Integrated water-cooling low-temperature type air-cooling heat pump module unit

An air-cooled heat pump and low-temperature technology, which is applied in the field of air-conditioning equipment, can solve the problems of difficult transportation, installation and maintenance of large-scale chillers, high difficulty in the construction of cooling pipe networks, noise pollution and refrigeration efficiency, etc., so as to reduce the amount of construction and avoid The effect of flying water and high comprehensive efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described in detail below in combination with specific embodiments.

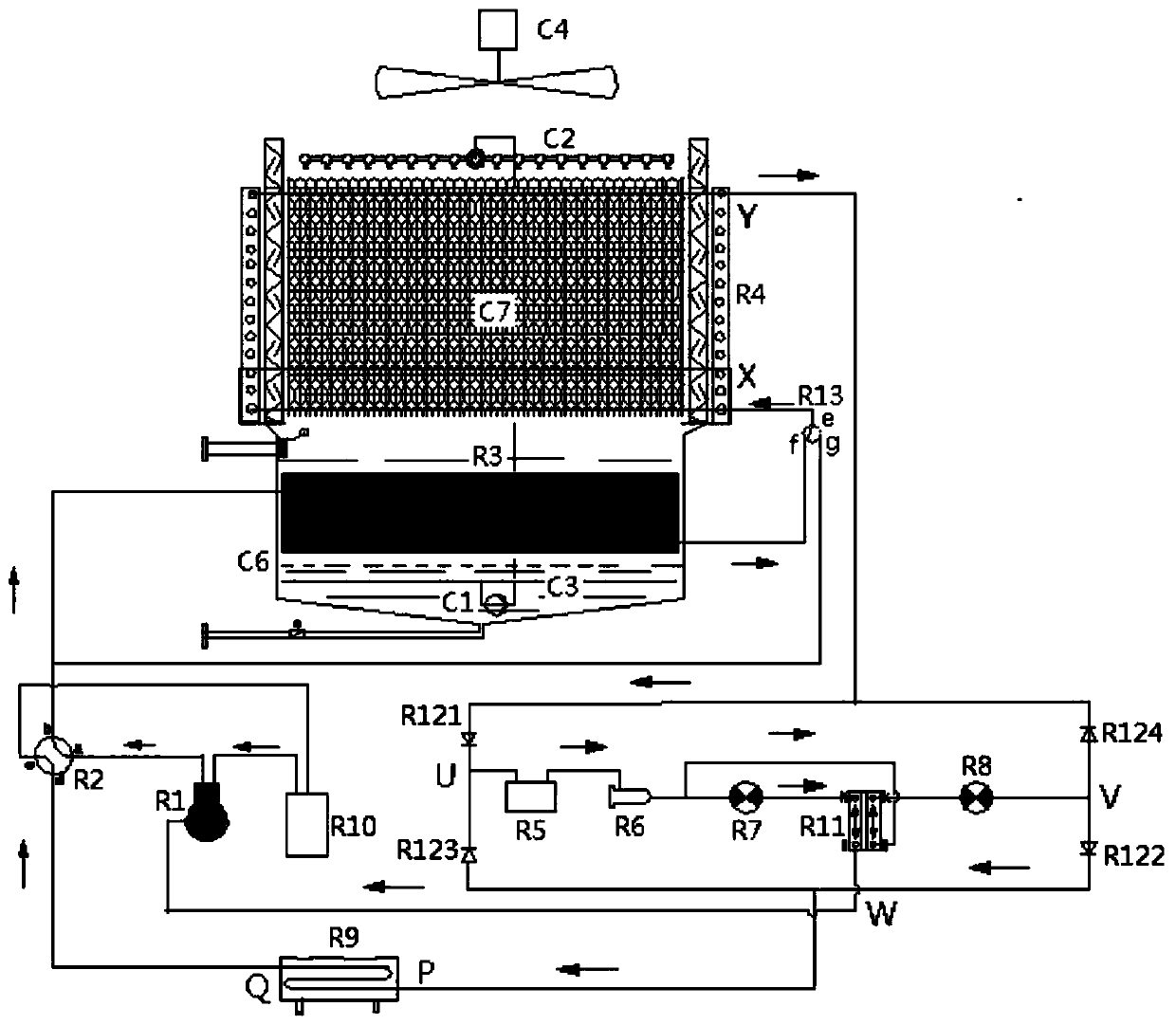

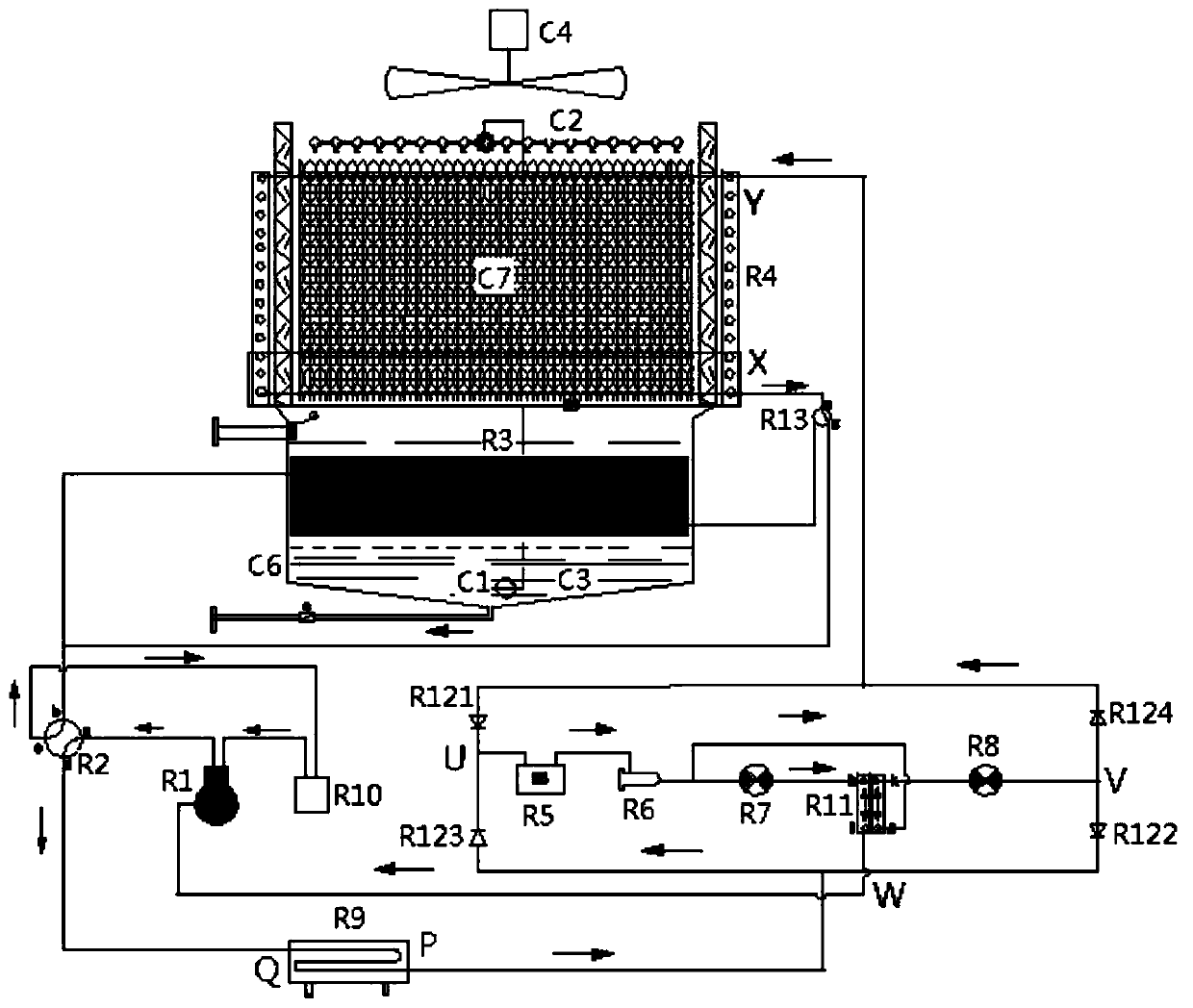

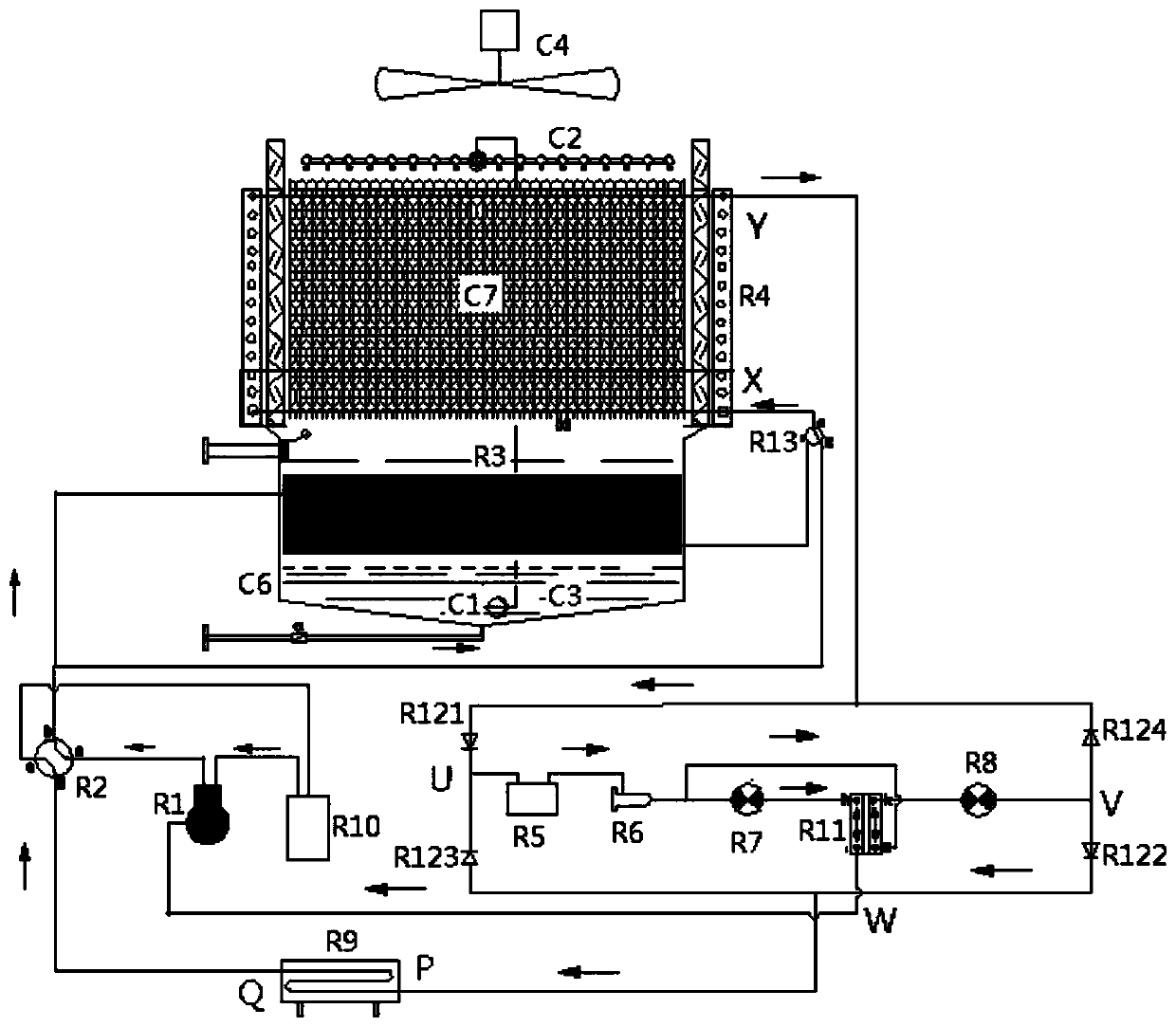

[0088] Such as figure 1As shown, the integrated water-cooled low-temperature air-cooled heat pump module unit includes a small cooling tower shell C5 and a cooling system, a refrigerant circulation system (refrigeration system), and functional modules assembled inside the small cooling tower shell C5; the cooling The system includes a fan C4, a water distributor C3, a cooling circulation pump C1, a sprayer C2, a cooling packing layer C7, and a cooling water tank C6. The refrigerant circulation system includes a small-power compressor R1 and an air-cooled finned heat exchanger R4 , open spiral wound condenser R3, four-way valve R2, indoor heat exchanger R9, gas-liquid separator R10; the functional modules include interconnected liquid storage tank R5, dry filter R6, economizer R11, A number of electronic expansion valves, a number of one-way valves, and a three-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com