Alkaline residue processing method

A treatment method, technology of alkali residue, applied in the direction of separation method, sustainable biological treatment, chemical instruments and methods, etc., can solve the problem of increasing the treatment load impact of the oily sewage treatment system, large one-time investment and operation costs, and one-time investment and high operating costs, to achieve the effect of low cost, easy operation and management, safe and reliable operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

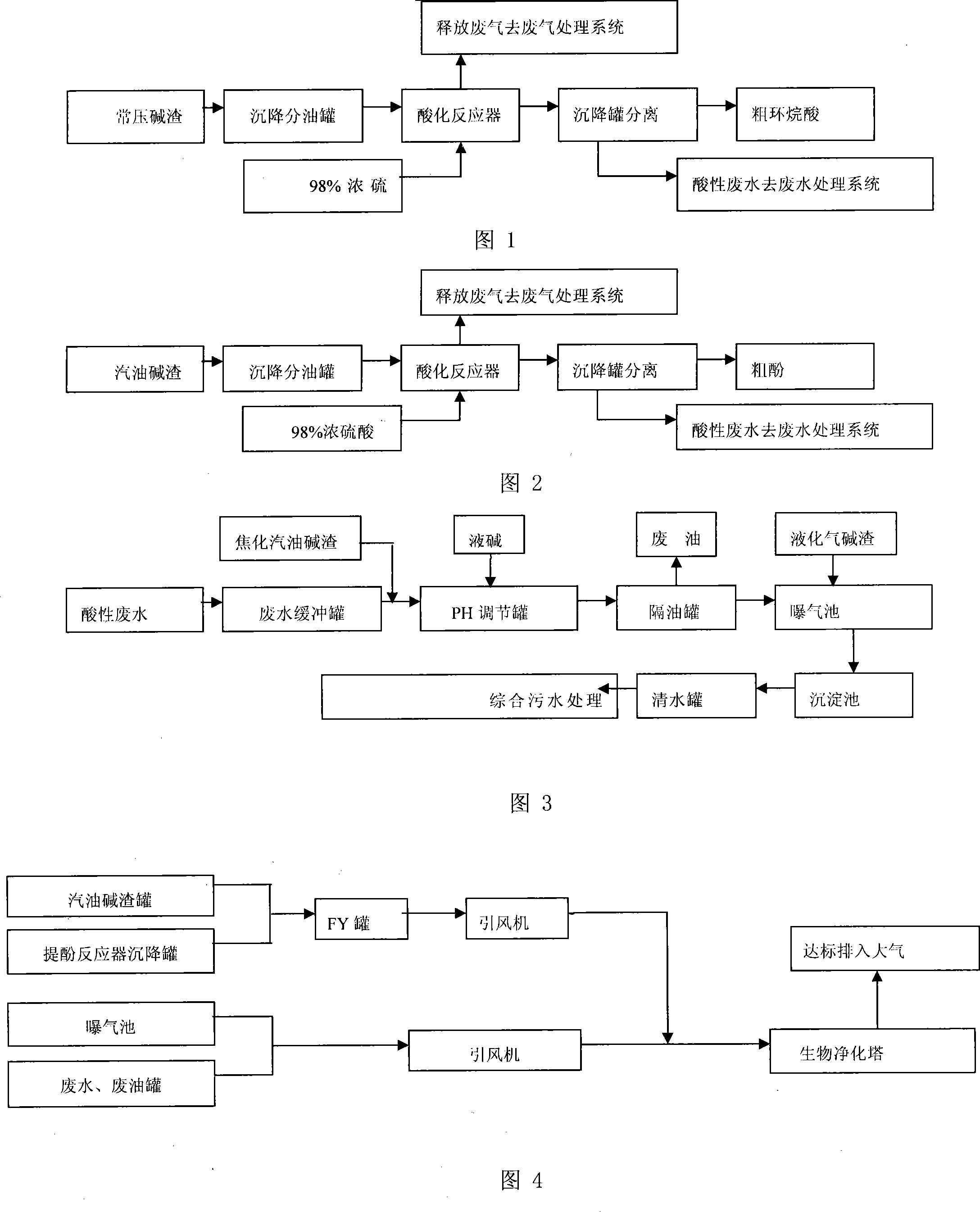

[0023] A method for treating alkali slag of the present invention will be described in detail with reference to the accompanying drawings and examples.

[0024] A kind of alkali slag processing method of the present invention, this method comprises the following steps:

[0025] ①. Alkali slag pretreatment system

[0026] a. Diesel alkali slag pretreatment, as shown in Figure 1.

[0027] Diesel soda slag comes from a combined workshop into the diesel soda slag sedimentation oil separation tank. After settling and oil separation, it is pressurized by a pump and mixed with 98% concentrated sulfuric acid from the concentrated sulfuric acid tank into the static mixer, and fully mixed in the static mixer. After the acid-base reaction, it enters the acidification reactor. In the tank, the naphthenic acid and the acidic wastewater settle and stratify to form an interface. The naphthenic acid enters the crude naphthenic acid storage tank from the upper overflow port, and the crude nap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com