System and method for recovering mixed phenol in phenol residual oil

A technology of mixing phenols and recovering phenols, applied in the field of coking, can solve the problems of not meeting the requirements of environmental protection, waste, etc., and achieve the effects of meeting environmental protection, increasing production, and avoiding coking and hanging on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

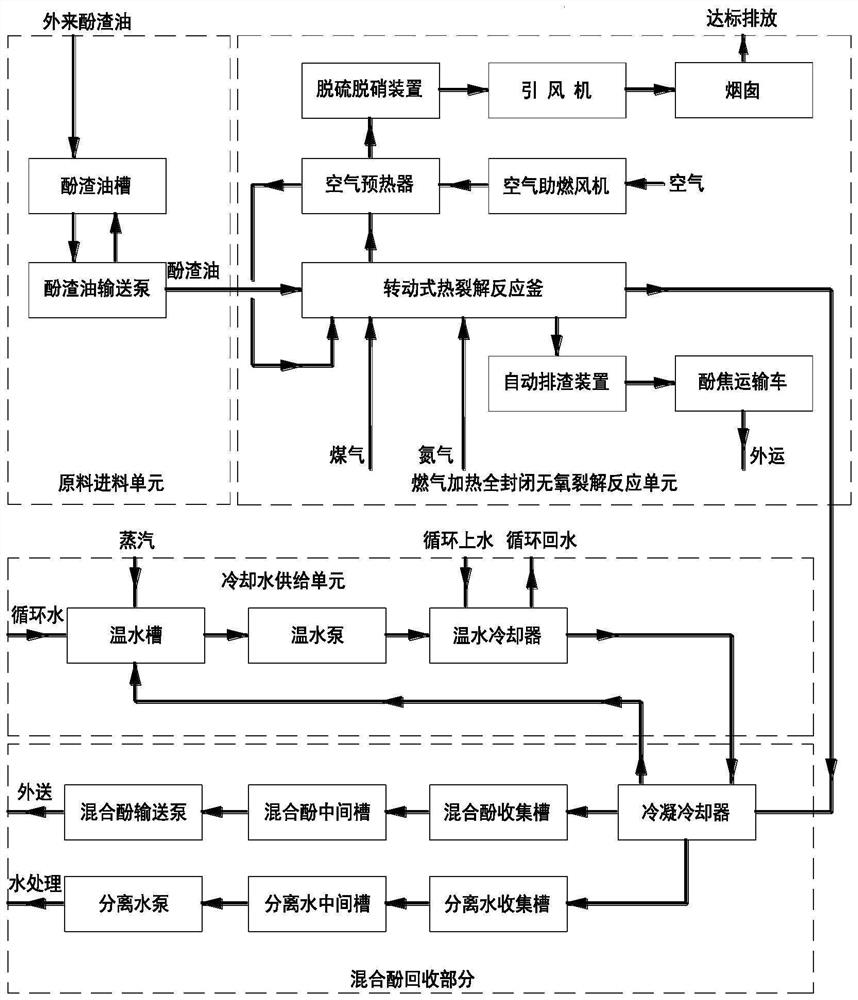

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] A system for recovering mixed phenols in phenol residue oil, comprising a raw material feeding unit, a fully enclosed anaerobic cracking reaction unit heated by gas, a mixed phenol recovery unit, and a cooling water supply unit. The closed anaerobic cracking reaction unit transports raw materials, the gas-heated mixed phenol gas produced by the fully enclosed anaerobic cracking reaction unit passes into the mixed phenol recovery unit, and the cooling water supply unit provides condensed circulating water to the mixed phenol recovery unit.

[0027] The raw material feeding unit includes a phenol residue oil tank and a phenol residue oil delivery pump, the external phenol residue oil is sent into the phenol residue oil tank, the inlet of the phenol residue oil delivery pump is connected to the phenol residue oil tank, and the outlet of the phe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com