A coke oven sealing and ventilation dust removal device and method

A dust removal device and coke oven technology, which is applied in coke ovens, furnaces to prevent/remove fouling, and the petroleum industry, etc. It can solve the problem of poor sealing of furnace doors and coal charging holes, failure to collect flue gas from dust-producing points, and increase the load of coke ovens To meet the requirements of environmental protection, improve the efficiency of ventilation and dust removal, and eliminate fugitive emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

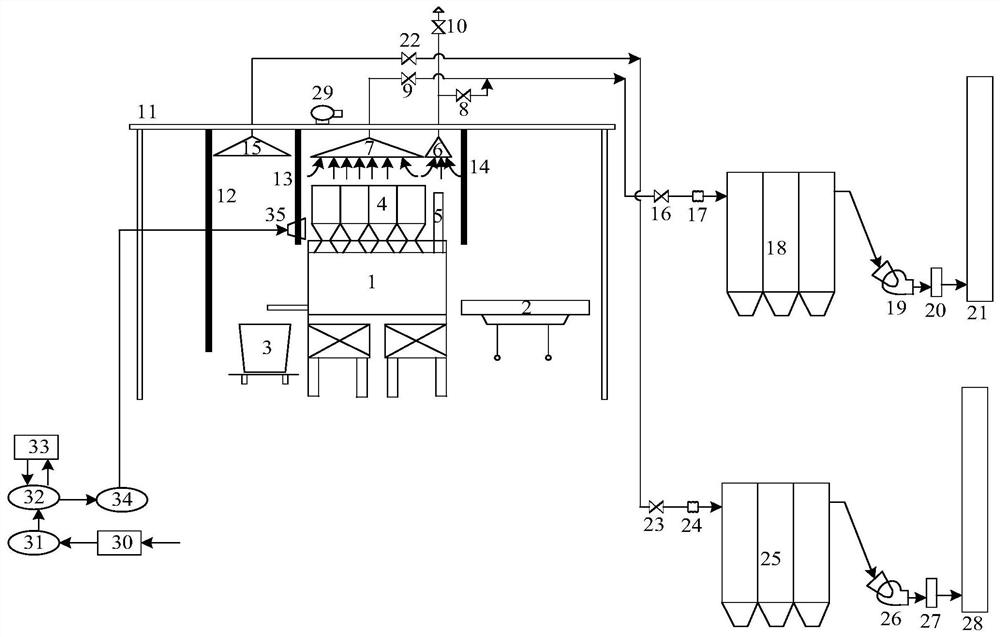

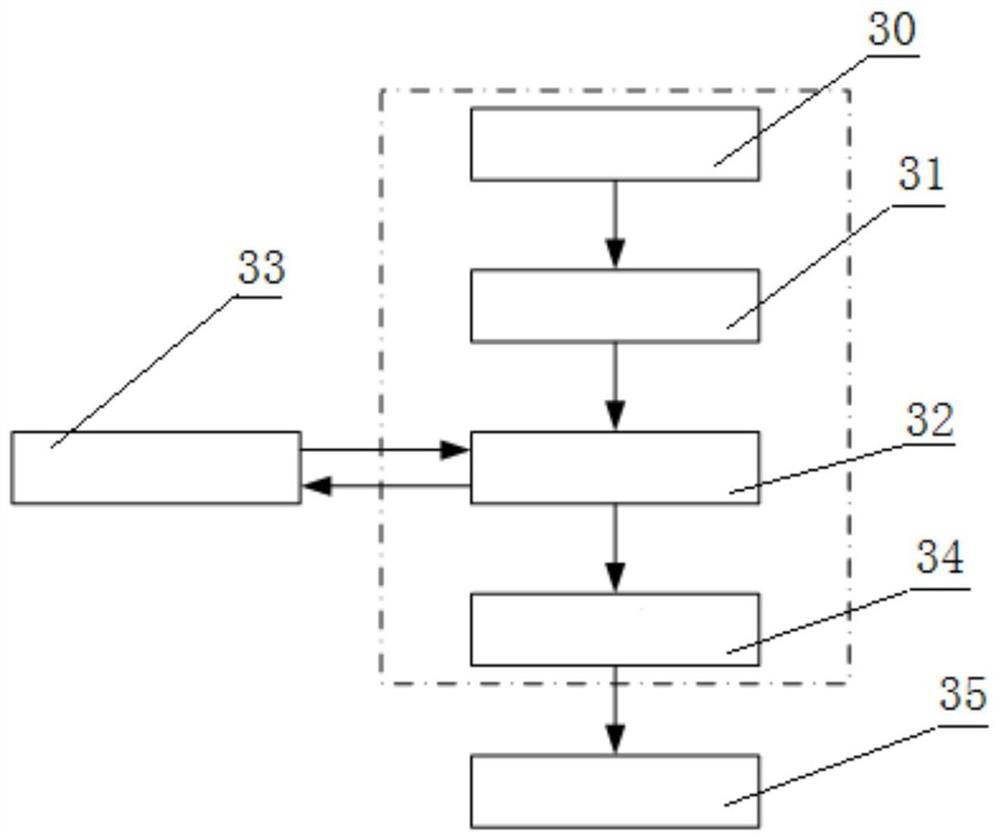

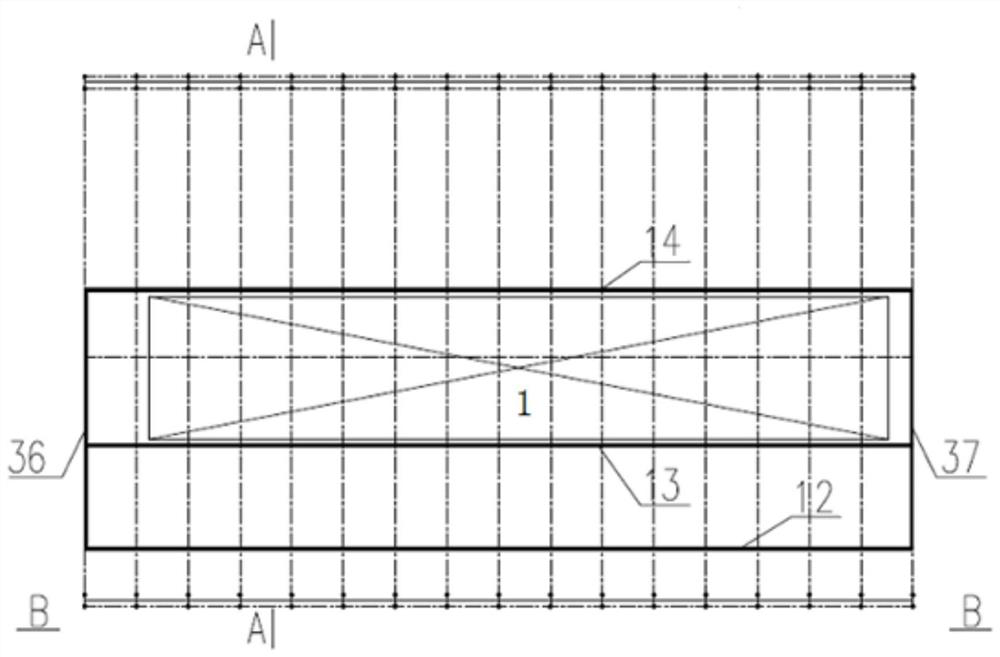

[0016] Embodiment 1: Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail: figure 1 Shown is a process flow chart of a coke oven sealing, ventilation and dust removal device and method, the device includes: coke oven 1, coke pushing car 2, coke quenching tank 3, coal charging machine 4, riser pipe 5, riser pipe smoke exhaust Hood 6, furnace top exhaust hood 7, manual butterfly valve 8, electric valve a9, pneumatic butterfly valve 10, closed workshop 11, hanging wall a12, hanging wall b13, hanging wall c14, coke side exhaust hood 15, electric valve b16, compensation Device a17, pulse bag filter a18, induced draft fan a19, silencer a20, chimney a21, electric valve c22, electric valve d23, compensator b24, pulse bag filter b25, induced draft fan b26, silencer b27, chimney b28 , emergency exhaust fan 29, fresh air duct 30, primary filter 31, surface cooler 32, refrigeration unit 33, air blower 34, air outlet 35, han...

Embodiment 2

[0017] Embodiment 2: Embodiment 2 is all the same as Embodiment 1, the difference is the following content.

[0018] The basic column spacing of factory building column 44 is 12m, and the local column spacing is 24m.

[0019] The ascending pipe exhaust hood 6 above the ascending pipe 5 can be arranged in groups, and one ascending pipe exhaust hood 6 is arranged above every 5 ascending pipes; Grouping, every 5 rows of coal charging holes are provided with a furnace top exhaust hood 7.

[0020] The air supply outlet 35 is arranged every 15m, the height of the air supply outlet is 1.5m, the air supply volume is designed to be 5000m3 / h, and the cold air temperature is 15°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com