Yellow phosphorus slag water quenching waste heat recovery device

A waste heat recovery device, a technology of yellow phosphorus slag, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as affecting the health of workers, harsh factory environment, corrosion, etc., to avoid unorganized emissions, improve environmental sanitation, Guarantee the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

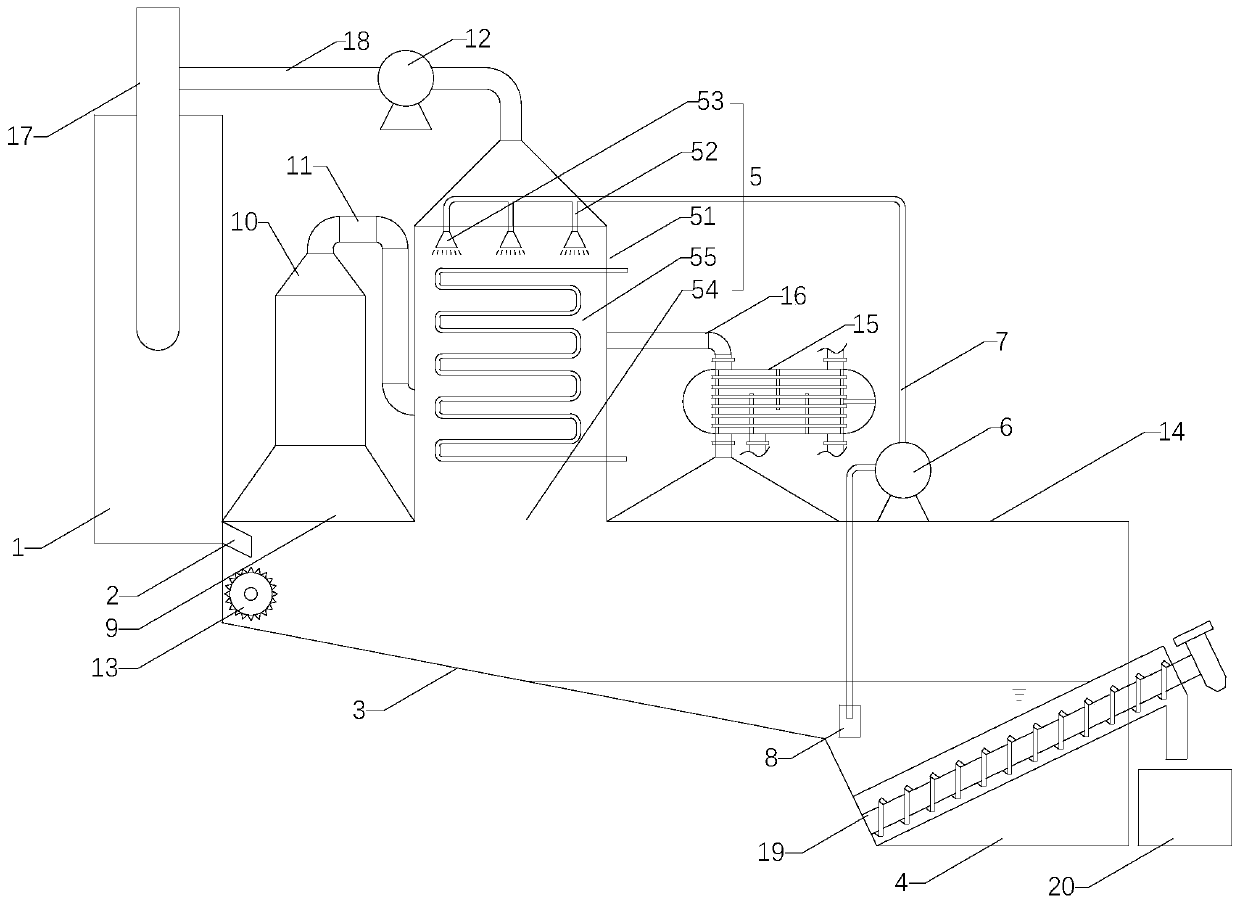

[0025] Example: A yellow phosphorus slag water quenching waste heat recovery device such as figure 1 As shown, the yellow phosphorus electric furnace 1 is included, and the side wall of the yellow phosphorus electric furnace 1 is provided with a slag outlet 2, and a chute 3 is arranged below the slag outlet 2, and the bottom of the chute 3 is connected with the water quenching pool 4; The spray heat exchanger 5 includes a shell 51, a spray water inlet 52 and a spray head 53 located inside the shell 51, and a heat exchange tube 55 is arranged in the shell 51, and the shell 51 There is a spray water outlet 54 below, and the spray water inlet 52 is connected with the water quenching pool 4 through the return pump 6 and the return pipe 7. After the slag enters the water quenching pool 4 to heat the water, the return pump 6 pumps hot water into the spray tank. Heat energy is recovered in the shower heat exchanger 5 , and the return pipe 7 is located in the water quenching tank 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com