Preparation method of C and N co-doped nano titania

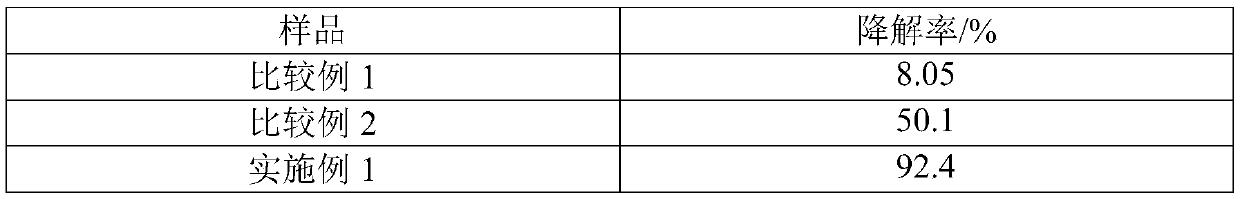

A technology of nano-titanium dioxide and titanium dioxide, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of low utilization rate of visible light, poor doping effect, cumbersome steps, etc., and achieve efficient use of light Catalytic activity, excellent effect, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A, 10g deionized water is added in 100g ammonium carbonate, grind while adding, deionized water adds flow rate and is 10mL / min, after adding, continue to grind 2h, make ammonium carbonate solid-liquid mixed slurry;

[0029] B. Add 4000g of metatitanic acid into the ammonium carbonate solid-liquid mixed slurry under stirring at 300r / min. The adding speed is 100g / min. ammonium carbonate;

[0030] C. Dry the product obtained in step B at 30° C. for 5 hours;

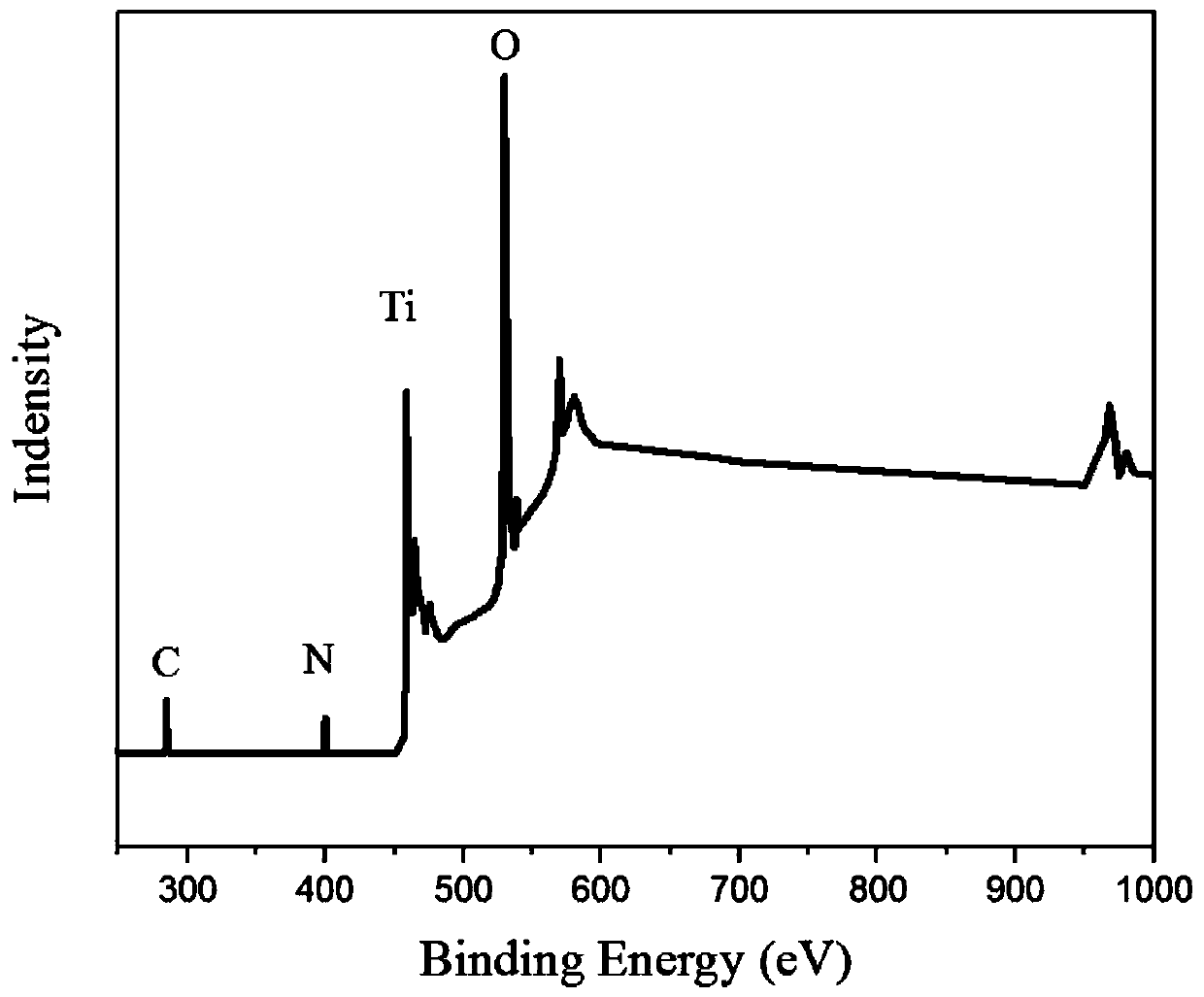

[0031] D. Calcining the dried metatitanic acid-coated ammonium carbonate obtained in step C at 500° C. for 4 hours to obtain C and N co-doped titanium dioxide;

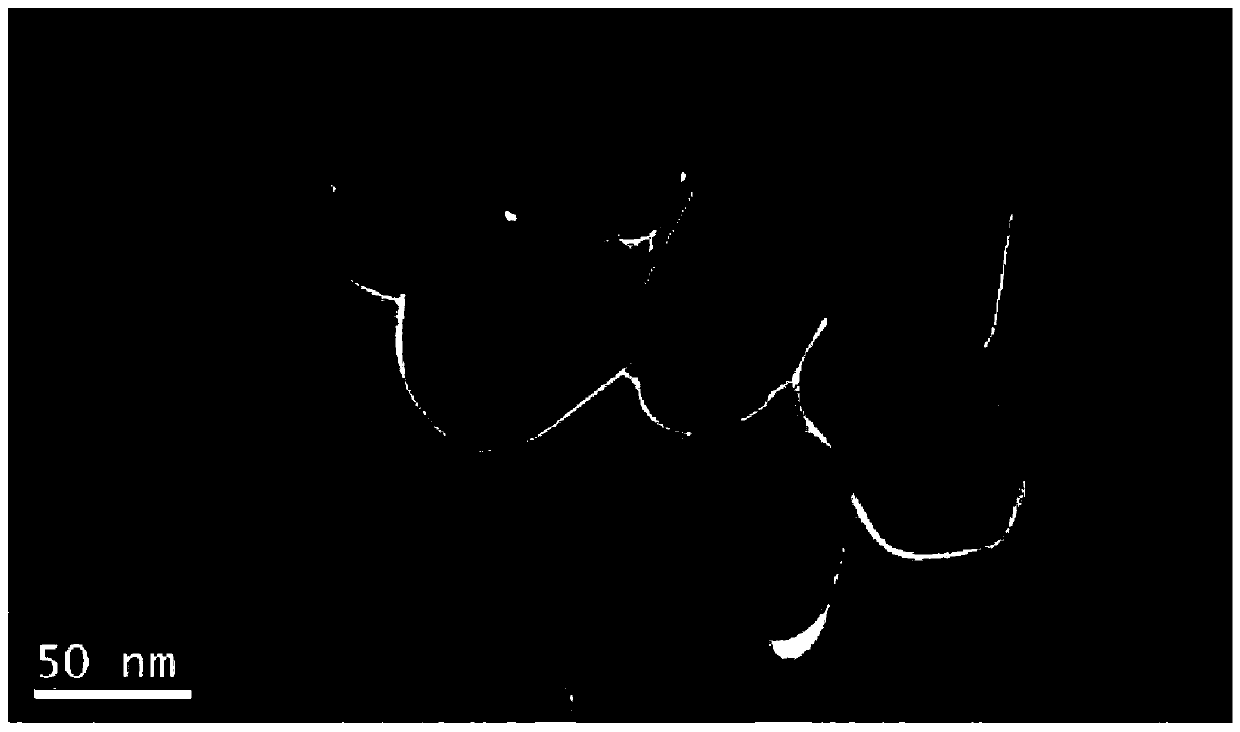

[0032] E. Jet milling the product obtained in step D to obtain C and N co-doped nano-titanium dioxide with an average particle size of 79 nm.

Embodiment 2

[0034] A, 8g deionized water is added in 100g ammonium carbonate, grind while adding, deionized water adds flow rate and is 8mL / min, after adding, continue to grind 2h, make ammonium carbonate solid-liquid mixed slurry;

[0035] B. Add 4000g of metatitanic acid into the ammonium carbonate solid-liquid mixed slurry under stirring at 300r / min. The adding speed is 80g / min. ammonium carbonate;

[0036] C. Dry the product obtained in step B at 30° C. for 4 hours;

[0037] D. Calcining the dried metatitanate-coated ammonium carbonate obtained in step C at 600° C. for 6 hours to obtain C and N co-doped titanium dioxide;

[0038] E. Jet milling the product obtained in step D to obtain C and N co-doped nano-titanium dioxide with an average particle size of 75 nm.

Embodiment 3

[0040] A, 9g deionized water is added in 100g ammonium carbonate, grind while adding, deionized water adds flow rate and is 9mL / min, after adding, continue to grind 2h, make ammonium carbonate solid-liquid mixed slurry;

[0041] B. Add 4000g of metatitanic acid to the ammonium carbonate solid-liquid mixed slurry under stirring at 300r / min. The adding speed is 90g / min. ammonium carbonate;

[0042] C. Dry the product obtained in step B at 40° C. for 5 hours;

[0043] D. Calcining the dried metatitanic acid-coated ammonium carbonate obtained in step C at 600° C. for 8 hours to obtain C and N co-doped titanium dioxide;

[0044] E. Jet milling the product obtained in step D to obtain C and N co-doped nano-titanium dioxide with an average particle size of 77 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com