Method and apparatus for absorbing asphalt smoke

A technology of asphalt fume and absorption device, which is applied in the field of coal chemical industry, can solve the problems of increased sewage treatment troubles, cumbersome operation and maintenance, and large system resistance, so as to avoid direct escape, increase the height of the chimney, and increase the secondary cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are preferred embodiments of the present invention. However, it should be understood that its specific description should not be construed as limiting the essence and scope of the present invention. Various modifications made to the above-mentioned implementation methods by those of ordinary skill in the art after reading this specification belong to the patent of the present invention. scope of protection.

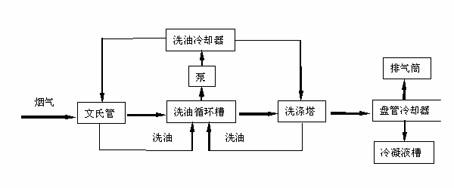

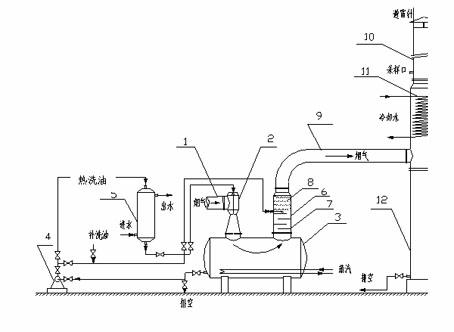

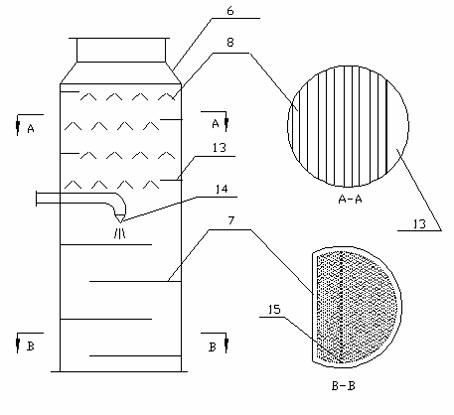

[0040] Asphalt fume absorption process such as figure 1 As shown, the structure of the absorber is as Figure 2~3 As shown, the wash oil cooler used is a shell and tube heat exchanger.

[0041] The structure of the asphalt fume absorption device includes a gas phase tube 1 and a venturi tube 2 connected in sequence, and the venturi tube 2 is also connected to the shell and tube heat exchanger 5;

[0042] The lower end of the Venturi tube 2 is connected to the oil washing circulation tank 3, and a washing tower 6 is also arranged on the oil washing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com