Method for performing advanced treatment and reuse on oil-refining sewage and matched device

A technology for refining sewage and advanced treatment, applied in the field of water treatment, can solve the problem of high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 The supporting device for the treatment of oil refinery sewage

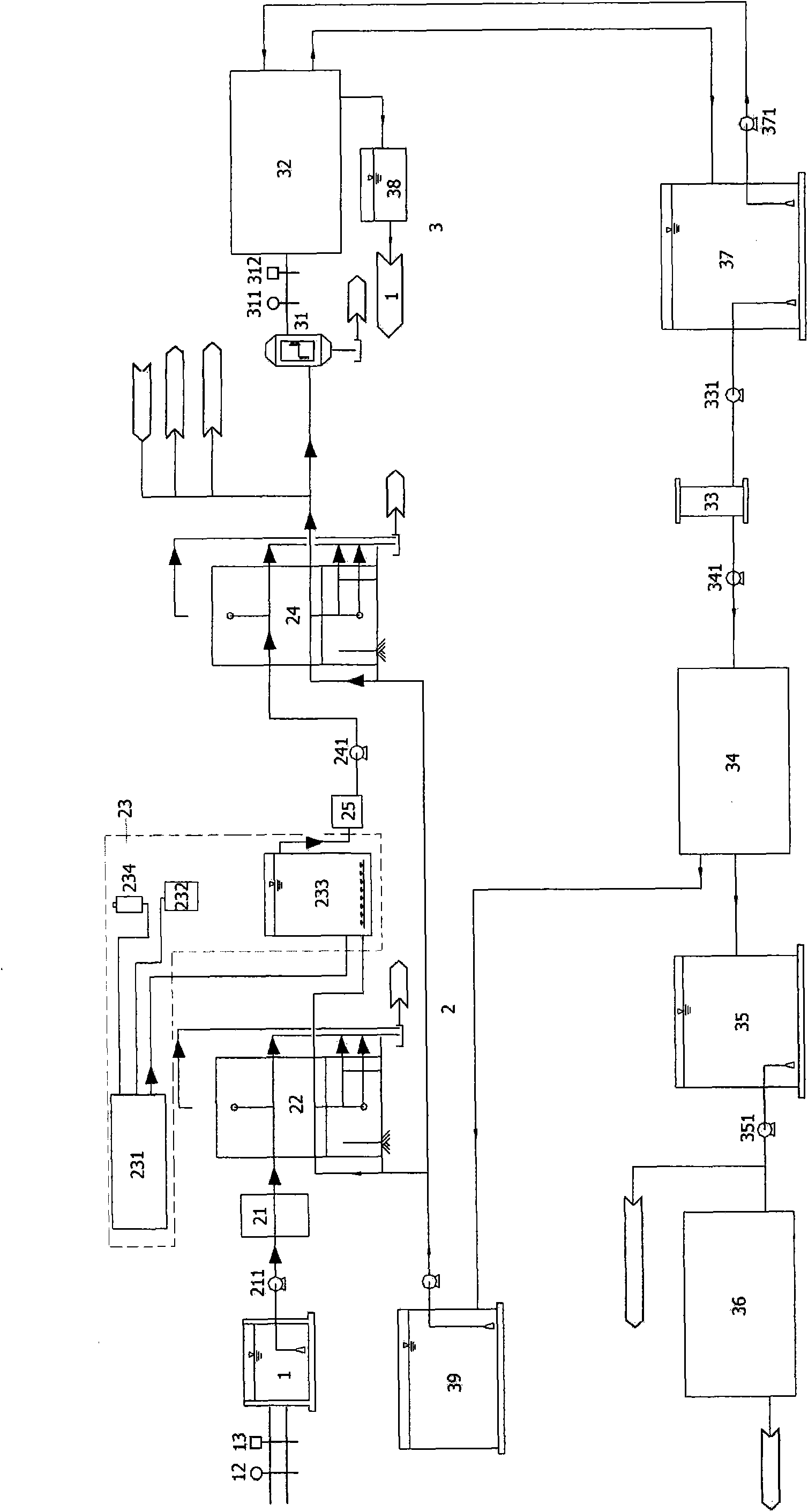

[0056] Such as figure 2 A supporting device for treating oil refinery sewage shown in , which includes a raw water tank 1 , a pretreatment device 2 and a post-treatment device 3 connected in sequence.

[0057] Wherein, the pretreatment device 2 includes a pipeline mixing device 21 , a multimedia filter device 22 , an ozone treatment device 23 and a biological activated carbon filter device 24 connected in sequence.

[0058] Wherein, the post-processing device 3 includes a self-cleaning filter device 31 , an ultrafiltration device 32 , a precision filter device 33 , a reverse osmosis device 34 , a pure water pool 35 and an anion-cation exchange bed 36 connected in sequence.

[0059] Wherein an intermediate pool 37 is also provided between the ultrafiltration device 32 and the precision filtration device 33 .

[0060] The ozone treatment device 23 is composed of an air source ozone generator ...

Embodiment 2

[0068] Example 2 Using the supporting equipment in Example 1 to treat the refinery sewage of Sinopec Tahe Branch

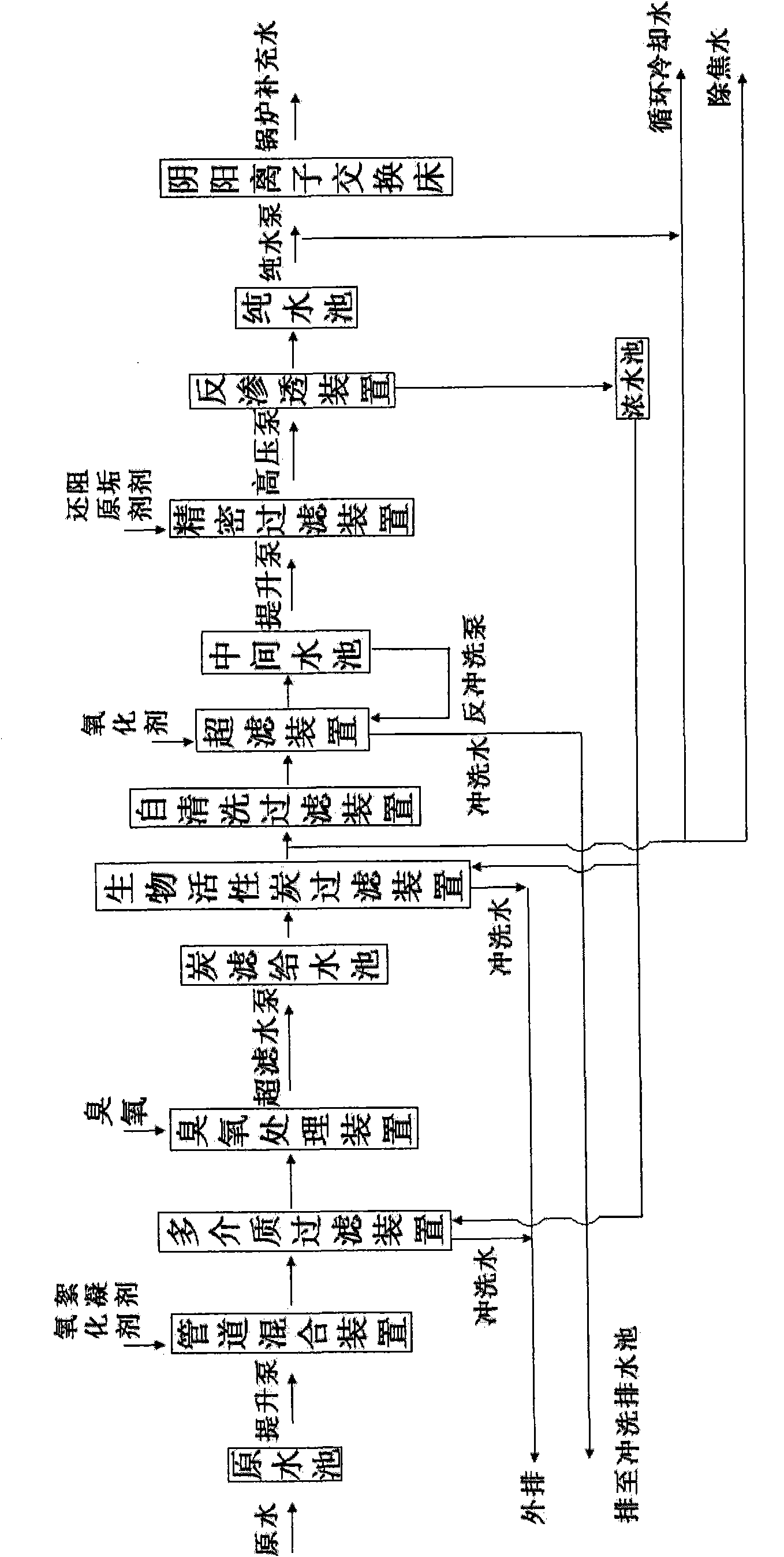

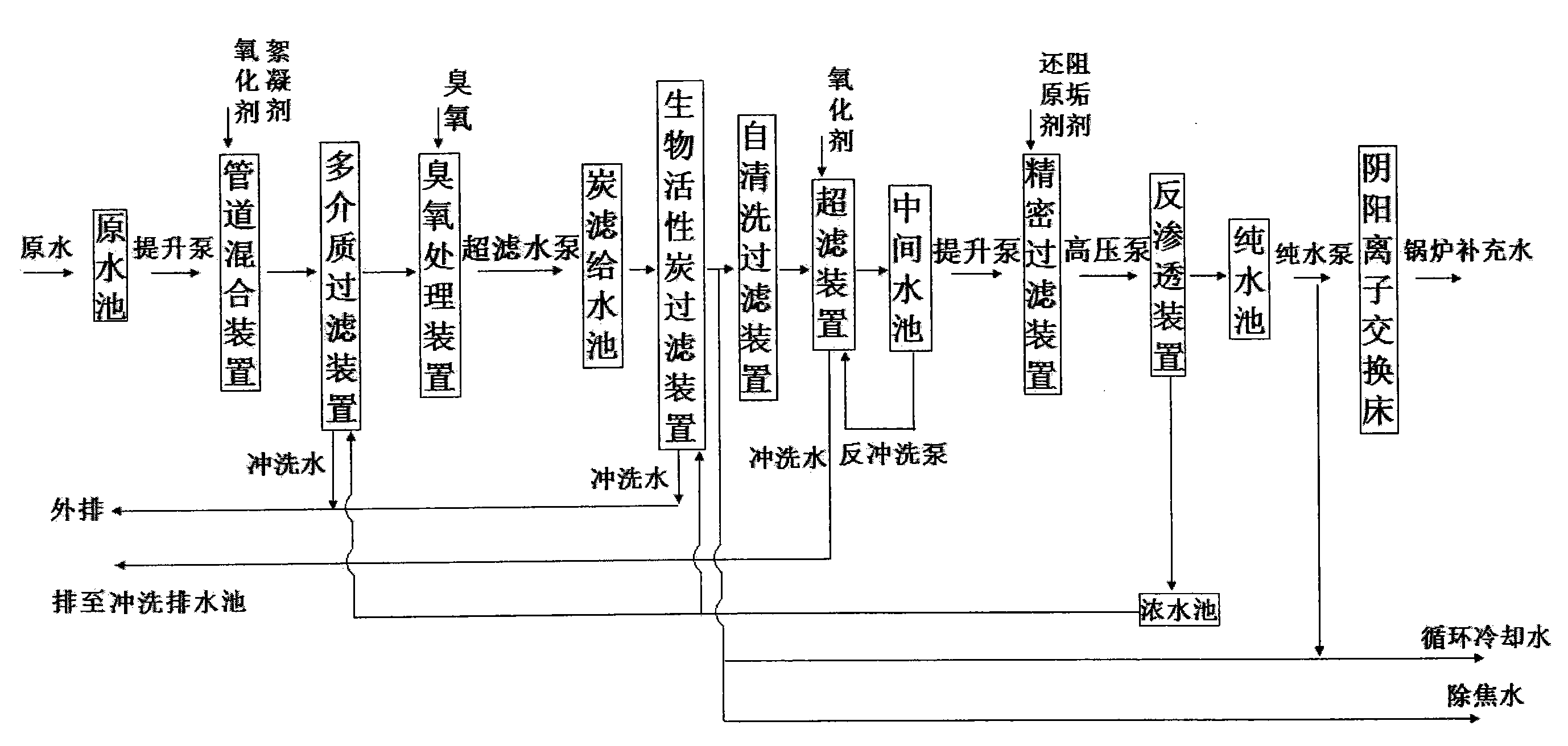

[0069] The source of the refinery sewage used in this example is: the refinery sewage of Sinopec Tahe Branch, which has undergone degreasing, traditional biochemical, and advanced biochemical treatment before; the impurities contained in it mainly include: COD, NH 3 -N, SS, oil, etc. The specific implementation steps are as figure 1 shown in .

[0070] 1. Advanced treatment process of oil refinery wastewater:

[0071] During the advanced treatment of oil refinery sewage, the oil refinery sewage first enters the raw water pool 1, then enters the pipeline mixing device 21 from the raw water pool 1, and adds a flocculant basic aluminum chloride flocculant (throwing agent) into the pipeline mixing device 21. The dosage is 3~10ppm) and the oxidant sodium hypochlorite (the dosage is 1~5ppm).

[0072] The sewage after adding flocculant and oxidant enters the multimed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com