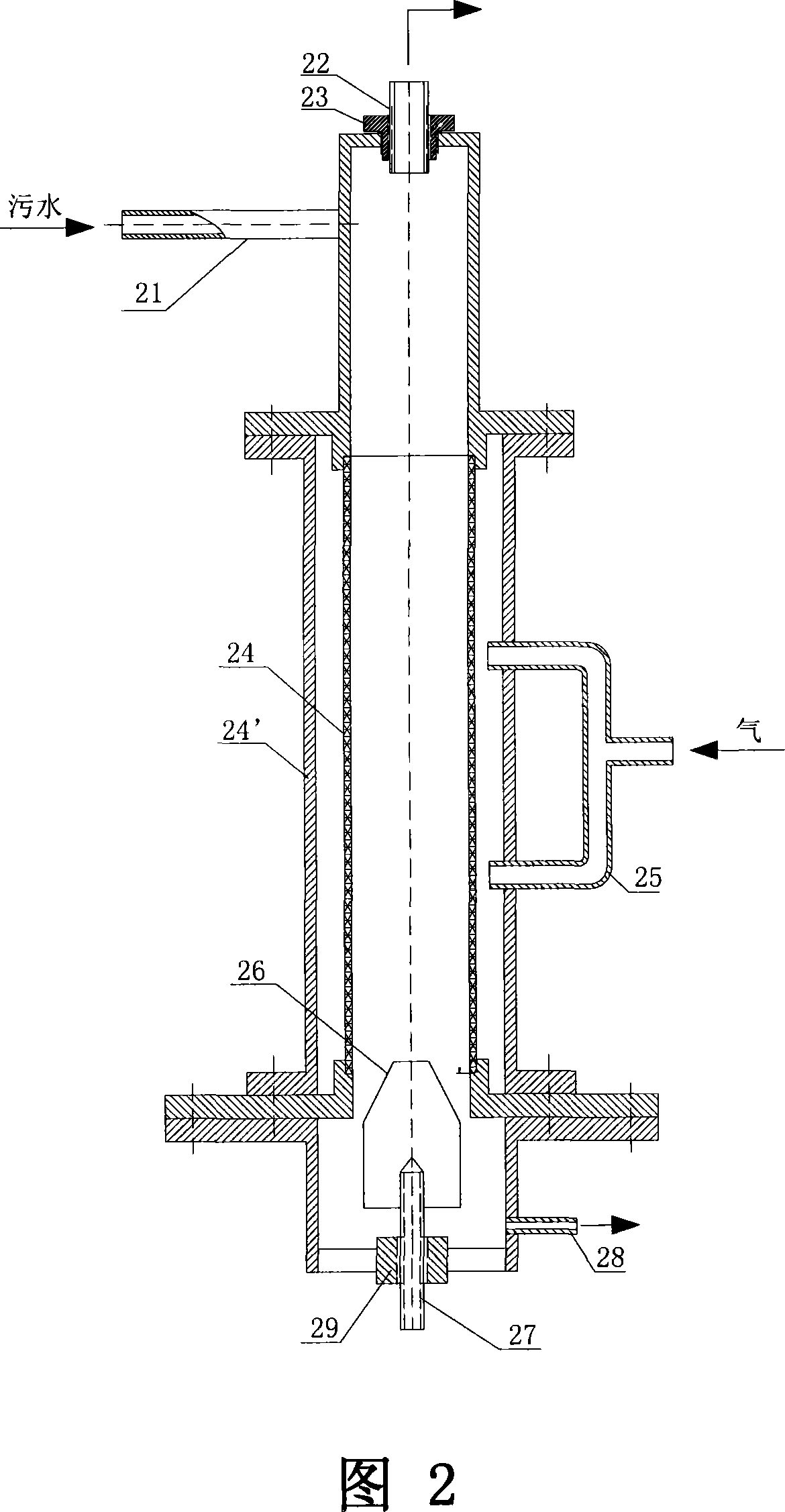

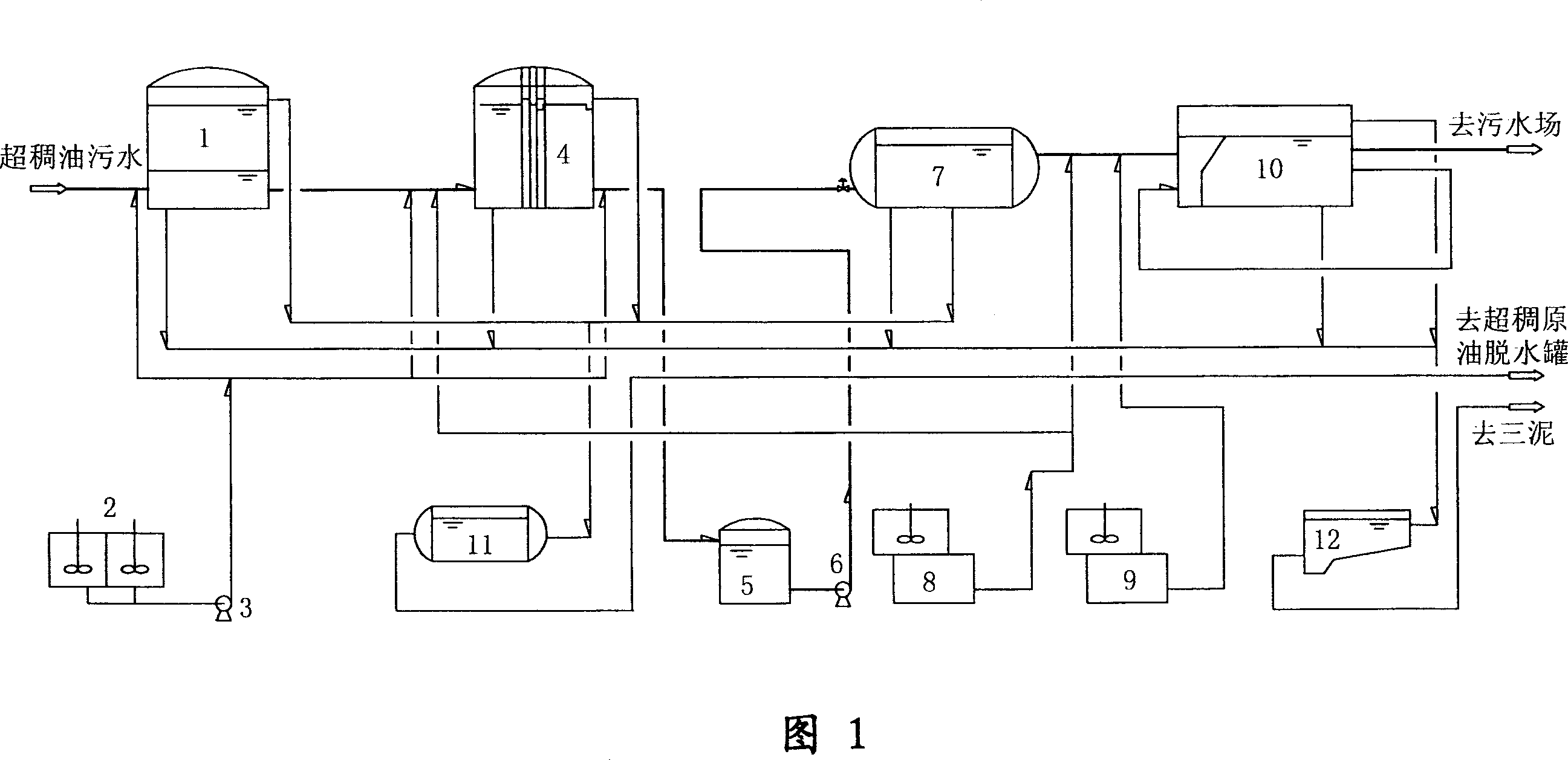

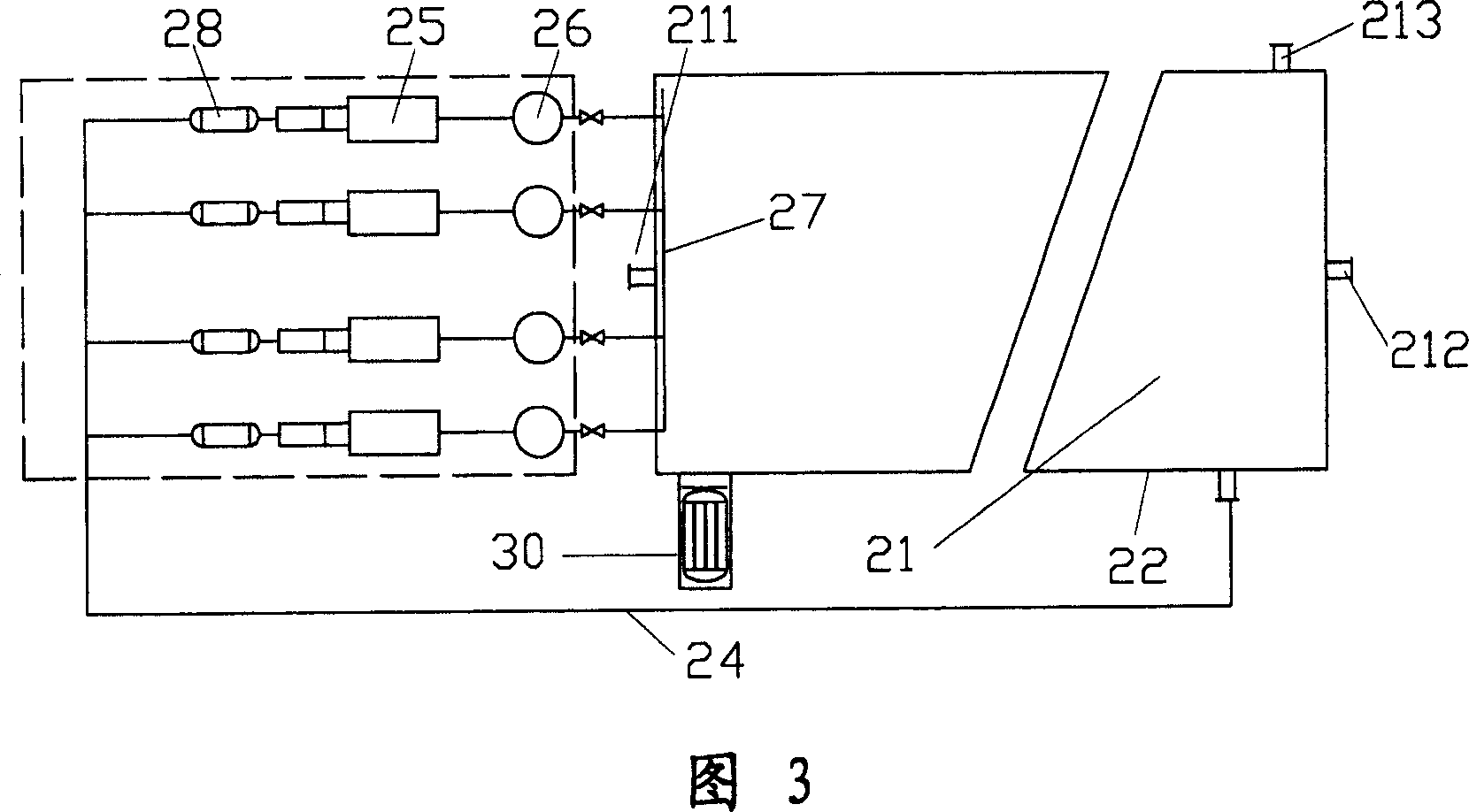

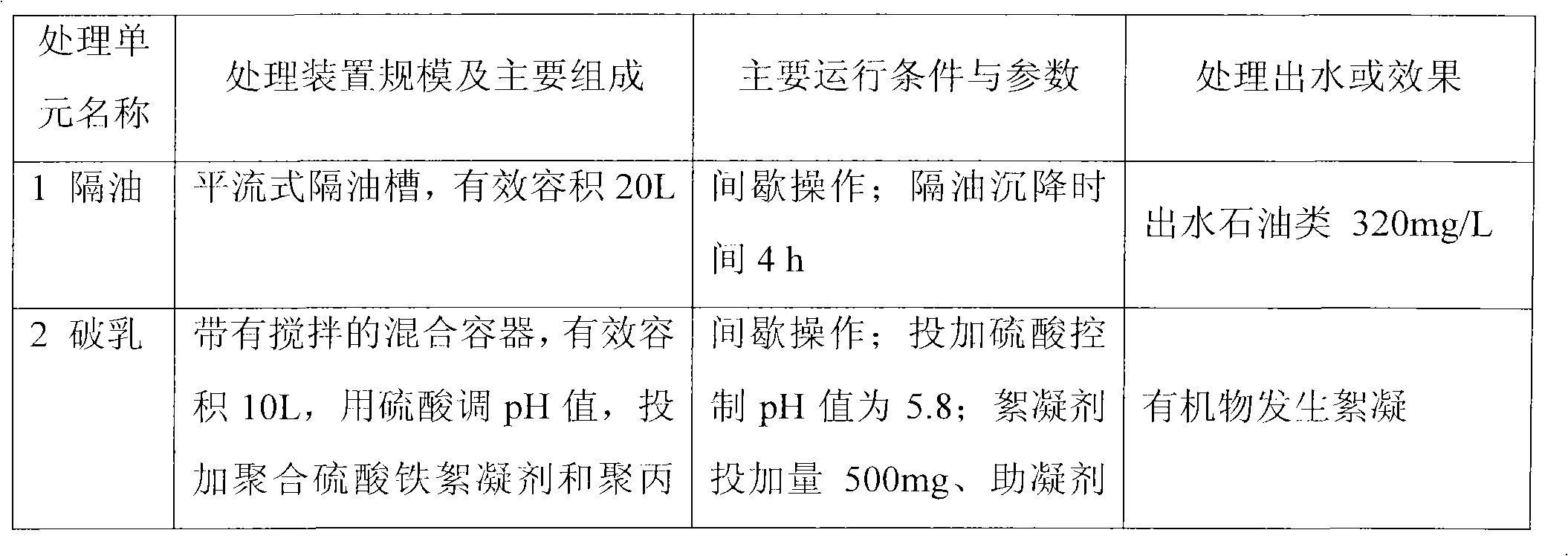

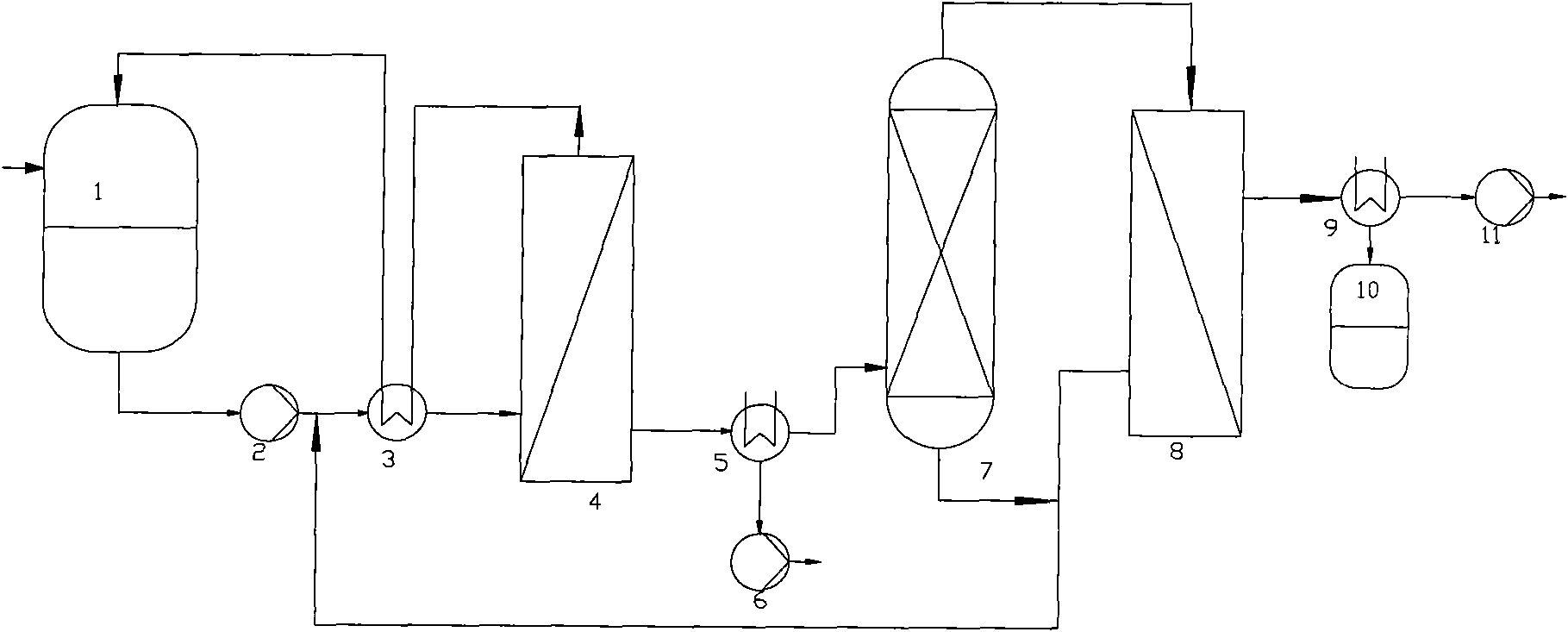

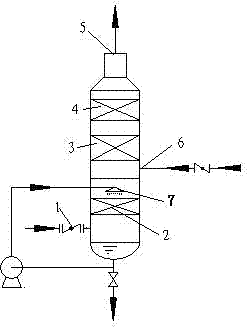

Method for treating oil refining sewage by employing multi-stage inflatable cyclonic current technology

InactiveCN101113035ADemulsification facilitates the realization ofShort stayWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesHigh concentrationEngineering

The invention provides a method for refinery waste water treatment by multi-stage air-sparged hydrocyclone technique, which can high effectively recycle floating oil, dispersed oil and emulsified oil of the refinery waste water, and eliminate most of suspension at the same time. The invention is mainly characterized in that: through setting at least two-stage air-sparged hydrocyclone, and combining the use of demulsifier, coagulant and coagulant aids, physiochemical treatment is carried out to high concentration oily waste water produced by all devices during the refinery process, and the releasing water after treatment can meet the biochemical stage water indices of normal waste water treatment field. The technique of the invention can substitute the physiochemical treatment stage (the first stage treatment) of the existing refinery waste water treatment process, and is characterized by high effect, occupying small land, and saving the investment, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

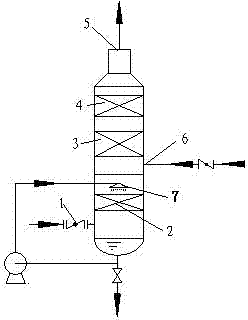

Purification for stink and organic waste gas

ActiveCN1745883AImprove purification rateStable growth environmentDispersed particle separationAir quality improvementSorbentSewage

A process for treating the offensive smell in petrochemical sewage treating plant and cleaning the low-concentration waste organic gas features use of immobilized microbial membrane as filler and 1-3 stages of microbial treatment. It includes such steps as wet dusting for pre-treating, microbial treating and post-treating by absorbent.

Owner:CHINA PETROLEUM & CHEM CORP +1

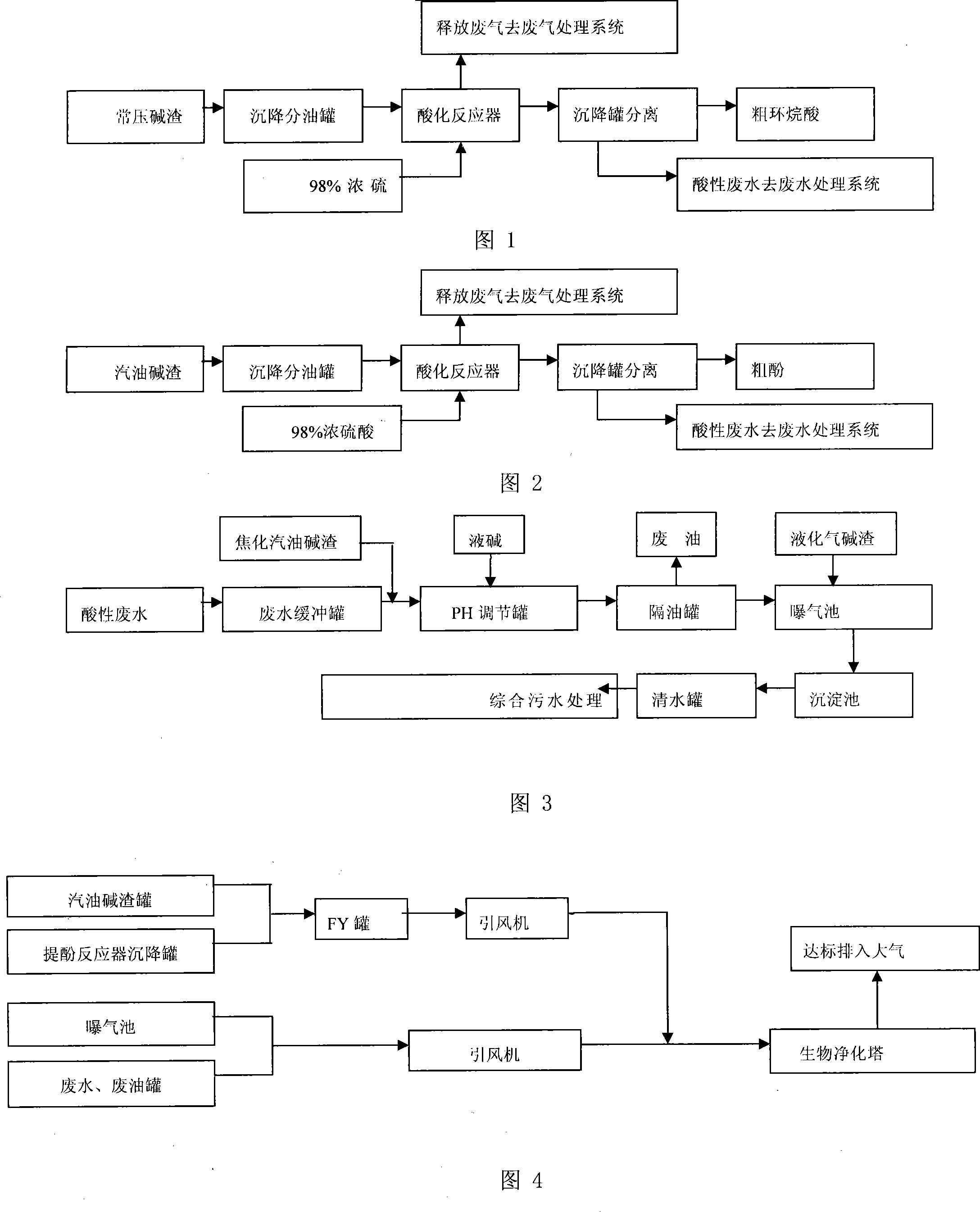

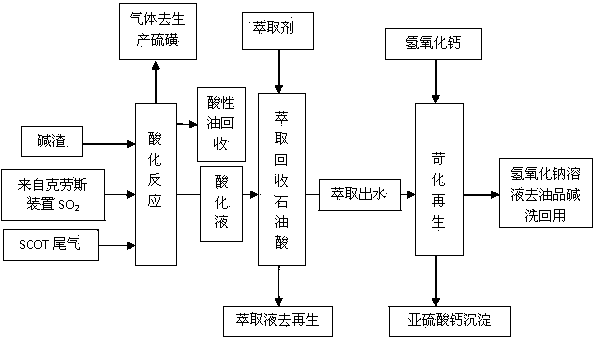

Comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid

ActiveCN103045288AReduce CODMild operating conditionsOrganic chemistryOrganic compound preparationLiquid wasteHigh concentration

The invention relates to a comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid. The comprehensive treatment method comprises the steps of: 1, acidizing high-sulphur high-COD caustic sludge waste liquid by using an N2 / SO2 mixed gas, when the pH value of the waste liquid reaches 2-6, stopping acidizing; 2, sending tail gas discharged in the acidizing process in the step 1 to a sulphur production device for preparing sulphur; 3, settling the waste liquid generated in acidizing treatment in the step 1and recovering an oil phase; 4, further reducing the COD of the waste liquid by adopting an extraction method when the COD of the waste liquid after the oil phase is separated in the step 3 is always high; and 5, regenerating the waste liquid extracted in the step 4 by using lime. The comprehensive treatment method is low in investment, is mild in operation conditions, is capable of recycling the caustic sludge waste liquid, avoiding the impact of the high-concentration wastewater on a wastewater treatment field, is also capable of recovering sulfide and crude carbolic acid from the caustic sludge waste liquid, and has a certain economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-containing sludge pyrolysis and its resource treatment method

InactiveCN102874997ARealize resourcesEasy to separateSludge treatment by pyrolysisByproduct vaporizationActivated sludgeSorbent

The invention relates to an oil-containing sludge pyrolysis and its resource treatment method, and belongs to the field of environmental protection and energy saving technologies. The oil-containing sludge pyrolysis and its resource treatment method comprises the following steps of: adding a gangue powder and Fe3O4 into an oil-containing sludge; respectively carrying out mixing, granulation, preheated drying (using a pyrolysis gas as a heat source) and pyrolysis on the mixture; cooling the pyrolysis gas discharged out from a pre-drier by the use of circulating water such that steam and hydrocarbons in the pyrolysis gas are condensed respectively in the forms of oil-containing sewage and liquid hydrocarbon; allowing the oil-containing sewage to enter a sewage treatment plant so as to reach the standard, recovering and utilizing liquid hydrocarbon, and activating sludge to prepare a magnetic carbonaceous adsorbent. According to the invention, resource of the oil-containing sludge can be completely realized, and the carbonaceous adsorbent with large pore volume and specific surface area can be prepared. The invention is especially suitable for pyrolysis treatment of oil-containing sludge (such as oil tank bottom mud, oil-field oil extraction sludge, tank car or oil tanker bottom mud and the like) with high oil content.

Owner:CHINA PETROLEUM & CHEM CORP +1

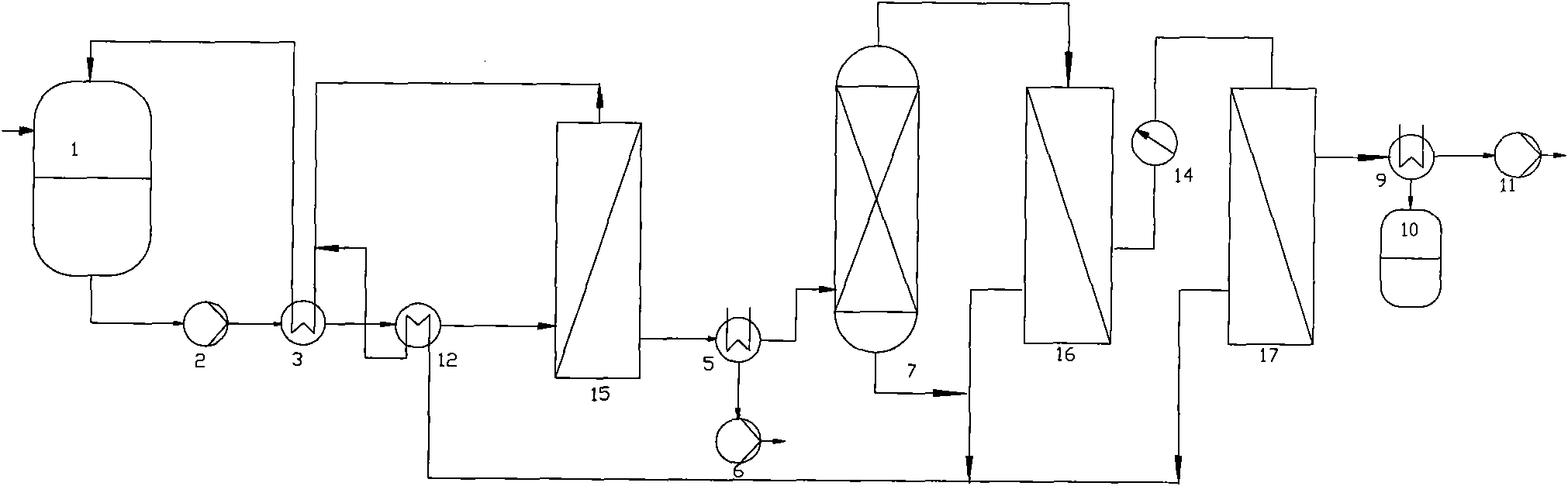

Technique for processing wastewater containing methanol and dimethyl ether

ActiveCN101139117AMeet the water quality requirementsLow costWater contaminantsWater/sewage treatment by heatingRefluxWastewater

The present invention discloses a wastewater treatment technics containing methanol and dimethyl ether and solves the problem that the wastewater produced by MTO device can not meet the need of the water inlet quality of wastewater treatment plant. The technics of the present invention includes that the wastewater containing methanol and dimethyl ether enters a dimethyl ether stripping tower after heat exchange. The top of the tower generates gas mixtures of dimethyl ether, etc. The bottom of the tower generates water containing methanol. The water containing methanol enters into a methanol stripping tower after heat exchange and pressuring. The top of the methanol stripping tower generates methanol gas which enters a methanol reflux drum after being cooled. After lifting pressure, part of the methanol gas return to the top of the methanol stripping tower as reflux and the other part as the products of methanol. The bottom of the methanol stripping tower generates purified water. The total content of methanol and dimethyl ether in the purified water acquired after treated by the technics of the present invention is less than or equal to 100ppm and the purified water can meet the need of the water inlet quality of wastewater treatment plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

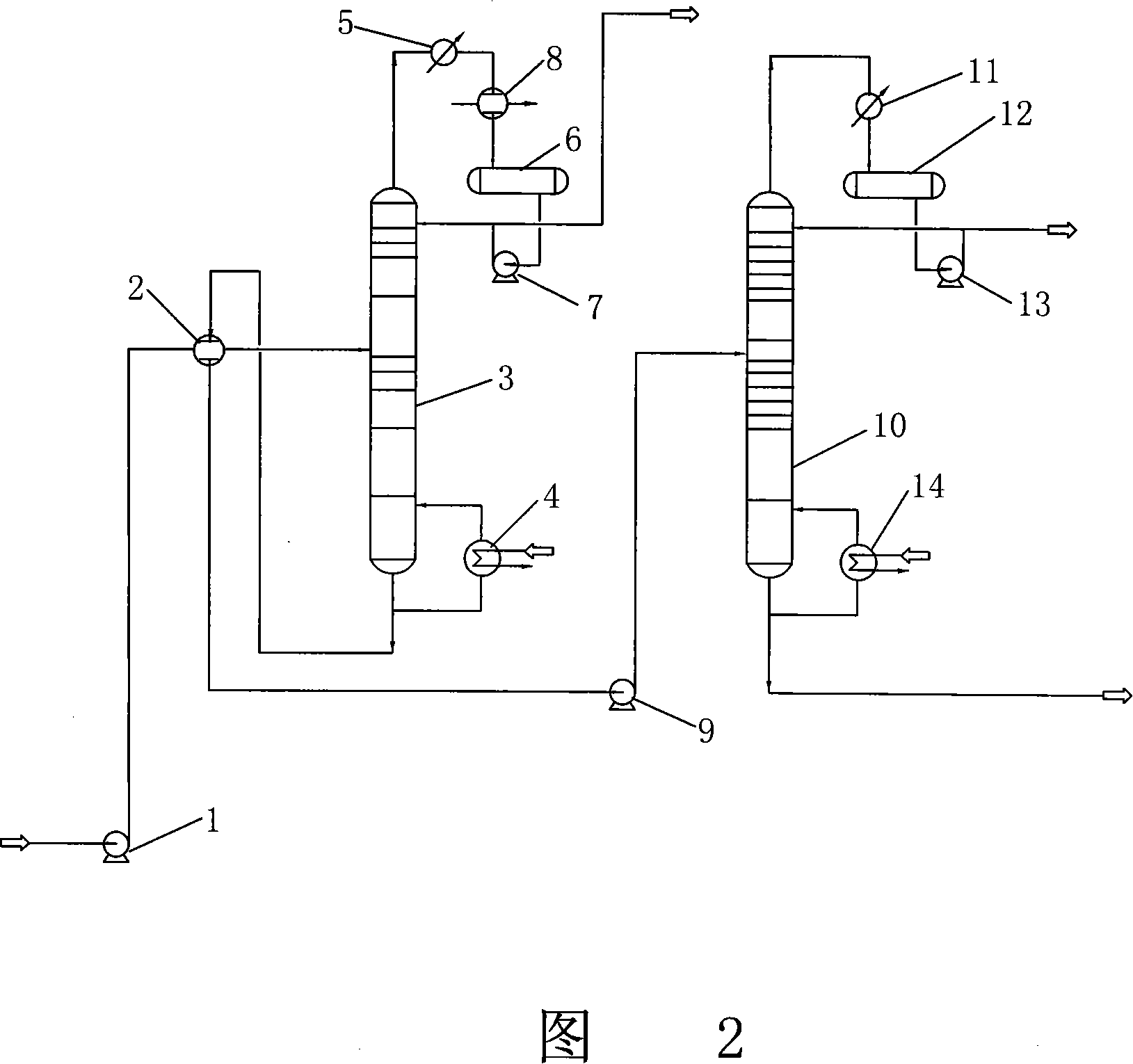

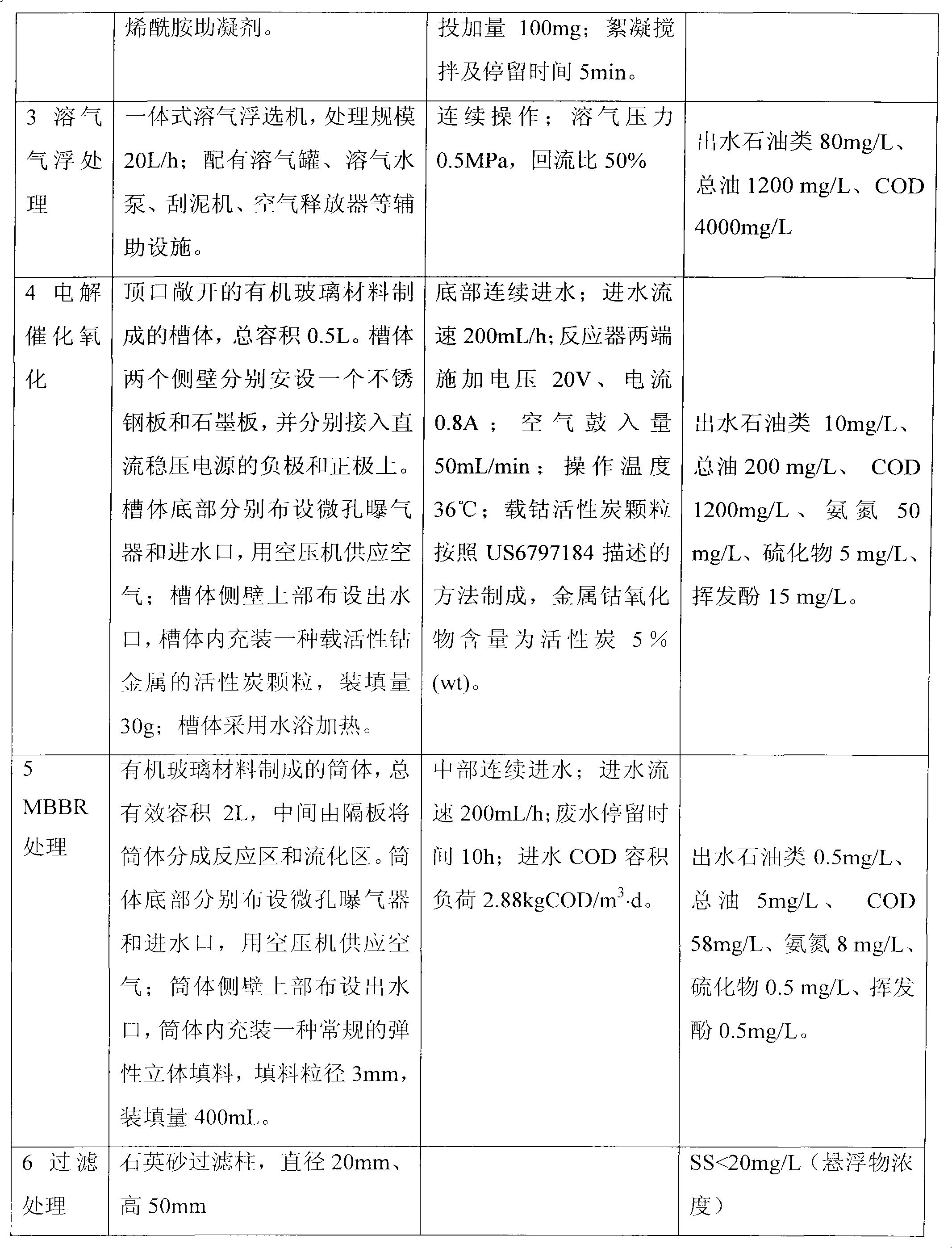

Pre-treating process for sewage from thick oil refining

InactiveCN1944289ATo achieve the purpose of controlRealize resourcesFatty/oily/floating substances removal devicesMultistage water/sewage treatmentDemulsifierWater quality

The present invention provides pre-treatment process for sewage from thick oil refining. The pre-treatment process has the technological path including water quality and amount regulation, demulsifying to eliminate oil, cyclonic oil-water separation and floating purification, and adopts the copolymer of acrylamide and dimethyl diallyl quaternary ammonium salt as the demulsifier. The pre-treated sewage can reach the influent standard of refinery sewage treating yard. The present invention can recover oil while purifying oil containing sewage.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

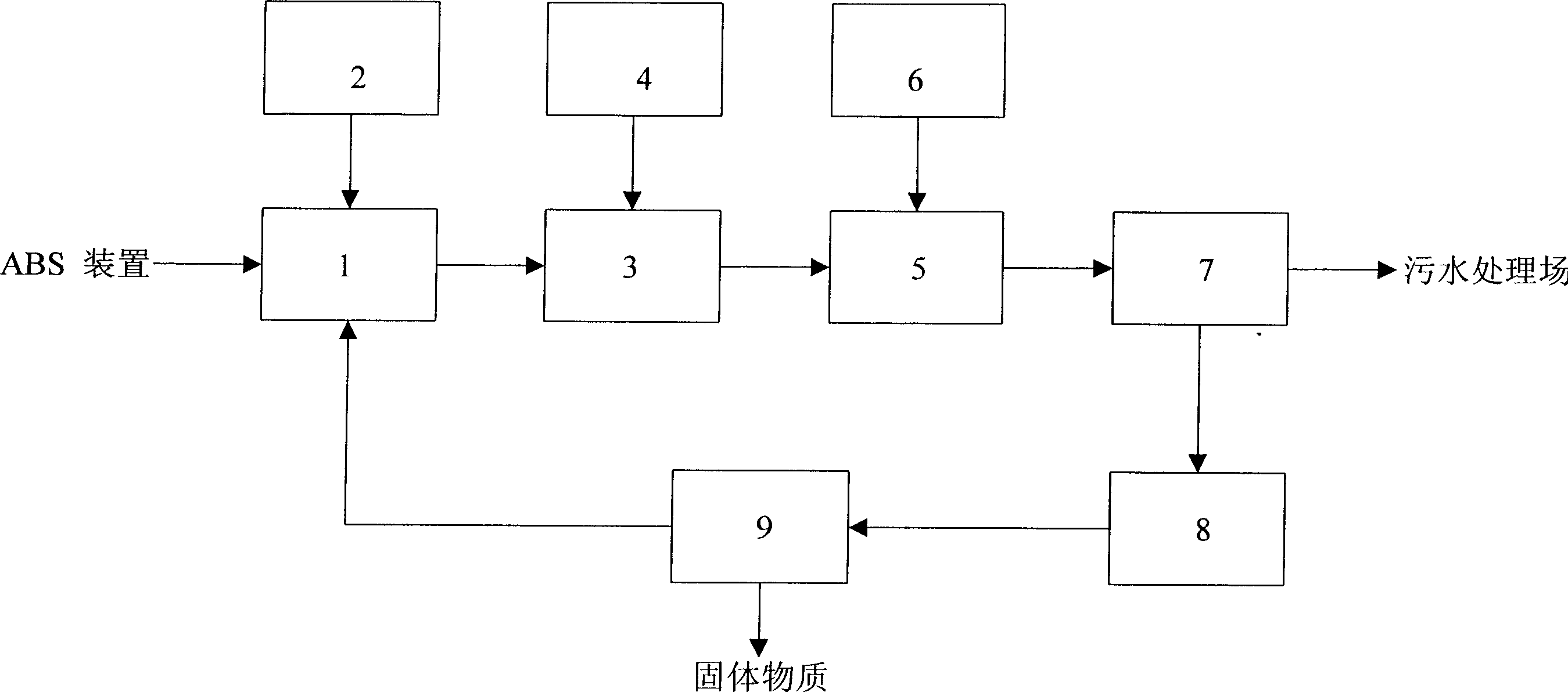

ABS sewage treating method

InactiveCN1417143AImprove biodegradabilityGuarantee normal productionMultistage water/sewage treatmentAluminium chlorohydrateSewage

The ABS sewage treating process includes the steps of: adding inorganic acid to regulate pH of sewage from ABS production to 6-8 while stirring; adding polyaluminum chloride in the amount of 50-200 ppm of ABS sewage while stirring; adding polyacrylamide in the amount of 1.7-6.7 ppm of ABS sewage while stirring; still standing to form water phase and settlings phase, and exhausting the water phaseto subsequent sewage treating field; and solid-liquid separation of the settlings with the liquid being returned to pH regulating step and the solid matter being recovered. The twice flocculation andsettlement separating process can eliminate SS content in ABS sewage and makes ABS sewage capable of being treated biochemically.

Owner:PETROCHINA CO LTD

Process for treating sewage to generate active mud and extract protein

InactiveCN1369445AReduce pollutionSimple processSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningCellular DebrisSludge

A process for extracting protein from the active mud generated by treating sewage includes dewatering said mud, stirring at 15-90 deg.C for 5-60 min, regulating pH value to 7-12, stirring at constanttemp for 5-30 min, filter to obtain aqueous solution of protein, stirring until the pH value of 3-7, laying aside, depositing, removing supernatant, and drying. Its filtered dregs can be used as fuelor feed.

Owner:邵胜学

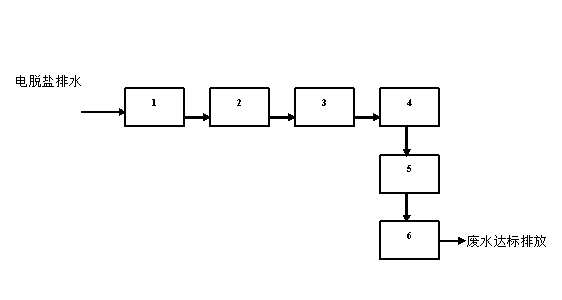

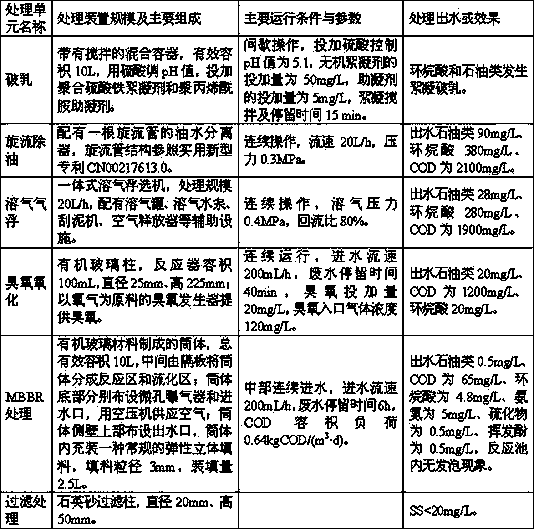

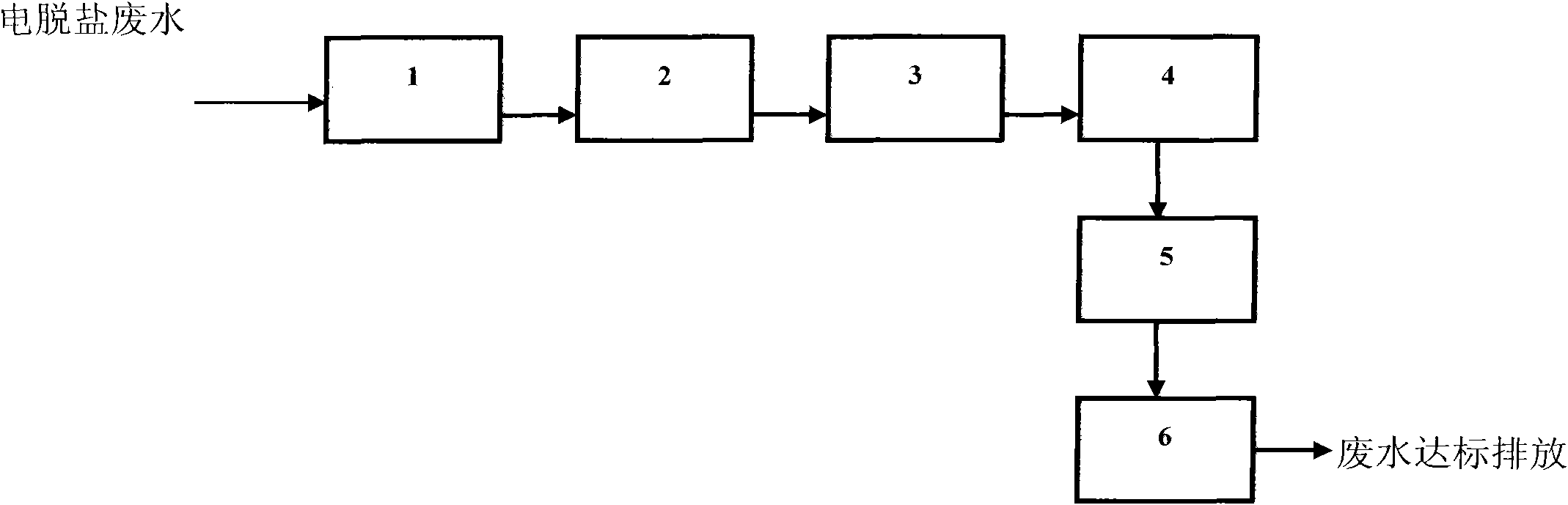

Treatment method for waste water from processing acid-containing crude oil

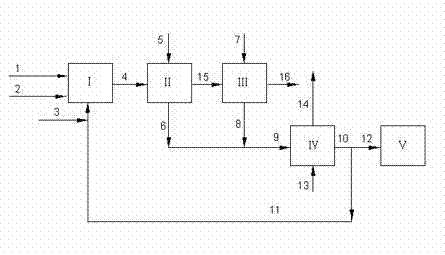

ActiveCN103771652ASolve the failure to meet the standardSolve processingMultistage water/sewage treatmentAfter treatmentOil separation

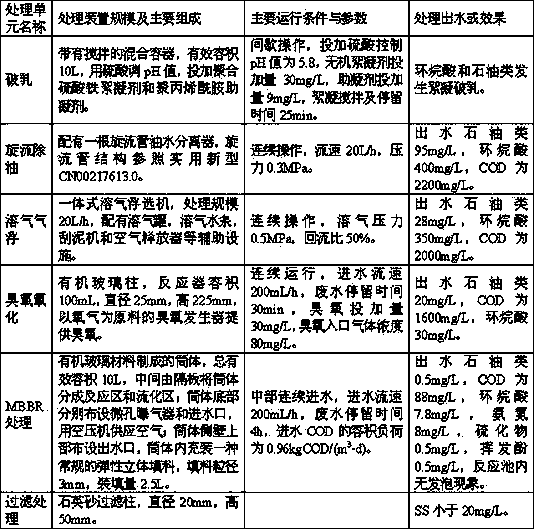

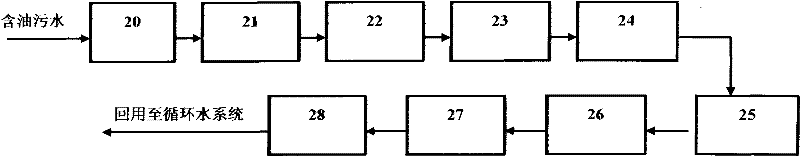

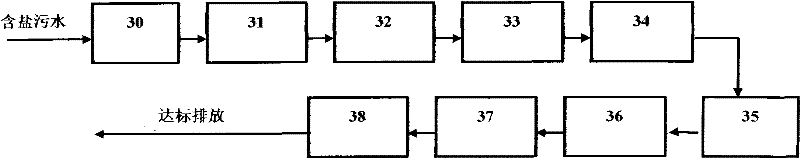

The invention relates to a treatment method for waste water from processing acid-containing crude oil, and the method is used in the treatment of waste water containing naphthenic acid from the refining process of acid-containing crude oil. The method adopts a combined process including demulsification, cyclone oil removal, dissolved air flotation, ozone oxidation, MBBR and filtering to treat the wastewater containing naphthenic acid discharged from an electric desalting device in the crude oil refining process, and the outlet water after treatment reaches discharge standards. The method can prevent the treatment process of other waste water, such as oil-containing sewage and salt-containing waste water from the influence from naphthenic acid, and benefit the stable operation of oil separation, flotation, biochemical treatment and depth treatment units in final sewage works, so as to solve the problems of unqualified waste water from processing acid-containing crude oil and foaming of biochemical treatment, and provide a good basis for waste water reuse.

Owner:CHINA PETROLEUM & CHEM CORP +1

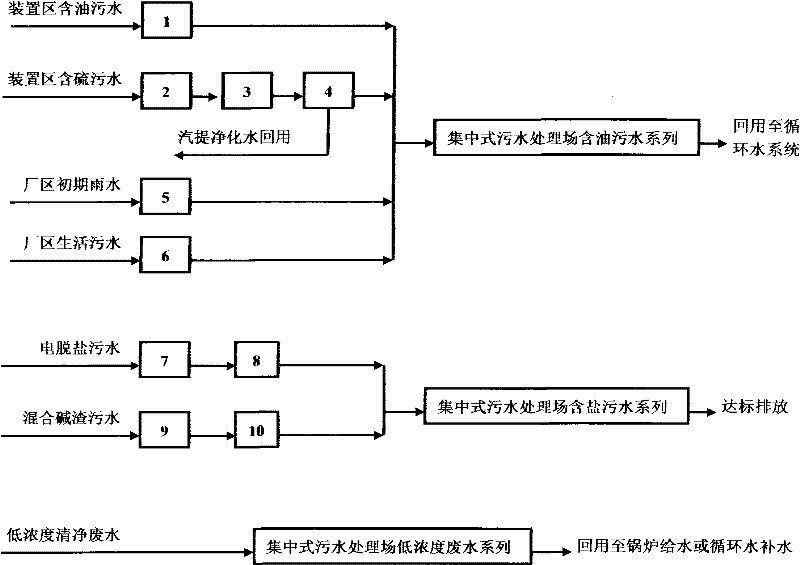

Method for oil refinery sewage classification control and grading treatment

ActiveCN102452750AHigh proportion of reuseMultistage water/sewage treatmentHigh concentrationSulfur containing

The invention relates to a method for oil refinery sewage classification control and grading treatment. The method divides oil refinery sewage into seven types of oil-containing sewage, sulfur-containing sewage, electro-desalting sewage, mixed alkaline residue sewage, low-concentration clean waste water, polluted rainwater in a plant area, and domestic sewage. The method comprises a source control process, a high-density sewage pretreatment process, a reclaimed water reuse or cascade use process, and a centralized separation treatment process on sewage in a sewage treatment plant. The method realizes high-proportion utilization of stripping purified water, complete recycle of oil-containing sewage, high-proportion recycle of low-concentration clean waste water, and stabilization and standardization treatment on high-concentration salt-containing sewage. The method realizes the purposes of water saving and emission reduction in oil refinery sewage treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkaline residue processing method

ActiveCN101172739AImprove impact performanceNo pollution in the processFatty/oily/floating substances removal devicesOrganic chemistryAlkali activated slagPollution

The invention provides an alkali dreg treatment method which includes the following steps: first, an alkali pretreatment system; second, a biological treatment system; and Third, a waste gas biological treatment system. Through the biological degradation, the organism in the waste gasis decomposed so as to eliminate the odor in the waste gas. The invention has the advantage that the highly efficient biological treatment process adopted by the comprehensive alkali treatment of the method has the characteristics of a little investment, low energy consumption, cheap treatment, safe and reliable performance, convenient operation and management, no pollution, friendliness to the environment, etc. The application of the method greatly reduces the attack to the sewage treatment field during the alkali dreg treatment and reduces the possible great amount of entrustment cost. On the one hand, the invention prevents the pollution of the alkali dreg to the environment, thereby protecting the environment, on the other hand, the invention makes full use of the potential value of the alkali dreg, thereby creating a new mode of benefit making through the circular economy. The invention conforms to the clean development of the enterprise, protects the natural environment and achieves the saving and sustainable development.

Owner:天津莱特化工有限公司

Comprehensive treatment method of liquid hydrocarbon alkali residue waste liquid

ActiveCN103045289AReduce CODSimple processOrganic chemistryOrganic compound preparationLiquid wasteHigh concentration

The invention relates to a comprehensive treatment method of liquid hydrocarbon alkali residue waste liquid. The comprehensive treatment method comprises the steps of: (1) acidizing the liquid hydrocarbon alkali residue waste liquid by a N2 / SO2 gas mixture, wherein sulfide in the waste liquid volatilizes in the form of H2S along with the continuous increase of the acidity of the waste liquid; and stopping acidizing when the pH value of the waste liquid reaches 2-6; (2) sending tail gases discharged in the acidizing process in the step (1) into a sulphur production device for preparing sulphur; (3) subsiding the waste liquid generated after the acidizing process in the step (1), and recovering an oil phase, wherein the oil phase mainly contains crude phenol which can be further recovered; and (4) regenerating the waste liquid without the oil phase by using lime, wherein the regenerated waste liquid can be recycled for refinement process of liquid hydrocarbon alkali after precipitates are separated out from the regenerated waste liquid. The comprehensive treatment method is low in investment; the process is simple and flexible; operation conditions are mild; due to the application of the comprehensive treatment method, the alkali residue waste liquid is recycled, the impact of high-concentration waste water on a sewage treatment plant is avoided, simultaneously the sulfide and crude phenol in the alkali residue waste liquid can be recycled, and certain economic benefit is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method for wastewater generated by processing high-acid crude oil

ActiveCN102311204AEasy to handlePromote demulsificationMultistage water/sewage treatmentNature of treatment waterElectrolysisCatalytic oxidation

The invention relates to a treatment method for wastewater generated by processing high-acid crude oil, which adopts the combined processes of oil isolation, demulsification, dissolved air flotation, electrochemical catalytic oxidation, biological membrane moving bed reactor and filtering. The electro-desalting wastewater in the high-acid crude oil refining process is treated. When the method provided by the invention is adopted, the treatment process of other wastewater such as oil-containing wastewater, salt-containing wastewater and the like in the high-acid crude oil processing process can not be influenced by the high-acid crude oil wastewater, and the beneficial effects are brought for the stable operation of the oil isolation, the flotation, biochemistry and deep treatment units ofthe final sewage treatment field, so the problem that the wastewater generated by processing the high-acid crude oil at present can not reach the standard is solved, and the good basis is provided for the sewage reuse.

Owner:CHINA PETROLEUM & CHEM CORP +1

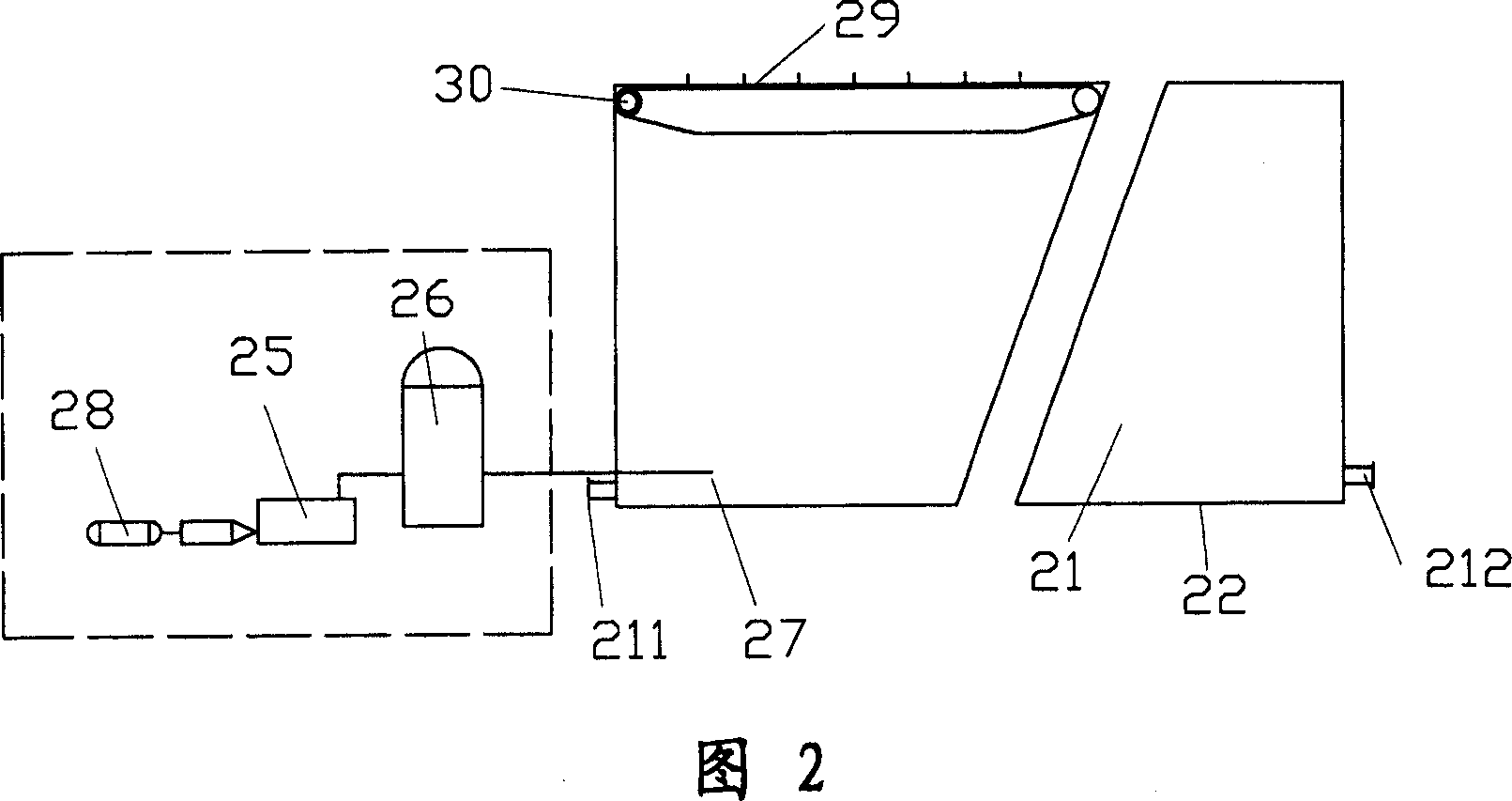

Recycling method for butylene oxidative dehydrogenation wastewater

ActiveCN103086829AEmission reductionReduced distribution water usageHydrocarbonsNature of treatment waterOrganic acidSaline water

The invention relates to a recycling method for butylene oxidative dehydrogenation wastewater, which is mainly used for solving the problems that the wastewater quantity is large and the dosage of water vapor is much in the prior art. The recycling method comprises the following steps of: (a) enabling butylenes, oxygen gas or air and water vapor to carry out oxidative dehydrogenation reaction under certain conditions, wherein reaction products enter a water-cooling tower after being cooled, so as to countercurrent contact washing water from the tower top for removing organic acid; (b), pressurizing water-cooling tower top gas to 0.5 Mpa-2.0MPa, enabling the pressurized water-cooling tower top gas to enter an aldehyde washing tower kettle and countercurrent contact fresh desalted water from the tower top for removing aldehyde impurities in the generated gas; and feeding the aldehyde-containing wastewater of the tower kettle and wastewater of the water-cooling tower to a wastewater pretreatment tower; and (c), removing part of aldehyde and micro hydrocarbon in the wastewater pretreatment tower to obtain aldehyde-deficient water, returning the part of aldehyde-deficient water to a butylene oxidative dehydrogenation reaction system, recycling part the aldehyde-deficient water as water distribution, and discharging part of the aldehyde-deficient water to a wastewater treatment site. According to the technical scheme, the technical problems are solved, and the recycling method can be used for industrial production process of butylene oxidative dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for recovering organic matters in wastewater generated in process for preparing olefin from methanol

ActiveCN102040303AEfficient recyclingIncrease valueMultistage water/sewage treatmentNature of treatment waterRecovery methodWastewater

The invention provides a method for recovering organic matters in wastewater generated in a process for preparing olefin from methanol. In the method, a pervaporation membrane or a vapor permeation membrane preferably permeating organic matters is adopted to separate the organic matters and water in the wastewater, methanol-containing organic matters are subjected to steam stripping, the steam stripping product is dehydrated by a pervaporation membrane or a vapor permeation membrane preferably permeating water so as to obtain the methanol and derivative products, and the wastewater from which the organic matters are removed can be directly discharged into a sewage farm or further treated to be reused in the production process. In the treatment method, the methanol and the derivative products in the wastewater are recovered, and the aim of treating the sewage is fulfilled.

Owner:CHINA PETROLEUM & CHEM CORP +1

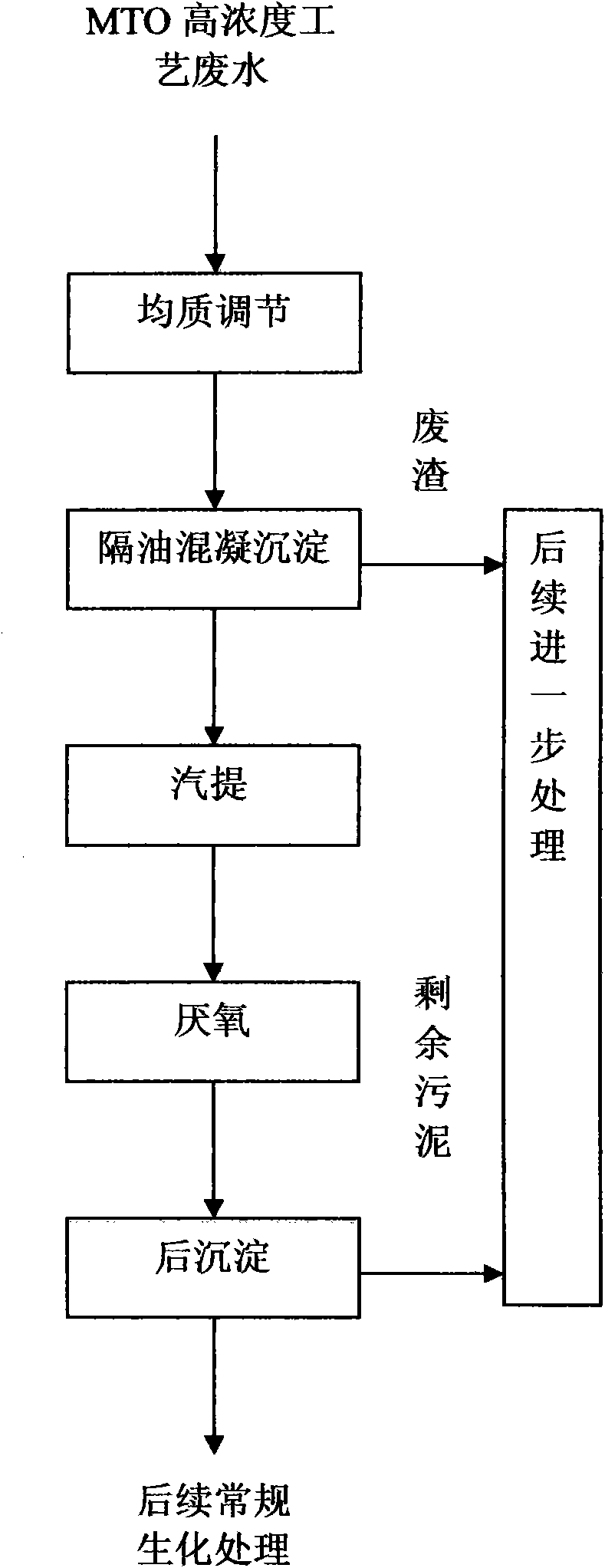

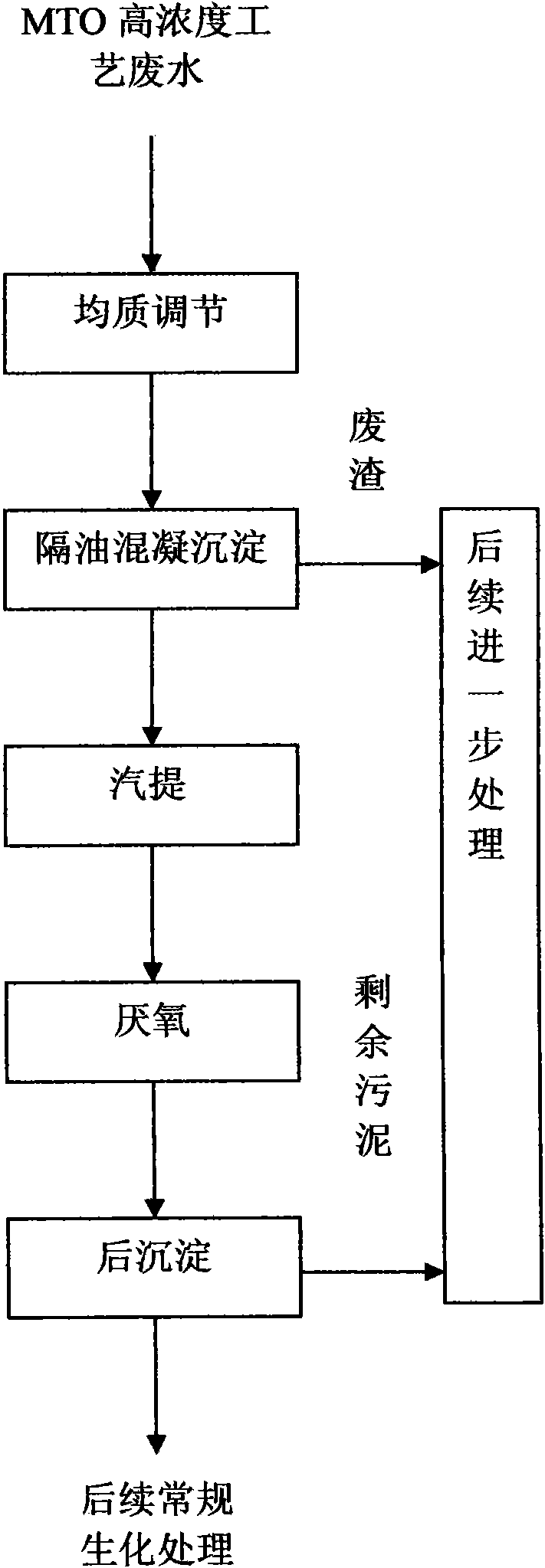

Treatment method of high-concentration process waste water during methanol-to-olefin process

ActiveCN102442744AReduce contentEasy to handleEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationPost precipitation

The invention relates to a treatment method of organic chemical waste water in the waste water treatment technical field, specifically to a treatment method of high-concentration process waste water during methanol-to-olefins (MTO) process, wherein after the MTO high-concentration process waste water is treated by the treatment flow of homogeneous regulation, oil-removing coagulating sedimentation, steam stripping, anaerobic treatment and post-precipitation, and corresponding condition, the COD of the waste water is reduced to be less than 500 mg / L from about 50000 mg / L, and the removal rate is more than 99%. The treatment method of high-concentration process waste water during methanol-to-olefin process has stable treatment effect, and simple and convenient operation, is easy to commercially produce and can be used for pre-treating MTO high-concentration process waste water before entering the normal sewage treatment plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

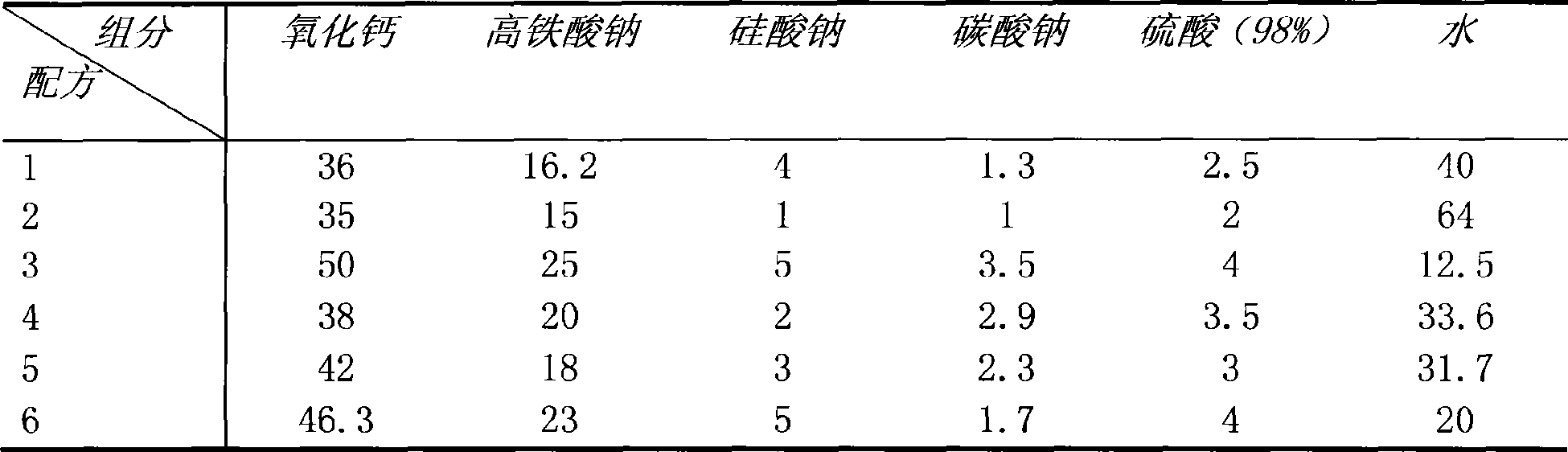

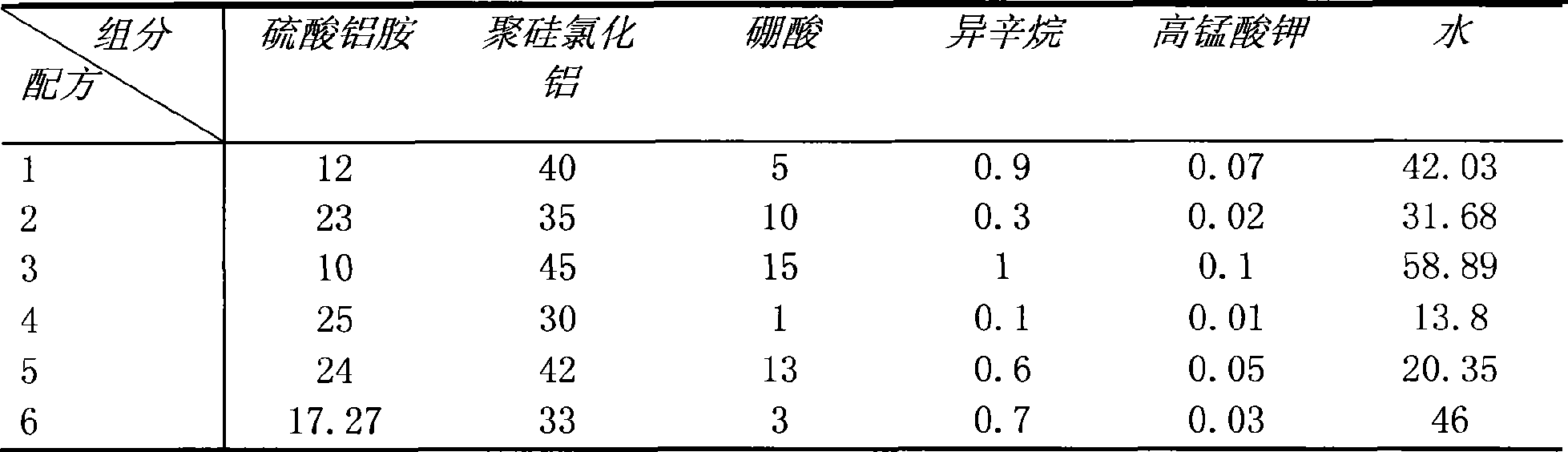

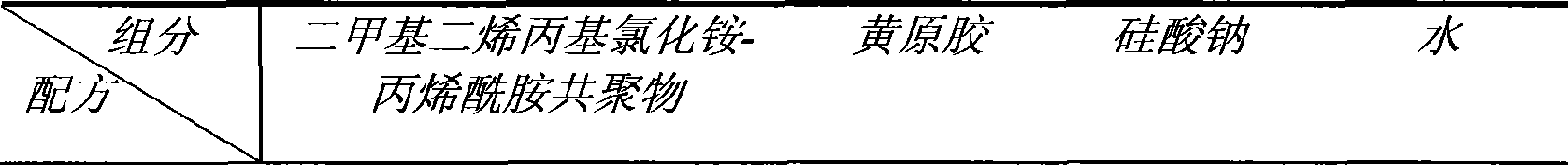

Coking wastewater treatment agent and use method thereof

ActiveCN101519239ALittle influence of temperatureReduce concentrationWater/sewage treatment by flocculation/precipitationHigh concentrationSewage

The invention provides a coking wastewater treatment agent and a coking wastewater treatment process. The coking wastewater treatment agent comprises activity transforming agent, highly-efficient dispersant and coacervating agent. The coking wastewater treatment process comprises the steps of adding the activity transforming agent in the coking wastewater and well mixing the activity transforming agent and the coking wastewater, adding the highly-efficient dispersant to the solution and well mixing the high-efficient dispersant and the solution, adding the coacervating agent to the new solution and well mixing the coacervating agent with the new solution, and standing the solution until the solution is layered with light oil at the upper layer, treated water in the middle layer and solid precipitate at the lower layer. The coking wastewater treatment agent has unique effect on the coking sewage of high-concentration petroleum, suspended substance and COD in the coking wastewater, and the coking wastewater treatment agent is less affected by temperature. The coking wastewater treatment process is stable and reliable and convenient to manage, ensures the stable running of a sewage treatment plant and the discharge of the sewage after reaching standard, can treat the coking wastewater through slightly renovating original equipment and reduces the coking wastewater treatment cost.

Owner:甘肃宇辰化工科技有限公司

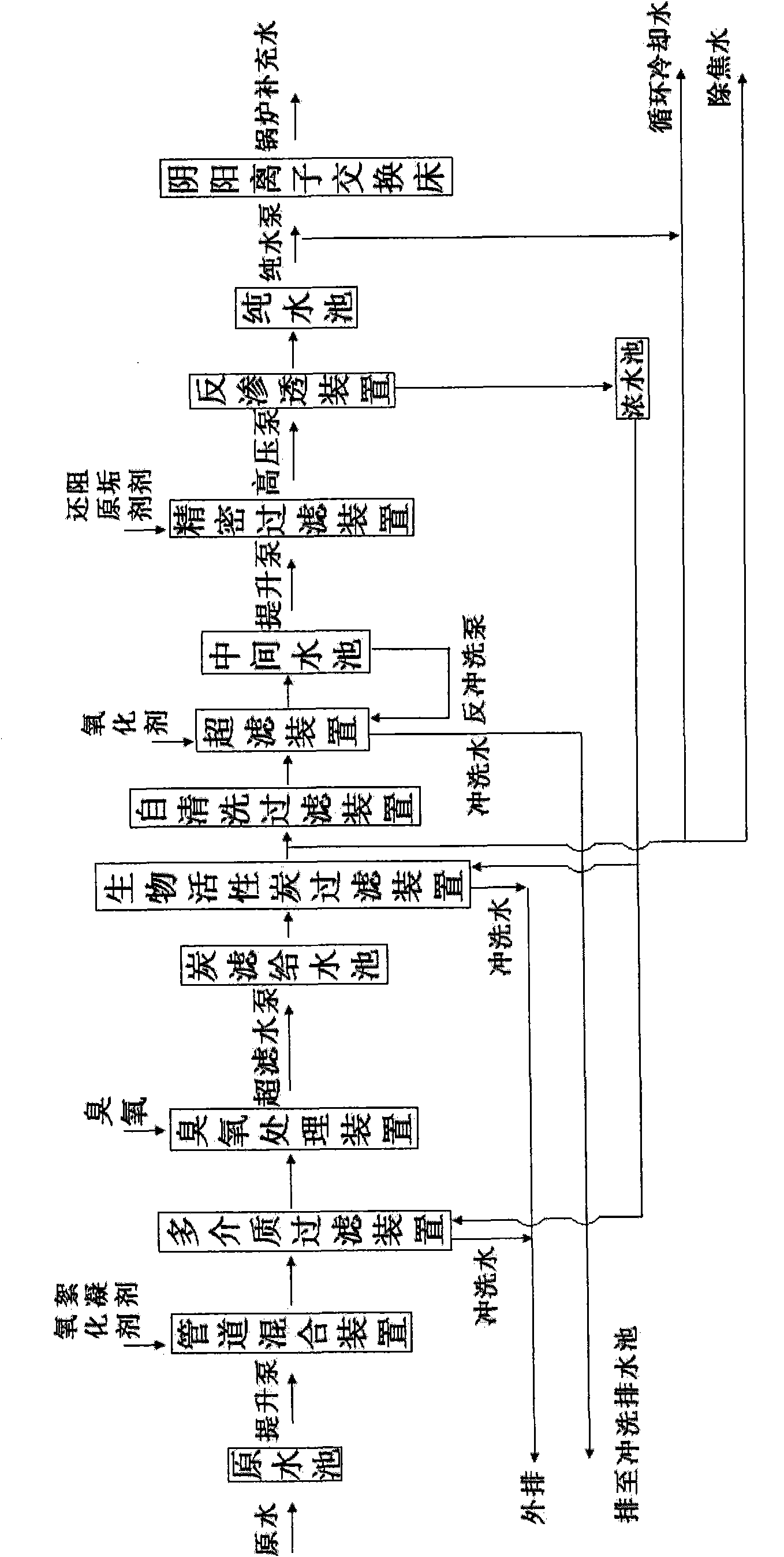

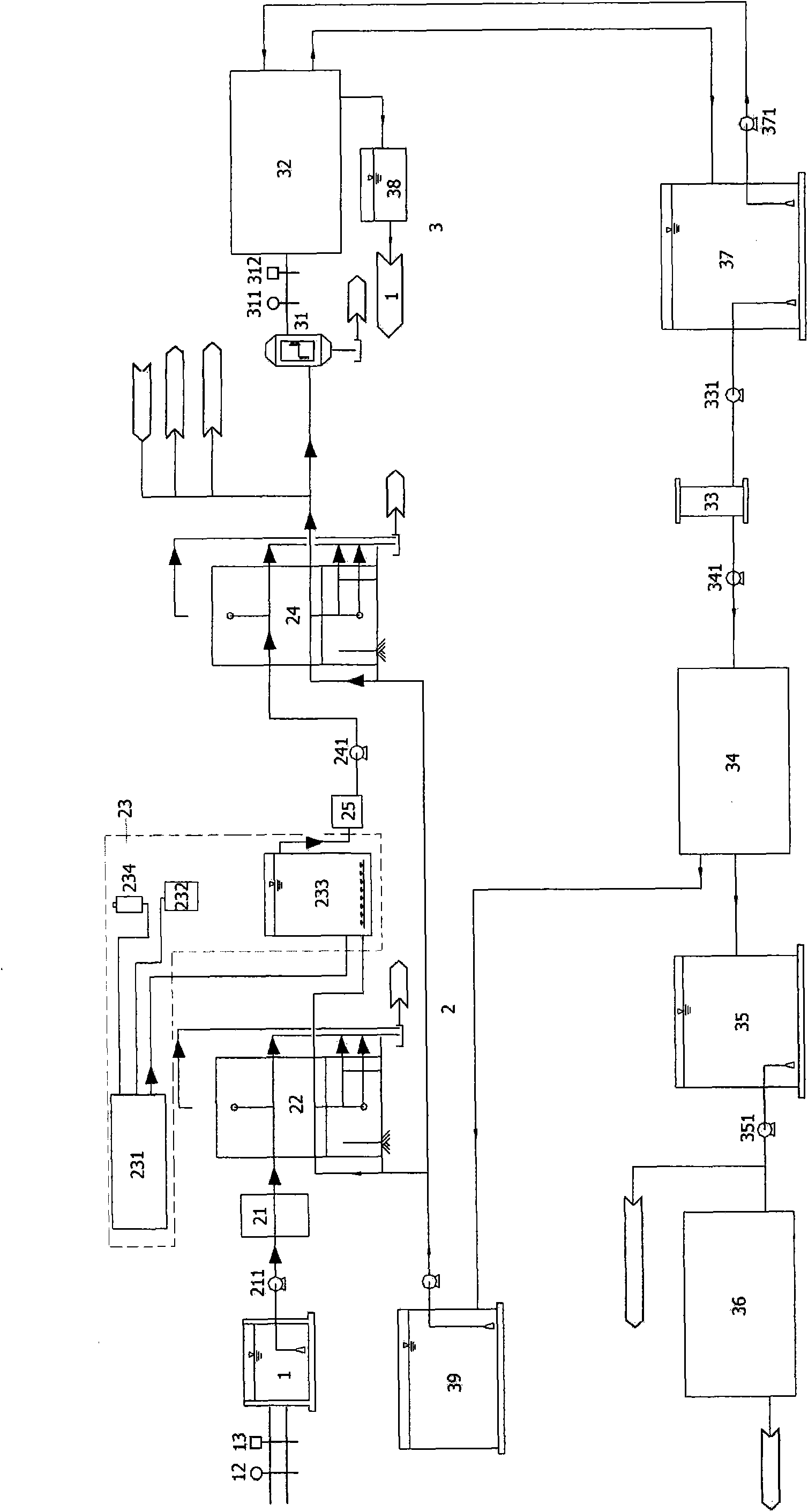

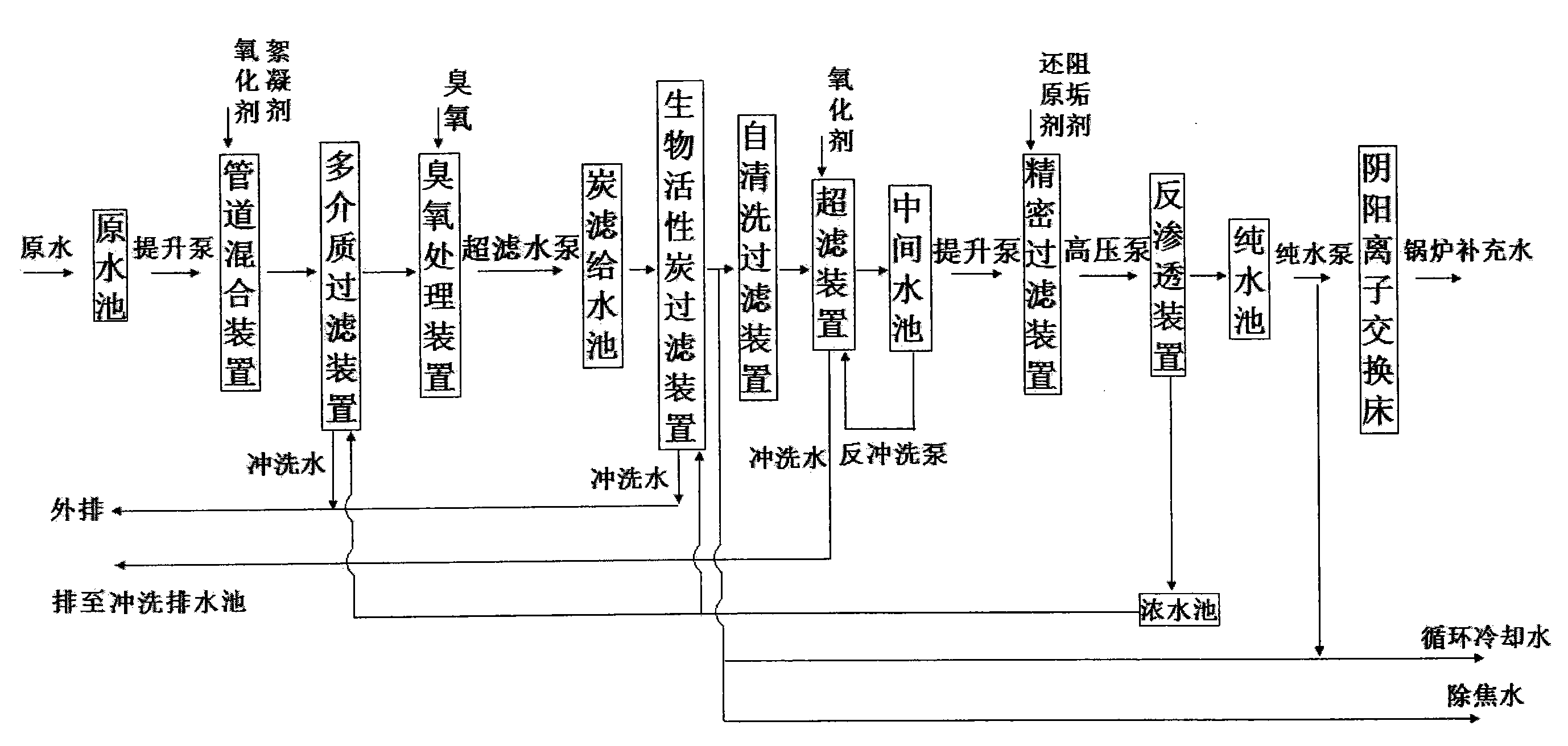

Method for performing advanced treatment and reuse on oil-refining sewage and matched device

ActiveCN102107958AFast constructionNice appearanceGeneral water supply conservationWater/sewage treatment by ion-exchangeTreatment costsBiological reaction

The invention belongs to the technical field of water treatment and in particular relates to a method for performing advanced treatment and reuse on oil-refining sewage and a matched device. The advanced treatment and reuse method comprises the following steps of: performing preoxidation flocculation filtering on effluent (pressure flow) from a sewage treatment field by using a multi-medium filter; allowing the filtered water to enter an ozone-biological active carbon unit; decomposing, degrading, and removing pollutants such as organic matters and the like by utilizing a chemical oxidation reaction principle and a biological reaction mechanism; allowing the obtained water to enter a UF-RO desalination system and a conventional anion-cation exchange bed system successively and then reusing continuously. After being treated by the method, the effluent meets various indexes of reuse water; treatment cost of acid and alkaline wastewater is reduced; service life of resin is prolonged; and advantages of economic and environmental benefits are obvious, in particular, the social benefit is more obvious in water-deficient areas.

Owner:贵州筑信水务环境产业有限公司

Industrial sewage treatment agent

InactiveCN104787821AQuick responseNothing producedWater/sewage treatmentSodium acetateAluminum sulphate

The invention relates to an industrial sewage treatment agent. The industrial sewage treatment agent is prepared from the ingredients in parts by mass: 20-40 parts of polysilicate aluminum sulfate, 20-40 parts of citric acid, 10-30 parts of corn starch, 15-30 parts of sodium acetate, 40-60 parts of polyacrylamide and 50-100 parts of secondary deionized water. According to the sewage treatment agent disclosed by the invention, the reaction speed is high, and no toxic and harmful gas is produced during reaction; a product, obtained after reaction, is stable and cannot be decomposed into toxic substances; the sewage treatment agent can be directly discharged to a sewage treatment plant, does not harm active bacteria of the sewage treatment plant and is impact-free to the sewage treatment plant; the sewage treatment agent is efficient and non-toxic, is safe to human before / after reaction and is corrosion-free to equipment; a use method is simple and convenient, does not change process flows and has no need of additionally arranging equipment and additional materials.

Owner:南平市延平区方腾飞投资合伙企业(有限合伙)

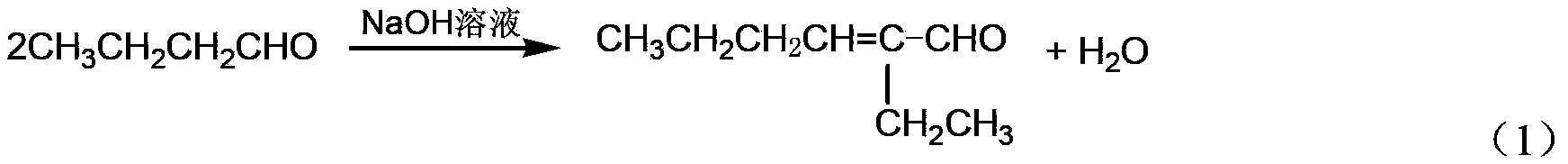

Processing method of butanol and octanol waste alkaline solution

ActiveCN104071940ARealize recycling of resourcesEmission reductionOrganic chemistryMultistage water/sewage treatmentSewageSodium salt

The invention relates to a processing method of a butanol and octanol waste alkaline solution. The method comprises the following steps: carrying out an acidification treatment on a waste alkaline solution with an inorganic acid until the pH value of the waste alkaline solution reaches 3 to 4.5; carrying out a pervaporation membrane evaporative concentration treatment on the acidified solution, carrying out an oil / water separation treatment on the evaporative concentrated solution, cooling to carry out crystallization, recycling the inorganic acid sodium salts, returning the crystallized residue to an acidification reactor to carry out a cyclic treatment, carrying out an adsorption treatment on the evaporative condensed liquid, returning the dehydrated part to a condensation reactor to prepare an alkaline solution, introducing the residue to a sewage processing field to carry out a bio-treatment, and finally discharging the sewage until the sewage reaches the discharge standards. The processing method can recycle organic substances in a waste alkaline solution, and turns the waste into valuable resources. At the same time the organic salts that are generated during the acidification process can be recycled as a by-product, and moreover, the processed effluent can be used to replace the fresh desalinated water to prepare fresh alkaline liquid, so the waste alkaline solution can be repeatedly used and production cost can be saved. The processing method has prominent environmental profits and economic profits.

Owner:PETROCHINA CO LTD

Biological agent for purifying air and preparation method thereof

The invention discloses an air purifying biological preparation and a preparation method thereof. The biological preparation of the invention is mainly composed of the following microorganisms by weight portions: 40-60 portions of rhodopseudomonas palustris, 10-30 portions of lactobacillus acidophilus, 10-30 portions of saccharomyces cerevisiae, and 10-30 portions of Jingyang streptomyces. The biological preparation of the invention contains multifold effective microbial floras, the beneficial microorganisms in the microbial inoculums can inhibit the effluvium components from being generated, on the other hand, the microorganisms act on the above components directly, thereby the content of harmful gases is reduced, the consistence of the effluvium is reduced, so that the biological preparation of the invention can quickly reduce the consistence of multifold harmful gases, such as ammonia, hydrogen sulfide, etc., can purify the air with notable deodorization effect, is applicable for deodorizing in culture farms, livestock houses, toilets, septic tanks, sewages, factories, odorous public places, sewage farms, etc.; in addition, the biological preparation of the invention can improve the immunity of the livestock, and can kill pathogen.

Owner:德胜平安福生态农业科技发展有限公司

Processing method for discharged exhaust gas in sewage disposal field

ActiveCN102380294AImprove processing efficiencyLow costUsing liquid separation agentSewage treatmentHydrocarbon

The invention discloses a processing method for discharged exhaust gas in the sewage disposal field, comprising the following steps of: 1) carrying out spray washing on exhaust gas discharged from the sewage disposal field by using a spray washing liquid with the addition of a bactericide; 2) carrying out desulphurization on the exhaust gas processed from step 1) by using a solid desulfurizer; 3)carrying out hydrocarbon concentration homogenization on the exhaust gas processed from step 2) by using a substance which has a concentration homogenization effect so as to satisfy the discharge requirement. In comparison with the prior art, the method provided by the invention has advantages of high processing efficiency, low cost, stable operation of equipment and the like, and is most suitable for purification treatment of exhaust gas discharged from various biochemical aeration sewage disposal fields.

Owner:CHINA PETROLEUM & CHEM CORP

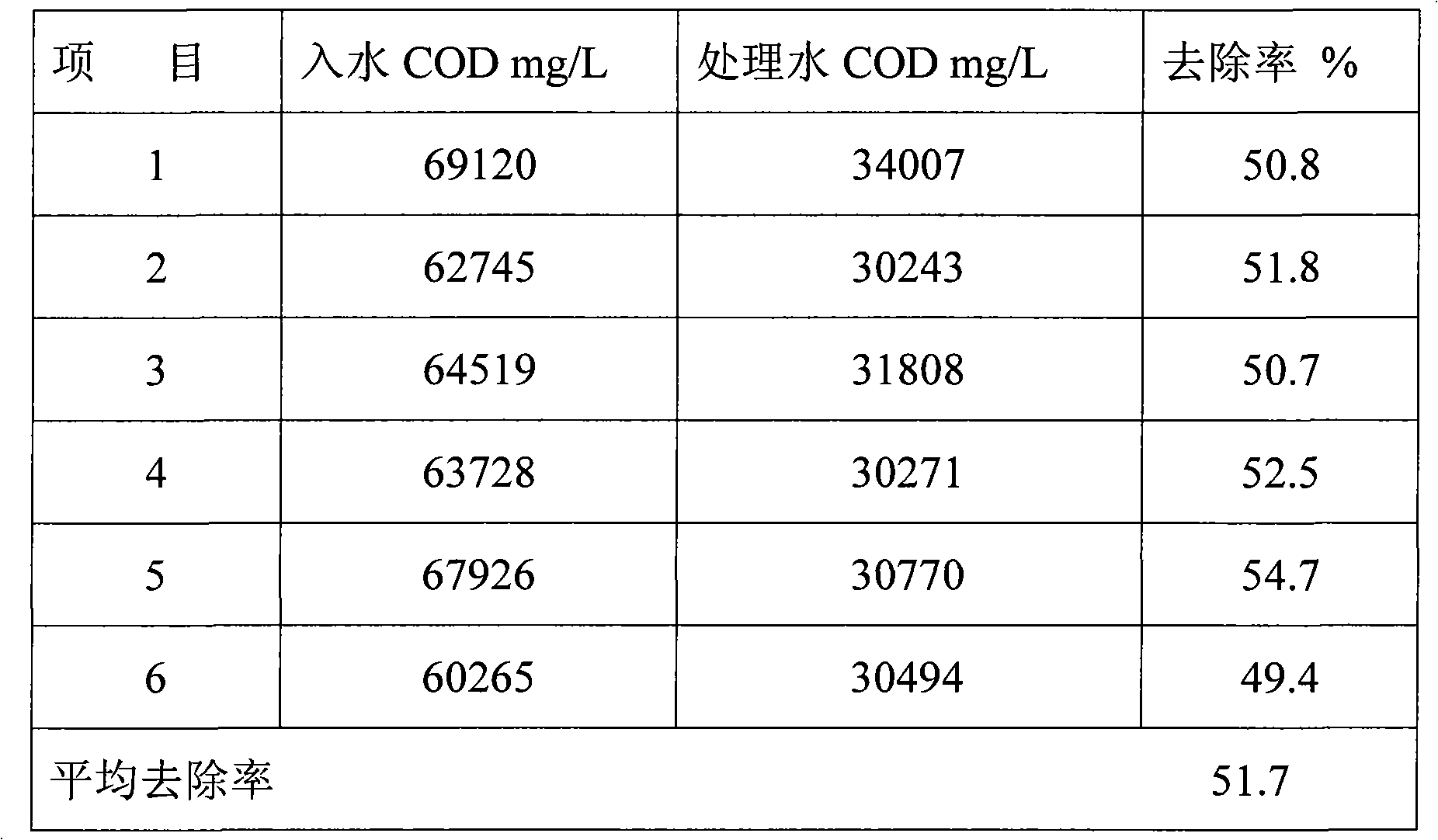

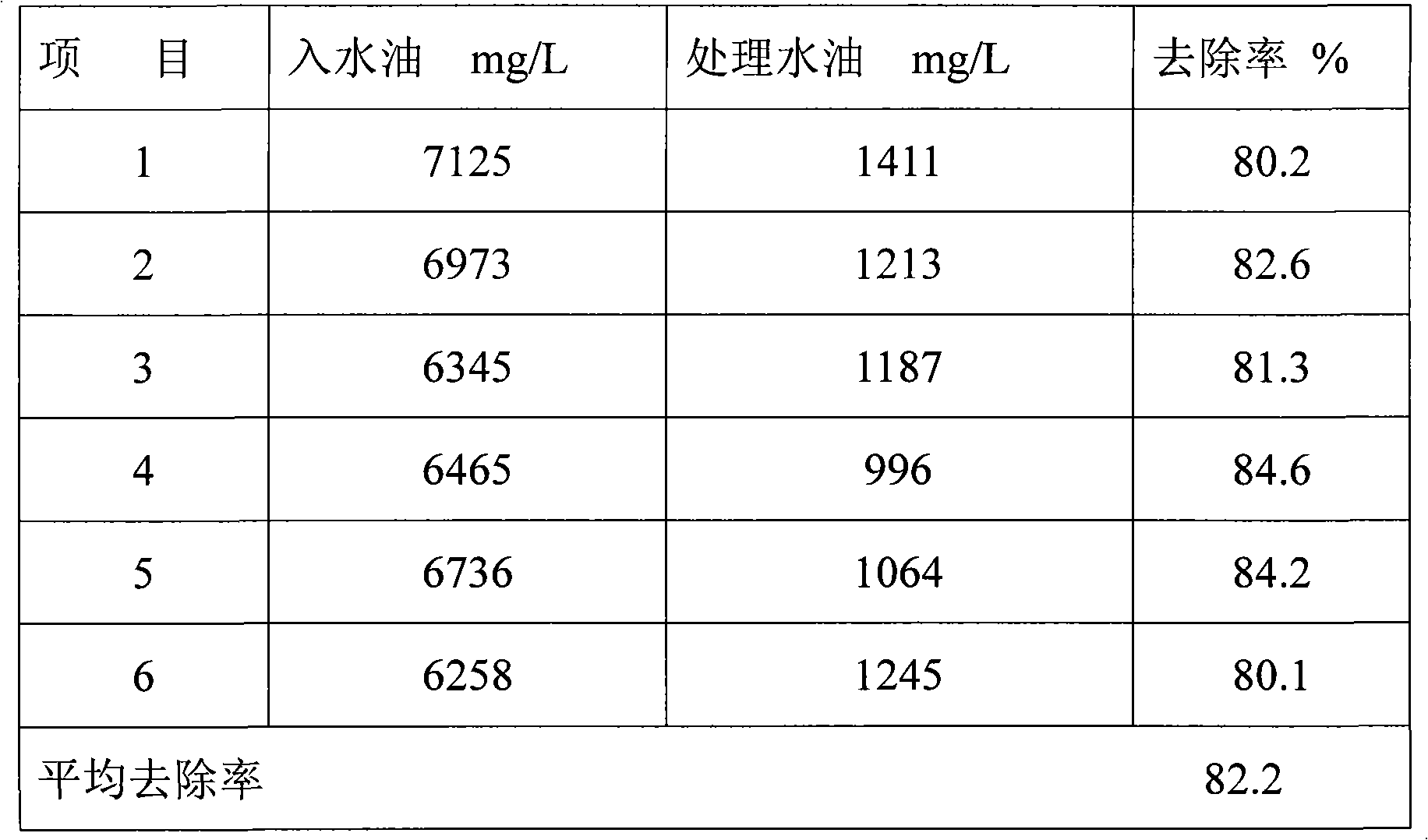

Method for treating octanol waste lye by miscellaneous alcohol acidization-extraction method

ActiveCN101353213ATo achieve the purpose of governanceImprove governance effectMultistage water/sewage treatmentWater/sewage treatment by extractionAfter treatmentAlcohol

The invention relates to a method for treating waste lye discharged by the reaction system when octanol is produced. The recycled lye part discharged by an octanol production device is sent to an acidification mixer, inorganic acid and fusel are added for acidification mixture, demixing fluid is clear and separated by quiescence; extraction phase returns to a fusel tank for recycling, wastewater after neutralization is discharged to sewage farms for carrying out biological treatment; the mixing time is 3-15 minutes, the proportion by volume between the extraction agent and the wastewater is 1:1-8, the pH value after acidification is 2.0-4.5, the proportion by volume between the wastewater and 93% of concentrated sulphuric acid is 40-80:1, normal temperature and normal pressure are kept, the separated time is 30-120 minutes, the pH value of the treated water by neutralization is 6-9, the deoiling ratio is over 82%, the ratio of CODcr removal reaches 50%, biodegradability of the wastewater after treatment is improved from 40% to over 90%, the wastewater after treatment can directly enter chemical sewage farms for carrying out biological treatment, and the extraction agent does not need be regenerated.

Owner:PETROCHINA CO LTD

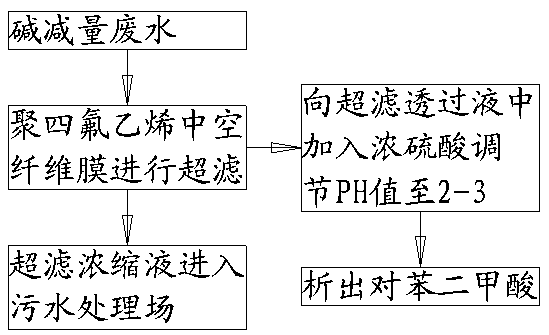

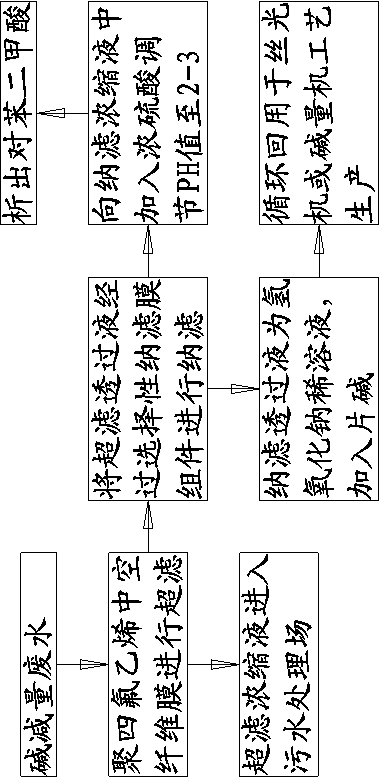

Recovery method using membranes for terephthalic acid and sodium hydroxide from printing and dyeing alkali-reduced waste water

InactiveCN103387300AReduce processingSolve the problem of meeting emission standardsMultistage water/sewage treatmentAlkali metal oxides/hydroxidesRecovery methodUltrafiltration

The invention discloses a recovery method using membranes for terephthalic acid and sodium hydroxide from printing and dyeing alkali-reduced waste water. The method comprises (1) a step of collecting the printing and dyeing alkali-reduced waste water, and performing ultrafiltration by using a polytetrafluoroethylene hollow fiber membrane to obtain an ultrafiltration concentrated liquid and an ultrafiltration permeating liquid; (2) a step of feeding the ultrafiltration concentrated liquid into a sewage treatment plant; (3) a step of subjecting the ultrafiltration permeating liquid to nanofiltration by using a selective nanofiltration membrane component to obtain a nanofiltration concentrated liquid and a nanofiltration permeating liquid; (4) a step of adding concentrated sulfuric acid to the nanofiltration concentrated liquid to adjust the pH value to 2-3, precipitating the terephthalic acid, recovering and recycling the mother liquor after the mother liquor is treated; and (5) a step of recycling and reusing the nanofiltration permeating liquid which is a dilute sodium hydroxide solution to process production of a mercerizing machine or an alkaline machine. By the above manner, the method has simple operation and the method is capable of saving water resources, reducing production cost, and achieving a double harvest of economic benefit and environment benefit.

Owner:SUZHOU INTER IND WATER TREATMENT ENG

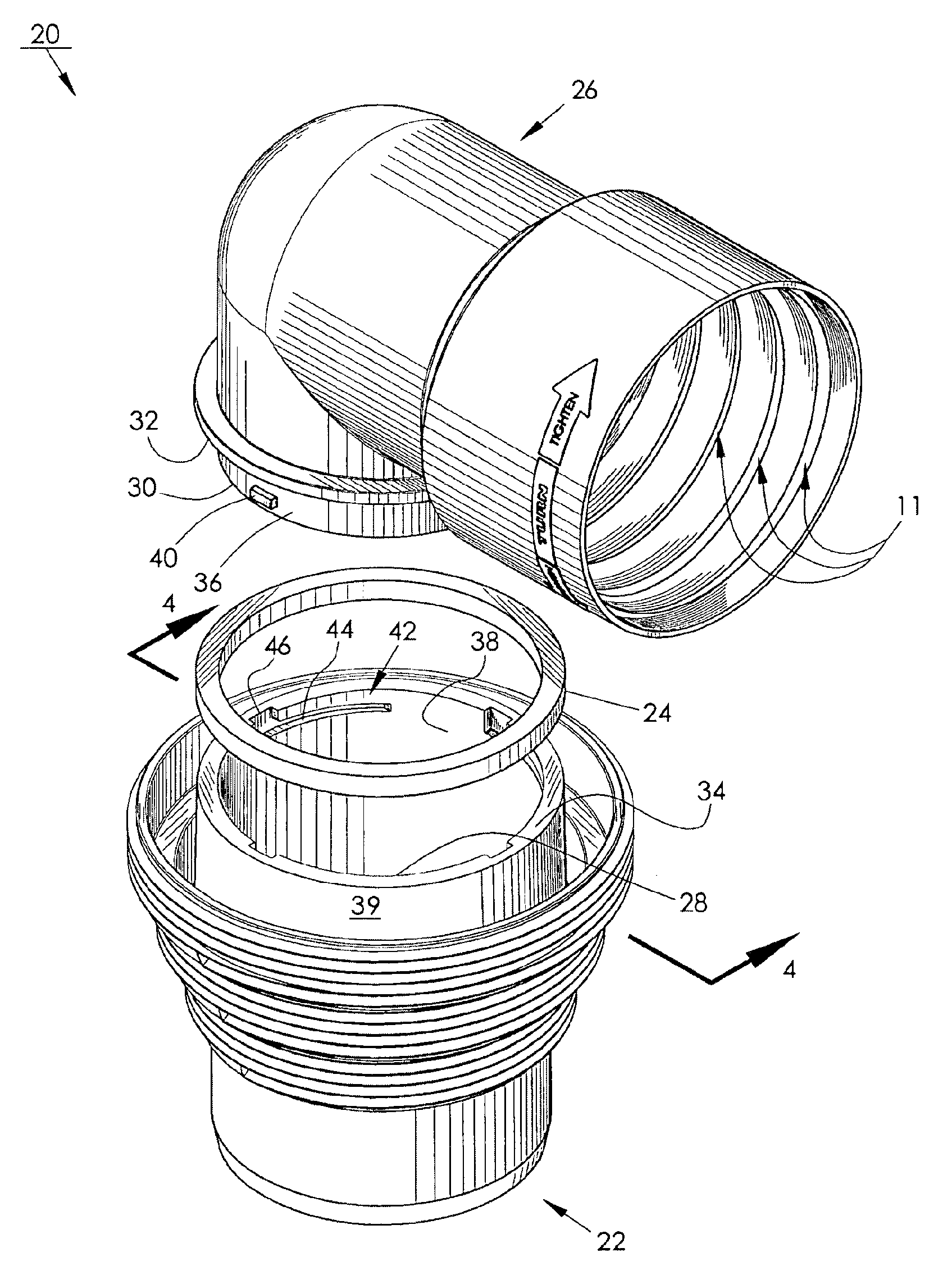

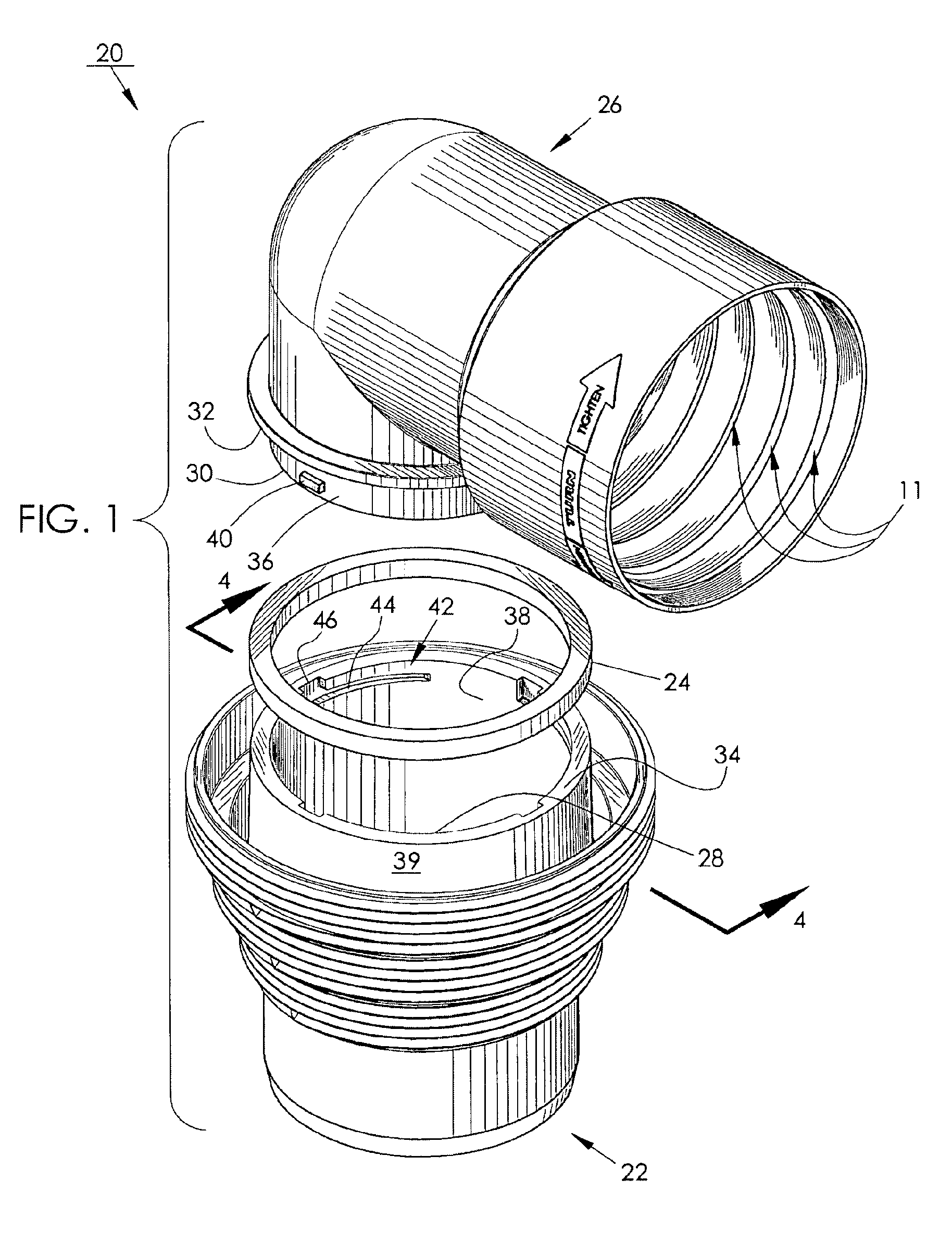

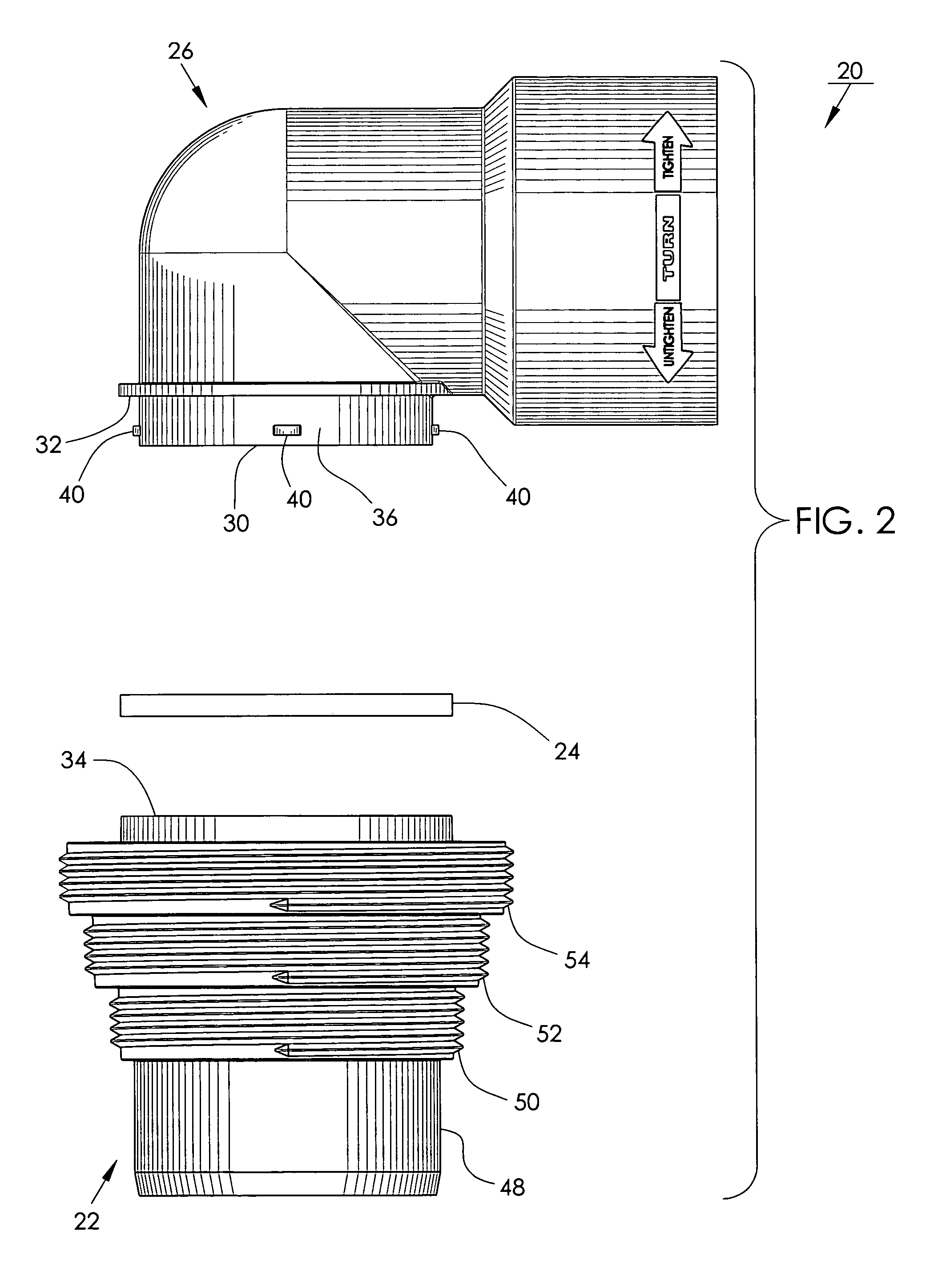

RV waste discharge sewer line two-part adapter assembly with flexible seal and locking mechanism

An adapter assembly for connecting a sewage drain pipe to a sewage disposal site inlet in fluid communication includes a hollow tubular member, a hollow adaptive member and flexible seal. The hollow tubular member having an open inlet adapted to engage threadable or otherwise to the end of a sewage drain pipe. A hollow adapter member having an open discharge end with adaptive features to be inserted into disposal site inlet. The tubular and adapter member interfacing via a rotational positive mechanical lock compressing an annular flexible seal radially or axially to ensure a dependable, long lasting low pressure fluid tight seal.

Owner:CAMCO MFG LLC

Regeneration method for sulphureous alkali residues

ActiveCN103769407AFull recoveryCausticizing regeneration is easySolid waste disposalSulfur preparation/purificationHigh concentrationCalcium sulfite

The invention relates to a regeneration method for sulphureous alkali residues comprises three parts, namely, SO2 acidification of the alkali residues, extraction and recycling of petroleum acid, and causticization and regeneration, wherein SO2 used in the step of SO2 acidification is SO2-containing gas from a Klaus sulfur production device, meanwhile tail gas of the Klaus sulfur production device is introduced as carrier gas, and acidification is stopped when the pH of acidulous water generated by acidification reaches 2-4. Three phases, including gas, oil and water, are generated in the acidification process, wherein the gas enters the Klaus sulfur production device so as to separate and recycle acid oil, and the water phase is subjected to solvent extraction so as to recycle petroleum acid, and then is causticized with Ca(OH)2 and precipitated to separate calcium sulfite to generate a sodium hydroxide solution which is recycled as alkali liquor for alkali washing of oil. The method provided by the invention has the advantages that the investment is low, the operation condition is mild, sulfide, petroleum acid and sodium ions can be recycled, no odorous gas is discharged, no high-concentration or high-salinity waste liquor flows into a sewage disposal station, and certain economic benefits are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sewage treatment process capable of recovering low-carbon hydrocarbons and low-carbon oxygen-containing organic matters

ActiveCN102060403AMeet the water quality requirementsAvoid harmEther separation/purificationHydrocarbon purification/separationWater qualityCarbon.organic

The invention discloses a sewage treatment process capable of recovering low-carbon hydrocarbons and low-carbon oxygen-containing organic matters. The process comprises the following steps: delivering a sewage raw material subjected to heat exchange into a flash evaporation separation tank; delivering a separated gas mixture containing ethene, propylene and low-carbon oxygen-containing organic matters into an oxide removing tower to obtain a low-carbon organic matter flow and a low-carbon hydrocarbon (such as ethene and propylene) flow; and delivering a separated liquid mixture into a stripping tower to obtain pure water. The total methanol and dimethyl ether content in pure water obtained by the method is not more than 100ppm. The pure water meets the inflow water quality requirement of sewage water treatment plant, and at the same time, the low-carbon hydrocarbon matters and low-carbon oxygen-containing organic matters in sewage are recovered.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com