Oil-containing sludge pyrolysis and its resource treatment method

A technology of oily sludge and recycling, which is applied in the direction of pyrolysis treatment of sludge and vaporization of by-products, etc., can solve the problem of difficult wastewater separation, and achieve the effect of low one-time investment and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

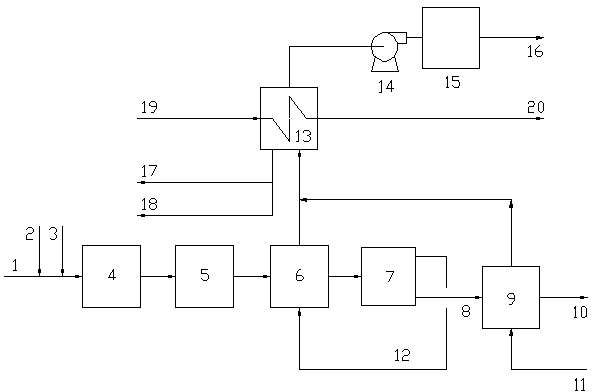

Image

Examples

Embodiment 1

[0042] The oil content of oily sludge in the sedimentation tank of an oil field is 30%, the water content is 15%, and the solid content is 55%.

[0043] Main operating conditions: oily sludge, coal gangue powder and Fe 3 O 4 The mass ratio is 1:0.2:0.06; the operating pressure of the granulator is 6.0MPa, and columnar granules with a diameter of 2mm and a length of 5mm are obtained. After the oily sludge particles are pre-dried, the moisture content is 2%; the pre-dried oily sludge particles enter the pyrolysis device, using nitrogen as the protective gas, gradually heating to 600 ℃, and keeping at this temperature for 40 minutes. The activation temperature of pyrolysis sludge is 500℃, and water vapor is used as the activation medium. The temperature of the high-temperature oil and gas discharged from the pre-dryer is 110°C, and the temperature of the oil and gas after being cooled by circulating water is 45°C. The oil and gas post-processing device is a condensing device, and th...

Embodiment 2

[0047] The oil content of the bottom mud of an oil tank is 50%, the water content is 5%, and the solid content is 45%.

[0048] Main operating conditions: oily sludge, coal gangue powder and Fe 3 O 4 The mass ratio is 1:0.5:0.06; KOH is added as activator at the same time, and the addition amount is 0.05%. The granulator has an operating pressure of 7.0 MPa to obtain columnar granules with a diameter of 2 mm and a length of 5 mm. After the oily sludge particles are pre-dried, the moisture content is 0.5%. The pre-dried oily sludge particles enter the pyrolysis unit, using nitrogen as the protective gas, gradually heating to 500°C, and keeping it at this temperature for 70 minutes. The temperature of the high-temperature oil and gas discharged from the pre-dryer is 100°C, and the temperature of the oil and gas after being cooled by circulating water is 45°C. The oil and gas post-processing device is a condensing device, and the condensation temperature of the oil and gas is -30°C...

Embodiment 3

[0052] The oil content of the bottom mud of an oil tank is 50%, the water content is 5%, and the solid content is 45%.

[0053] Main operating conditions: oily sludge, coal powder and Fe 3 O 4 The mass ratio is 1:0.3:0.06. The granulator has an operating pressure of 7.0 MPa to obtain columnar granules with a diameter of 2 mm and a length of 5 mm. After the oily sludge particles are pre-dried, the moisture content is 0.5%. The pre-dried oily sludge particles enter the pyrolysis unit, using nitrogen as the protective gas, gradually heating to 600°C, and keeping it at this temperature for 40 minutes. The activation temperature of pyrolysis sludge is 500℃, and water vapor is used as the activation medium. The temperature of the high-temperature oil and gas discharged from the pre-dryer is 110°C, and the temperature of the oil and gas after being cooled by circulating water is 50°C. The oil and gas post-processing device is a condensing device, and the condensation temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com