A method for surface modification of metal-organic framework adsorption materials

A metal-organic framework and adsorption material technology, applied in the field of ambient air purification, can solve the problems of non-polar organic molecule adsorption performance decline, internal structure damage, etc., achieve high furnace temperature uniformity, prevent fugitive emissions, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] MOFs material: HKUST-1, adsorption gas: methane CH 4 .

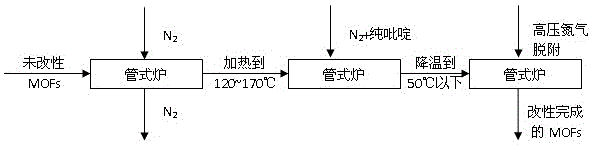

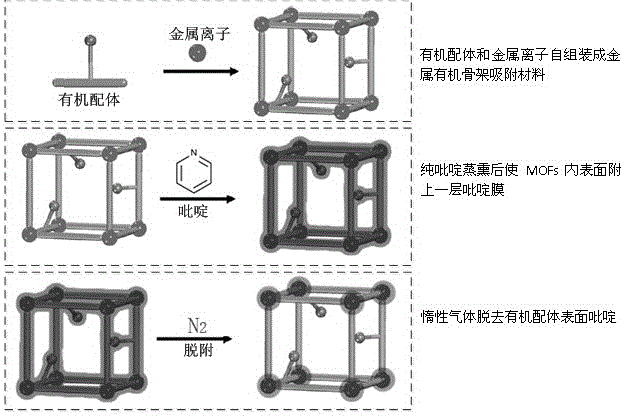

[0023] A certain amount of synthesized HKUST-1 was taken as the MOFs material to be modified and placed in a tube furnace, and N 2 In order to ensure that there is no air residue inside, turn on the electric furnace for heating, so that the temperature in the tube furnace is at 140°C, and 2 A certain amount of pure pyridine was passed into the gas-to-tube furnace, and the constant temperature reaction was maintained at 140°C. The reaction time was 3 hours. The molar ratio of pure pyridine and copper content in MOFs was 1.5:1. 2 The mole percent in gas is 0.1%. After the MOFs reaction tube fumigated by pure pyridine was cooled to below 50 °C, N was introduced into the tube furnace. 2 , to ensure that the N in the tube furnace 2 The air pressure is 0.4MPa, the desorption flow rate is 500mL / min, and the desorption time is 1.5h. After the desorption is completed, the modified MOFs material is obtained and packag...

Embodiment 2

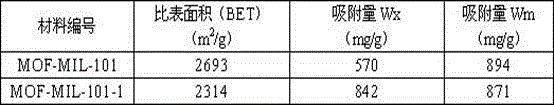

[0029] The improvement of the adsorption performance of modified MOFs materials to benzene under a certain humidity. The material of MOFs is MIL-101.

[0030] A certain amount of synthesized MIL-101 was taken as the MOFs material to be modified and placed in a tube furnace, and N 2 In order to ensure that there is no air residue inside, turn on the electric furnace for heating, so that the temperature in the tube furnace is at 140°C, and 2 A certain amount of pure pyridine was passed into the gas-to-tube furnace, and the constant temperature reaction was maintained at 140 ° C. The reaction time was 3 h. The molar ratio of chromium content in pure pyridine and MOFs was 1.5:1. 2 The molar percentage in gas is 0.5%. After the MOFs reaction tube fumigated by pure pyridine was cooled to below 50 °C, N was introduced into the tube furnace. 2 , to ensure that the N in the tube furnace 2 The air pressure is 0.4MPa, the desorption flow rate is 500mL / min, and the desorption time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com