Circulating blow-down water treatment system and treatment process

A technology of circulating sewage and treatment process, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Yield and recovery rate, ensure normal stability, and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

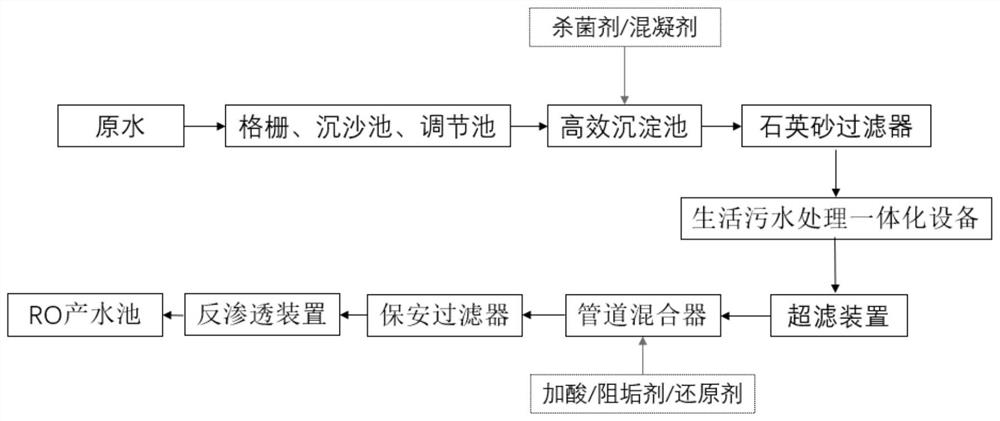

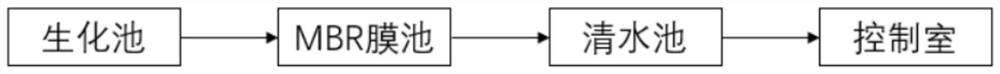

[0050] A circulating sewage treatment system, including sequentially connected grilles, grit chambers, raw water adjustment tanks, high-efficiency sedimentation tanks, intermediate pools, quartz sand filters, integrated domestic sewage treatment equipment, filtered pools, and self-cleaning filters , ultrafiltration device, pipeline mixer, security filter, RO high-pressure pump, reverse osmosis equipment, reverse osmosis production tank, and the pipeline mixer is also connected with the dosing equipment.

[0051] The treatment process using the above-mentioned circulating sewage treatment system includes the following procedures:

[0052] (1) Water intake process: The raw water enters the grid and the lifting pump station through gravity flow, and enters the grit chamber through the pump lifting method, where the coarse and heavy sand is precipitated and removed, and the effluent enters the raw water adjustment tank for homogenization.

[0053] (2) Sewage treatment process: the...

Embodiment 2

[0065] A circulating sewage treatment process, similar to Example 1, the difference is that in the step (1), when the water body passes through the grit chamber in the water inlet process, the flow rate is 0.1m / s, and the residence time is 40s.

Embodiment 3

[0067] A circulating sewage treatment process, similar to Example 1, the difference is that in the step (1), when the water body passes through the grit chamber in the water inlet process, the flow rate is 0.2m / s, and the residence time is 50s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com