Comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid

A technology for comprehensive treatment of alkali slag waste liquid, applied in sulfur compounds, chemical instruments and methods, sulfur preparation/purification, etc., to achieve the effects of low equipment investment and operating costs, good economic benefits, and low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

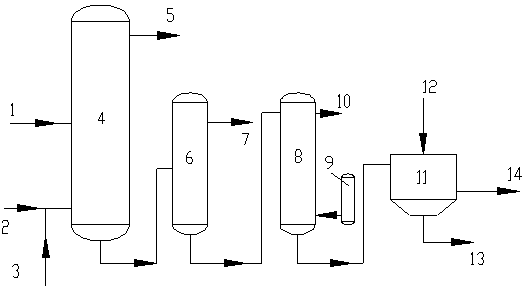

Embodiment 1

[0032] Catalytic gasoline alkali slag waste liquid in an oil refinery, in which COD is 2.83×10 5 mg / L, the sulfide is 1.68×10 4 mg / L, volatile phenol 7.19×10 4 mg / L. Use the method of the present invention to process, first use N 2 and SO 2 The mixed gas acidifies the alkali slag waste liquid, N 2 / SO 2=30 (molar ratio), until the pH of the alkali slag waste liquid drops to 3-4. The acidified tail gas is condensed to recover organic sulfides and then sent to the sulfur workshop Claus plant for sulfur production. The organic sulfides recovered by condensation are mainly methyl mercaptan and ethanethiol and a small amount of dimethyl disulfide. The water phase after acidification and dephenolization is subjected to 10-stage cross-flow extraction with crude kerosene, the ratio of extractant to waste liquid is 1:3, and the waste extractant is returned to the kerosene hydrotreating unit. The alkali residue waste liquid is acidified to remove more than 99.7% of sulfides, reco...

Embodiment 2

[0036] A refinery liquid hydrocarbon and gasoline mixed alkali residue waste liquid, in which COD is 1.65×10 5 mg / L, sulfide is 1.38×10 4 mg / L, volatile phenol 4.17×10 4 mg / L. Use the method of the present invention to process, first use N 2 and SO 2 The mixed gas acidifies the alkali slag waste liquid, N 2 / SO 2 =50 (molar ratio), until the pH of the alkali slag waste liquid drops to 3-4. After the acidification tail gas is condensed to recover organic sulfides, it is sent to the Claus plant in the sulfur workshop to produce sulfur. The organic sulfides recovered by condensation are mainly methyl mercaptan and ethyl mercaptan. The acidified aqueous phase was left to stand to recover crude phenol. Then use straight-run diesel to perform 10-stage cross-flow extraction on the dephenolized wastewater, the ratio of extractant to waste liquid is 1:5, and the waste extractant is returned to the diesel hydrotreating unit. The alkali residue waste liquid is acidified, the sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com