Acidification treatment method of oil refining alkali residue waste liquid

A kind of technology of acidification treatment and oil refining alkali residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

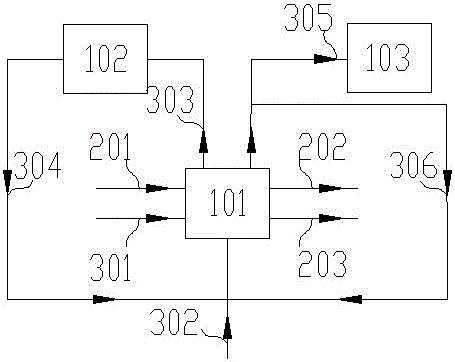

[0035] A company's catalytic gasoline alkali residue and liquid hydrocarbon alkali residue mixed alkali residue waste liquid, of which COD is 3.21×10 5 mg / L, Na 2 S (measured in S) is 1.18×10 4 mg / L, mercaptan sulfur (calculated as S) is 1.71×10 4 mg / L, the total sulfide (calculated as S) is 3.12×10 4 mg / L, volatile phenol is 8.07×10 4 mg / L. Using the present invention figure 1 According to the method shown, firstly, sulfuric acid with a volume concentration of 75% is used to acidify the alkali slag waste liquid, and nitrogen gas is introduced as a carrier gas.

[0036] Before the pH drops to 10, the acidified tail gas containing organic sulfides produced by acidification enters the condensing device, and the condensation temperature is controlled at 5°C and the pressure is 0.5 MPa to recover organic sulfides. The non-condensable gas discharged from the condensing device is mainly nitrogen. Main, return to acidifying unit as carrier gas. Organic sulfides such as methyl ...

Embodiment 2

[0040] A company's catalytic gasoline alkali residue and liquid hydrocarbon alkali residue mixed alkali residue waste liquid, of which COD is 2.83×10 5 mg / L, Na 2 S (measured in S) is 1.33×10 4 mg / L, mercaptan sulfur (calculated as S) is 2.03×10 4 mg / L, the total sulfide (calculated as S) is 3.69×10 4 mg / L, volatile phenol is 5.26×10 4 mg / L. Using the present invention figure 1 Process as shown, first using SO-containing 2 The gas is used to acidify the alkali slag waste liquid, and nitrogen is used as the diluted carrier gas.

[0041] Before the pH drops to 9.5, the acidified tail gas containing organic sulfides produced by acidification enters the condensing device, and the condensation temperature is controlled at -5°C and the pressure is 0.2MPa to recover organic sulfides. The non-condensable gas discharged from the condensing device is mainly nitrogen Mainly, return to the acidification unit as carrier gas. Organic sulfides such as methyl mercaptan, ethyl mercapta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com