Method for recovering organic matters in wastewater generated in process for preparing olefin from methanol

A methanol-to-olefins and wastewater recovery technology, applied in chemical instruments and methods, natural water treatment, water/sewage treatment, etc., can solve the problems of low recovery efficiency and high energy consumption, and achieve the reduction of recycled resources, simple operation, and compact equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

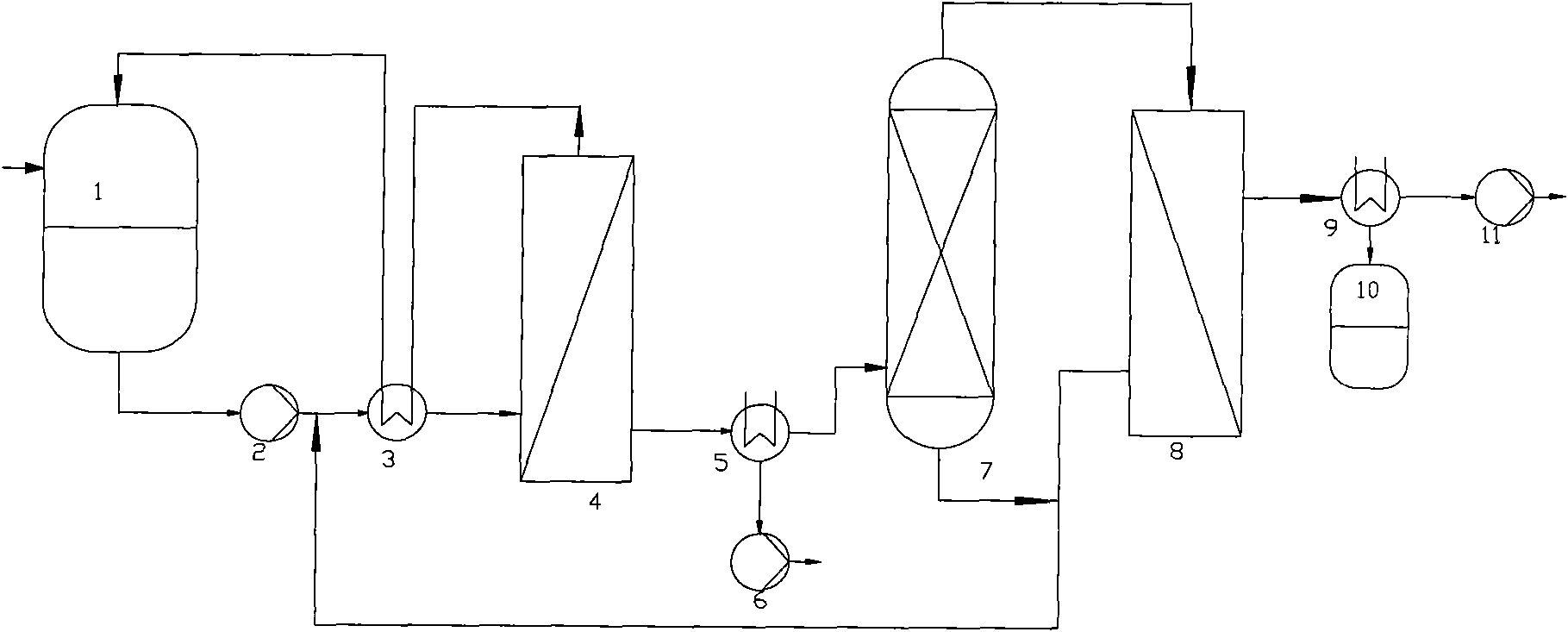

[0031] A kind of MTO process waste water, the main component of waste water: 95wt% water, methanol (35000mg L -1 ), acetone (1050mg·L -1 ), ethanol (345mg·L -1 ), acetaldehyde (224mg·L -1 ), 2-butanone (332mg·L -1 ), the pH value is 6.61, the conductivity is 150μS / cm, and the COD is 25000mg·L -1 . Processing flow such as figure 1 shown.

[0032] In the figure, 1. Feed liquid tank, 2. Feed pump, 3. Heat exchanger, 4. Pervaporation membrane module that preferentially permeates organic matter, 5 / 9. Condenser, 6 / 11. Vacuum pump, 7. Stripper , 8. Pervaporation membrane modules with preferential water permeability, 10. Product tank.

[0033] Send the MTO process wastewater through 2 into 3 to preheat to 40°C; the preheated MTO wastewater into 4, the feed pressure is 0.01MPa, the membrane surface flow rate is 0.01m / s, and the membrane material is cross-linked PDMS / PVDF membrane. Vacuum the permeate side of the membrane module, control the pressure on the permeate side at 5KPa...

Embodiment 2

[0035] A kind of MTO process reaction waste water, the main component of waste water: 95wt% water, methanol (41130mg L -1 ), acetone (2520mg·L -1 ), ethanol (200mg·L -1 ), acetaldehyde (20mg·L -1 ), 2-butanone (20mg·L -1 ) pH value is 5.60, conductivity is 241μS / cm, COD is 36980mg L -1 . Processing flow such as figure 1 shown.

[0036] Send the MTO process wastewater through 2 into 3 to preheat to 50°C; the preheated MTO wastewater into 4, the feed pressure is 0.02MPa, the membrane surface flow rate is 0.5m / s, and the membrane material is cross-linked PDMS / PVDF membrane. Vacuum the permeate side of the membrane module, control the permeate side pressure at 2KPa, and the membrane flux is 1250g m -2 h -1 The permeate is cooled by 5, the temperature of the condenser is controlled at -20°C, and then separated by the gas-liquid separator. The total organic content of the collected permeate is 30wt%, and the organic content in the water from which the organic matter has been...

Embodiment 3

[0038] A kind of MTO process reaction waste water, the main component of waste water: 95wt% water, methanol (40500mg L -1 ), acetone (1175mg·L -1 ), ethanol (493mg·L -1 ), acetaldehyde (20mg·L -1 ), 2-butanone (488mg·L -1 ) pH value is 5.44, conductivity is 199μS / cm, COD is 66350mg L -1 . Processing flow such as figure 1 shown.

[0039] The MTO process wastewater is sent into 3 through 2 to preheat to 70°C; the preheated MTO wastewater enters 4, the feed pressure is 0.05MPa, the membrane surface flow rate is 0.01m / s, and the membrane material is cross-linked PDMS / PVDF membrane. Vacuum the permeate side of the membrane module, control the pressure on the permeate side at 1KPa, and the membrane flux is 2400g m -2 h -1 ;

[0040] The permeate is cooled by 5, the temperature of the condenser is controlled at -10°C, and it is separated by a gas-liquid separator. The total organic content of the collected permeate is 21wt%, and the organic content of the water from which th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com