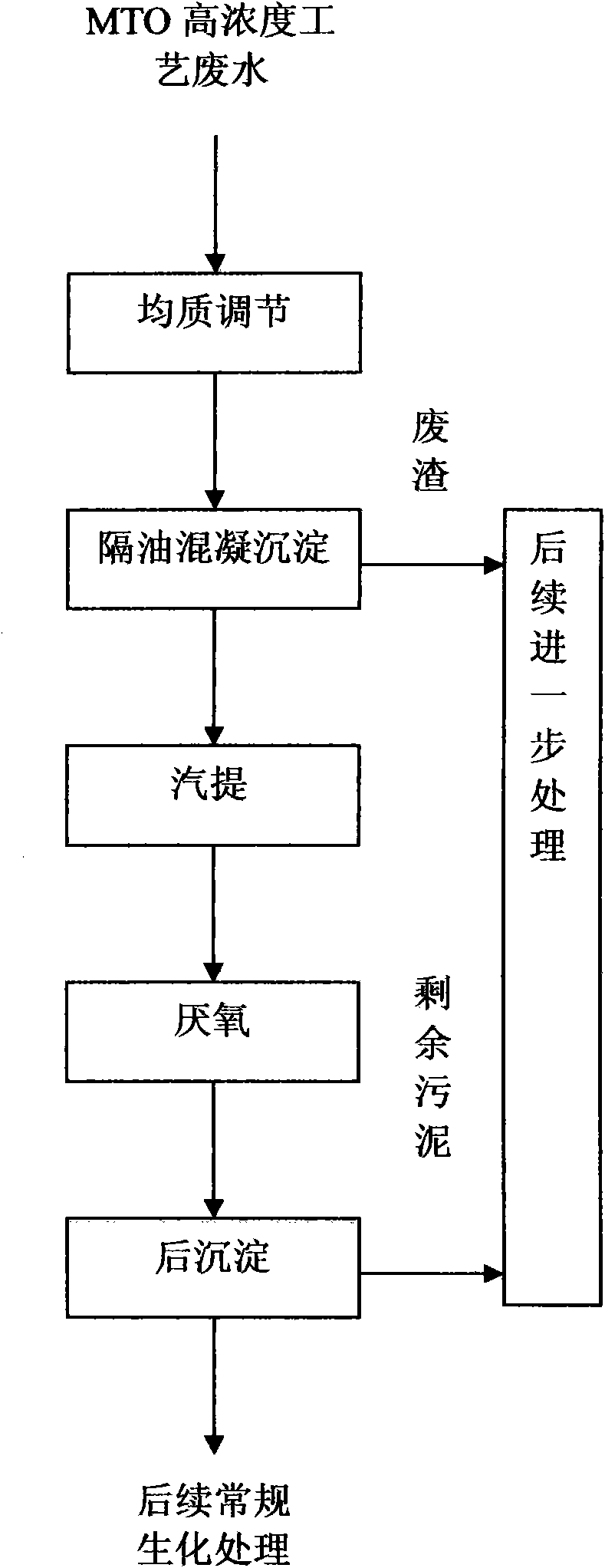

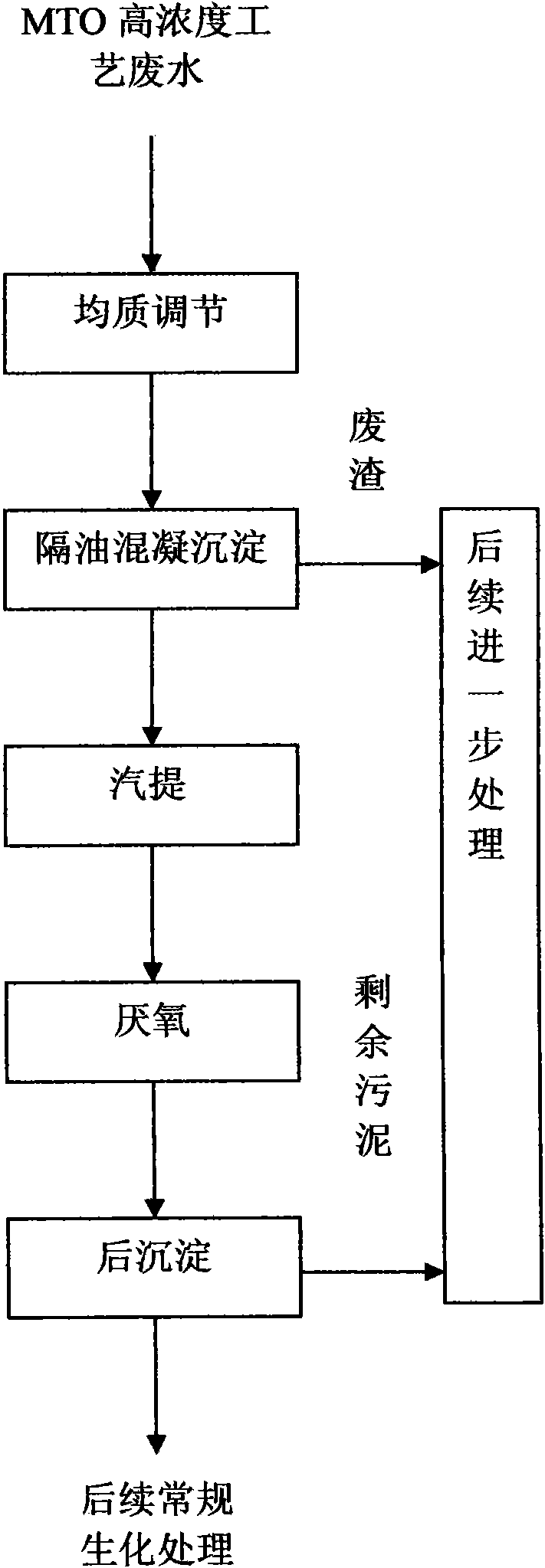

Treatment method of high-concentration process waste water during methanol-to-olefin process

A technology of methanol to olefins and a treatment method, which is applied in the field of treatment of high-concentration process wastewater from methanol to olefins, can solve problems such as no mention of wastewater, and achieve the effects of reducing the content of organic pollutants, stable treatment effect and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] The high-concentration MTO process wastewater undergoes homogenization treatment with an average residence time of 24 hours in the homogeneous adjustment unit, and the pH is adjusted by adding sodium hydroxide solution. The main water quality indicators of the effluent are as follows: water temperature is 35°C, pH is 6.5, and COD is 45500mg / L, the content of methanol is 9500mg / L, the content of acetic acid is 4050mg / L, the content of acetone is 6650mg / L, the content of petroleum is 900mg / L, the content of SS is 2300mg / L, and the conductivity is 3560μS / cm.

[0086]In the oil separation coagulation sedimentation unit, polyaluminum chloride and polyacrylamide are used as coagulants, wherein the dosage of polyaluminum chloride is 50mg / L, and the dosage of polyacrylamide is 5mg / L. After the oil separation coagulation sedimentation treatment, the petroleum in the wastewater dropped to 20mg / L, and the SS dropped to 50mg / L.

[0087] In the stripping unit, the waste water is pu...

Embodiment 2

[0092] The high-concentration MTO process wastewater is homogenized in the homogeneous adjustment unit with an average residence time of 12 hours, and the pH is adjusted by adding sodium hydroxide solution. The main water quality indicators of the effluent are as follows: water temperature is 25°C, pH is 7.0, and COD is 50500mg / L, the content of methanol is 10100mg / L, the content of acetic acid is 4500mg / L, the content of acetone is 7200mg / L, the content of petroleum is 1050mg / L, the content of SS is 5200mg / L, and the conductivity is 4560μS / cm.

[0093] In the oil separation coagulation sedimentation unit, polyaluminum chloride and polyacrylamide are used as coagulants, wherein the dosage of polyaluminum chloride is 80mg / L, and the dosage of polyacrylamide is 5mg / L. After the oil separation coagulation sedimentation treatment, the petroleum in the wastewater dropped to 35mg / L, and the SS dropped to 65mg / L.

[0094] In the stripping unit, the waste water is pumped into the pac...

Embodiment 3

[0099] The high-concentration MTO process wastewater has undergone homogenization treatment with an average residence time of 12 hours in the homogeneous adjustment unit, and the pH is adjusted by adding sodium hydroxide solution. The main water quality indicators of the effluent are as follows: water temperature is 40°C, pH is 7.5, and COD is 57500mg / L, the content of methanol is 11000mg / L, the content of acetic acid is 4950mg / L, the content of acetone is 8000mg / L, the content of petroleum is 1450mg / L, the content of SS is 7800mg / L, and the conductivity is 5960μS / cm.

[0100] In the oil separation coagulation and sedimentation unit, polyaluminum chloride and polyacrylamide are used as coagulants, and the dosage of polyaluminum chloride is 120mg / L, and no polyacrylamide is added. After the oil separation coagulation sedimentation treatment, the petroleum in the wastewater dropped to 45mg / L, and the SS dropped to 70mg / L.

[0101] In the stripping unit, the waste water is pumpe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com