ABS sewage treating method

A sewage and mechanical stirring technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as sewage ABS sewage treatment methods that are not specified, and improve reliability Biochemical properties, simple process, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

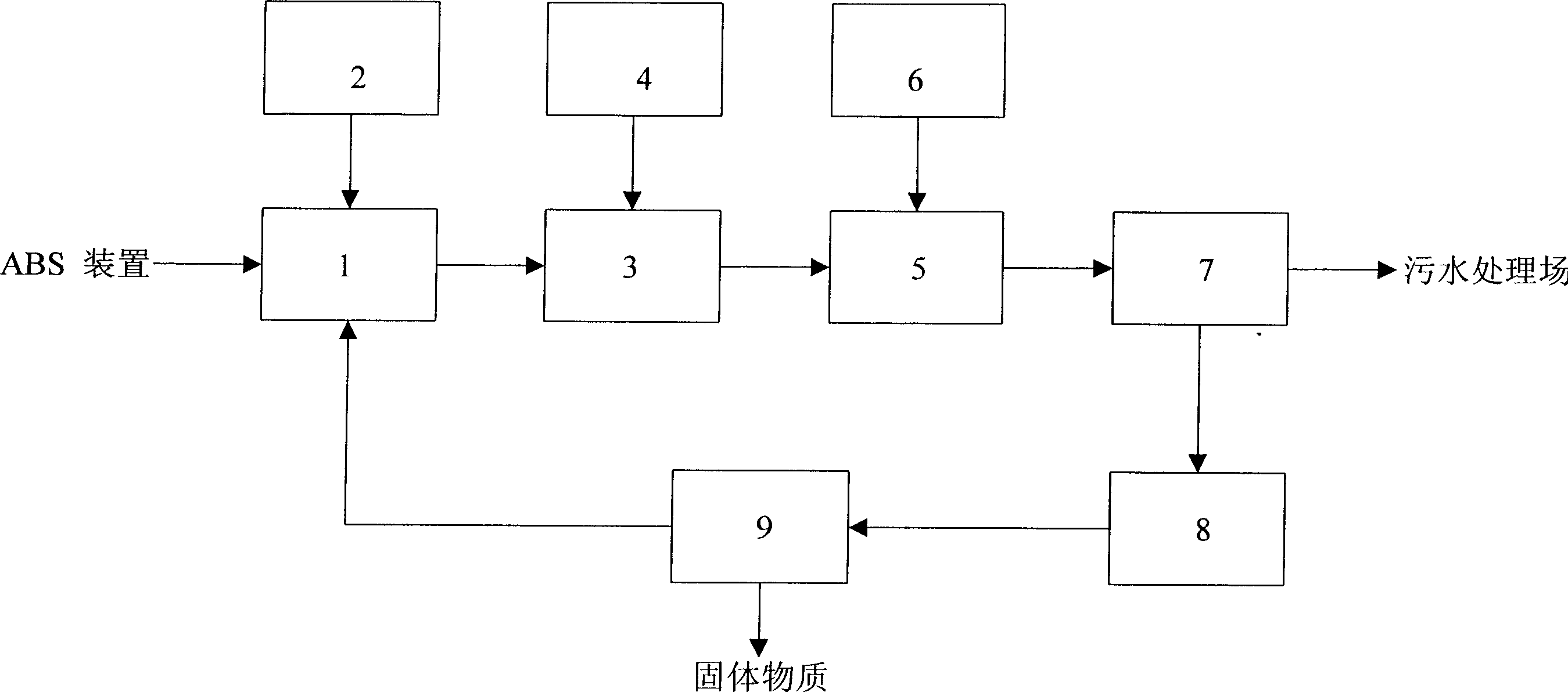

Method used

Image

Examples

Embodiment 1

[0024] Get 6L of ABS sewage, adjust the pH value of ABS sewage to 6.8 by sulfuric acid, the addition of basic polyaluminum chloride is 15ml (4%), the stirring speed is 260r / min, and the addition of polyacrylamide is 1.9ml ( 1%), the stirring speed is 80r / min, and the clarification and separation time is 40 minutes. The whole process is carried out at a temperature of about 32°C and normal pressure. The SS content before and after sewage treatment and the SS removal rate after treatment are shown in Table 1.

Embodiment 2

[0026] Take 6.5L of ABS sewage, adjust the pH value of ABS sewage from 9.2 to 7.1 with hydrochloric acid, the addition of basic polyaluminum chloride is 14ml (4%), the stirring speed is 280r / min, and the addition of polyacrylamide is 1.7ml (1%), the stirring speed is 100r / min, and the clarification and separation time is 1 hour, and the treatment process is carried out at a temperature of about 28°C under normal pressure. The SS content and SS removal rate after treatment of ABS sewage before and after treatment are shown in Table 1.

Embodiment 3

[0028] Get 6L of ABS sewage, adjust the pH value of ABS sewage from 8.4 to 7.6 with nitric acid, the addition of basic polyaluminum chloride is 24ml (2.4%), the stirring speed is 270r / min, and the addition of polyacrylamide is 1.5ml ( 1%), the stirring speed is 90r / min, the clarification and separation time is 1.5 hours, and the treatment process is carried out at a temperature of about 30°C under normal pressure. The SS content and SS removal rate after treatment of ABS sewage before and after treatment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com