Methane gas recovering system for anaerobic reactor

An anaerobic reactor, methane gas technology, applied in anaerobic digestion treatment, combustion methods, lighting and heating equipment, etc., can solve problems such as environmental damage, and achieve low transformation costs, saving coal consumption, and effective environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

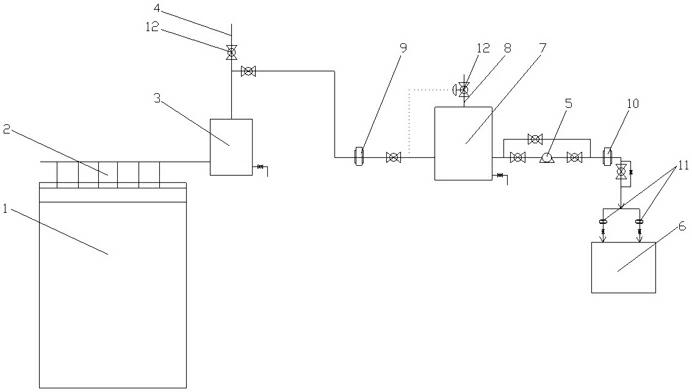

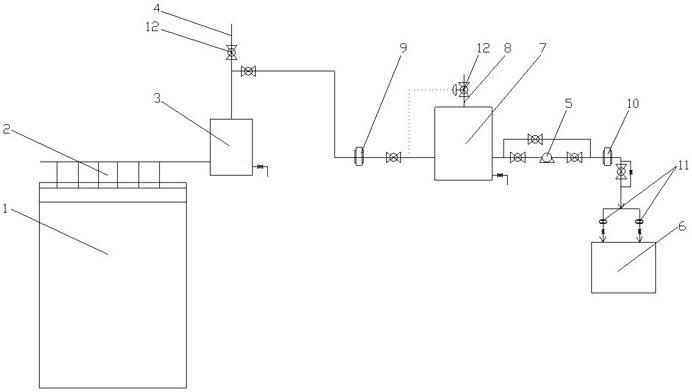

[0015] Embodiment: the anaerobic reactor methane gas recovery system of this example, as figure 1 , there is an anaerobic reactor 1, the anaerobic reactor is connected with the first water-sealed tank 3 through the three-phase separator 2, the first water-sealed tank is provided with the first vent pipe 4, and the first vent pipe 4 is provided with There are valves 12 . The first water-sealed tank is connected to the second water-sealed tank 7 through pipelines, the second water-sealed tank is provided with a second vent pipe 8, and a valve is provided on the second vent pipe. A first flame arrester 9 is provided on the pipeline between the first water-sealed tank and the second water-sealed tank. The second water-sealed tank is connected with pipeline fan 5 through pipeline, and pipeline fan is connected with hot coal furnace 6 through pipeline. There are two third flame arresters 11 arranged in parallel.

[0016] The gas production rate of organic matter in polyester wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com