Comprehensive treatment method of liquid hydrocarbon alkali residue waste liquid

A technology for comprehensive treatment of alkali slag waste liquid, applied to chemical instruments and methods, sulfur compounds, refined hydrocarbon oil, etc., to achieve mild operating conditions, good economic benefits, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

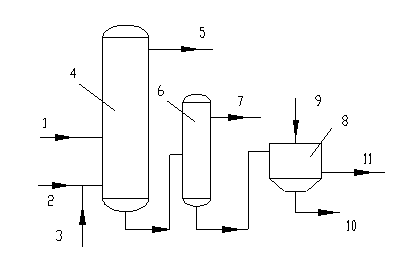

Method used

Image

Examples

Embodiment 1

[0031] A certain enterprise alkali washing liquid hydrocarbon alkali slag waste liquid, in which COD is 1.27×10 5 mg / L, the sulfide is 1.08×10 4 mg / L, volatile phenol 1.99×10 4 mg / L. Use the method of the present invention to process, at first with N 2 As a carrier gas, carrying SO 2 Acidification of alkali slag waste liquid, N 2 / SO 2 =100 (molar ratio), until the pH of the alkali slag waste liquid drops to 3-4. The desulfurization adsorbent is used to absorb the organic sulfide in the tail gas and then sent to the Claus plant in the sulfur plant to make sulfur. The desulfurizer can be recycled and used through regeneration. After acidifying the water phase, let it stand to recover the phenol in the water layer. After acidification treatment, more than 99.5% of sulfides are removed, more than 80% of phenols are removed, and COD is reduced by more than 60%.

[0032] Use Ca(OH) 2 Precipitate and regenerate the acidic water after recovering phenol to produce calcium sul...

Embodiment 2

[0035] Liquid hydrocarbon alkali slag waste liquid of an enterprise, in which COD is 1.25×10 5 mg / L, sulfide is 1.78×10 4 mg / L, volatile phenol 7.17×104 mg / L. Use the method of the present invention to process, at first with N 2 As a carrier gas, carrying SO 2 Acidification of alkali slag waste liquid, N 2 / SO 2 =50 (molar ratio), until the pH of the alkali slag waste liquid drops to 3-4. The desulfurization adsorbent is used to absorb the organic sulfide in the tail gas and then sent to the Claus plant in the sulfur plant to make sulfur. The desulfurizer can be recycled and used through regeneration. The aqueous phase after acidification is left to stand to recover the crude phenol in the water layer. After acidification treatment, the removal rate of sulfide in the water phase can reach more than 99.7%, the removal rate of phenol can reach more than 80%, and the COD can be reduced by more than 60%.

[0036] Use Ca(OH) 2 Precipitate and regenerate the acidic water aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com