Coking tail gas treating method and device

A technology of coking tail gas and tail gas blower, which is applied in the direction of chemical instruments and methods, separation methods, gas fuel, etc., can solve the problems of electric tar collector jumping, hidden dangers of tail gas purification, and affecting normal production, so as to avoid frequent parking problems, Solve the effect of excessive oxygen content in gas and avoid fugitive emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

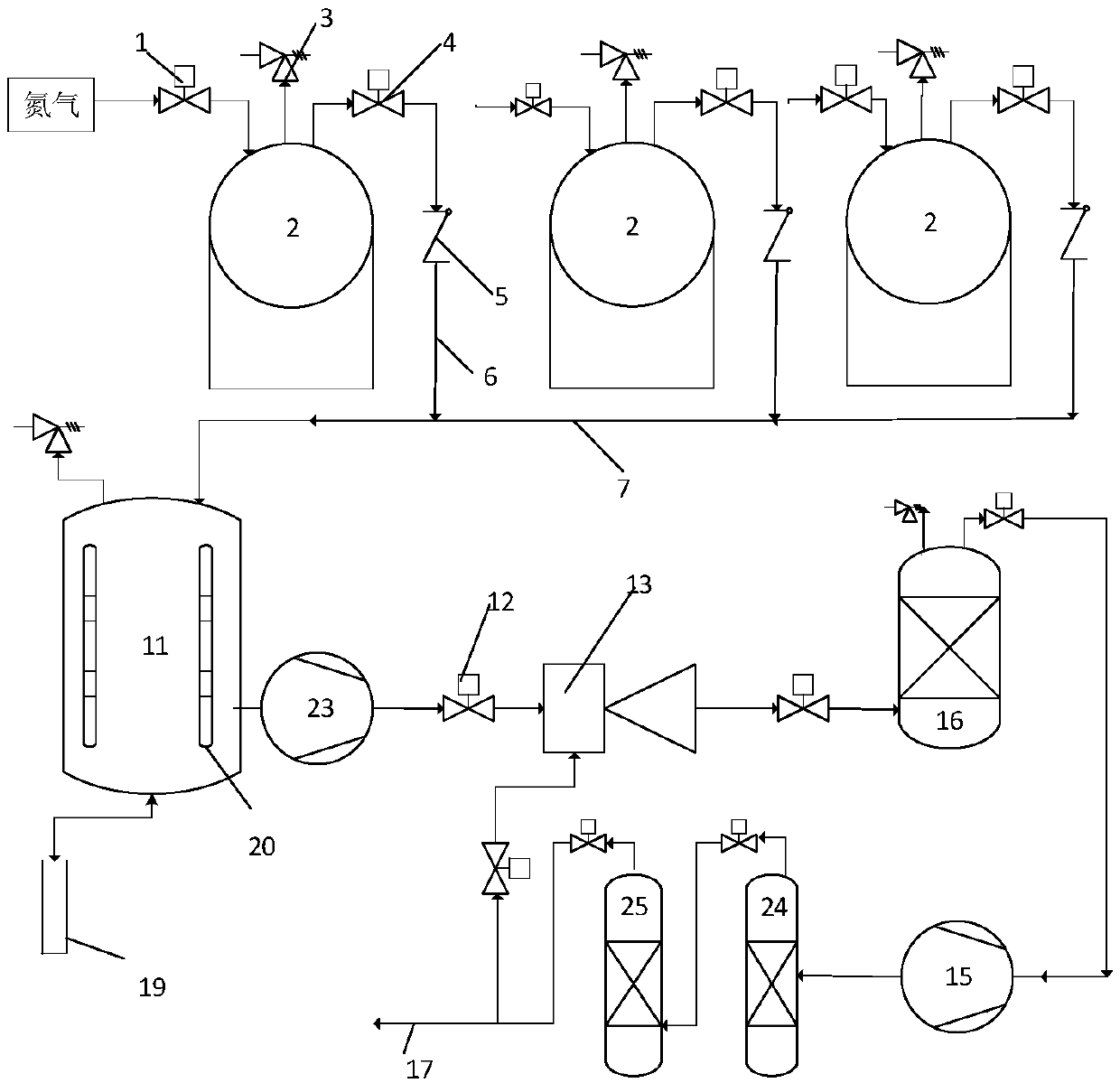

[0028] Embodiment 1: as figure 1 Shown, a kind of coking tail gas treatment method comprises the following steps:

[0029] (1) Seal the storage tank 2 storing the coking tail gas or fill it with nitrogen;

[0030] (2) discharge the coking tail gas of the storage tank 2 into the buffer tank 11 for separating the gas and liquid of the coking tail gas, and cool the preliminary dehydration, naphthalene removal and detarring in the buffer tank 11;

[0031] (3) Adopt tail gas fan 23 to suck the coking tail gas from the buffer tank 11 into the Venturi mixer 13 for removing impurities from the coking tail gas, and feed the hydrogenation gas source into the Venturi mixer 13, and the hydrogenation gas source is connected with the venturi mixer 13 The coking tail gas is fully mixed in the Venturi mixer 13, and the hydrogen content of the hydrogenation gas source is 30% to 60%;

[0032] (4) The gas mixed in the Venturi mixer 13 is discharged into the deoxygenation tank 16 for catalytic ...

Embodiment 2

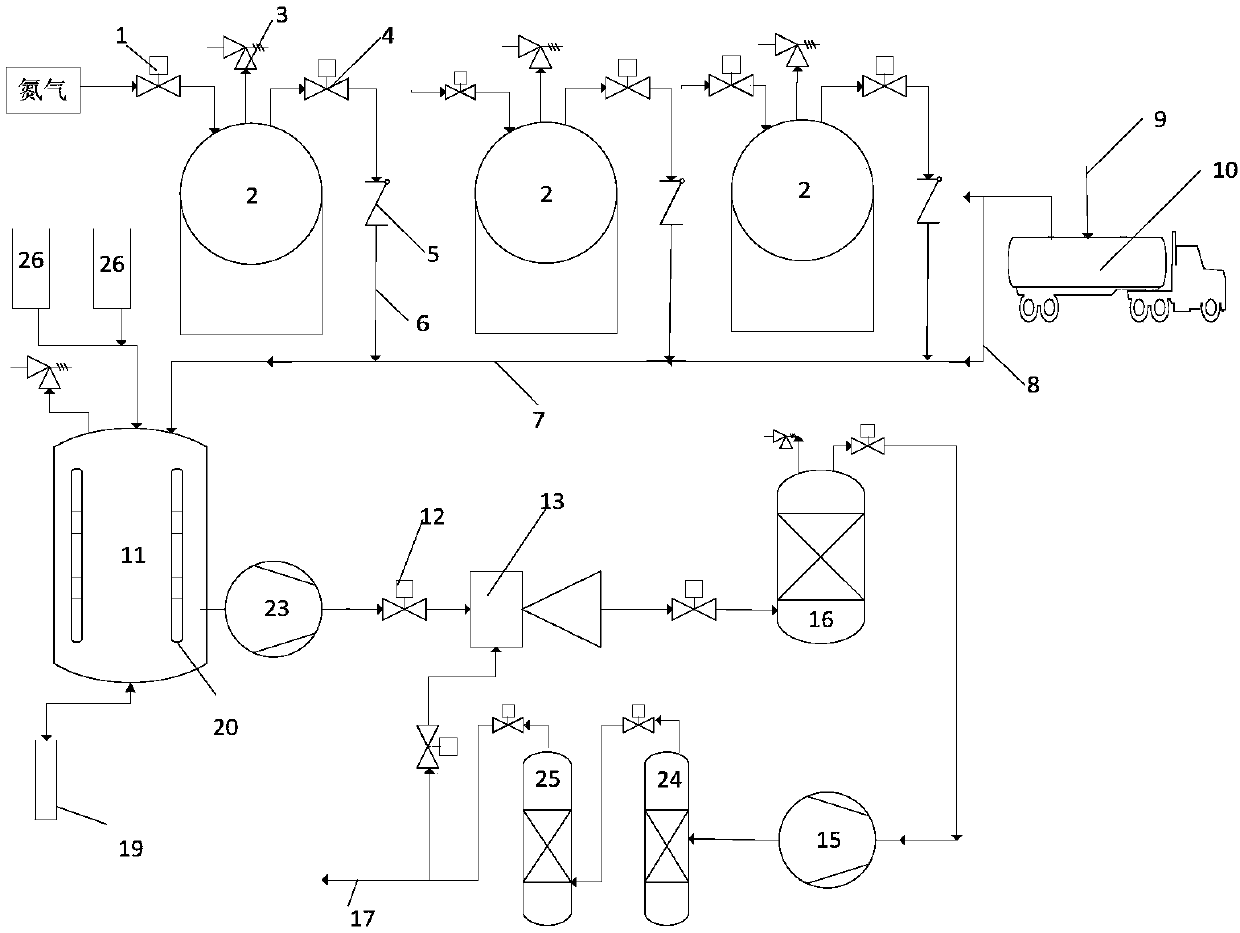

[0037] Embodiment 2: as figure 2 As shown, it is the same as Example 1, except that the described coking tail gas treatment method also includes the step of collecting and discharging the coking tail gas of the tar ammonia water separation tank 26 that is not easy to seal and discharging it into the buffer tank 11; The tar ammonia water separation tank 26 carries out micro-positive pressure nitrogen filling process, and the nitrogen filling pressure is higher than atmospheric pressure 0-400Pa.

[0038]At the same time, it also includes the step of mixing the vehicle loading exhaust gas with the coking exhaust gas of the storage tank 2 and collecting them together into the buffer tank 11 to ensure the air pressure balance in the buffer tank 11 . That is, while collecting the coking tail gas from the storage tank 2 into the buffer tank 11, the vehicle loading tail gas is collected into the buffer tank 11 and mixed with the coking tail gas from the storage tank 2, and the loadin...

Embodiment 3

[0039] Example 3, such as figure 2 As shown, the present invention also provides a device using the coking tail gas treatment method described in Embodiment 1 and 2, a coking tail gas treatment device, including at least one storage tank 2 and a buffer tank 11 that is sequentially communicated with the storage tank 2 , Venturi mixer 13, deoxygenation tank 16, the nitrogen pipeline is communicated with the top of the storage tank 2, a nitrogen charging valve 1 is provided on the nitrogen pipeline, and a quick discharge valve 3 is provided at the top of the storage tank 2; The coking tail gas in the tank 2 flows into the tail gas collection main pipe 7 through the tail gas collection branch pipe 6, and the flame arrester single exhalation valve 4 and the one-way valve 5 are arranged in sequence on the exhaust gas collection branch pipe 6, and the flame arrester single exhalation valve 4 is also installed in the storage tank top of 2;

[0040] Exhaust gas collection main pipe 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com