Harmless treatment method for waste lithium battery electrolyte

A treatment method and electrolyte technology, applied in the field of environmental protection, can solve problems such as inability to effectively treat electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

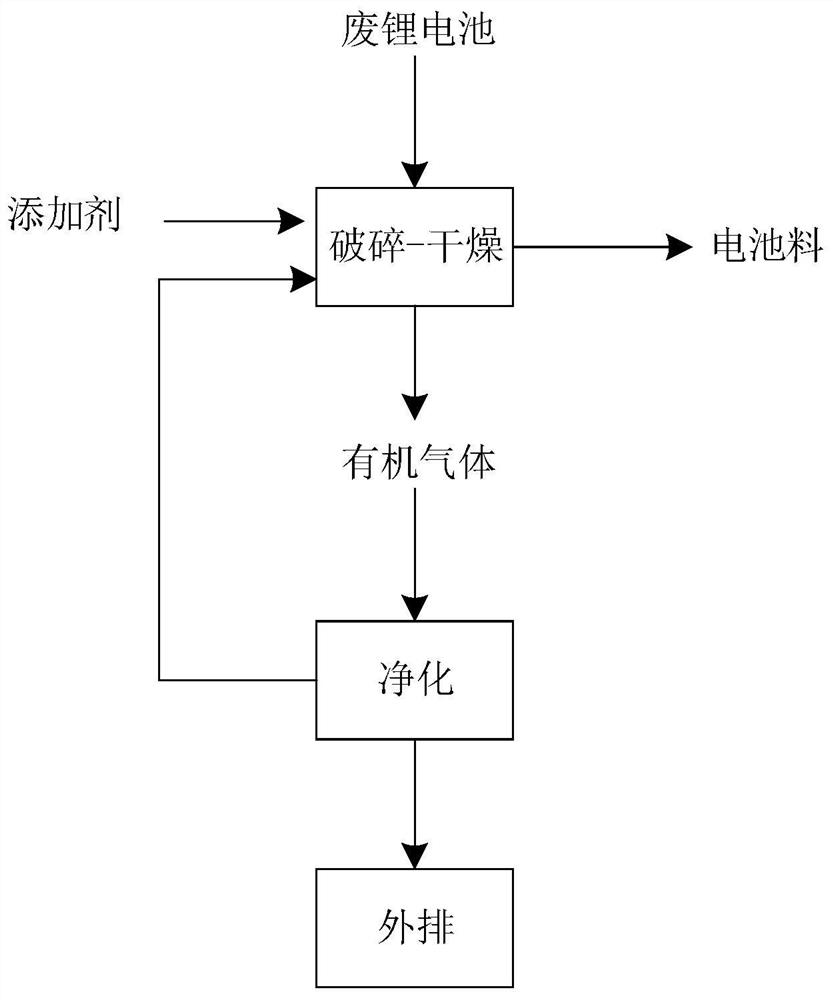

[0048] This embodiment provides a harmless treatment method for waste lithium battery electrolyte, and the treatment method includes the following methods:

[0049] (1) Carry out crushing treatment and drying treatment to the waste lithium battery after discharge successively, obtain the battery material and organic gas that remove electrolyte; The time interval of the drying treatment is 20s, and the end point of the crushing treatment is to make the material with a particle size<50mm account for 90wt% of the total material; during the drying treatment, the removal rate of the electrolyte is 90%; the temperature of the drying treatment is 150°C, the treatment time is 30s, and the drying treatment method is hot air drying;

[0050] (2) After the organic gas is dedusted, the temperature is raised to 150° C., and part of it is reused in the drying treatment described in step (1), and the remaining gas is discharged; the recycled gas accounts for 80 vol% of the total amount of th...

Embodiment 2

[0055] This embodiment provides a harmless treatment method for waste lithium battery electrolyte, and the treatment method includes the following methods:

[0056] (1) Carry out crushing treatment and drying treatment to the waste lithium battery after discharge successively, obtain the battery material and organic gas that remove electrolyte; The time interval of the drying treatment is 30s, and the end point of the crushing treatment is to make the material with a particle size<50mm account for 95wt% of the total material; during the drying treatment, the removal rate of the electrolyte is 92%; the temperature of the drying treatment is 160°C, the treatment time is 25s, and the drying treatment method is hot air drying;

[0057] (2) After the organic gas is dedusted, the temperature is raised to 160°C, and part of it is reused in the drying treatment described in step (1), and the remaining gas is discharged; the recycled gas accounts for 60vol% of the total amount of the o...

Embodiment 3

[0062] This embodiment provides a harmless treatment method for waste lithium battery electrolyte, and the treatment method includes the following methods:

[0063] (1) Carry out crushing treatment and drying treatment to the waste lithium battery after discharge successively, obtain the battery material and organic gas that remove electrolyte; The time interval of the drying treatment is 10s, and the end point of the crushing treatment is to make the material with a particle size<50mm account for 96wt% of the total material; during the drying treatment, the removal rate of the electrolyte is 95%; the temperature of the drying treatment is 180°C, the treatment time is 18s, and the drying treatment method is hot air drying;

[0064] (2) After the organic gas is dedusted, the temperature is raised to 180° C., and part of it is reused for the drying treatment described in step (1), and the remaining gas is discharged; the recycled gas accounts for 80 vol% of the total amount of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com