Method for treating oil refining sewage by employing multi-stage inflatable cyclonic current technology

A technology for treating and refining sewage, which is applied in separation methods, centrifugal separation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve equipment investment, high infrastructure and operation and maintenance costs, deterioration separation, and floor space major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

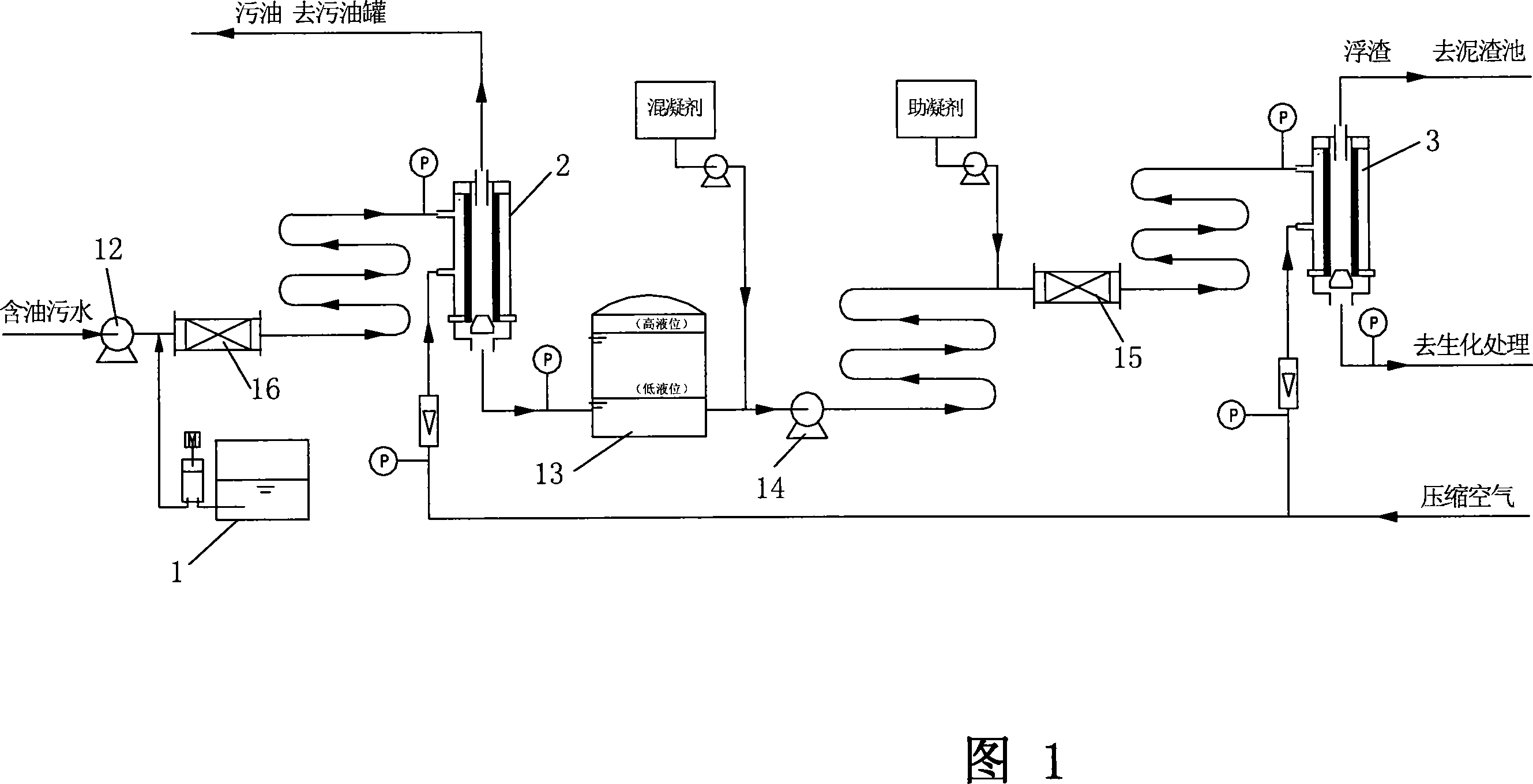

[0029] Embodiment 1 The process of using multi-stage inflatable cyclone technology to treat oil refinery sewage

[0030] Please refer to Figure 1. The high-concentration oily sewage produced by each device in the refinery is firstly pressurized to 0.2-0.3 MPa by the centrifugal pump 12 connected in series on the pipeline to the first-stage aerated hydrocyclone 2, and then passed through The demulsifier dosing tank 1 is mixed with an appropriate amount of demulsifier, so that the pressurized sewage mixed with demulsifier passes through the static mixer 16 (or Venturi mixer) and then remains in the pipeline for 15-25 seconds (depending on the amount of emulsified oil in the sewage). depends on the SS content) and then enters the first-stage inflatable hydrocyclone 2 for oil-water separation. The air source used for the cyclone separation operation can be provided by compressed air or air compressor in the factory, and the petroleum oil in the sewage overflows from the upper part ...

Embodiment 2

[0034] Embodiment 2 Inflatable hydrocyclone

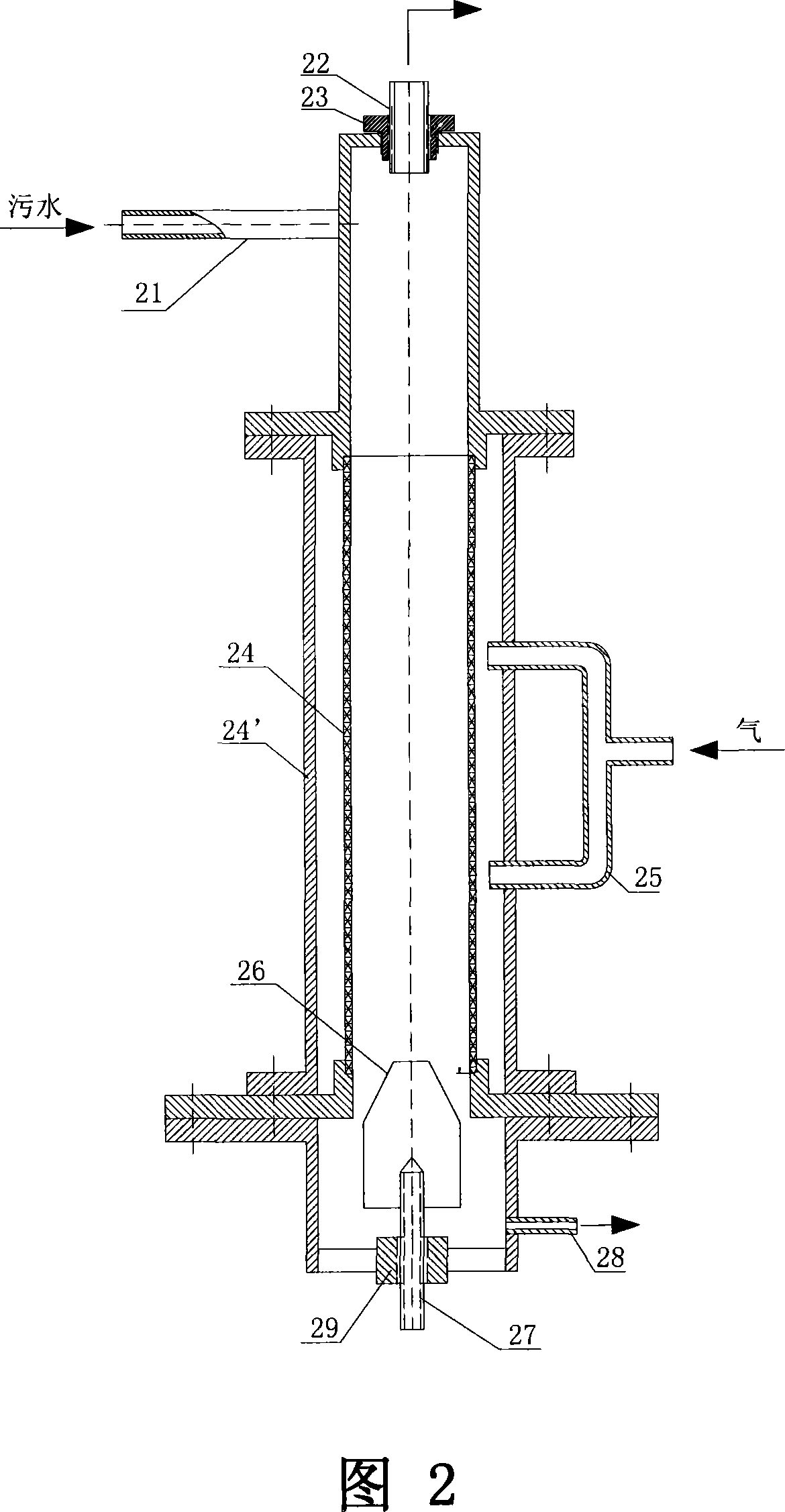

[0035] The primary and secondary aerated hydrocyclones 2 and 3 used in the process of Example 1 can be conventional aerated hydrocyclones, or an aerated hydrocyclone (ASH) as described in FIG. 2 .

[0036] Referring to Figure 2, the aerated hydrocyclone consists of three parts: the feed section, the flotation section, and the underflow section. The sections are connected by flanges. The shape of the entire cyclone device is cylindrical.

[0037] In the middle and upper part of the feeding section is the feeding pipe 21, from which the sewage enters the cyclone in a tangential feeding manner. An overflow pipe 22 and a gland 23 are designed on the top of the feed section. The outer side of the gland 23 is threaded with the top of the feed section, and the inner side is threaded with the overflow pipe 22, so that glands and overflow pipes with different inner diameters can be used according to water quality requirements, while the ...

Embodiment 3

[0041] According to the process and operation of Example 1 and Example 2, the field pilot test of using multi-stage aerated hydrocyclone technology to treat oil refinery sewage was first carried out in Liaohe Petrochemical Branch Company. The design processing capacity is 5t / h; the expected operation effect is achieved.

[0042] Liaohe Petrochemical Company mainly processes heavy oil and super heavy oil from Liaohe Oilfield, and the sewage to be treated has the typical characteristics of heavy oil sewage. The percentages of slick oil, dispersed oil, emulsified oil, and dissolved oil in raw water were 40.4%, 6.1%, 51.7%, and 1.6%, respectively. It can be seen that the oil contained in raw water is mainly slick oil and emulsified oil, and the degree of emulsification is relatively high, so the oily sewage to be treated in this embodiment belongs to the refractory oily sewage with high oil content, high emulsification, and high suspended solids.

[0043] The scope of main water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com