Sewage treatment process capable of recovering low-carbon hydrocarbons and low-carbon oxygen-containing organic matters

A low-carbon hydrocarbon and organic matter technology, which is applied in the field of sewage treatment process for the recovery of low-carbon hydrocarbons and low-carbon oxygen-containing organic matter, and can solve the problem that low-carbon oxygen-containing organic matter cannot be recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

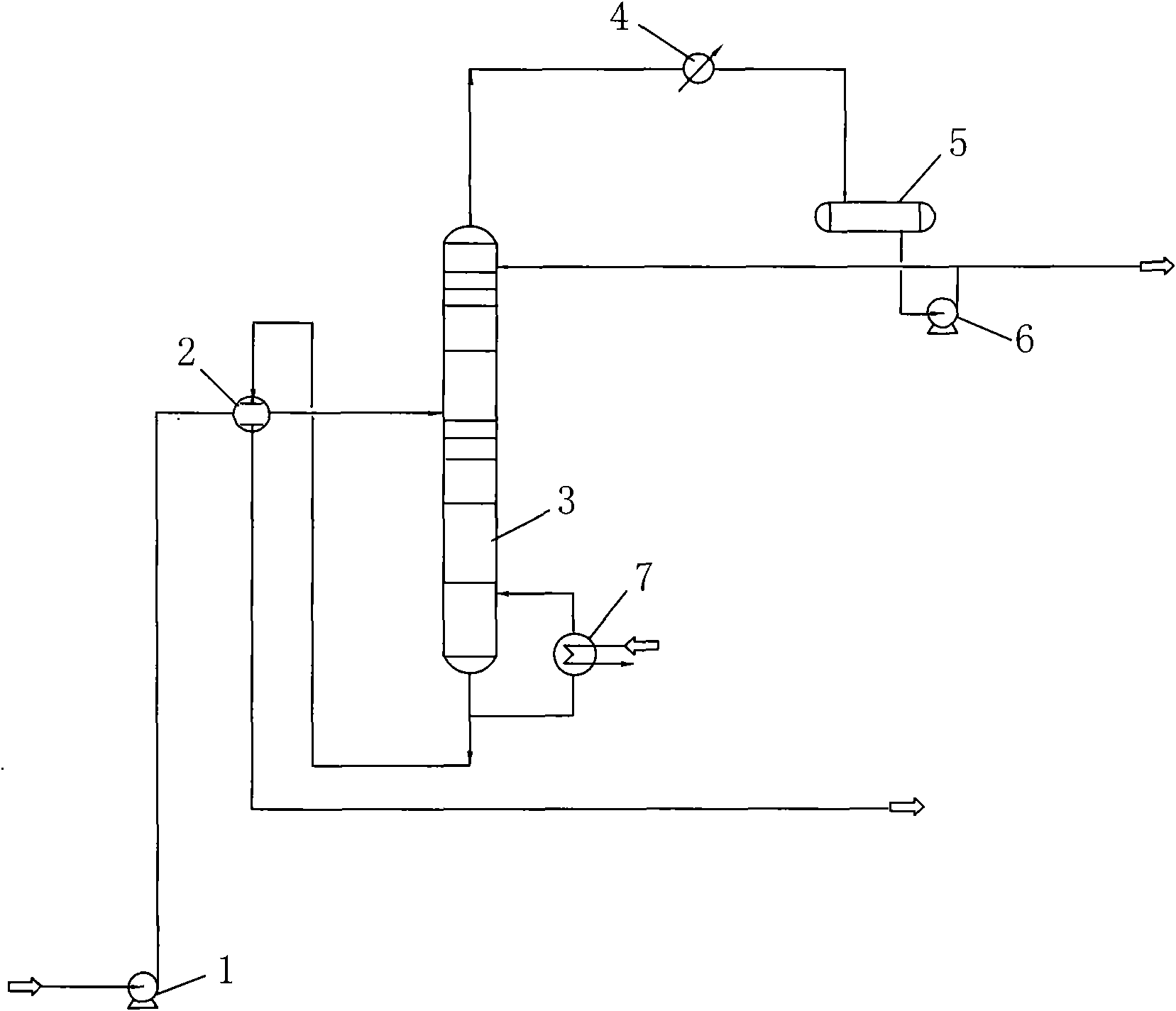

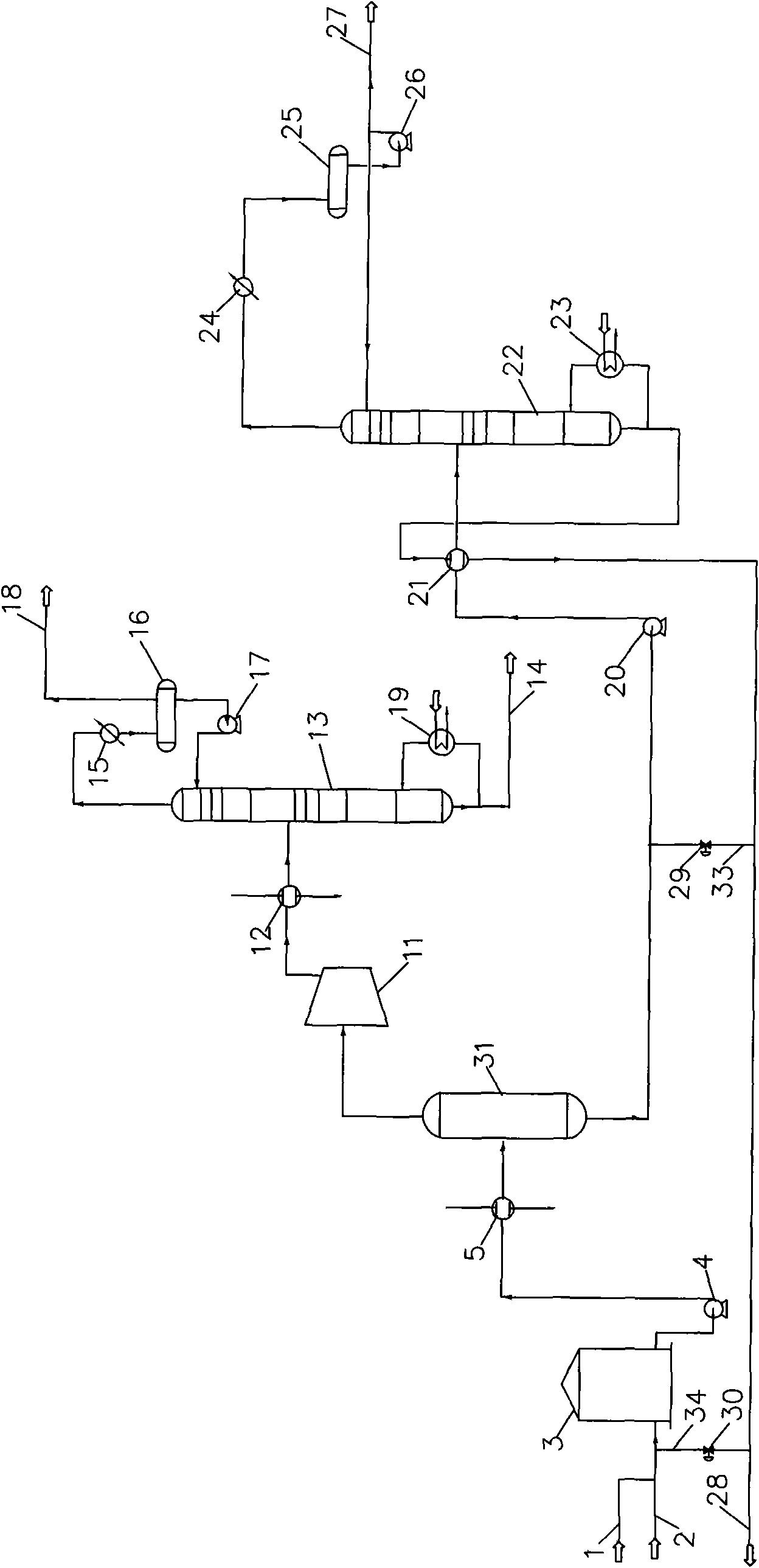

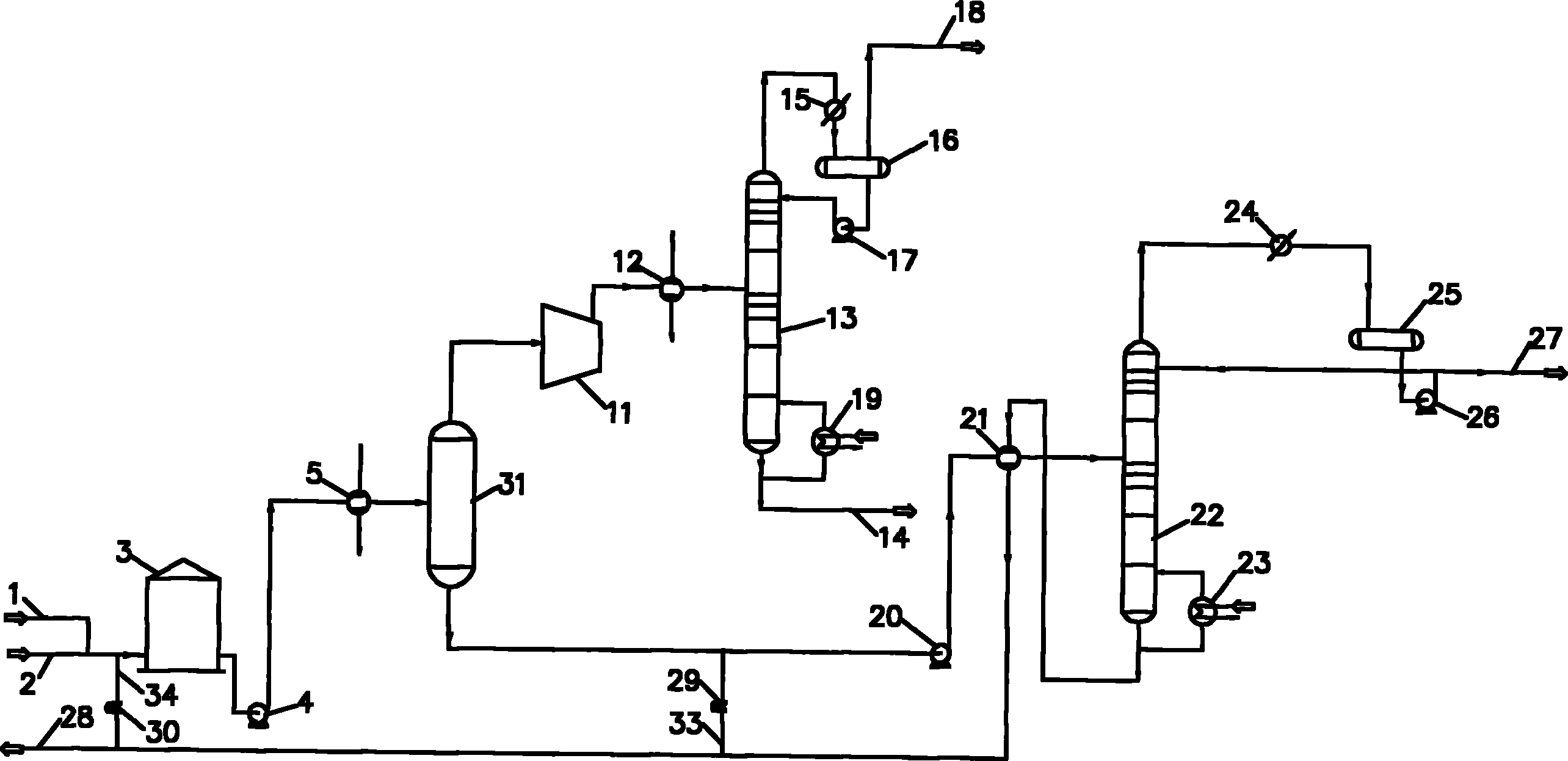

[0036] Such as figure 2 As shown, the sewage from the MTO unit and the olefin separation unit enters the raw material water tank 3 through the sewage pipeline 1 of the MTO unit and the sewage pipeline 2 of the olefin separation unit respectively. Low-carbon hydrocarbons and low-carbon oxygen-containing organic substances containing methanol, dimethyl ether, acetone and acetaldehyde, etc., and the total weight content of low-carbon hydrocarbons and low-carbon oxygen-containing organic substances is not more than 50%. The sewage pump 4 conveys and exchanges heat with the heat exchanger 5 and then enters the flash separation tank 31 . The operating temperature of the flash separation tank 31 is 5-100°C, and the operating pressure is 0.05-0.6Mpa. The gas mixture containing ethylene, propylene, a small amount of water and low-carbon oxygen-containing organic matter produced in the upper part of the flash separation tank 31 enters the deoxidation tower 13 after being pressurized b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com