Method for treating octanol waste lye by miscellaneous alcohol acidization-extraction method

A technology of waste lye and extraction method, which is applied in chemical instruments and methods, extraction water/sewage treatment, water/sewage treatment, etc., and can solve problems such as high investment and operating costs, large separation equipment, and unfeasible processes , to achieve significant governance effects, low operating costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Most of the circulating lye discharged from the device 1143 chromatograph returns to the condensation system after being pressurized by the pump, and the remaining part is metered by the flow meter and then sent to the acidifying mixer to be mixed with the concentrated sulfuric acid and the extractant from the concentrated sulfuric acid storage tank (inside the device) The by-product shinol) is pumped into an acidification mixer, and the concentrated sulfuric acid, spent lye and shinol are fully mixed through the mixer to complete the acidification extraction process. Mixing time is 3~15min, compared (extractant: waste water) is 1: 1~1:8 (volume ratio), makes the pH value after acidification guarantee between 2.0~4.5, and actual consumption is waste water: concentrated sulfuric acid ( 93%)=40~80:1 (volume ratio). Then the mixed liquid enters the clarification and separation tank, and the residence time of the clarification and separation chamber is 30 to 120 minutes. Af...

Embodiment 2

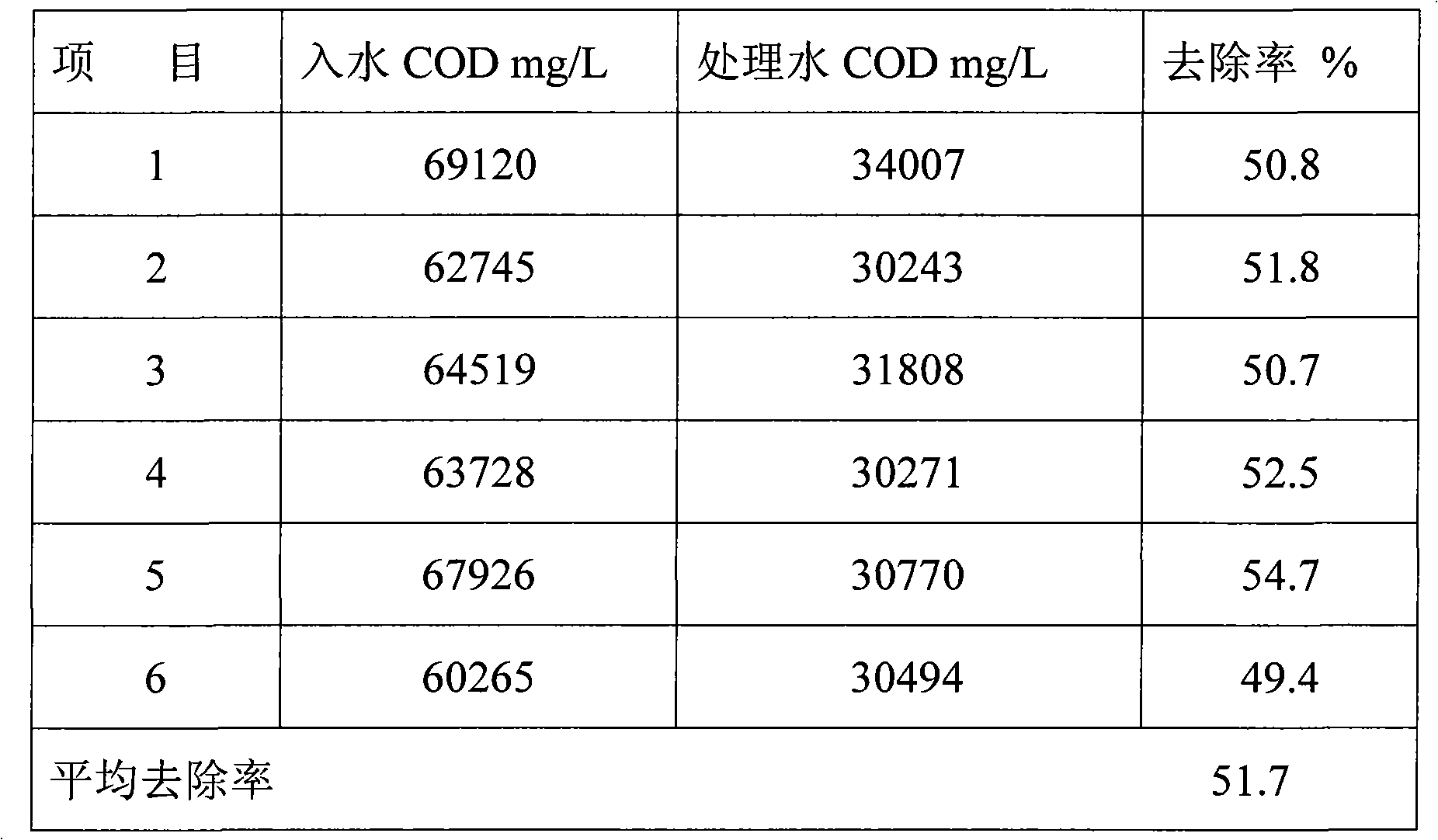

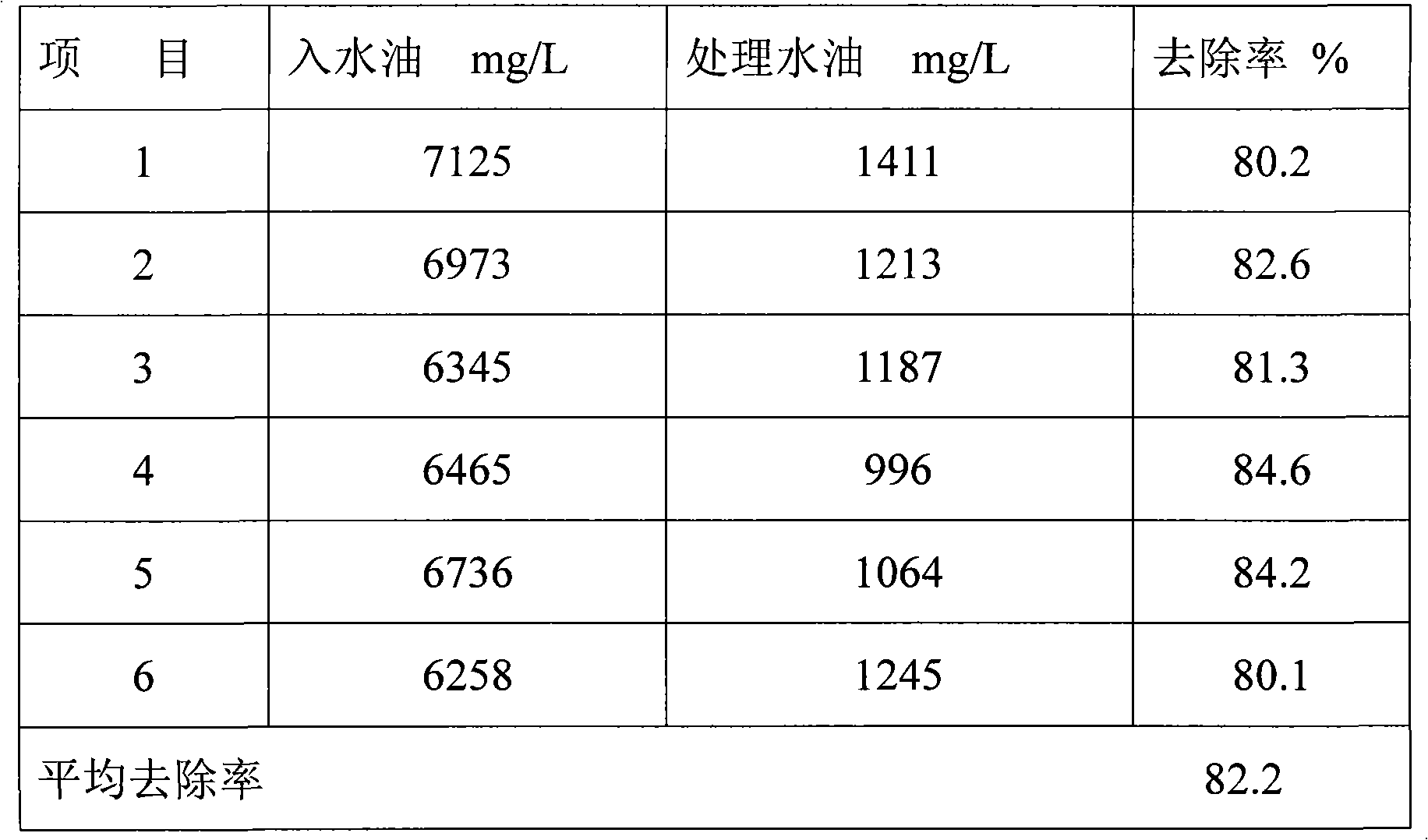

[0017] Technological process is the same as embodiment 1, octanol waste lye (COD value is 5~70,000 mg / L), gets waste caustic slag 600ml, the pH value after acidification is 3.6, is 1: 4 compared to, mixing time is 7min, clarification time is 80min, the COD removal rate of treated wastewater is 50.8%, and the oil removal rate is 80.2%.

Embodiment 3

[0019] Technical process is the same as embodiment 1, octanol spent lye (COD value is 5~70,000 mg / L), gets spent lye 600ml, the pH value after acidification is 2.9, is 1: 3 compared to, mixing time is 10min, clarification time is 60min, the COD removal rate of treated wastewater is 51.8%, and the oil removal rate is 82.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com