Technique for processing wastewater containing methanol and dimethyl ether

A technology of dimethyl ether and methanol, which is applied in the field of sewage treatment process containing methanol and dimethyl ether, can solve the problems of incapable of sewage treatment and no sewage treatment device is found, and achieves low operating pressure, saving of utility costs, and flexible operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

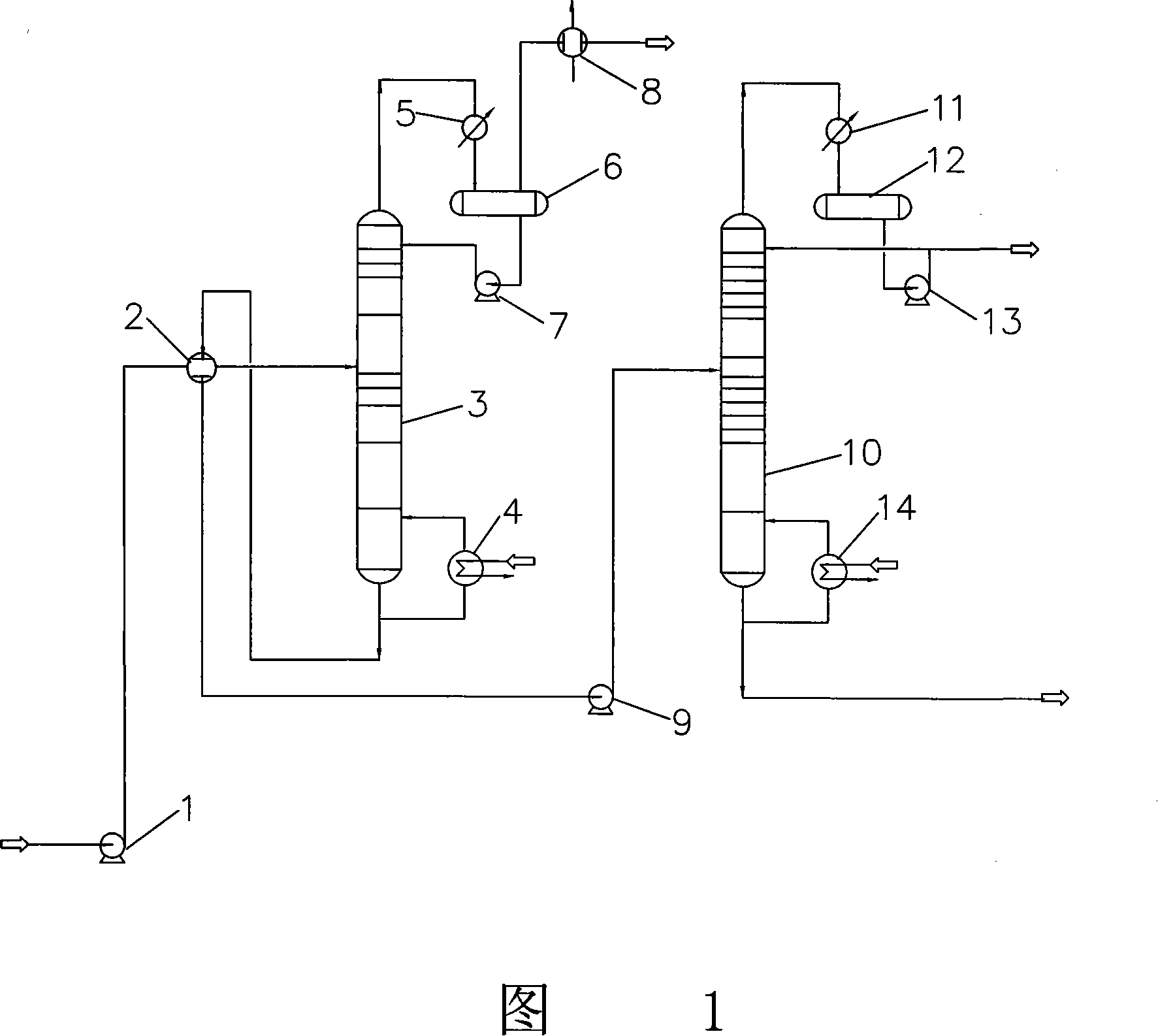

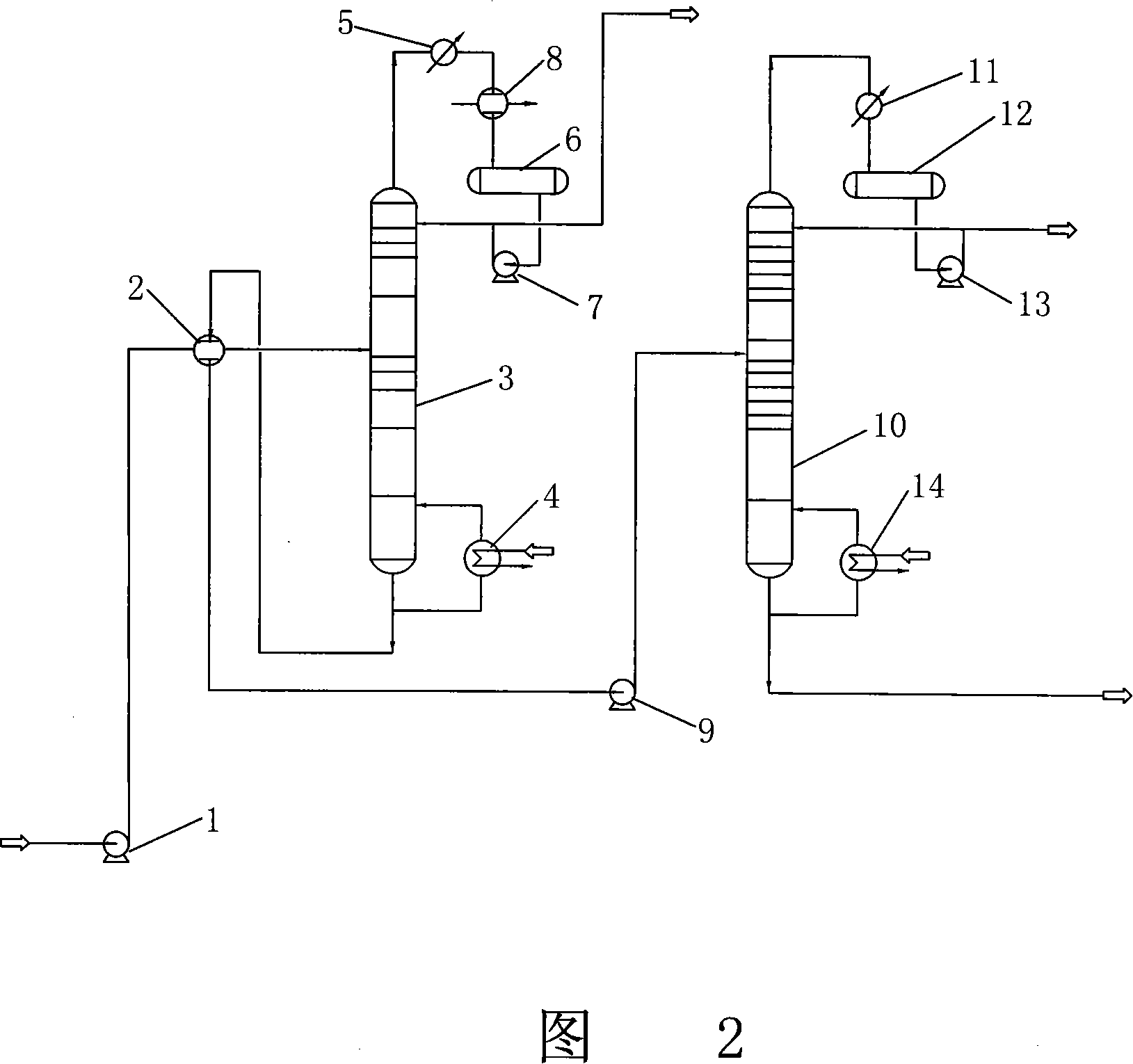

[0021] As shown in Figure 1, the sewage containing methanol and dimethyl ether is pressurized by sewage pump 1, and then enters dimethyl ether after heat exchange with methanol-containing water from the bottom of dimethyl ether stripping tower 3 through heat exchanger 2 Stripping tower 3, dimethyl ether stripping tower 3 overhead produces gaseous mixtures such as dimethyl ether, enters reflux tank 6 after being cooled by cooler 5, and the liquid phase flow in reflux tank 6, after reflux pump 7 boosts, Return to the top of the dimethyl ether stripping tower 3 as reflux, and the dimethyl ether vapor phase stream in the reflux tank 6 is condensed into a liquid phase as a dimethyl ether product through a condenser 8, and the dimethyl ether product can be used as methanol to produce low-carbon The raw materials of olefins are returned to the reaction part of the MTO unit, and can also be sent out of the unit for other purposes. Methanol-containing water is discharged from the 3 bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com