Recycling method for butylene oxidative dehydrogenation wastewater

A technology of oxidative dehydrogenation and butene, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as equipment corrosion, equipment blockage, and excessive waste water, and achieve reduced water consumption, reduced waste water discharge, and better The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

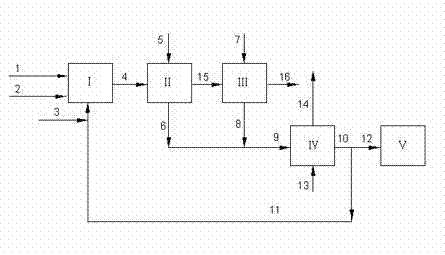

[0033] A 100,000 tons / year butene oxidative dehydrogenation production butadiene plant adopts figure 1 Advanced technology, the total amount of raw material butene is 18,000 kg / h, the total amount of air is 32,000 kg / h, the total amount of water vapor is 29,000 kg / h, the flow rate of the cooled butene oxidative dehydrogenation product is 79,000 kg / h, and the temperature is 90°C , pressure 0.15MPa, see Table 1 for the composition, wherein the total amount of oxygenated compounds is 1200ppm, the butene oxidative dehydrogenation reaction gas enters the water cooling tower tower kettle, and the tower top is passed into industrial circulating water with a temperature of 32 ° C, and the circulating water consumption is 10 tons / hour, the water-cooling tower is a plate tower with 8 plates, and the tower kettle is water-cooled wastewater. The gas temperature at the top of the tower is 35°C and pressurized to 1.0 MPa before entering the aldehyde washing tower. The aldehyde washing tower ...

Embodiment 2

[0038] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant adopts figure 1 Advanced technology, the total amount of raw material butene is 18,000 kg / h, the total amount of air is 32,000 kg / h, the total amount of water vapor is 29,000 kg / h, the flow rate of the cooled butene oxidative dehydrogenation product is 79,000 kg / h, and the temperature is 90°C , the pressure is 0.15MPa, the composition is shown in Table 1, wherein the total amount of oxygenated compounds is 1200ppm, the butene oxidative dehydrogenation reaction gas enters the water-cooled tower reactor, and the low-temperature desalted water with a temperature of 5°C is passed into the top of the tower, and the amount of low-temperature desalted water 5 tons / hour, the water cooling tower is a plate tower with 8 plates, the tower kettle is water-cooled waste water, the gas temperature at the top of the tower is 35°C and pressurized to 1.0 MPa, and then enters the aldehyde washing tower, which is a plat...

Embodiment 3

[0042] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant adopts figure 1 Advanced technology, the total amount of raw material butene is 18,000 kg / h, the total amount of air is 32,000 kg / h, the total amount of water vapor is 29,000 kg / h, the flow rate of the cooled butene oxidative dehydrogenation product is 79,000 kg / h, and the temperature is 90°C , the pressure is 0.15MPa, the composition is shown in Table 1, wherein the total amount of oxygenated compounds is 1200ppm, the butene oxidative dehydrogenation reaction gas enters the water-cooled tower reactor, and the low-temperature desalted water with a temperature of 5°C is passed into the top of the tower, and the amount of low-temperature desalted water 5 tons / hour, the water-cooling tower is a plate tower with 8 plates, and the tower kettle is water-cooled wastewater. The gas temperature at the top of the tower is 35°C and pressurized to 1.5 MPa before entering the aldehyde washing tower. The aldehyde ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com