Coking wastewater treatment agent and use method thereof

A wastewater treatment agent and coking wastewater technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of large floor space, high treatment cost, and unsatisfactory removal of organic matter, so as to reduce treatment costs and ensure stable operation. , the effect of easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

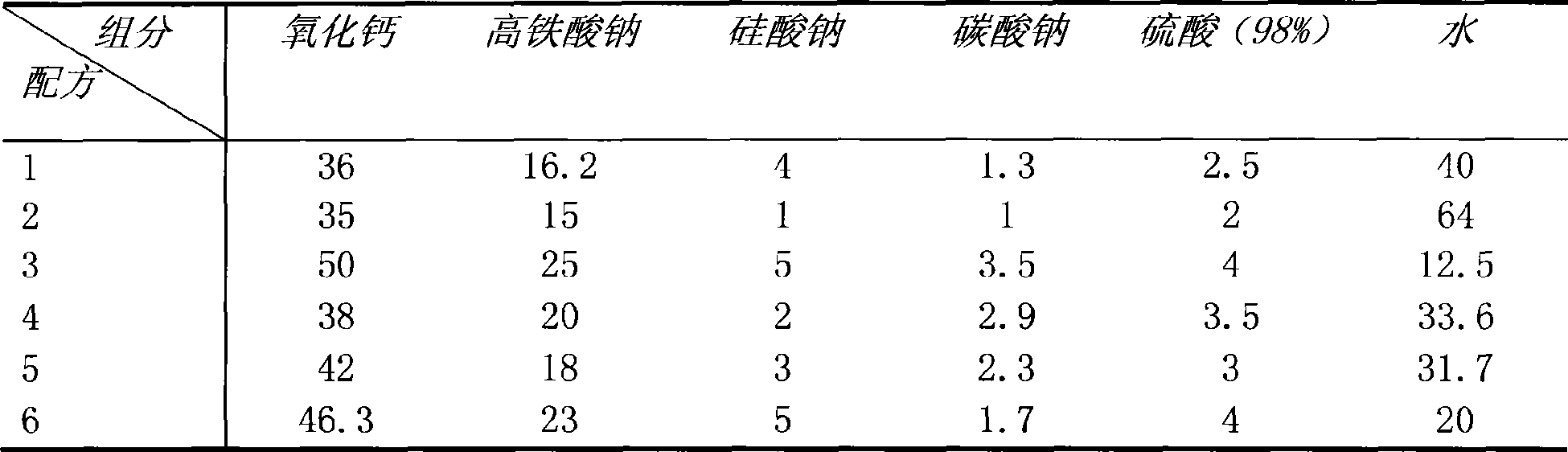

[0020] Preparation example 1 of active transforming agent: according to the data in formula 1 of the above table, get 40 grams of water and put it into the reaction kettle, add 36 grams of calcium oxide, 16.2 grams of sodium ferrate and 2.5 grams of 98% sulfuric acid into the water while stirring. Stir the solution for 30 minutes, slowly add 4 grams of sodium silicate and 1.3 grams of sodium carbonate to the above solution within 10 minutes while stirring, heat the solvent to control the temperature within 60°C to 80°C, keep stirring for 1 hour, then cool to room temperature, and visually inspect the finished product It is a white liquid with a pH value of 6.6.

preparation Embodiment 2

[0021] Example 2 of preparation of active conversion agent: according to formula 2 in the above table, take each component and repeat the step of preparation example 1 of active conversion agent. The finished product is a white liquid with a pH value of 6.8.

preparation Embodiment 3

[0022] Example 3 of preparation of active conversion agent: according to formula 3 in the above table, each component was taken and the steps of Example 1 of preparation of active conversion agent were repeated. The finished product was a white liquid with a pH value of 5.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| escape rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com