High-temperature heavy-oil-stain waste gas treatment system

A waste gas treatment, high-temperature waste gas technology, applied in the direction of gas treatment, air quality improvement, membrane technology, etc., can solve the problems of secondary pollution, limited purification capacity, high use and maintenance costs, etc., to achieve strong practicability, small wind resistance, easy operation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

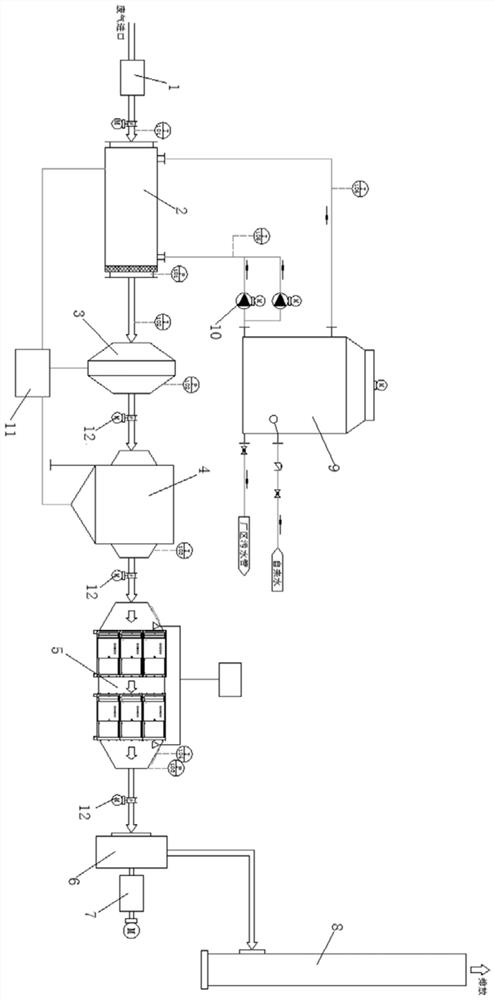

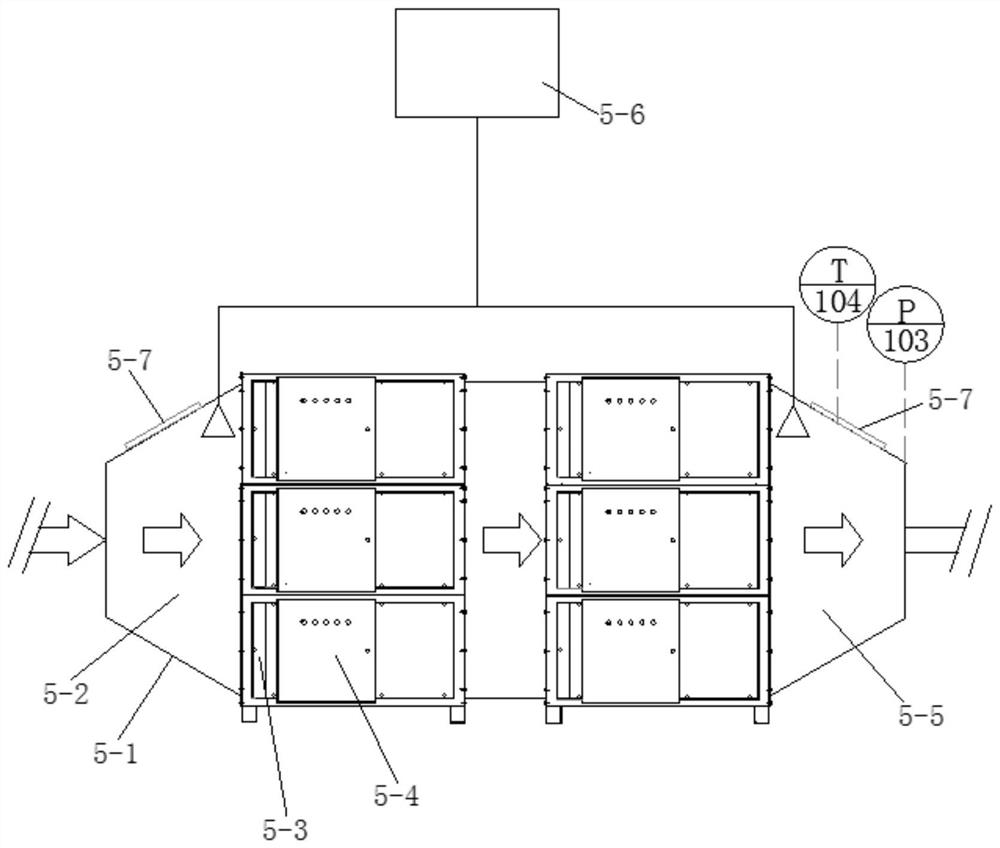

[0045] Such as figure 1 and figure 2 As shown, a high-temperature heavy oil waste gas treatment system includes a waste gas collection unit connected in sequence, a gas-liquid quick cooling unit, a purification unit, a cracking unit and a discharge unit; the waste gas collection unit includes a high-temperature waste gas collection device 1; the gas-liquid quick cooling unit Including condensation device 2; purification unit includes filter device 3 and oil removal device 4; cracking unit includes molecular breaking device 5; discharge unit includes exhaust gas collection device 6, air induction device 7 and exhaust pipe 8; high temperature exhaust gas collection device 1 The air outlet of the condensing device 2 is connected to the air inlet of the condensing device 2, the air outlet of the condensing device 2 is connected to the air inlet of the filter device 3, and the air outlet of the filter device 3 is connected to the air inlet of the degreasing device 4. The gas outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com