Patents

Literature

33results about How to "Additional load is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

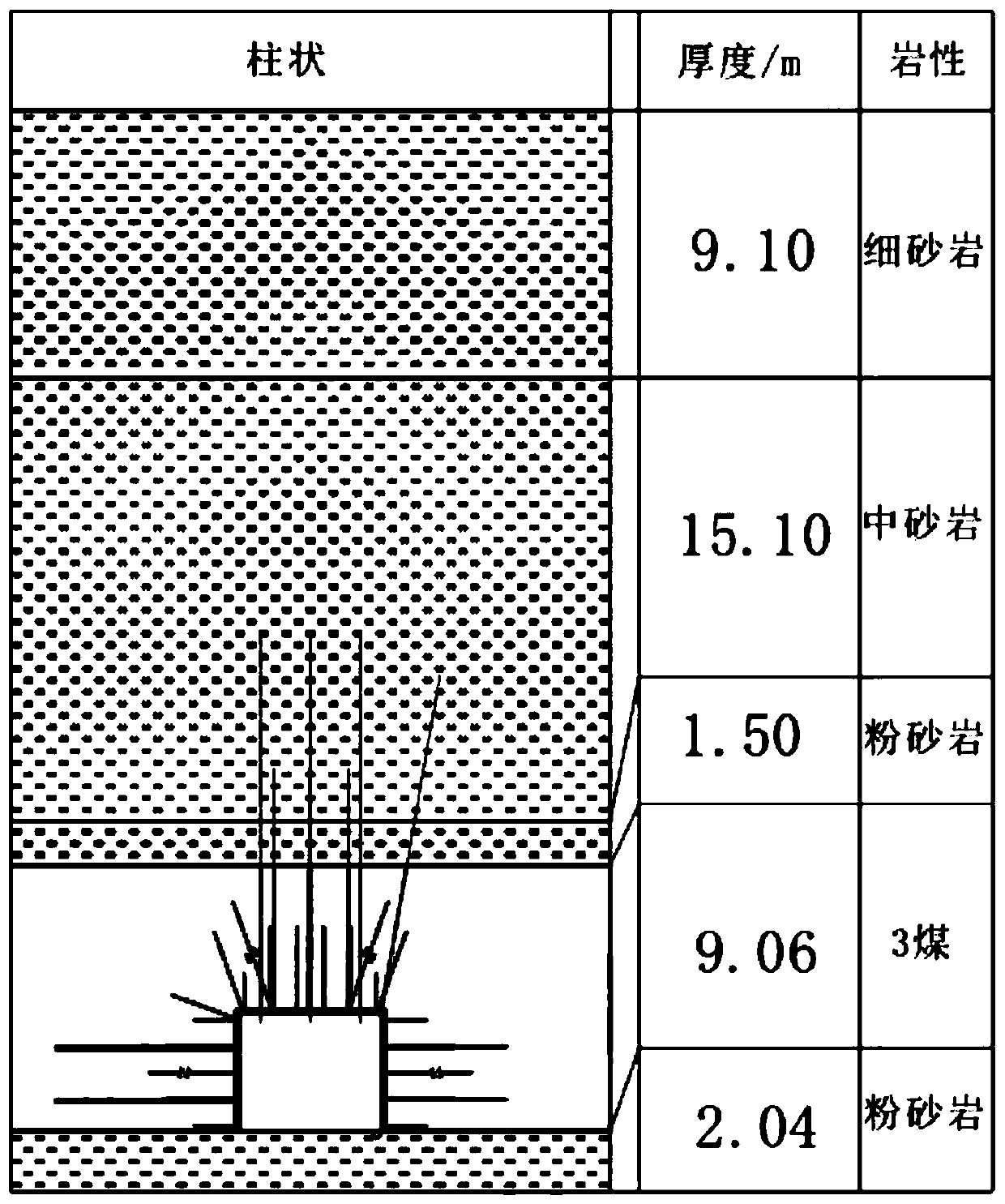

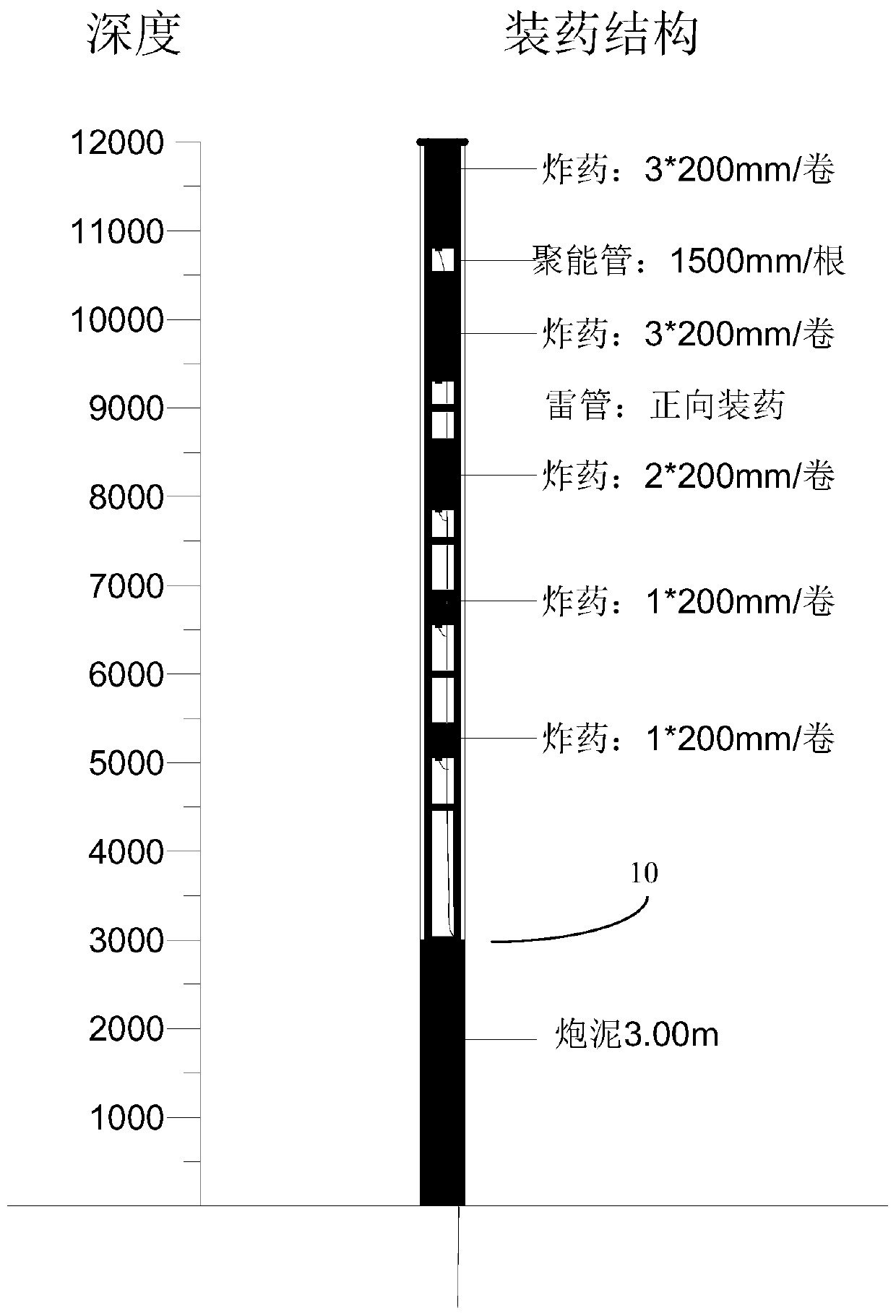

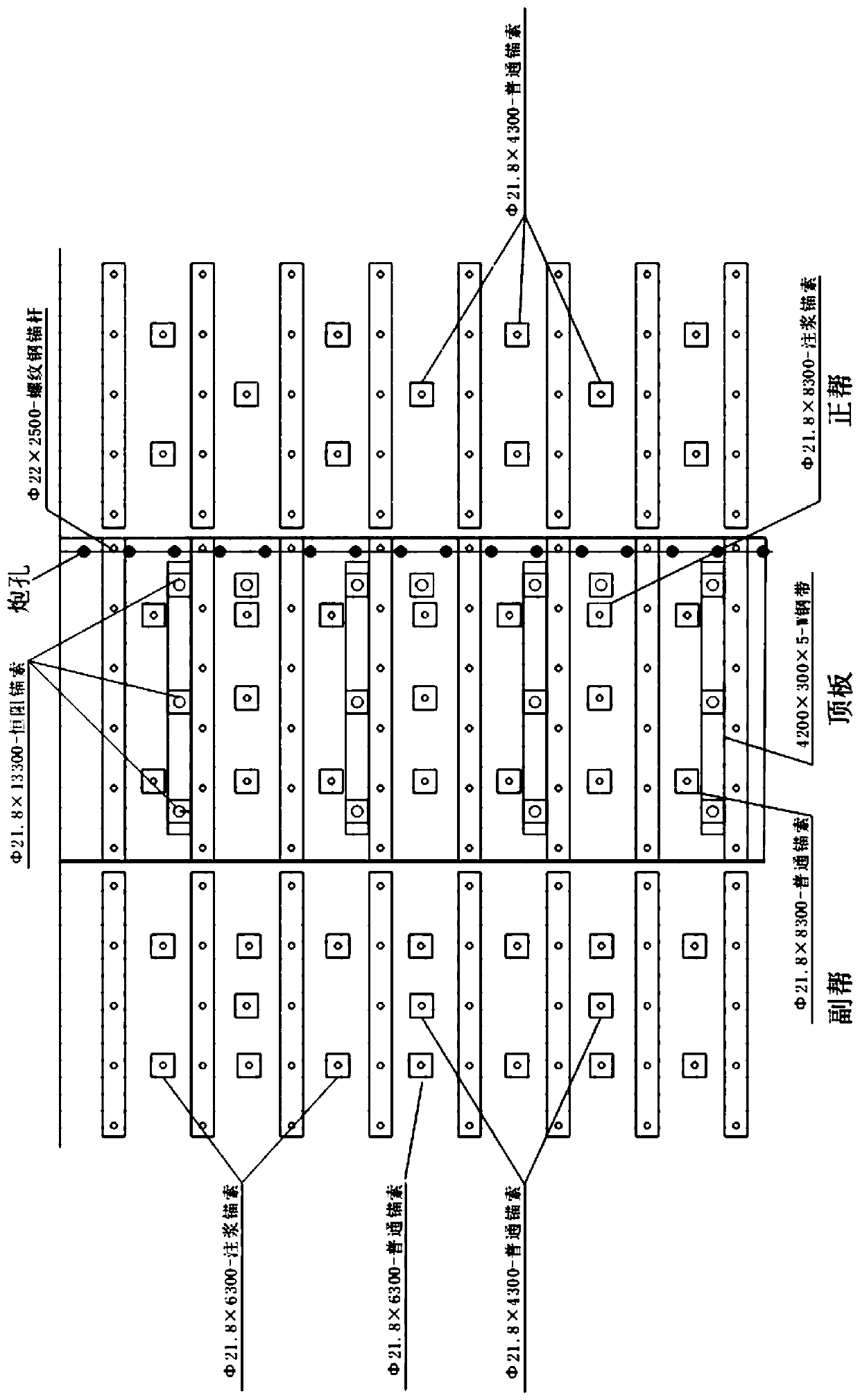

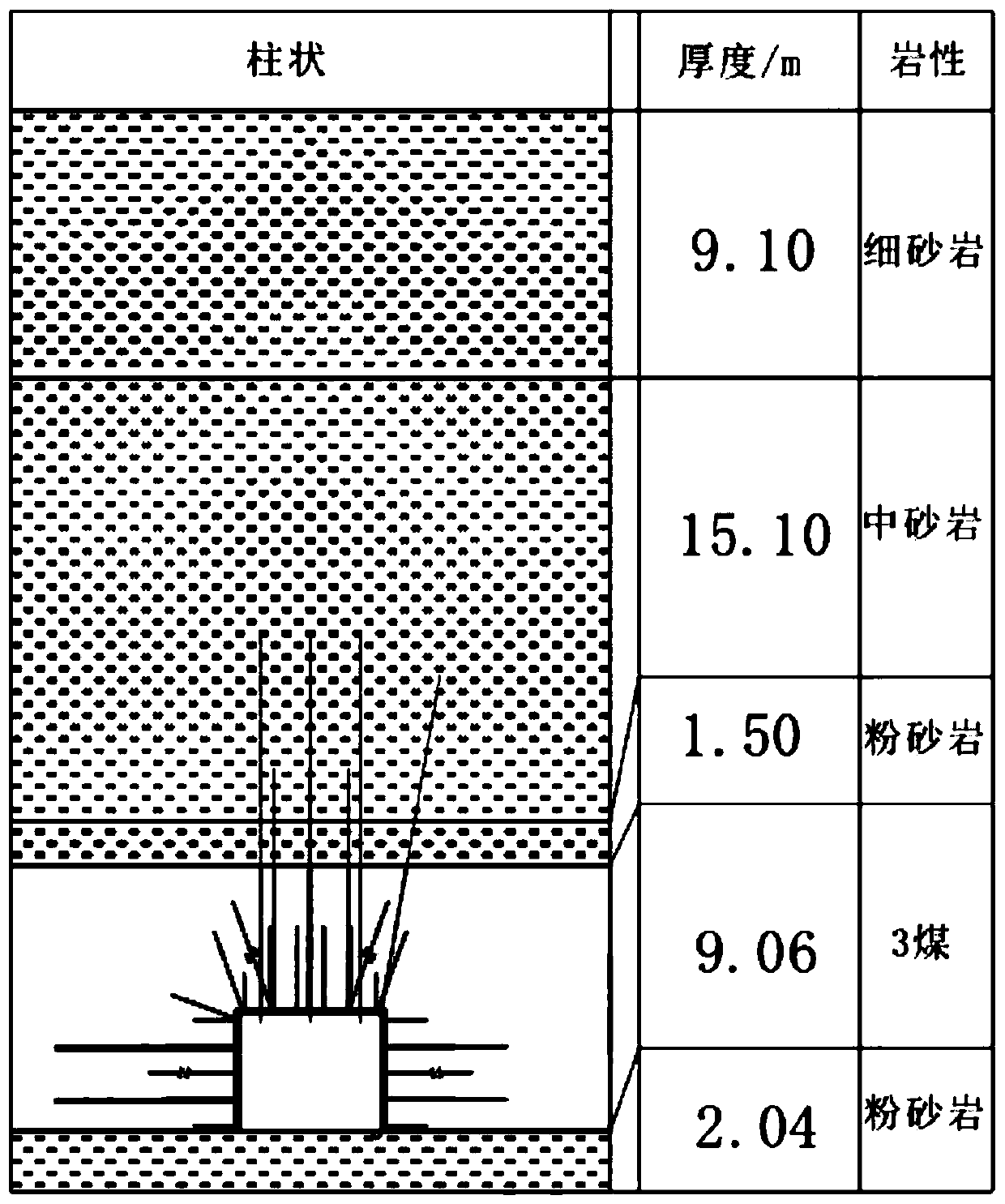

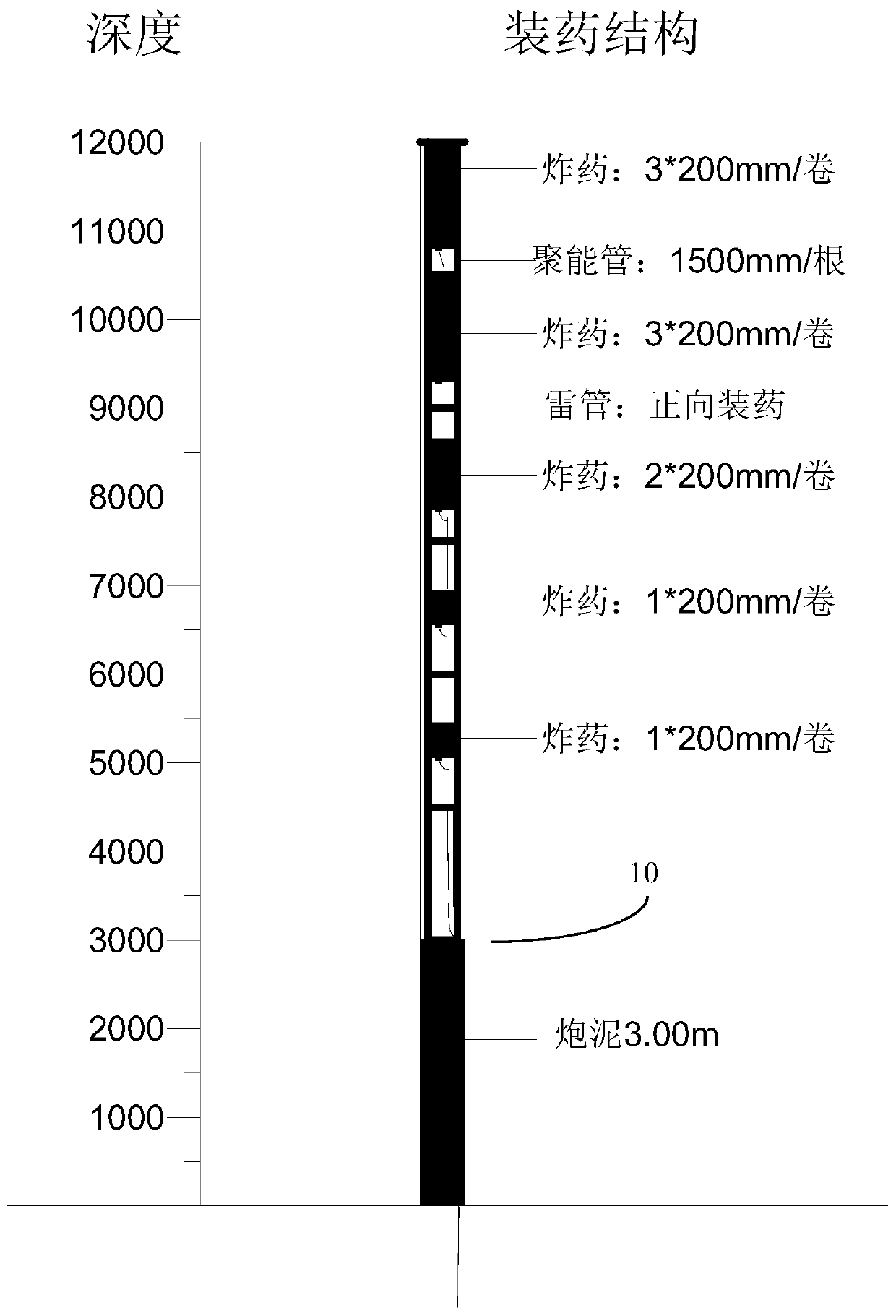

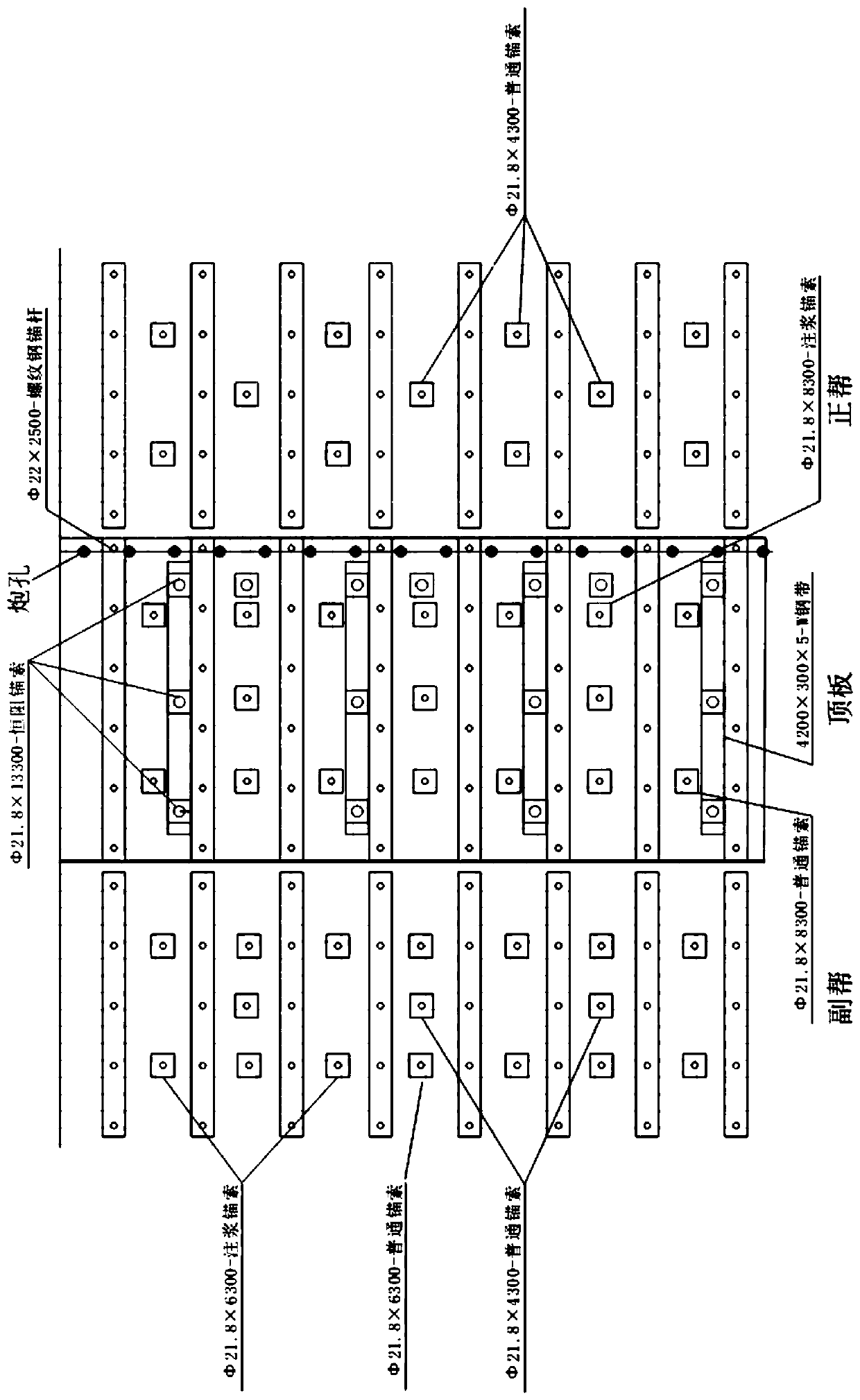

Non-coal-pillar auto-roadway-forming mining method suitable for thick-seam fully mechanized top coal caving

ActiveCN110206542AConducive to collapseIncrease stressDisloding machinesUnderground miningPre crackingCoal pillar

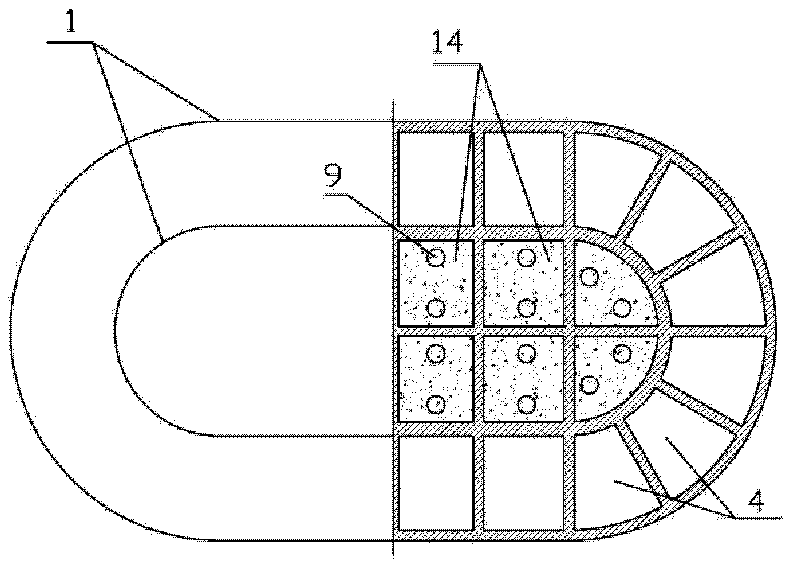

The invention relates to the technical field of coal mine mining, in particular to a non-coal-pillar auto-roadway-forming mining method suitable for thick-seam fully mechanized top coal caving. The method includes the following steps that reinforcing and supporting are carried out on a roof and two walls of a roadway; roof cutting explosion is carried out to form a pre-cracking seam; a temporary supporting device in the roadway and a gangue blocking device are erected along a retained entry; coal caving is not performed within a preset distance to the working face end close to the entry retaining side; after the roadway is stabilized, the temporary supporting device in the roadway is removed, a goaf is closed, and the entry retaining is completed. The roof cutting explosion better facilitates collapsing of the rock stratum in the goaf, the stoping space can be well filled after the rock stratum in the seam is collapsed, a short arm beam structure is formed in the lateral direction of the entry-retaining roof, a long suspended roof formed in the goaf is avoided, and the surrounding rock stress of the gob-side entry is improved; coal caving is not performed within a certain range ofthe working face end of the entry retaining side, the filling effect of the empty area of the entry retaining side is further guaranteed, rotary sinking of basic top block bodies is effectively limited, and the influence on the entry retaining stability is greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

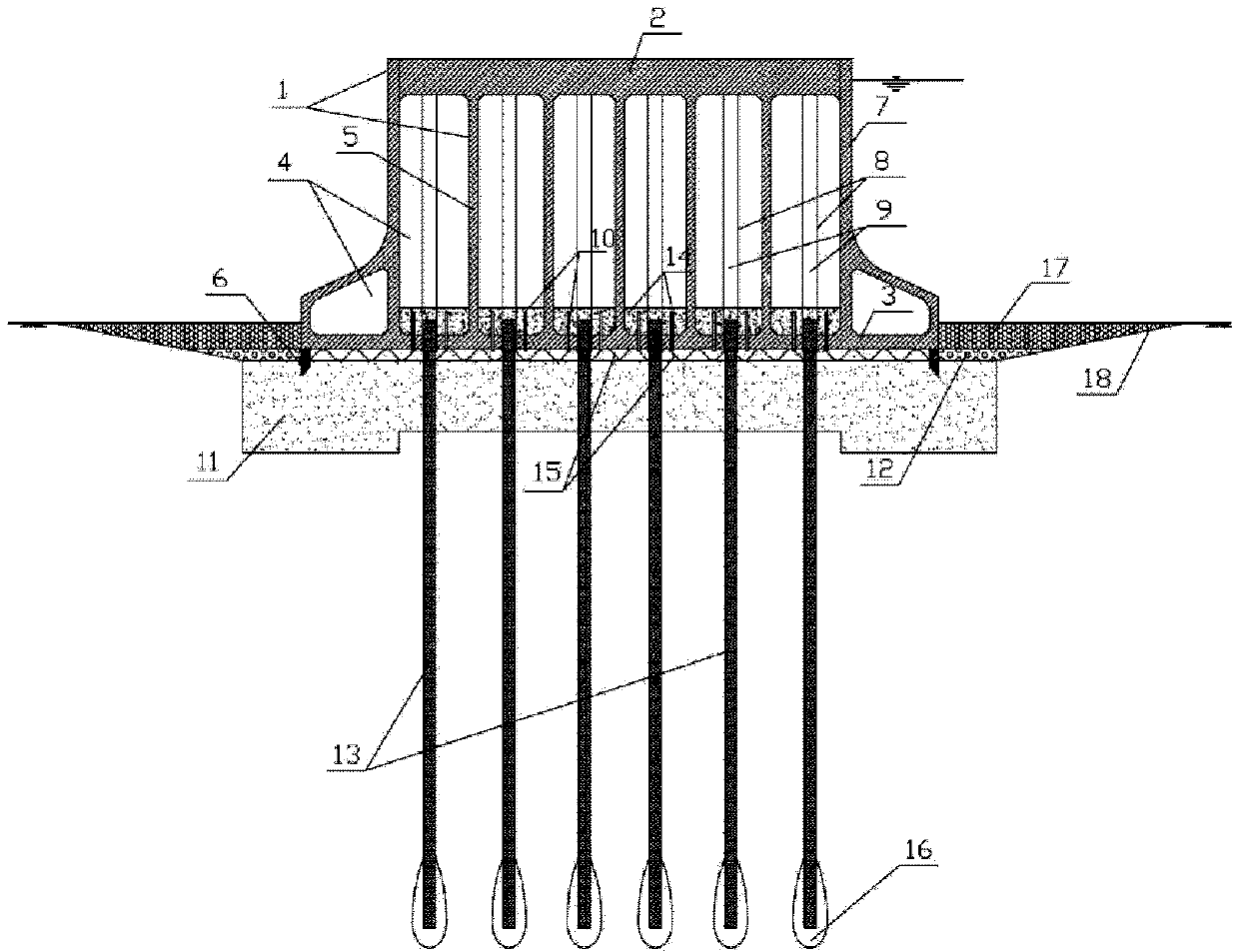

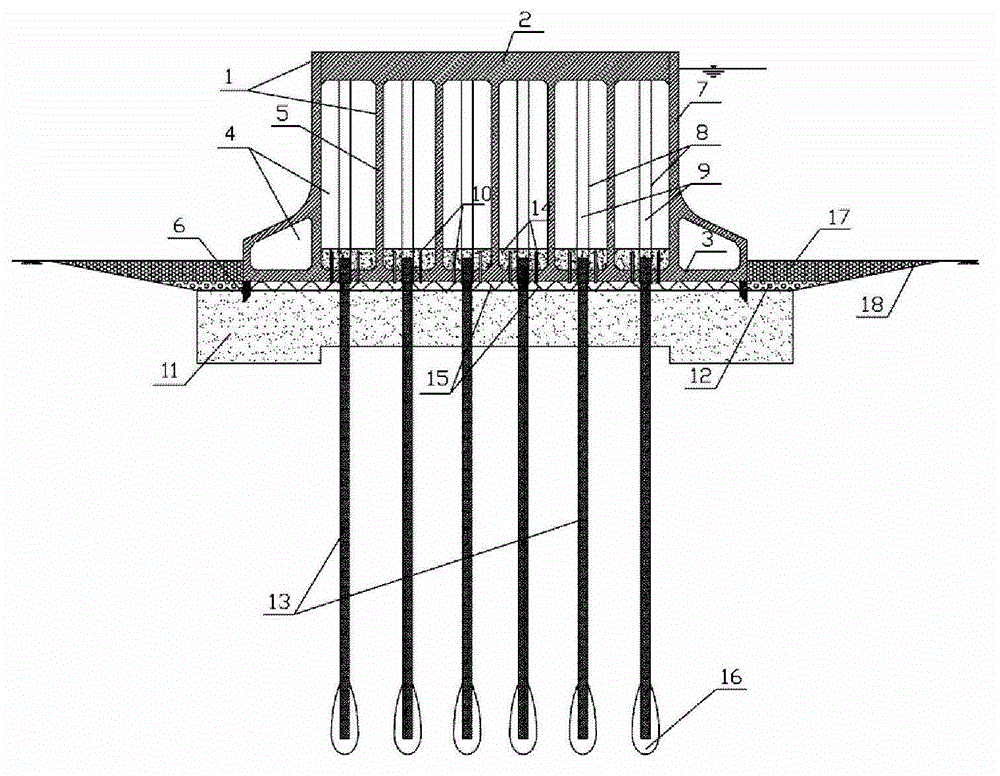

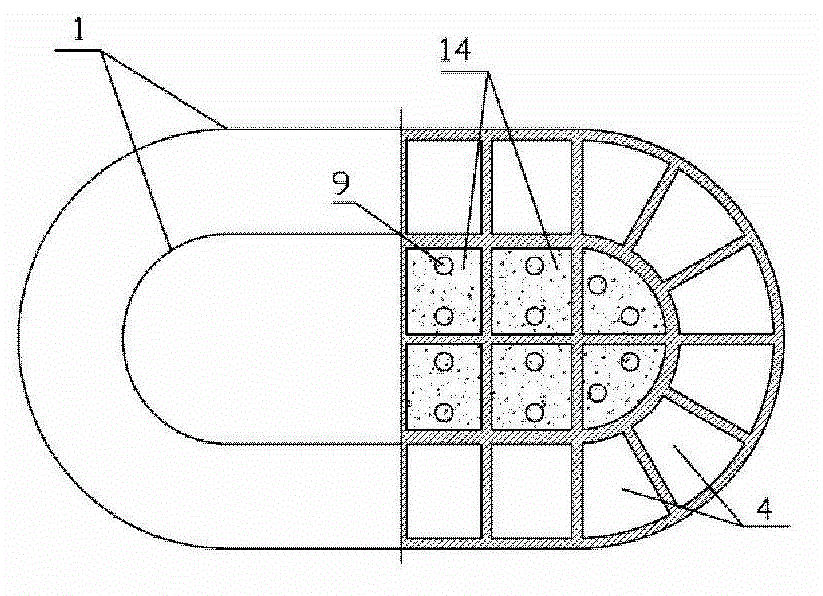

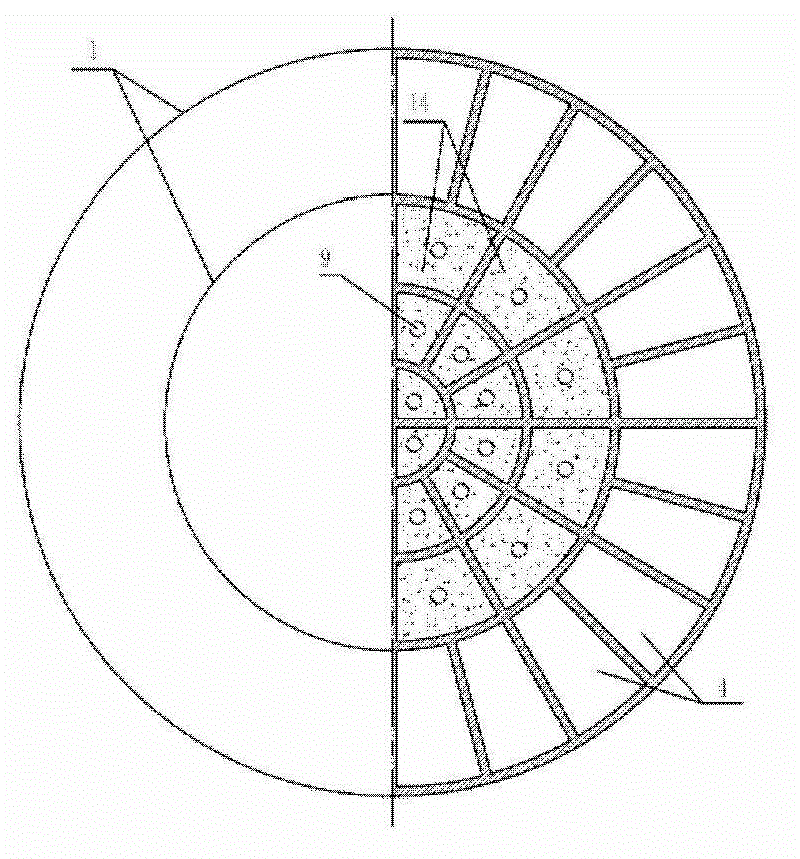

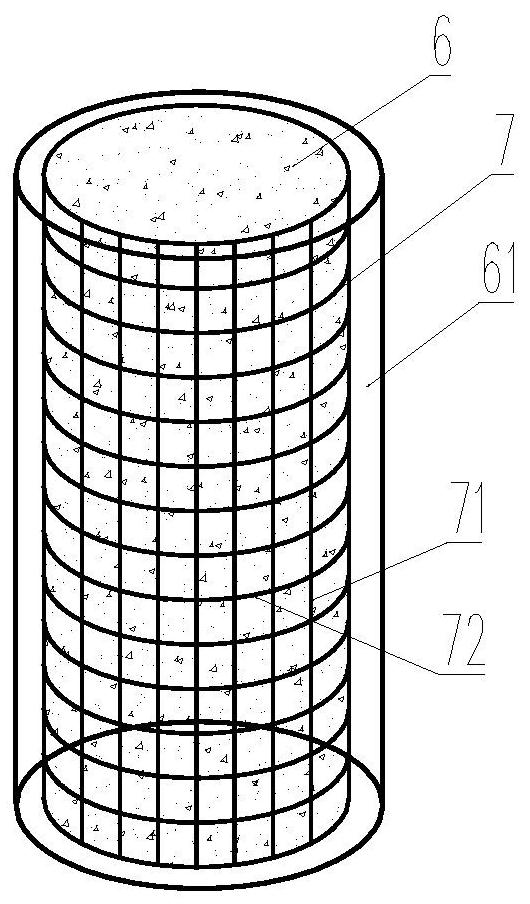

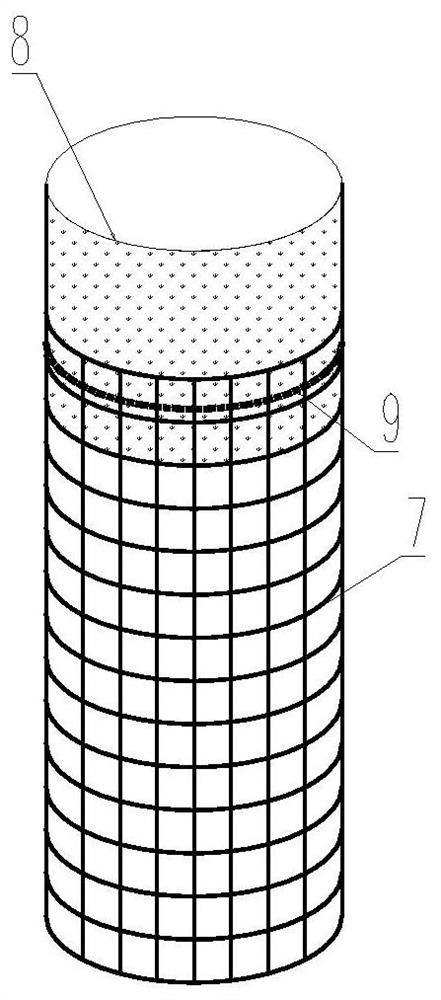

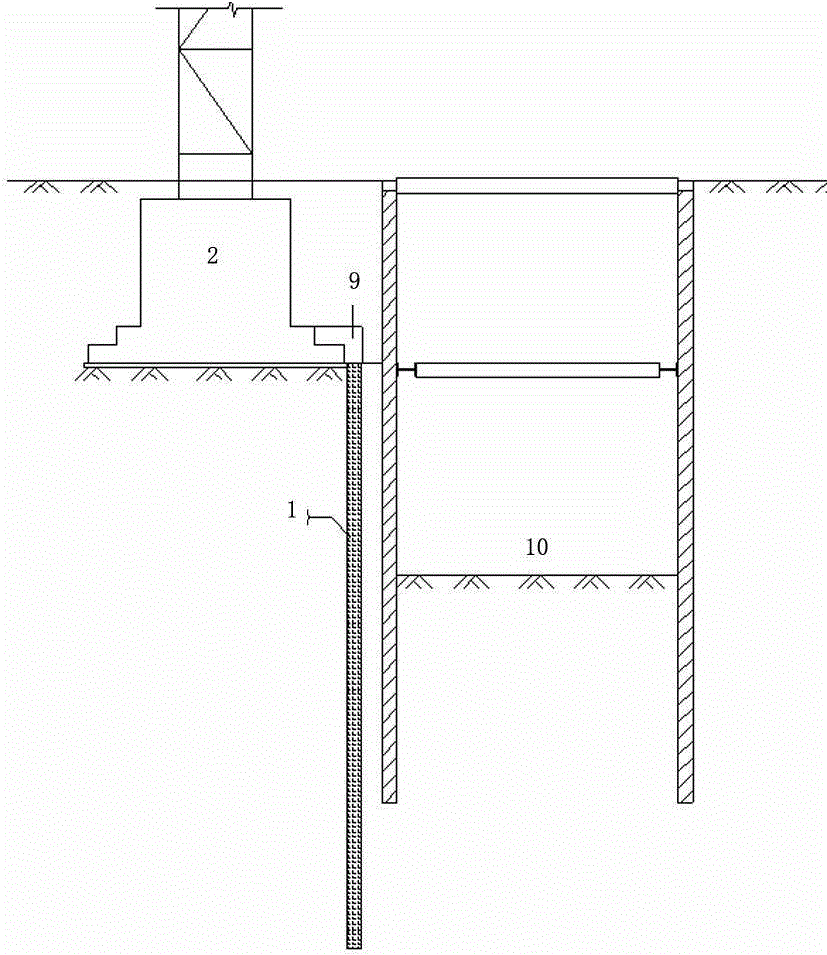

Caisson and pile combined foundation of consolidated subsoil and construction method of caisson and pile combined foundation

The invention discloses a caisson and pile combined foundation of consolidated subsoil and a construction method of the caisson and pile combined foundation. The caisson and pile combined foundation of the consolidated subsoil comprises the consolidated subsoil, a sand-gravel cushion, a caisson, bored piles, pile bottom grout, top seal concrete and scour protection. The main construction method comprises the following steps: consolidating the foundation with an underwater compaction sand pile or a deep-layer cement mixing pile; laying the sand-gravel cushion on the consolidated subsoil; sinking the caisson with a skirt, pile sinking guide holes and grouting reserved pipes on the sand-gravel cushion; after the caisson is located, constructing bored piles through the pile sinking guide holes; after construction of the bored piles, casting the top seal concrete at the bottom in the caisson; grouting the bottom of the caisson through the grouting reserved pipes at the bottom of the caisson, carrying out pile bottom grouting through grouting pipes in the pile, and at last casting the top plate of the caisson. In the construction process, the scour protection shall be performed around the caisson according to requirements. The caisson and pile combined foundation of the consolidated subsoil and the construction method of the caisson and pile combined foundation, disclosed by the invention, can effectively improve vertical and horizontal bearing capacity of the caisson, and control sedimentation and horizontal displacement of the caisson.

Owner:CCCC HIGHWAY CONSULTANTS +1

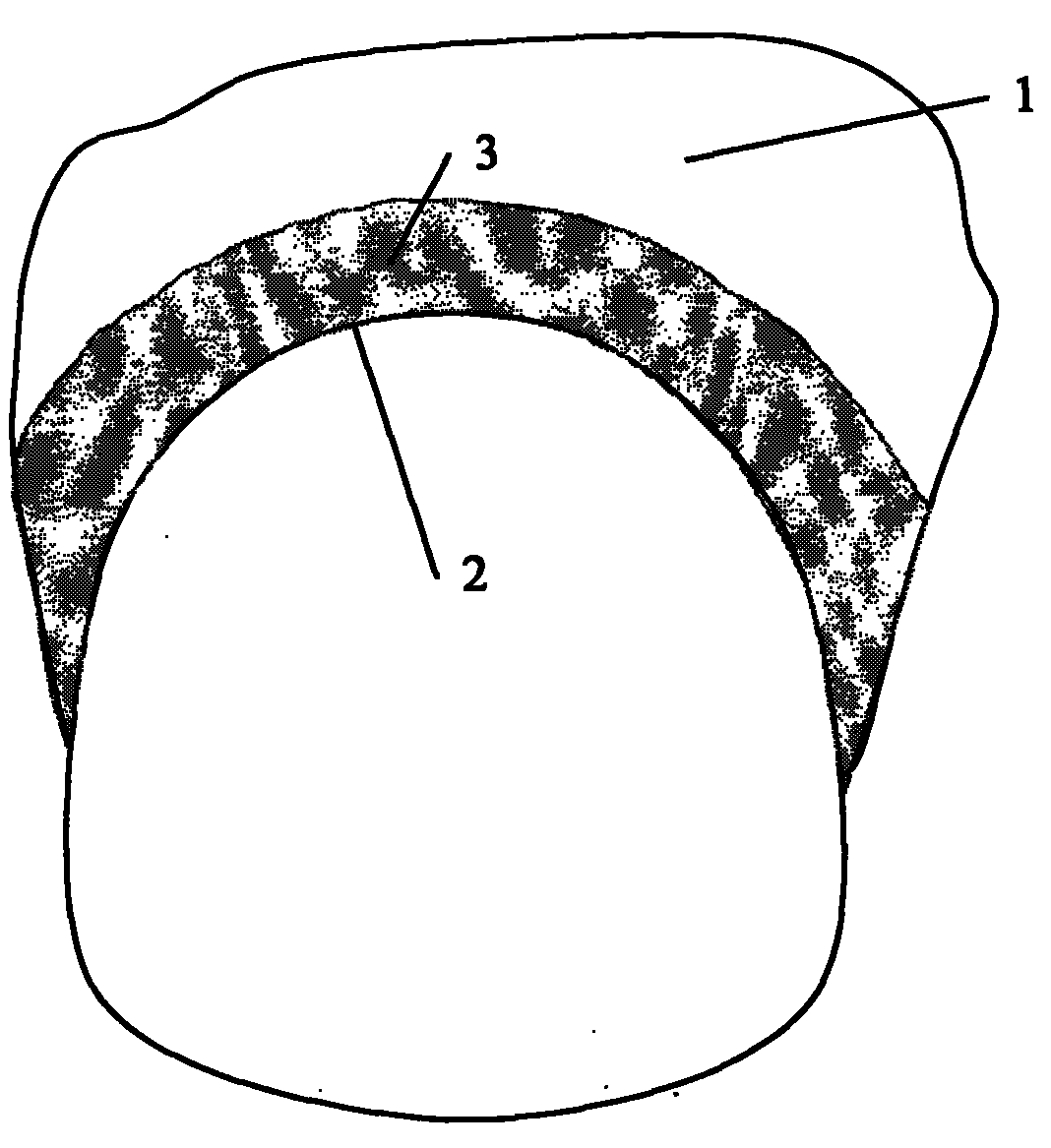

Method for grouting polymers for tunnel protection

InactiveCN102140919AStrong targetingImprove controllabilityUnderground chambersTunnel liningSocial benefitsControllability

The invention discloses a method for grouting polymers for tunnel protection. According to the method, a polymer material is grouted to the periphery of the lining structure of a tunnel aiming at dissolved cavities existing in tunnel surrounding rock or cavities caused by collapse of a tunnel, and the polymer material expands rapidly after a reaction to form a polymer buffer layer in the cavity at the periphery of the lining structure, thereby preventing rocks above the tunnel from falling to impact the tunnel lining. The method has the advantages of strong pertinence, good controllability, no disturbance to the lining, rapidness in construction, simple process, high efficiency and the like. Therefore, the polymer material with light weight and good elasticity has been successfully applied in the tunnel engineering, and shows the huge economic and social benefits and wide application prospect.

Owner:ZHENGZHOU URETEK TECH

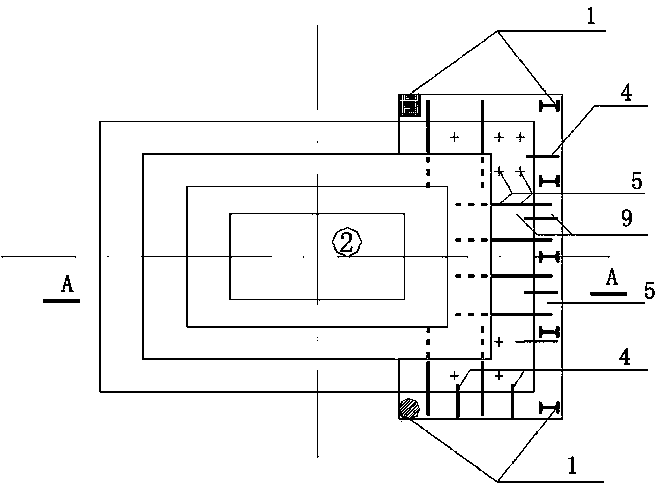

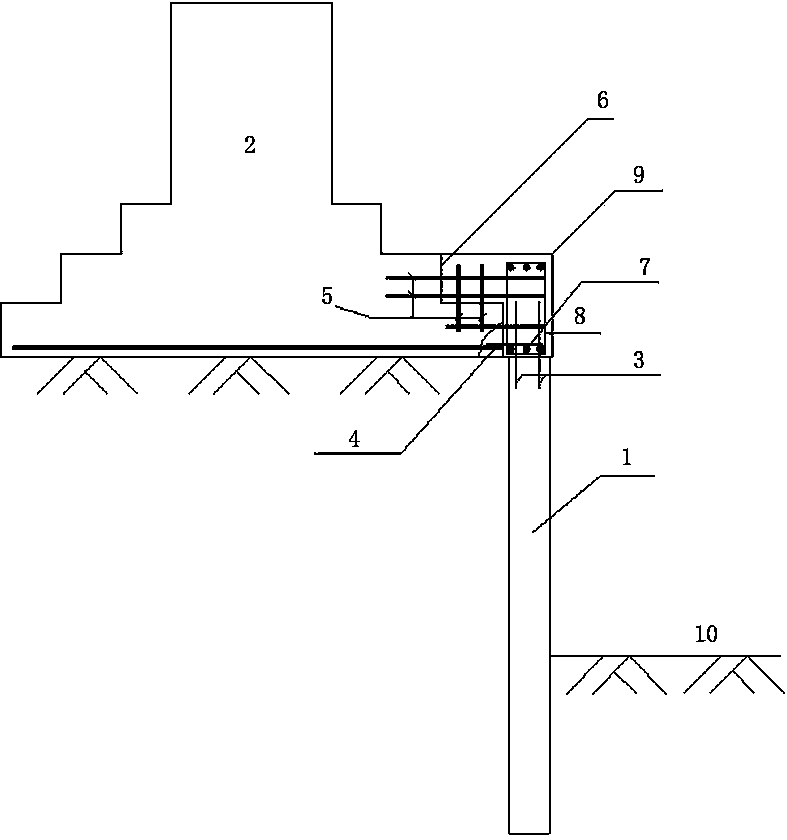

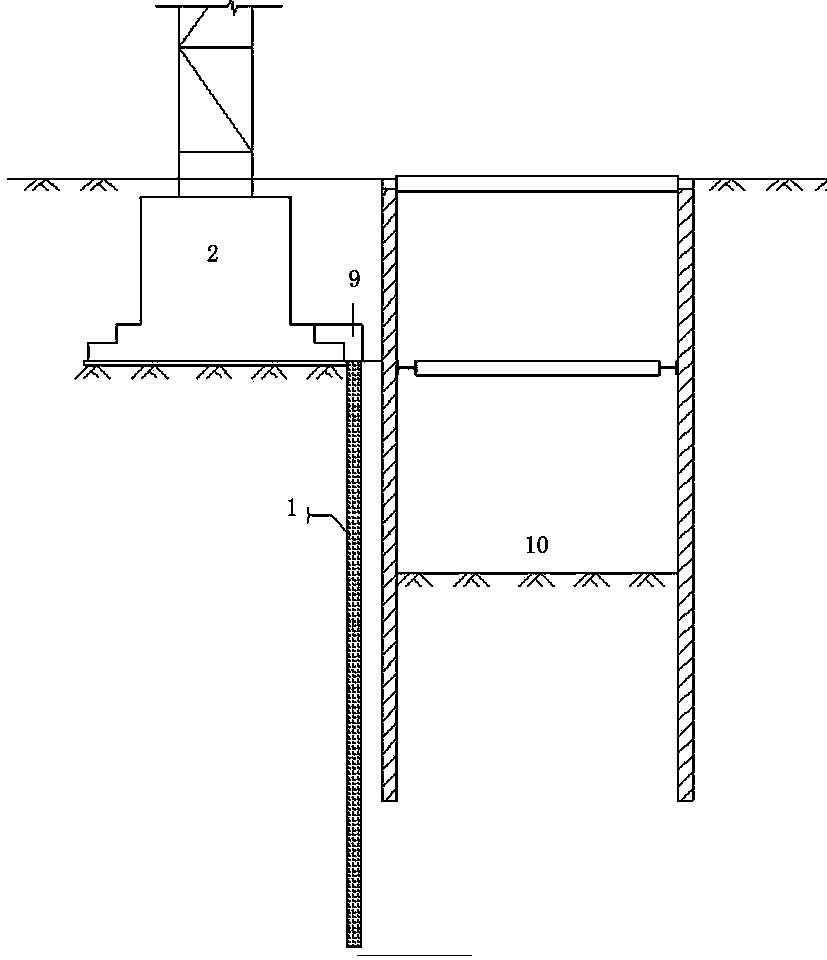

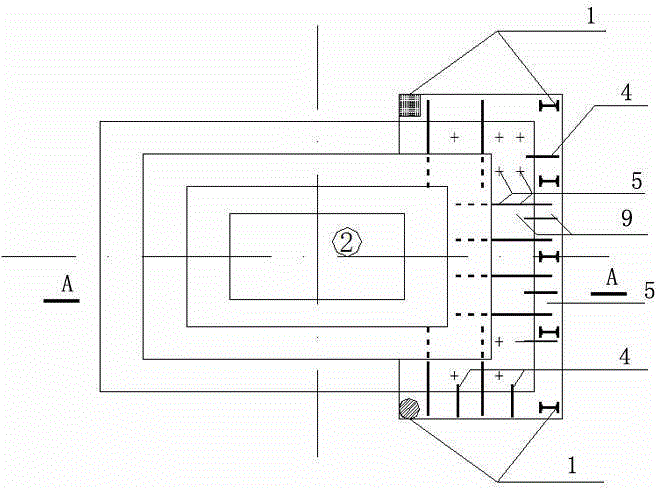

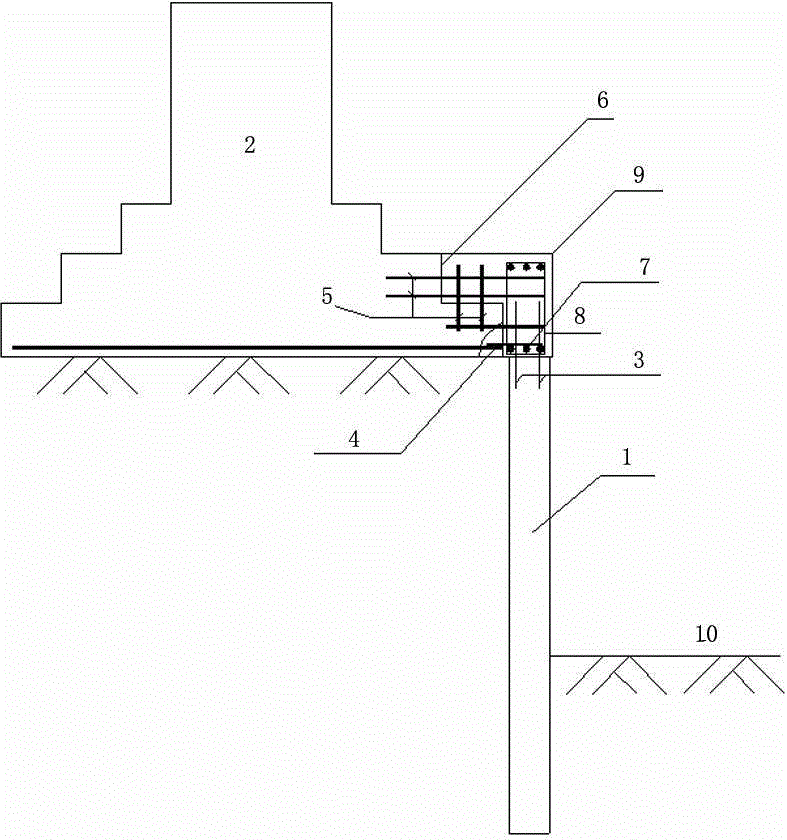

Pile foundation underpinning method for building foundation adjacent to deep foundation pit

ActiveCN104179204AMeet bending resistanceMeet punching resistanceFoundation repairArchitectural engineeringShear resistance

The invention relates to the technical field of civil engineering foundation reinforcing of industrial and civil construction projects, in particular to a pile foundation underpinning method for a building foundation adjacent to a deep foundation pit. The method includes the steps of firstly, investigating and designing, to be more specific, investigating the existing building, selecting foundation underpinning pile types according to building foundation size, buried depth, distance between the building foundation and the deep foundation pit and the depth of the deep foundation pit, calculating to determine the required length and number of foundation underpinning piles according to bearing capacity, allowing the foundation underpinning piles to exceed the depth of the bottom of the deep foundation pit, and completing ring beam design; secondly, pressing the piles at the edges of the building foundation; thirdly, performing pile foundation underpinning on the building foundation. The method has the advantages that the building foundation satisfies the requirements of bending resistance, punching resistance and shearing resistance by the aid of pile foundation underpinning, natural foundation bearing of the building foundation is changed into pile foundation bearing, additional load of the building foundation to the deep foundation pit is lowered greatly, sedimentation and horizontal displacement of the building foundation adjacent to the deep foundation pit are solved, and factory building safety is guaranteed.

Owner:山西钢铁建设(集团)有限公司

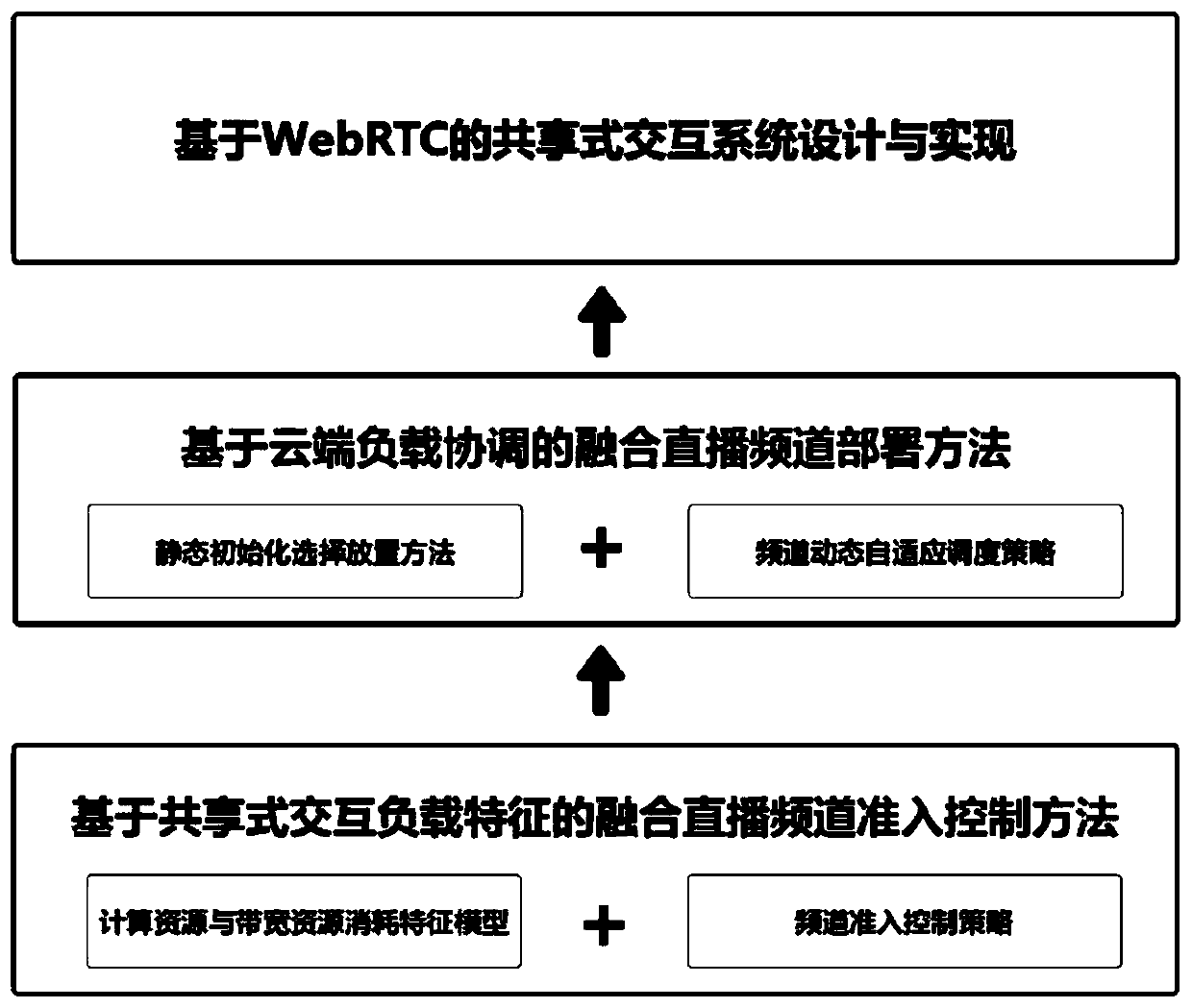

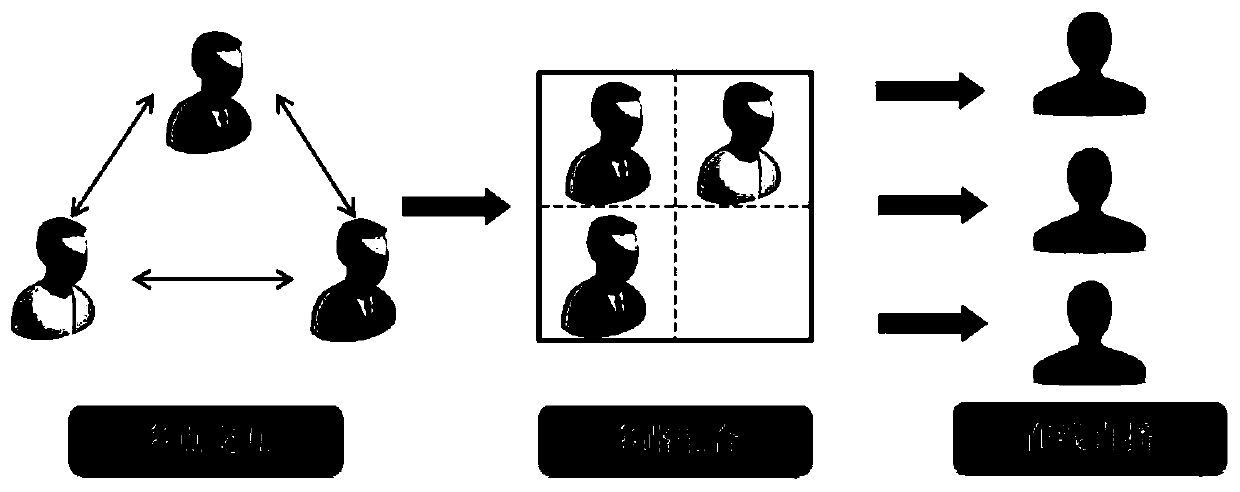

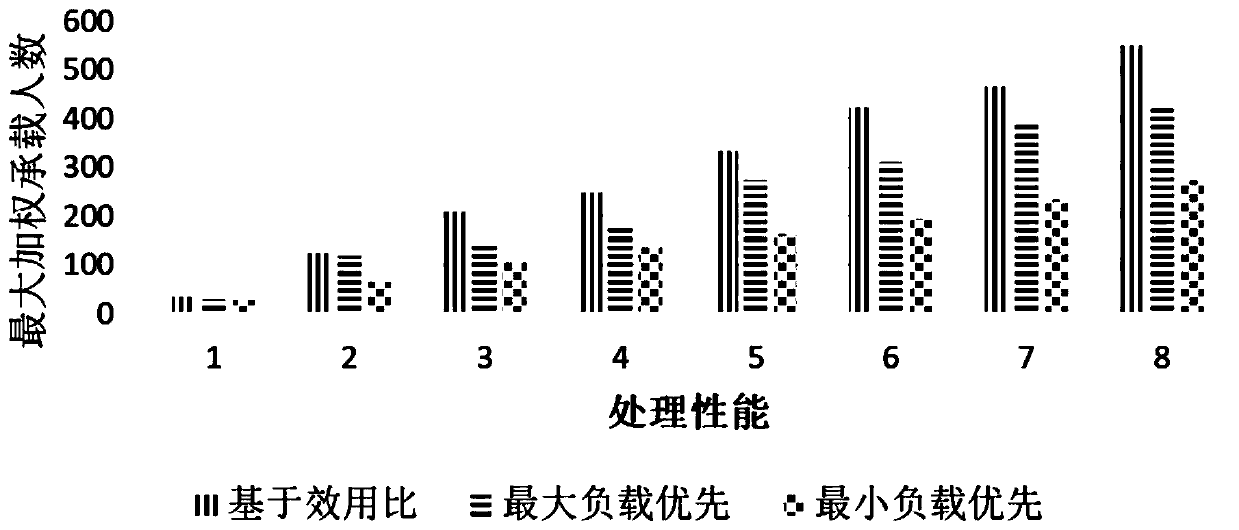

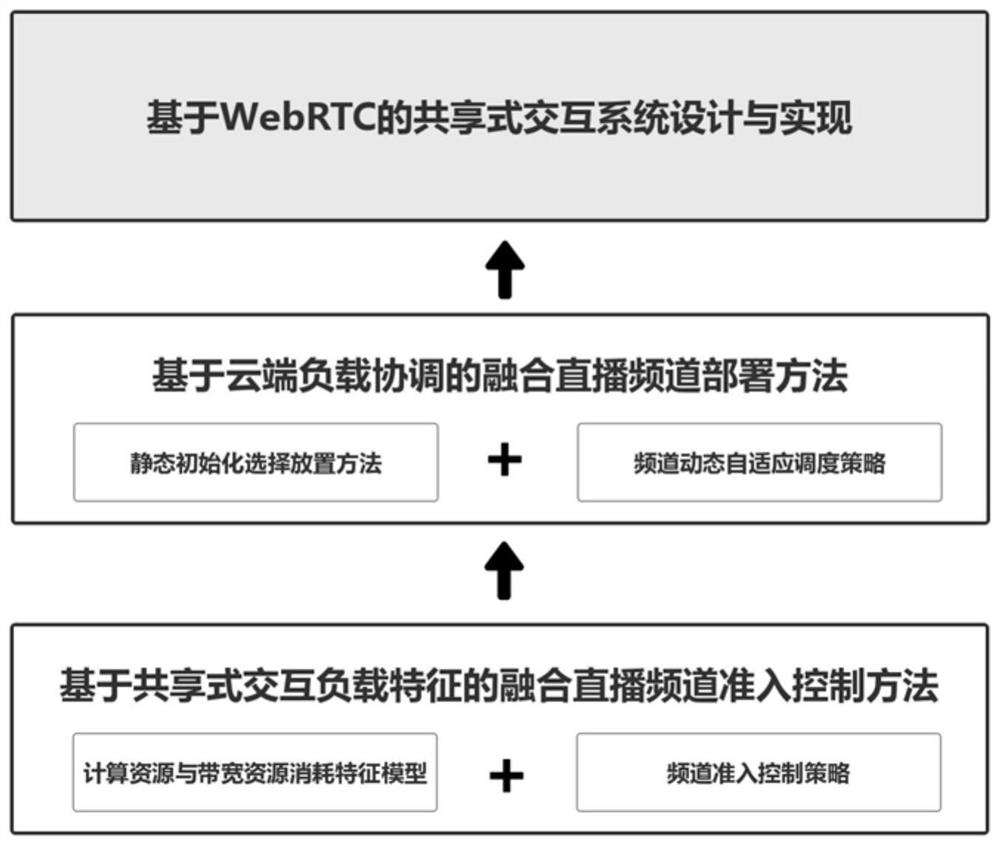

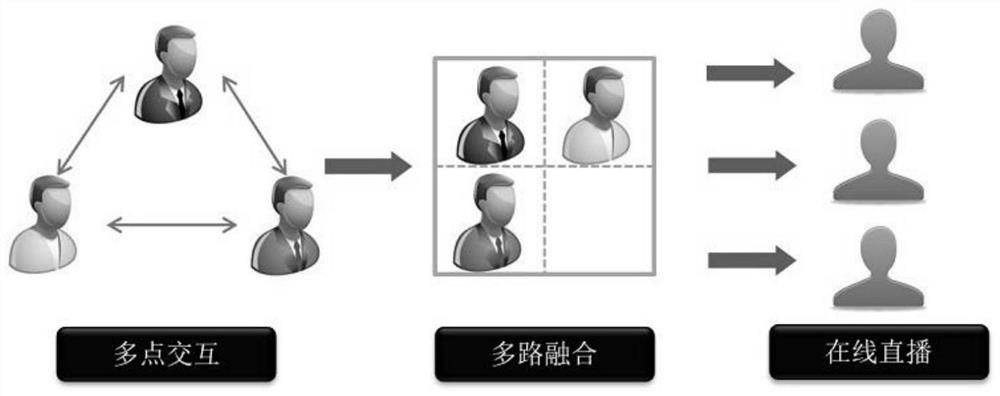

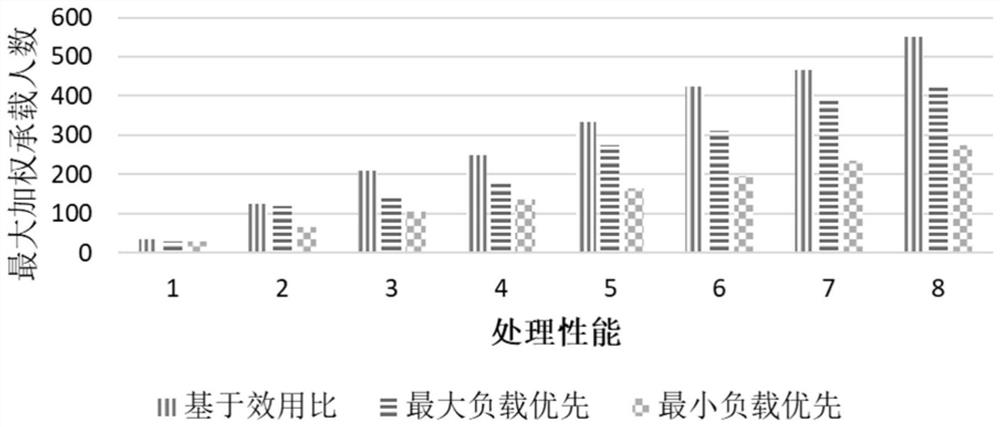

Fused video live channel deployment method in mobile cloud computing environment

ActiveCN110069342AImprove carrying capacityIncrease the number of usersResource allocationTransmissionSelf adaptiveTotal delay

The invention provides a deployment method of a fused video channel for balancing channel resources and coordinating cloud delay and local loads in a self-adaptive manner for a video application witha shared interactive load characteristic. The method comprises the following steps: firstly, a shared interactive system with a fused video live broadcast function is realized based on WebRTC and OpenCV; on the basis of the system, the three processes of application dissociation and independence are subjected to experiments, and a shared interactive resource-load model is obtained. On the basis,the channel resource load is estimated on the basis of the model, an admission control strategy is realized through a greedy heuristic algorithm based on a utility ratio, an admission priority sequence of the channel is generated, and a basis is provided for maximizing the system bearing capacity. In the deployment stage, firstly, a server for the channel is selected according to the principle ofminimum total delay for initial placement. Adaptive load balancing is carried out, and the load-delay model of the server is combined; a part of CPU load is released to the terminal so as to realize load-delay balancing between the terminal and the cloud end.

Owner:XI AN JIAOTONG UNIV +1

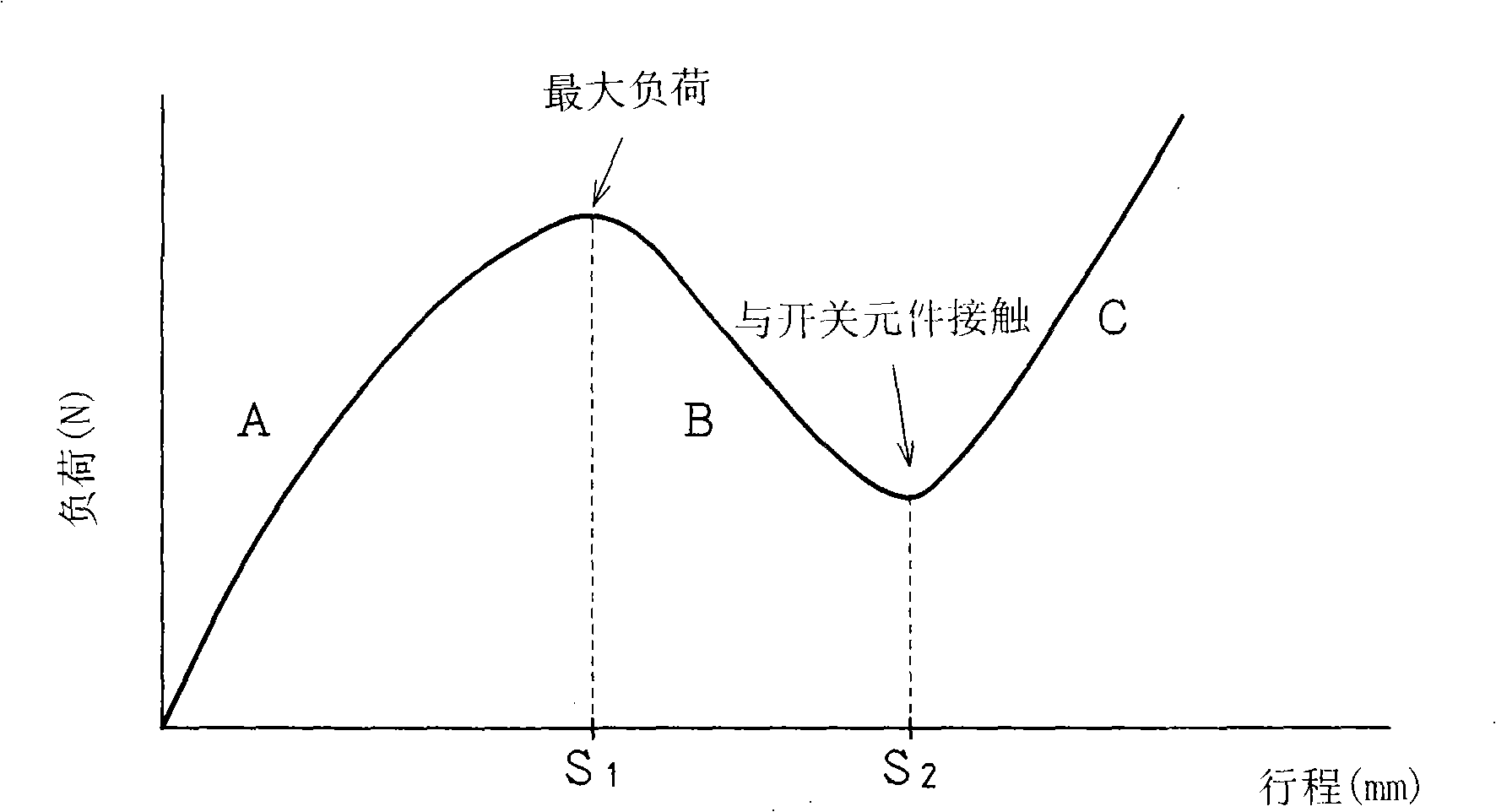

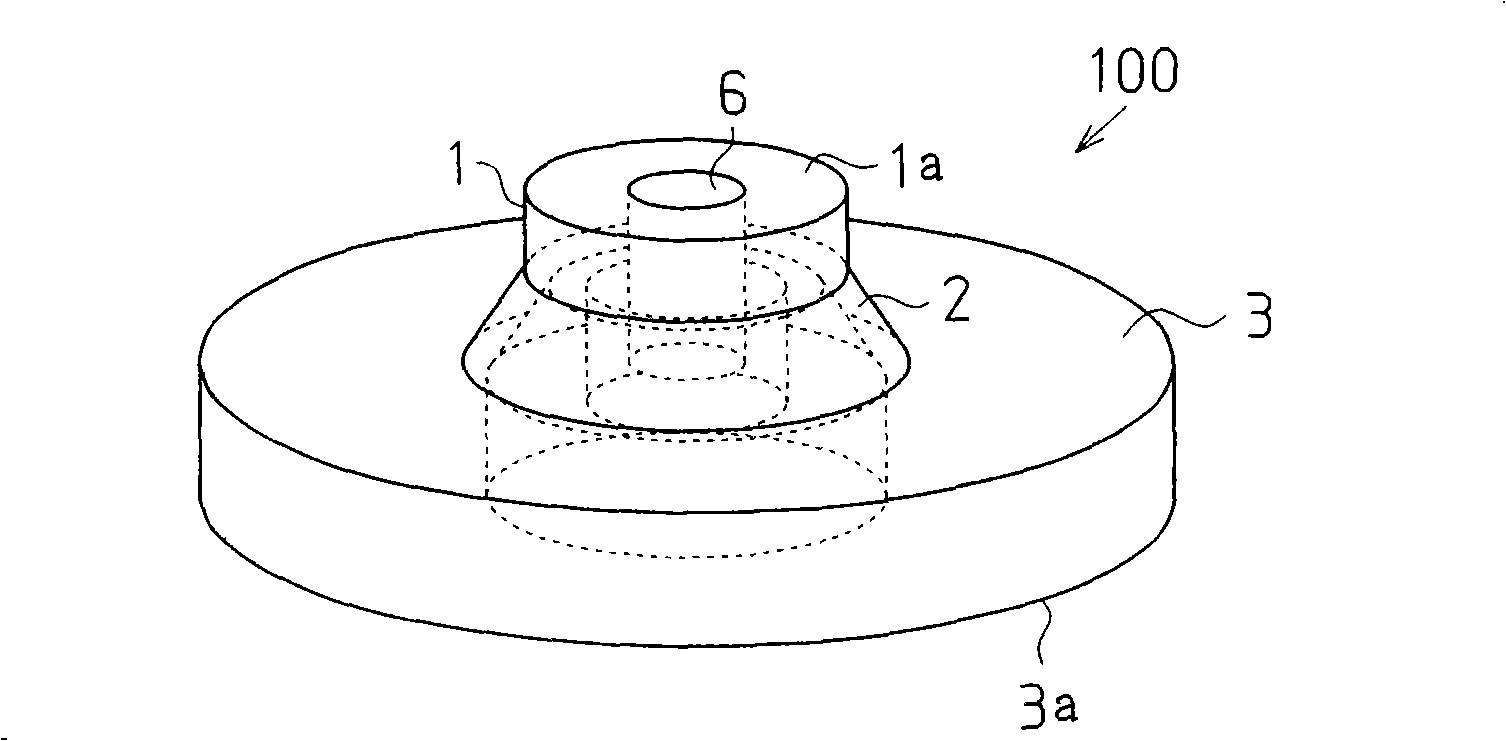

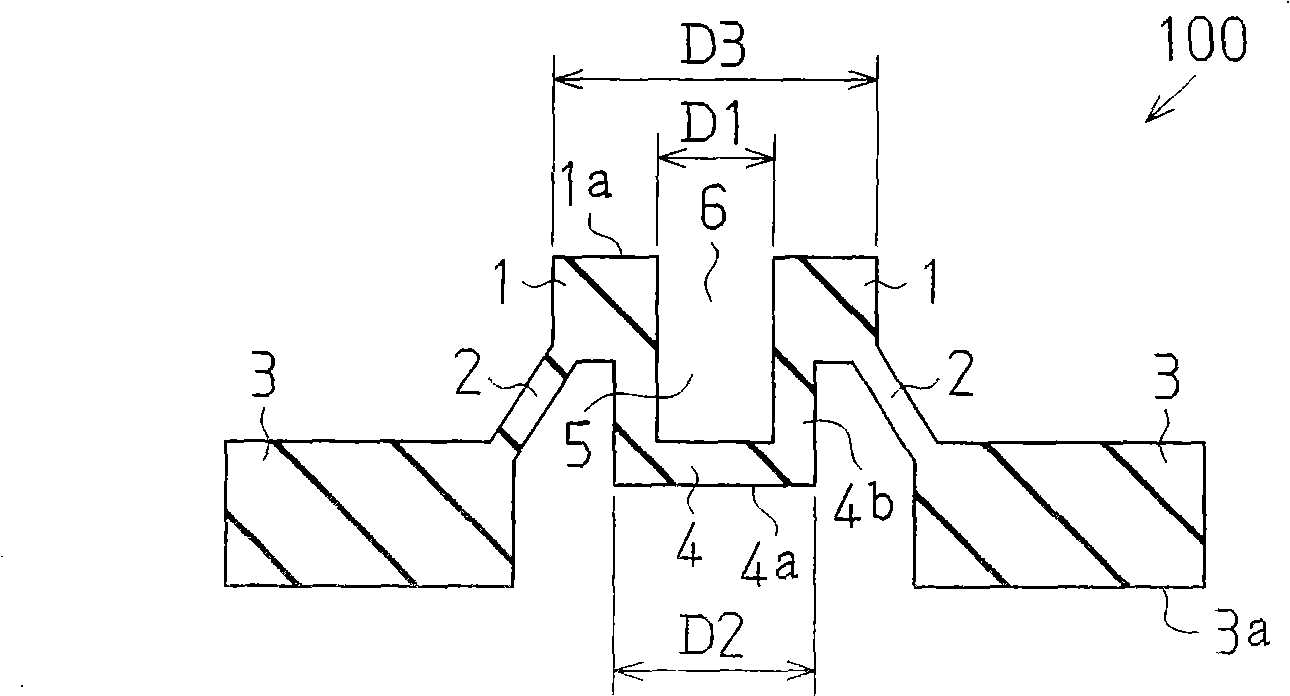

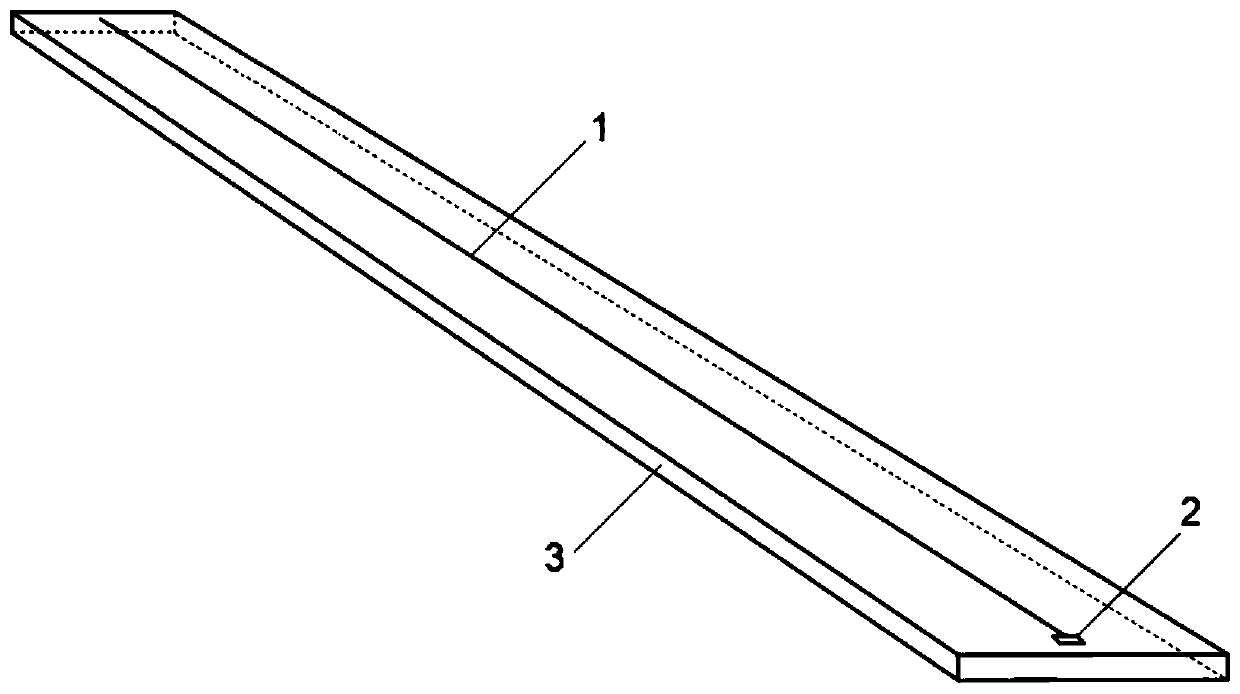

Elastic member for pushbutton switch

InactiveCN101297385AAdditional load is smallKey modulesElectric switchesTactile sensationEngineering

An elastic member for a pushbutton switch, providing soft tactile sensation to the operator when it is pushed down. The elastic material for a pushbutton switch has a base, a connection section extending from the base, a pressing section supported above the base by the connection section, and a projection section projecting downward from the pressing section. The inside of the projection section is hollow.

Owner:POLYMATECH CO LTD

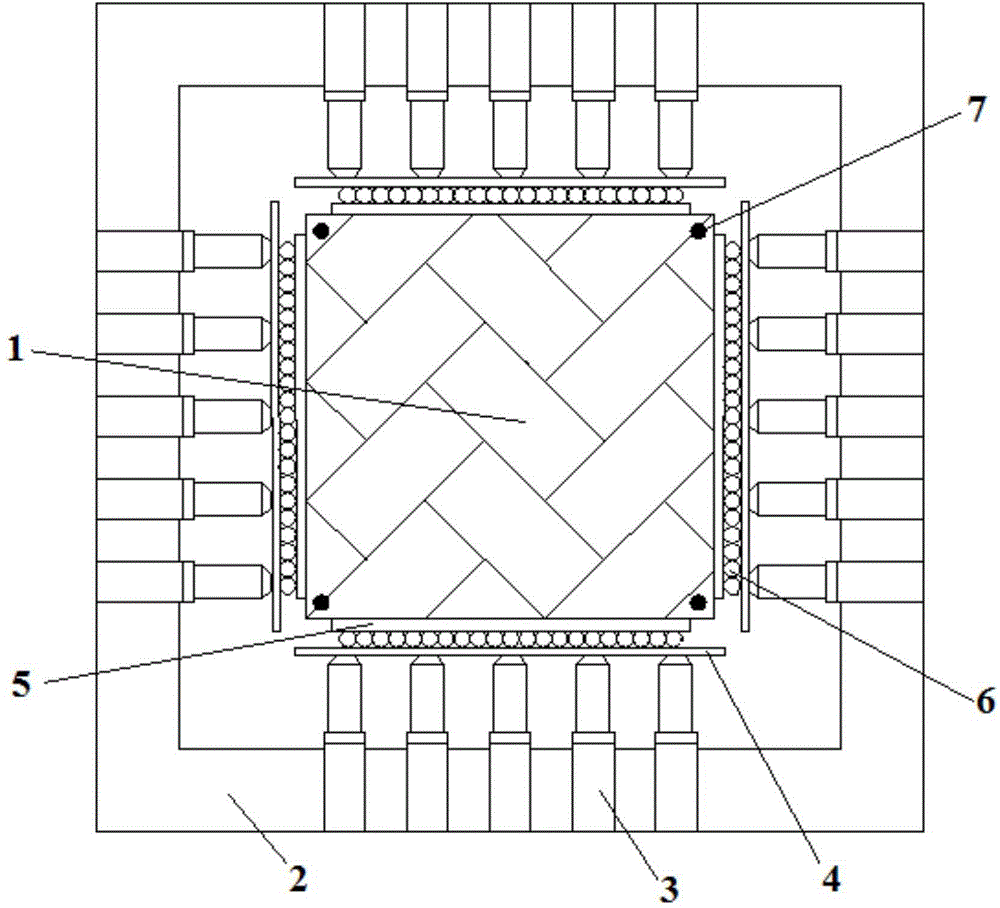

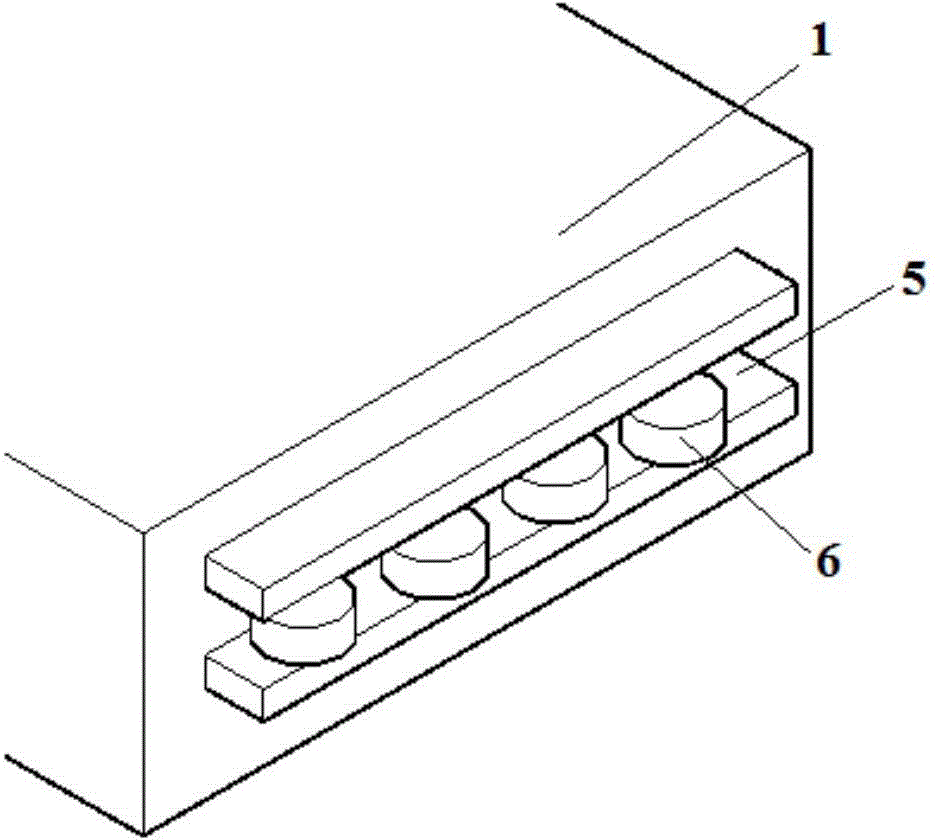

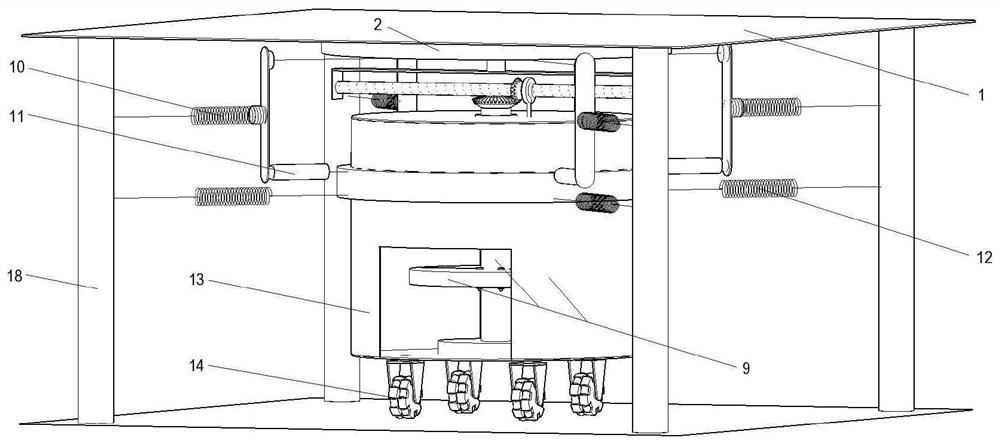

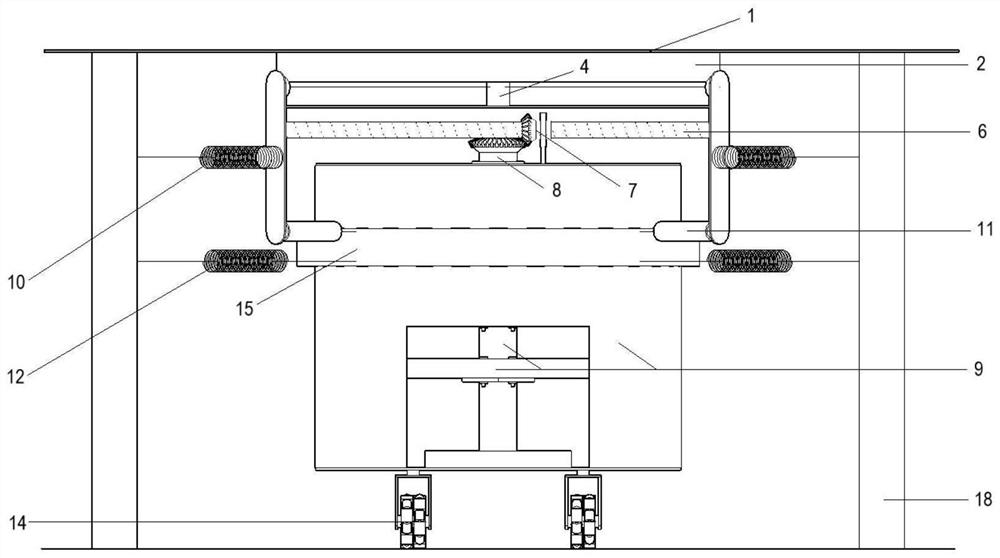

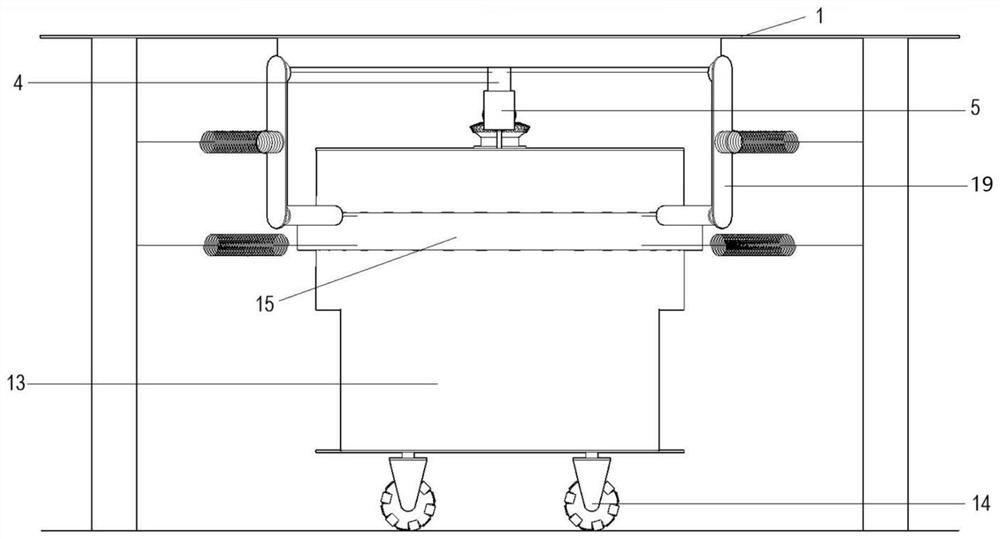

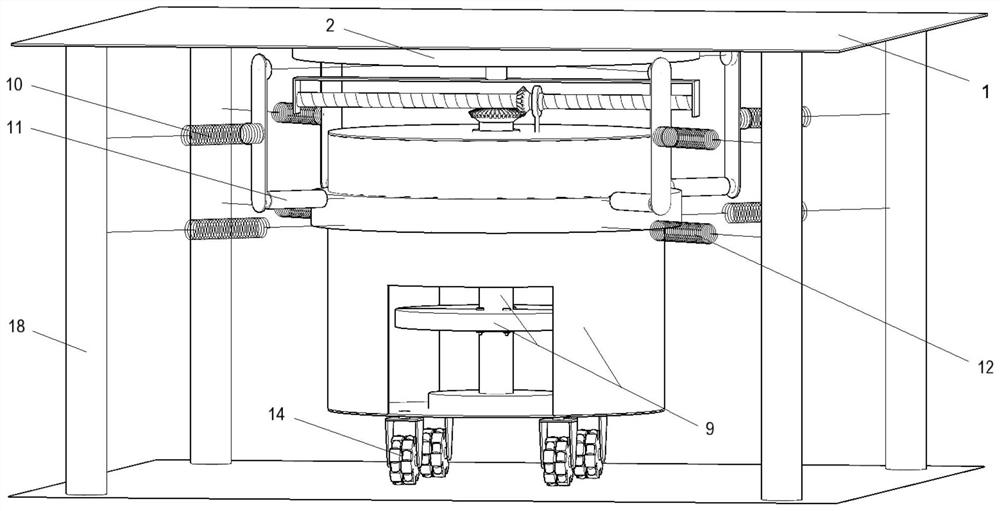

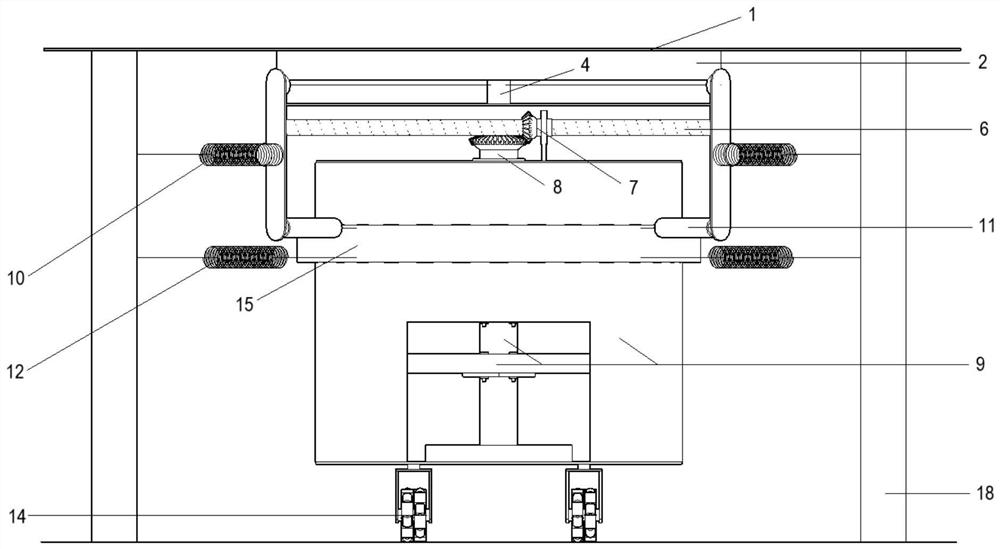

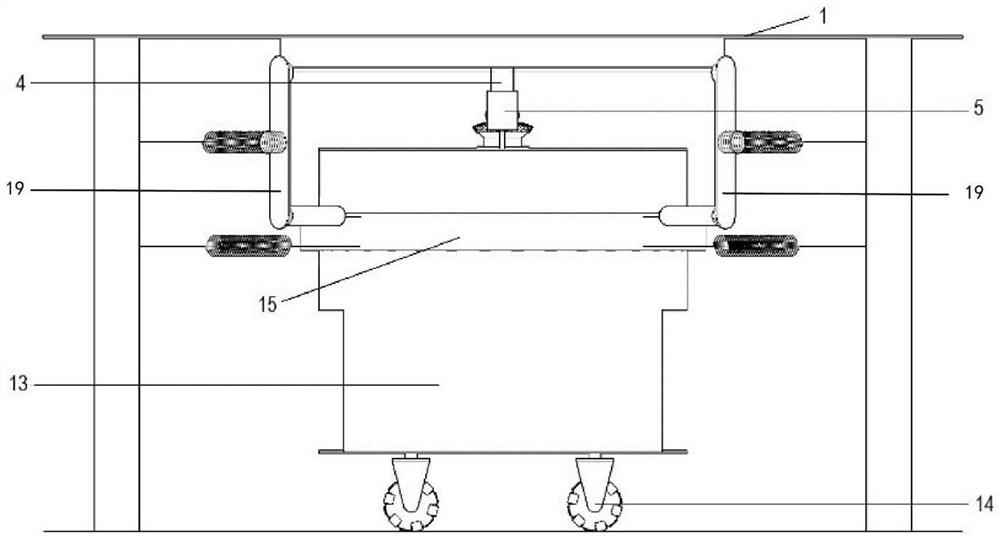

High-rise structure floor slab shock absorption structure releasing multi-direction freedom degrees

InactiveCN104790549AMulti-directional freedom releaseRealize the effect of shock absorption and shock resistanceFloorsShock proofingFloor slabEngineering

The invention relates to a high-rise structure floor slab shock absorption structure releasing multi-direction freedom degrees. The floor slab shock absorption structure comprises a body stress frame and a buffering damping mechanism arranged in the body stress frame and applying a tuning function on the body stress frame; the body stress frame comprises a foundation slab, shear walls vertically arranged on the foundation slab and rigid cross beams arranged at the tops of the shear walls, the buffering damping mechanism comprises floor slabs arranged on multiple layers in parallel at equal intervals and elastic buffering units arranged around the floor slabs, and the floor slabs are connected with the shear walls through the elastic buffering units in a sliding mode. Compared with the prior art, the shock absorption structure is simple in structure and compact in layout; as viscous dampers are arranged in the four directions of the body stress frame, and rolling wheels are arranged in the four directions of the floor slab, the multi-direction freedom degrees of the floor slabs can be released, the shock absorption effect is excellent, and the shock absorption structure has excellent application prospects.

Owner:TONGJI UNIV

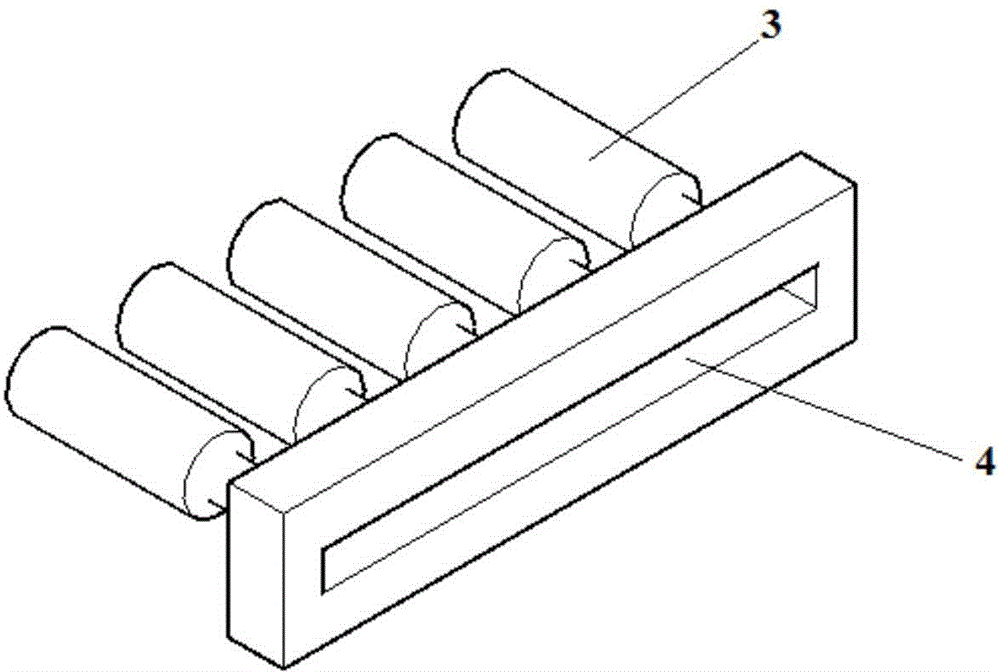

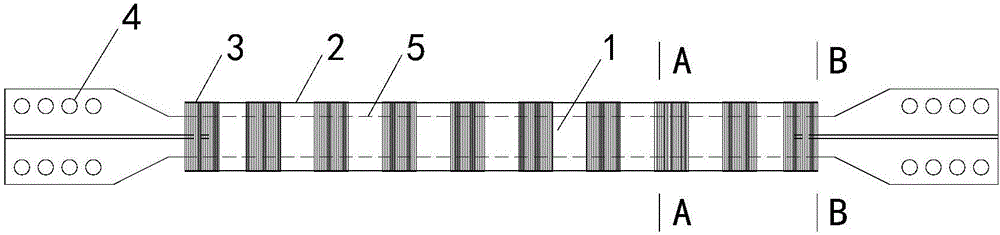

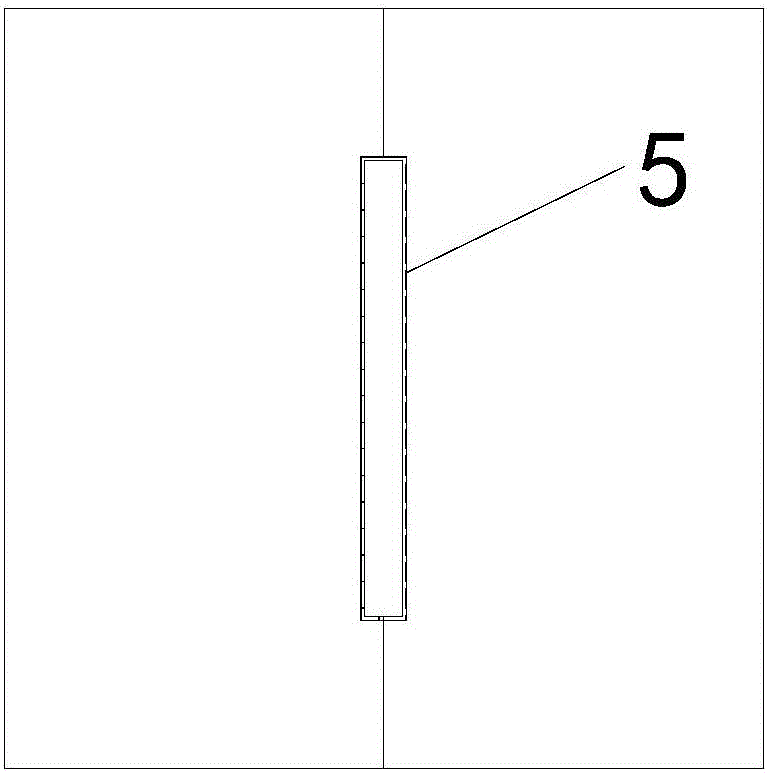

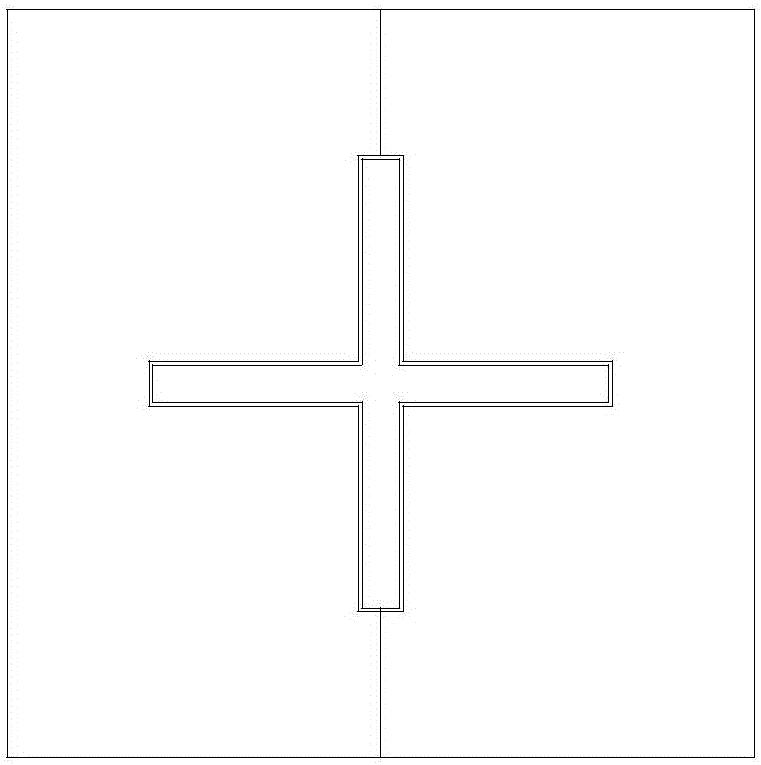

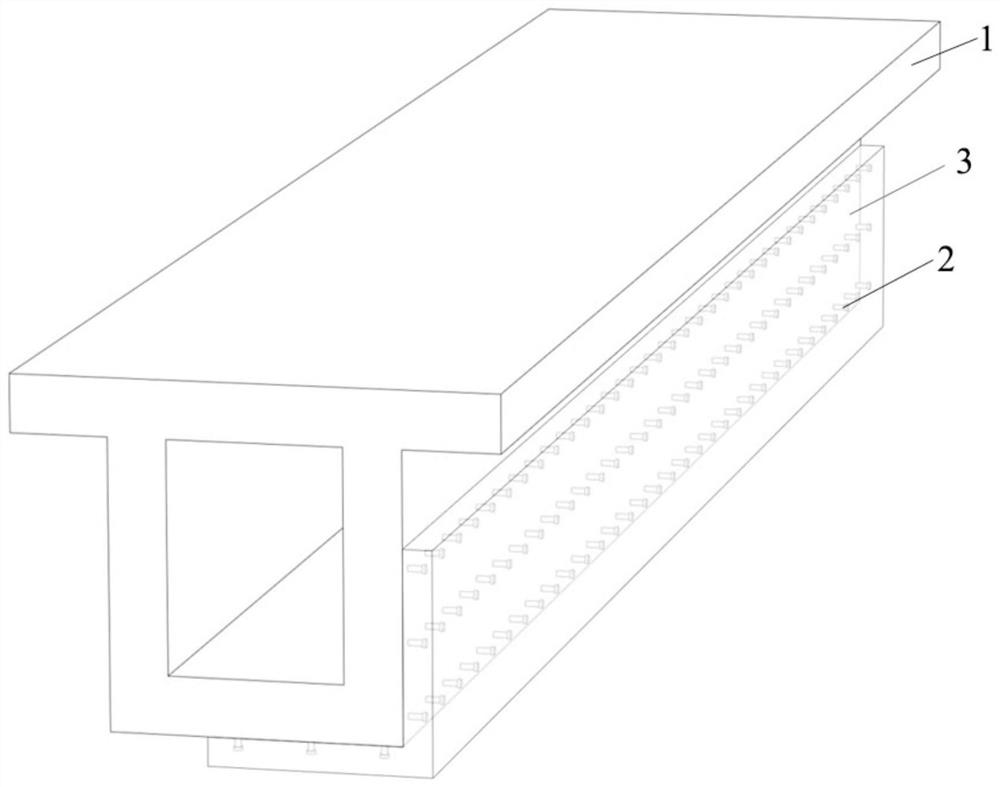

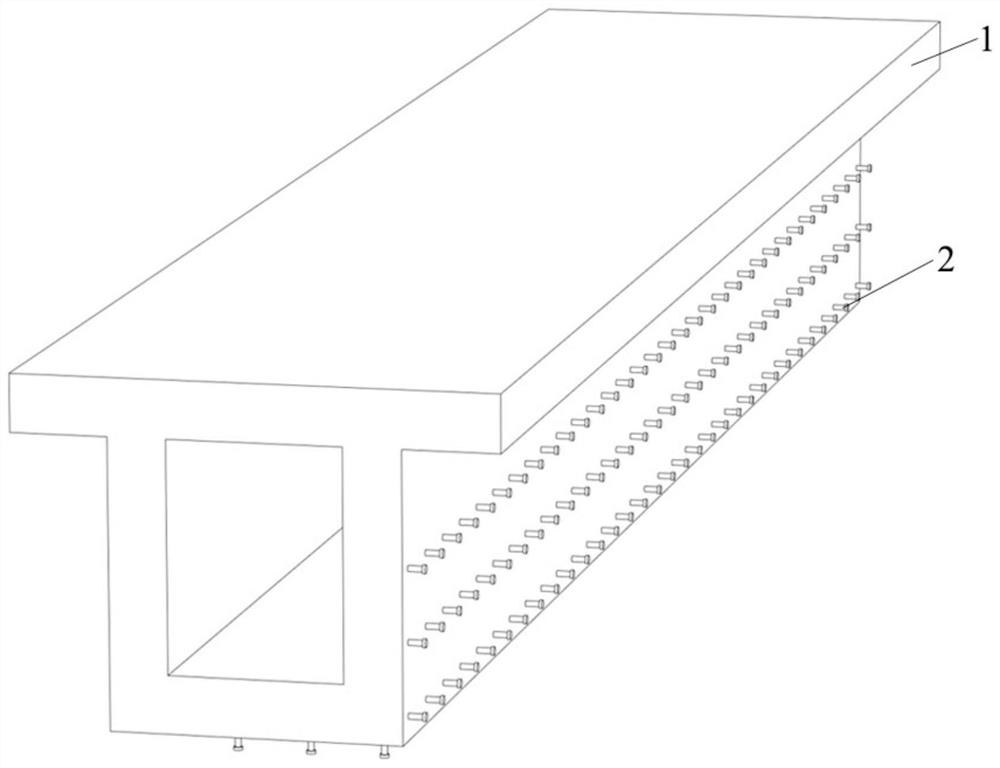

Novel buckling energy consumption support

InactiveCN106593060ALight weightAdditional load is smallProtective buildings/sheltersShock proofingEngineeringEnergy consumption

The invention discloses a steel and wood buckling energy consumption support and belongs to the technical field of structural engineering. The buckling energy consumption support comprises a core force bearing steel plate, a periphery constraint part and a no-bonding layer, wherein the main body part of inner core force bearing steel plate is in a linear shape. Connecting sections and transition sections at the two ends of the inner core force bearing steel plate are welded to an auxiliary connecting plate to form a cross-shaped cross section. The periphery constraint part is composed of a wood block wrapped with a steel plate and a CFRP material wrapped transversely in the length direction of a member together. The no-bonding layer is arranged between the core steel plate and the constraint wood block. The invention belongs to the technical field of civil engineering structural damping. Hysteretic energy performance of the steel support member under the effect of a strong earthquake is obviously improved. Compared with the prior art, the process of twining the CFRP outside is adopted in the steel and wood buckling energy consumption support, the structure is compact, the economical and practical effects are achieved. A constraint unit is made of light weight timber, so that the shortcoming that the self weight of a traditional buckling preventing energy consumption support is large is overcome. The steel and wood buckling energy consumption support is easy to machine, is convenient and flexible to use, and has wide market popularizing prospects.

Owner:TONGJI UNIV

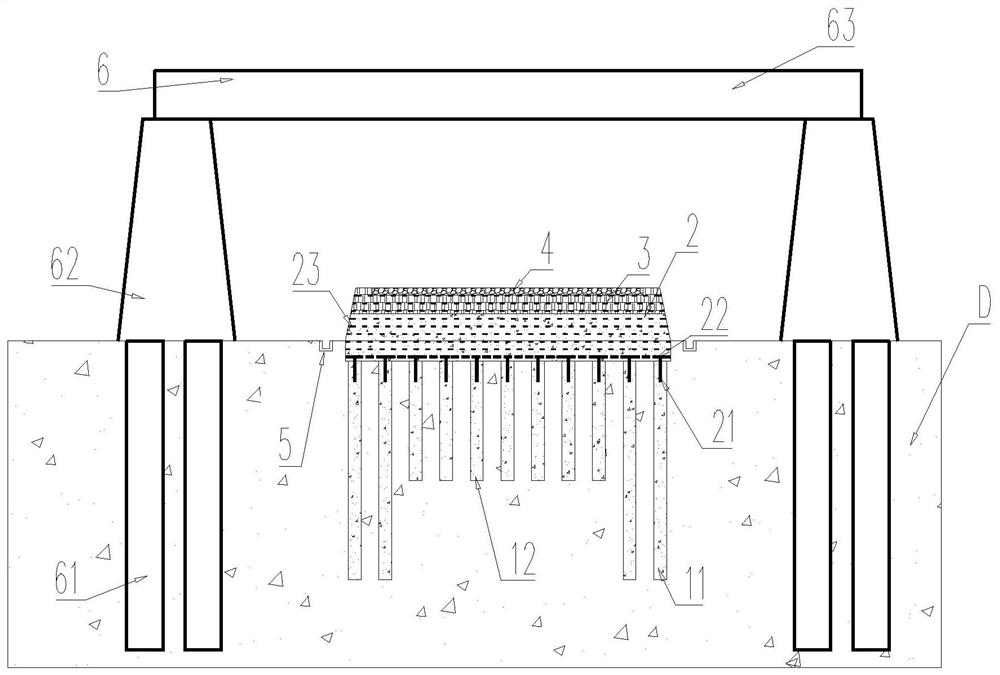

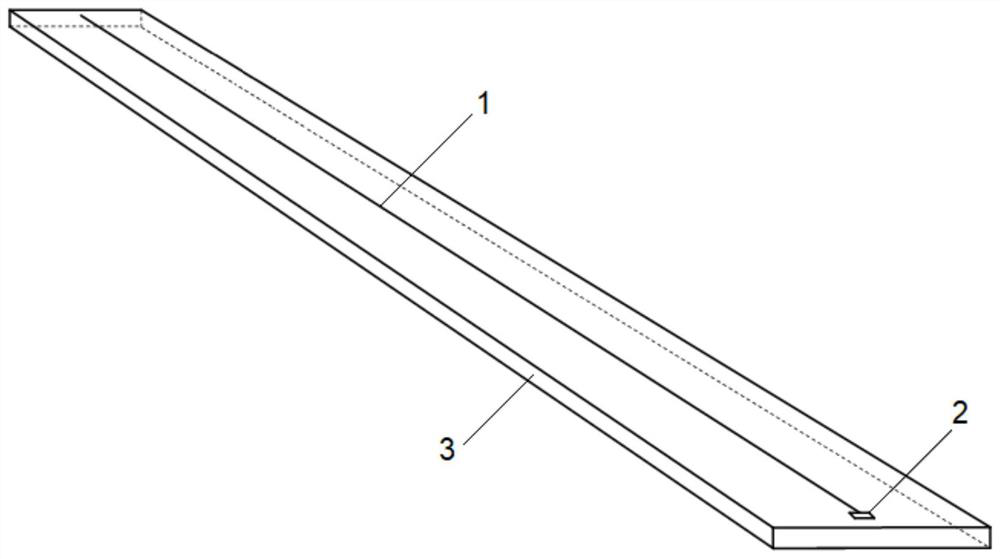

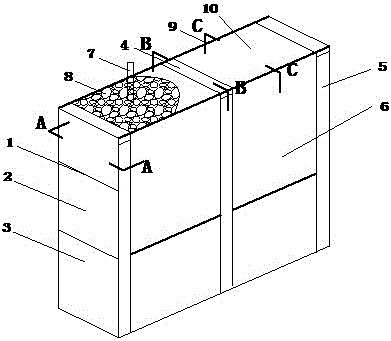

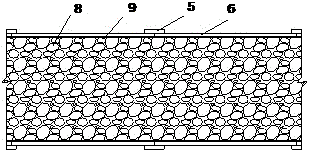

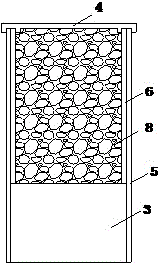

Novel wharf structure quickly constructed on soft foundation and construction method thereof

ActiveCN104389291ASimple structureFast chemical reactionBreakwatersQuaysEngineeringStructural engineering

The invention discloses a novel wharf structure quickly constructed on a soft foundation, and belongs to the field of wharf engineering. The novel wharf structure comprises two rows of long piles and two rows of short pile plates which are symmetrically arranged, the two rows of short pipe plates are respectively arranged inside the two rows of long piles in an opposite direction, a short plate pile is arranged between two adjacent long piles in each row of long piles, and a joint between every adjacent short plate piles is covered by the long pile arranged outside the short plate pipes; geotechnical cloths are paved in the opposite sides of the two rows of short pile plates, an area for filling is formed between the geotechnical cloths at the two sides and internally and vertically provided with grouting pipes in an equal interval way, and rubble complexes are filled in the area. The invention further discloses a construction method of the wharf. By adopting the long piles and short pile plates, the wharf structure is simple, and the stability of the wharf can be improved; furthermore, the structure has the characteristics of being light in weight and smaller in additional load to the foundation; meanwhile, the construction method of the wharf structure is simple to operate and low in cost, and is likely to popularize and apply.

Owner:YUSHUN ECOLOGICAL CONSTR +1

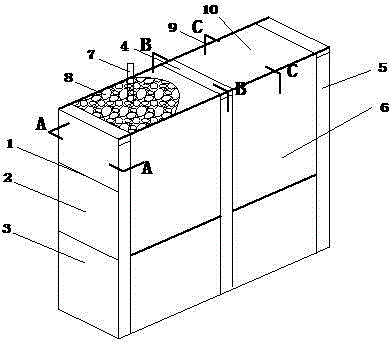

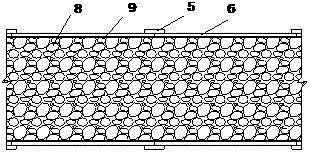

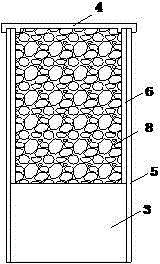

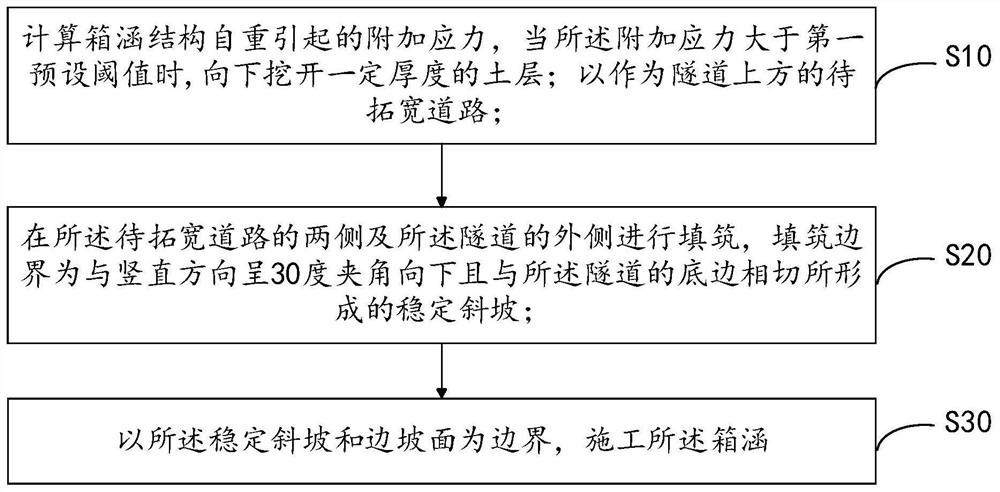

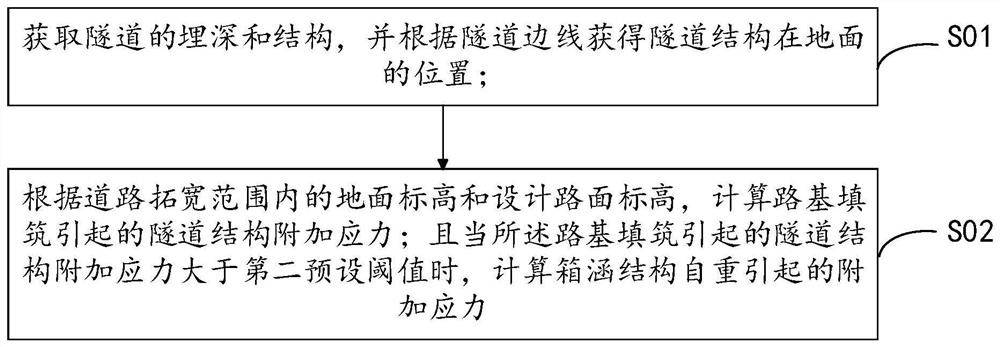

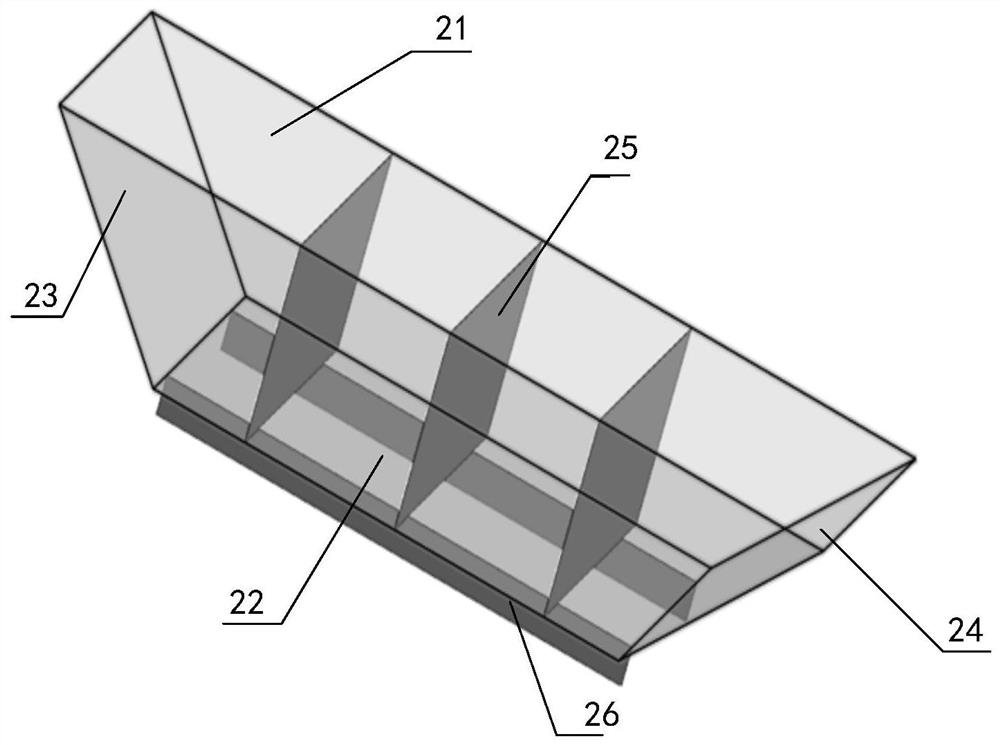

Box culvert construction method for broadening road and box culvert

ActiveCN112695656AReduce roadbed fill loadAdditional load is smallGround-workClimate change adaptationCulvertCivil engineering

The invention discloses a box culvert construction method for broadening a road and a box culvert, the method comprises the following steps: calculating additional stress caused by self weight of a box culvert structure, and when the additional stress is greater than a first preset threshold, digging a soil layer with a certain thickness downwards; wherein the optimal thickness range is 1-3m, and then the road to be broadened above the tunnel is formed; performing filling on the two sides of the road to be widened and the outer side of the tunnel, and the filling boundary is a stable slope which forms a downward 30-degree included angle with the vertical direction and is tangent to the bottom edge of the tunnel; and constructing the box culvert with the stable slope and the side slope face as boundaries. According to the box culvert construction method for widening the road, the roadbed filling load of a newly-built widening road is reduced, the additional load of a tunnel structure and disturbance of tunnel surrounding rock are reduced, tunnel structure deformation cracking and differential settlement caused by filling construction above the tunnel are avoided, and the box culvert construction method has the advantages of being fast in construction, high in reliability and good in durability.

Owner:GUANGZHOU METRO DESIGN & RES INST

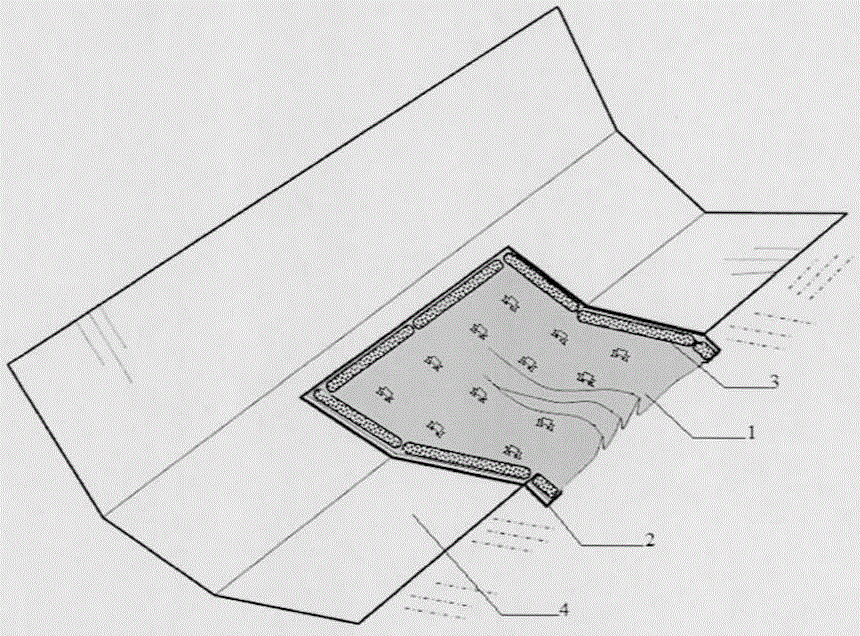

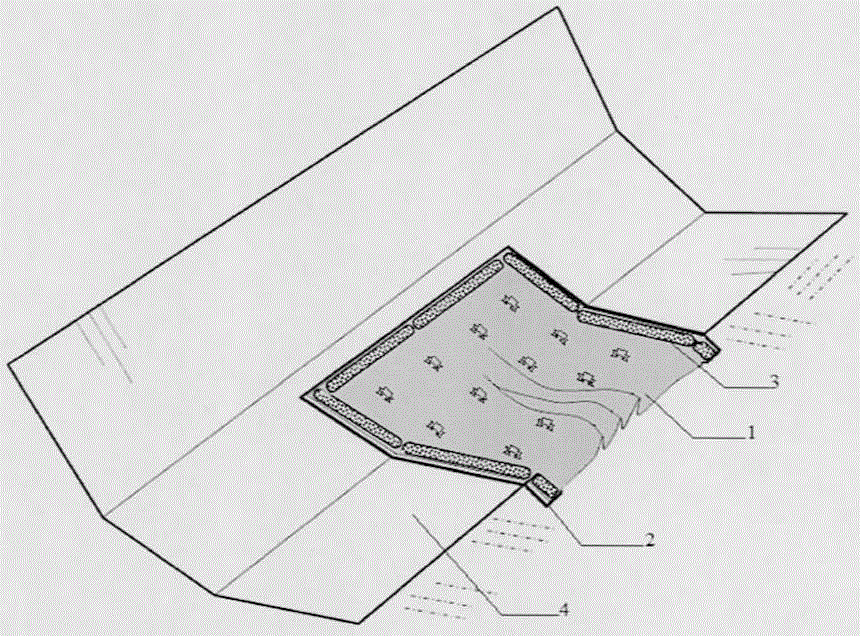

Top film water-retaining method for underwater canal lining overhaul

InactiveCN105040645ALess investmentWon't hurtArtificial water canalsMarine site engineeringWorking spaceEnvironmental geology

The invention relates to a top film water-retaining method for underwater canal lining overhaul. The top film water-retaining method comprises the following construction process steps: additionally installing a sealing layer on an edge needing to be sealed and a downstream face of a flexible waterproof film respectively, and additionally installing a counter weight on an upstream face; sinking downwards the downstream face of the flexible waterproof film into water, laying the flexible waterproof film on the surface of a canal lining in an area to be overhauled, and exposing the unsealed edge of the flexible waterproof film above the water level of water edge. The waterproof film in the top film water-retaining method disclosed by the invention is low in investment, simple in structure, environment-friendly in material selection, good in water-stopping effect, low in additional load, free from damages to the canal lining, convenient and fast to transport, install and transfer in water, capable of being supported by a floating crane, a movable maintenance cabin and a maintenance gallery, and the like to provide a flexible working space for lining maintenance on the provided working base surface, and also capable of being used as a rush emergency water-retaining curtain for preventing a slide area from expansion.

Owner:贾永奕

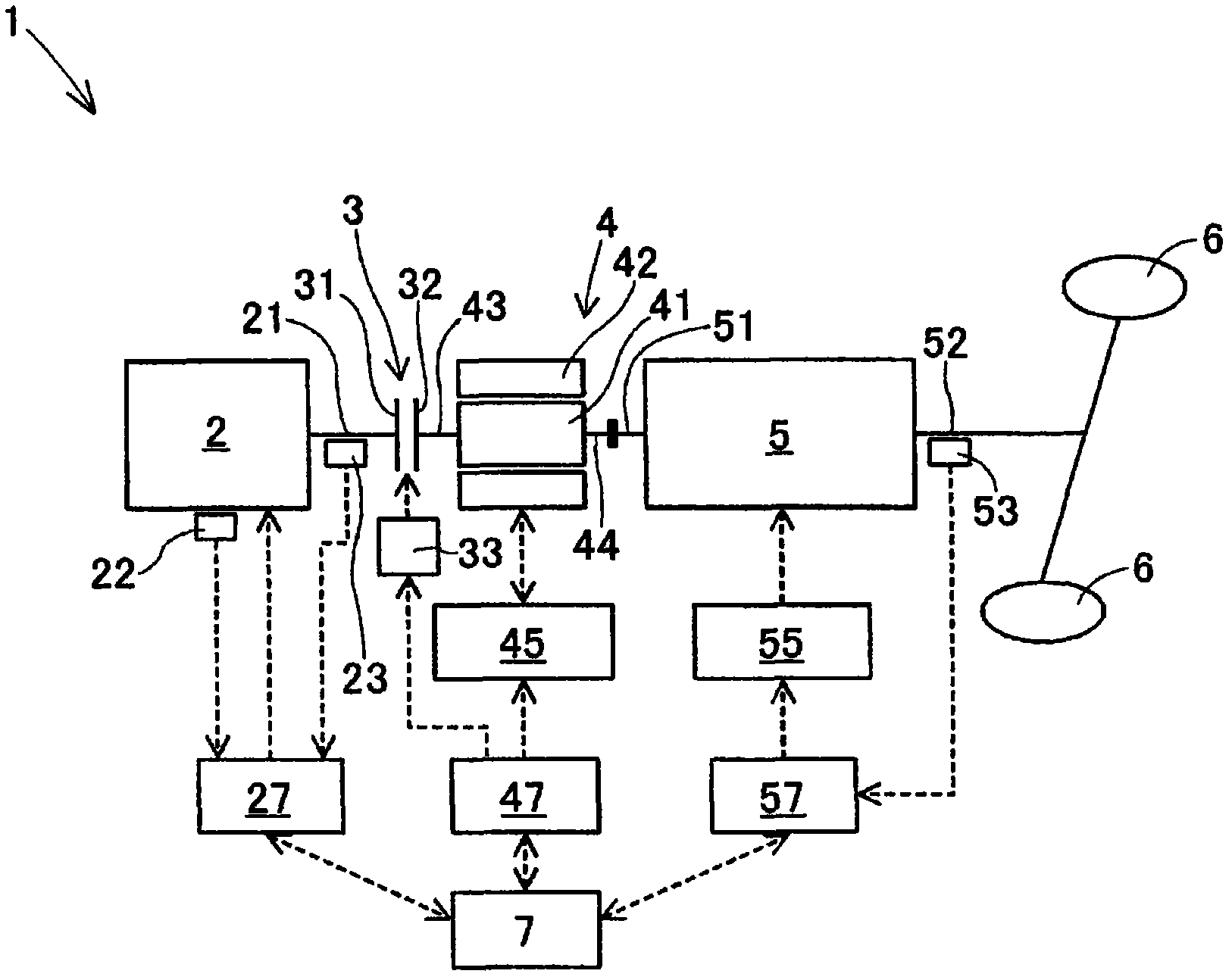

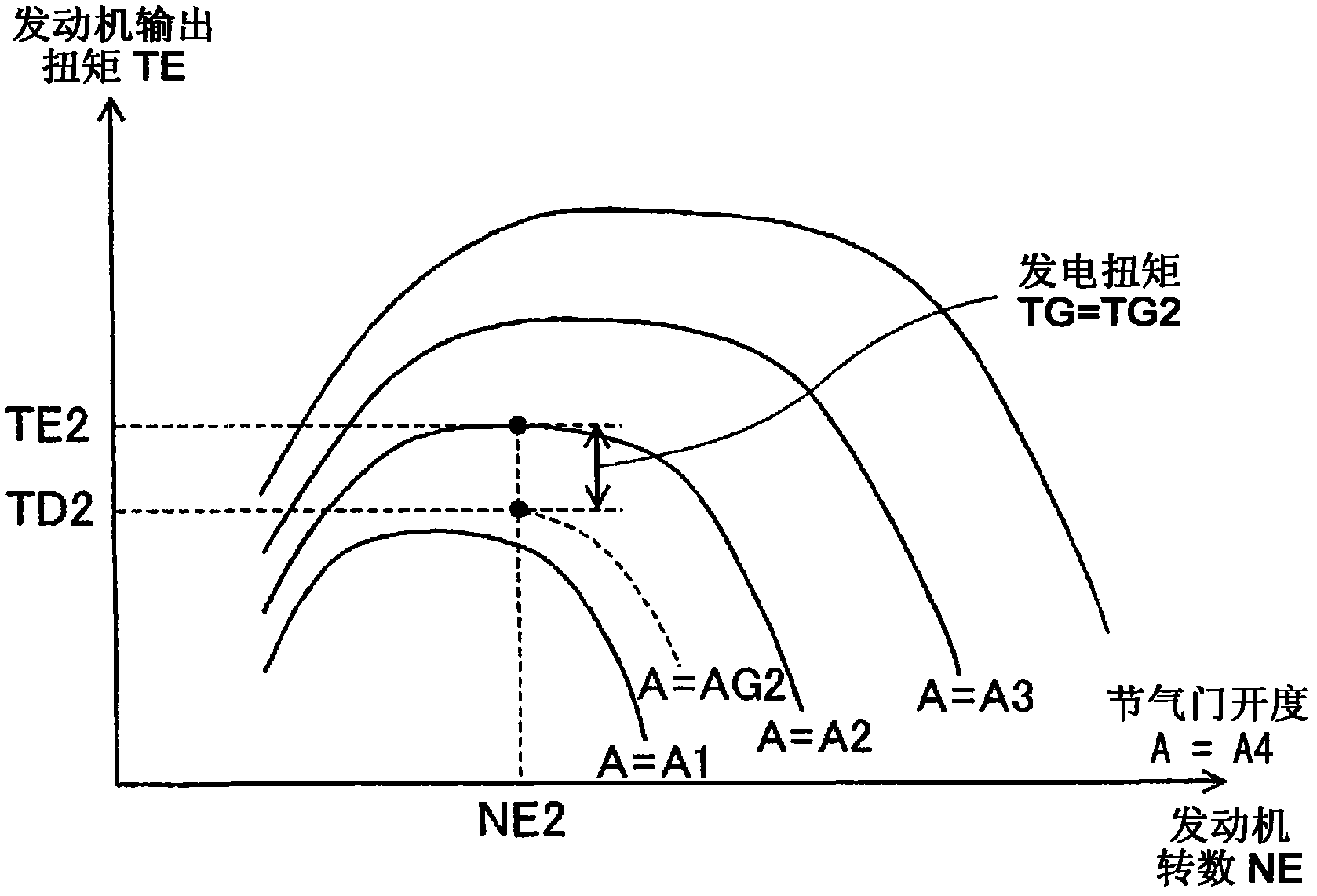

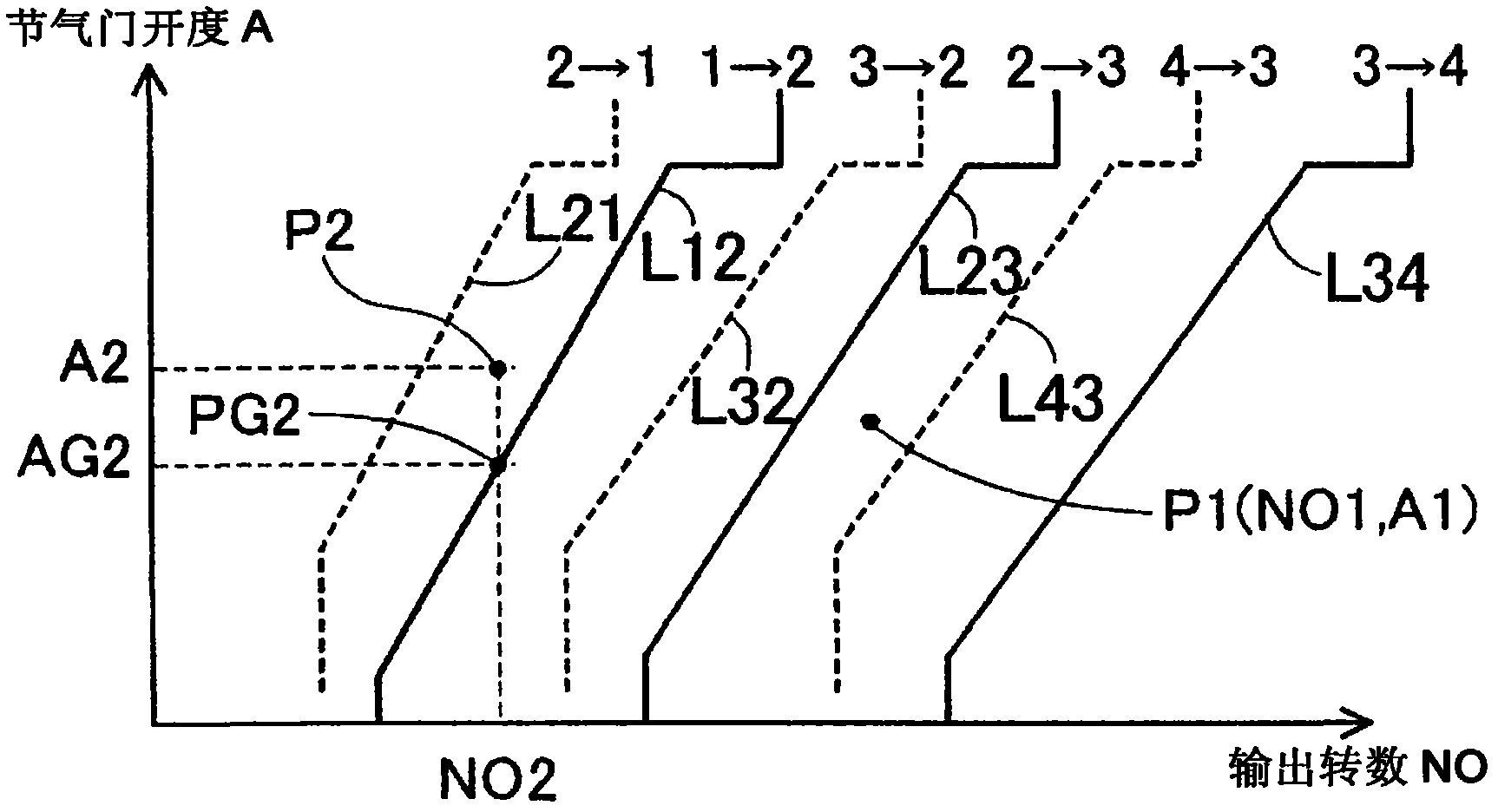

Speed control method and speed control device for automatic transmission

InactiveCN102418784AProper drive performanceProper shift feelInternal combustion piston enginesPropulsion using engine-driven generatorsElectricityAutomatic transmission

A speed control method for an automatic transmission adapted to a power train apparatus (1) for a hybrid vehicle having an engine (2), a motor-generator (4), the automatic transmission, and a speed control device (7,27,47,57) controlling the automatic transmission based on a throttle opening degree (A) of the engine and an output rotation number (NO) of the automatic transmission, the speed control method executed when the electricity is simultaneously generated while the vehicle is driven by the engine, includes a power generation torque calculating process (S5) of calculating a power generation torque (TG) necessary for the motor-generator to generate a required electricity, an output torque calculating process (S6) of calculating an output torque (TE), a drive torque calculating process (S7) of calculating a drive torque, a throttle opening degree during power generation-calculating process (S8) of calculating a throttle opening degree-during power generation, and a speed control process (S9) of controlling the automatic transmission based on the throttle opening degree-during power generation.

Owner:AISIN SEIKI KK

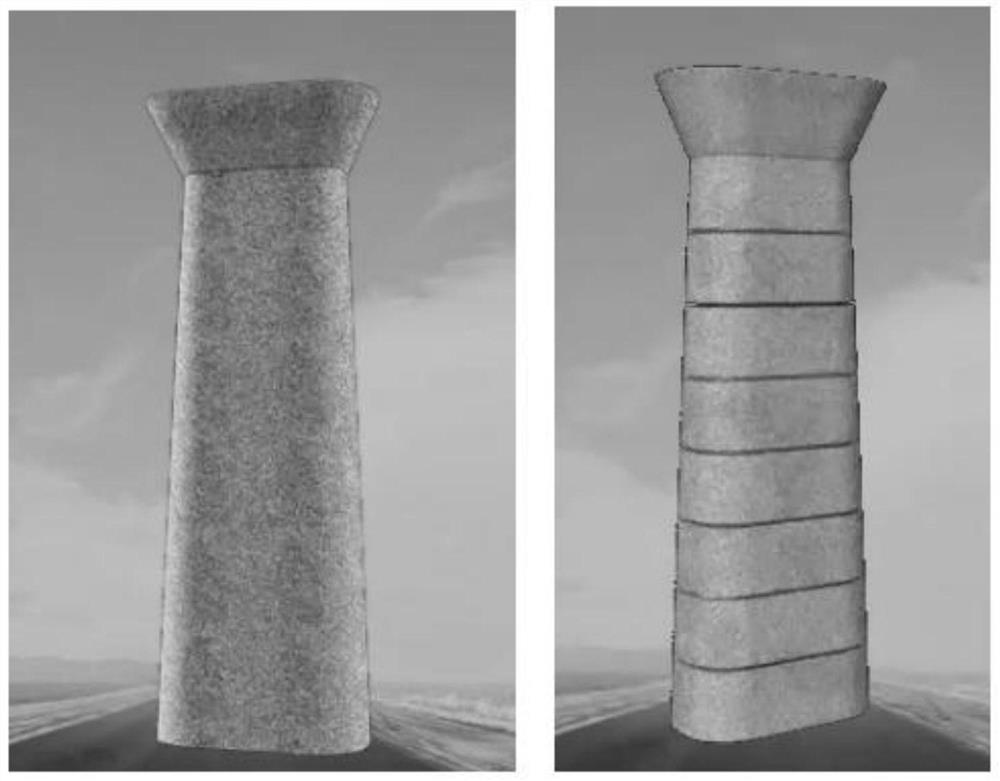

Novel method for reinforcing concrete pier by implanting prestressed high-performance rib material into surface layer

ActiveCN113774816AHighlight substantive featuresAppearance has no effectBridge structural detailsBridge erection/assemblyReinforced concretePre stress

The invention relates to a novel method for reinforcing a concrete pier by implanting a prestressed high-performance rib material into a surface layer, which comprises the following steps of: slotting in a concrete protection layer on the surface of the concrete pier needing to be reinforced, and ensuring that the slotting depth does not exceed 2 / 3 of the thickness of the concrete protection layer; then implanting the high-performance rib materials into the groove, and applying prestress to the high-performance rib materials through a tensioning jack; after the prestress is applied in place, butt-welding the ends of the high-performance rib materials and finally sealing and filling a groove channel with a gel material so as to complete the repair of the surface of concrete. On the premise that the thickness of concrete on the surface layer of the pier is not increased, the grooved area and the non-grooved area on the surface of the pier form a whole, and the embedded pre-stressed rib material of the concrete pier is reinforced. According to the new method, the bearing capacity of the concrete pier with insufficient bearing capacity can be rapidly repaired and improved, the bearing capacity of the concrete pier can be improved to 1.4-2 times of the bearing capacity before reinforcement, wherein the reinforcement effect advantage is obvious, and the reinforcement construction process is simple.

Owner:HUNAN INSTITUTE OF ENGINEERING

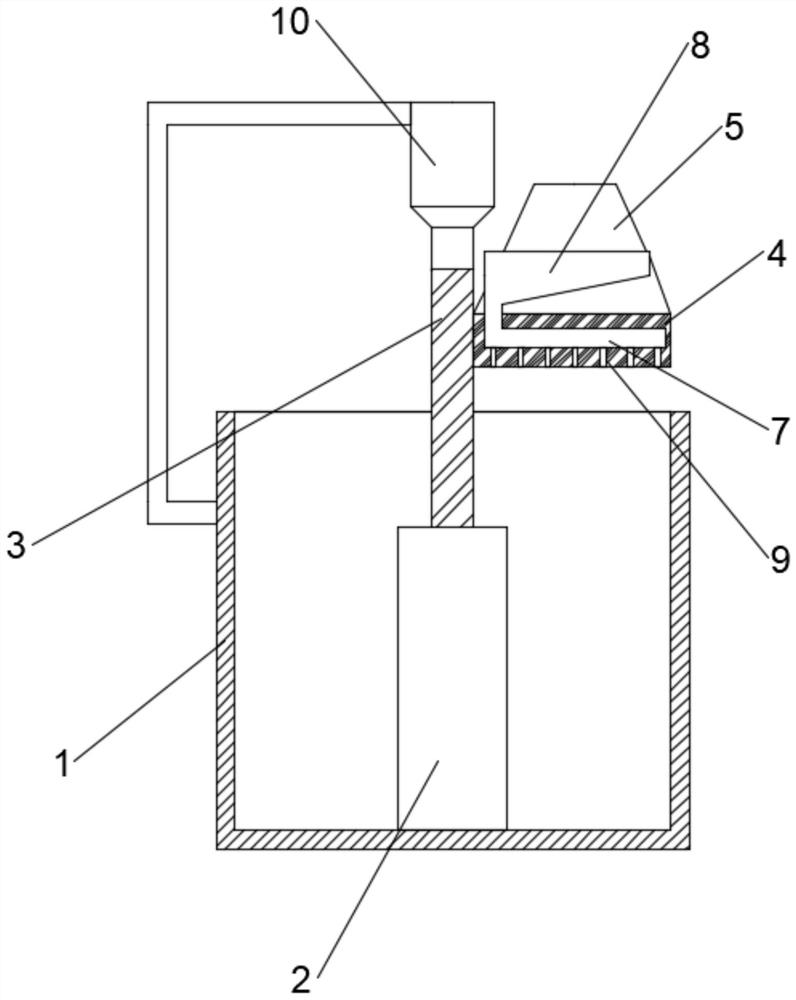

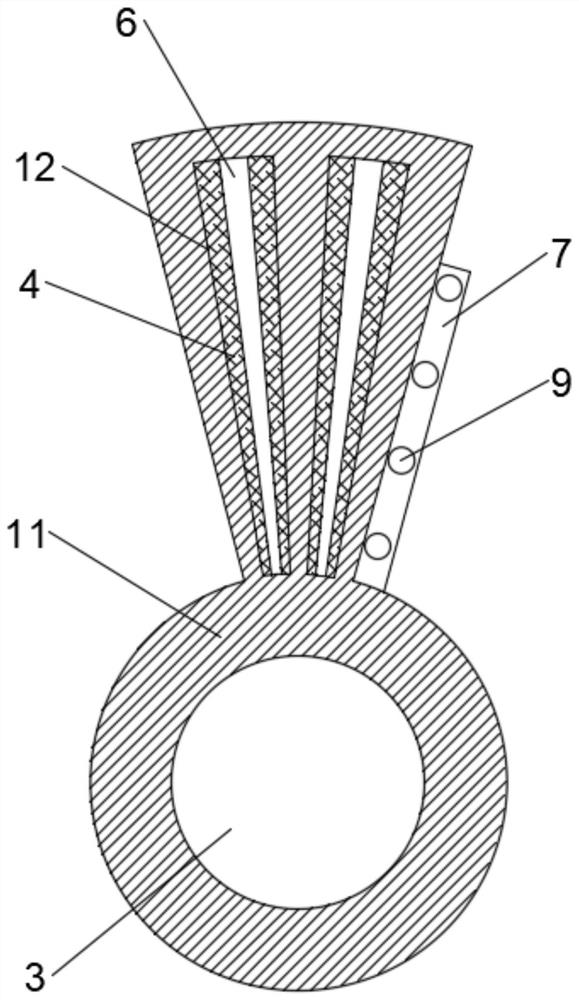

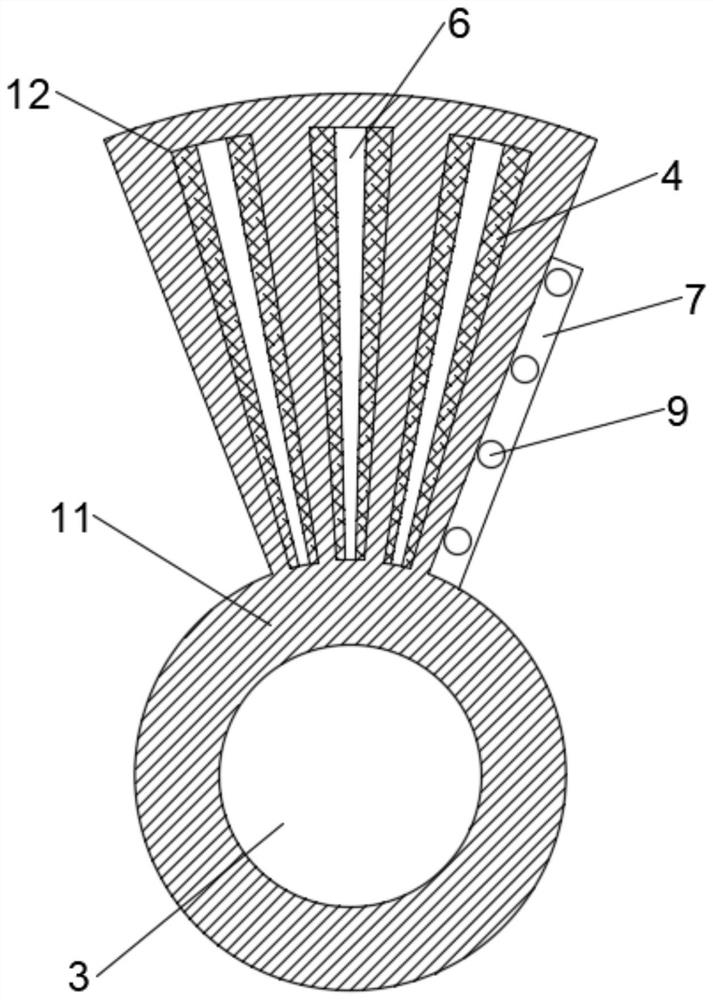

Inertial-capacitance type multidirectional tuning type energy absorption and vibration reduction device

InactiveCN112814191ARealize multi-directional vibration damping controlImprove the efficiency of vibration damping and energy consumptionProtective buildings/sheltersShock proofingCapacitanceEnergy absorption

The invention belongs to the technical field of engineering structure vibration reduction, and particularly relates to a multidirectional tuning type energy absorption and vibration reduction device. The inertial-capacitance type multidirectional tuning type energy absorption and vibration reduction device comprises a mass block, a transmission device and a rotating device, wherein the mass block is connected with the rotating device through the transmission device. According to the inertial-capacitance type multidirectional tuning type energy absorption and vibration reduction device, the structure form of the mass block is changed so as to realize the inertial-capacitance effect, the mass tuning mode of the vibration reduction device is improved, and the energy absorption and energy consumption efficiency of the vibration reduction device is improved.

Owner:SICHUAN UNIV

Combined caisson and pile foundation for strengthening foundation and construction method thereof

The invention discloses a caisson and pile combined foundation of consolidated subsoil and a construction method of the caisson and pile combined foundation. The caisson and pile combined foundation of the consolidated subsoil comprises the consolidated subsoil, a sand-gravel cushion, a caisson, bored piles, pile bottom grout, top seal concrete and scour protection. The main construction method comprises the following steps: consolidating the foundation with an underwater compaction sand pile or a deep-layer cement mixing pile; laying the sand-gravel cushion on the consolidated subsoil; sinking the caisson with a skirt, pile sinking guide holes and grouting reserved pipes on the sand-gravel cushion; after the caisson is located, constructing bored piles through the pile sinking guide holes; after construction of the bored piles, casting the top seal concrete at the bottom in the caisson; grouting the bottom of the caisson through the grouting reserved pipes at the bottom of the caisson, carrying out pile bottom grouting through grouting pipes in the pile, and at last casting the top plate of the caisson. In the construction process, the scour protection shall be performed around the caisson according to requirements. The caisson and pile combined foundation of the consolidated subsoil and the construction method of the caisson and pile combined foundation, disclosed by the invention, can effectively improve vertical and horizontal bearing capacity of the caisson, and control sedimentation and horizontal displacement of the caisson.

Owner:CCCC HIGHWAY CONSULTANTS +1

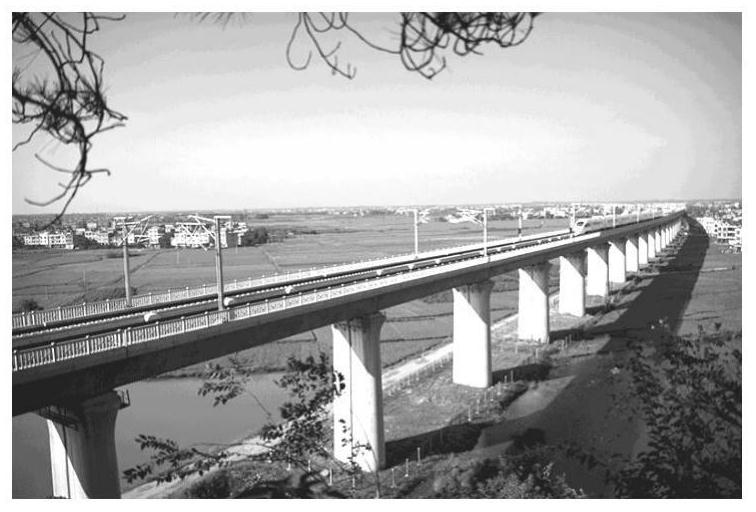

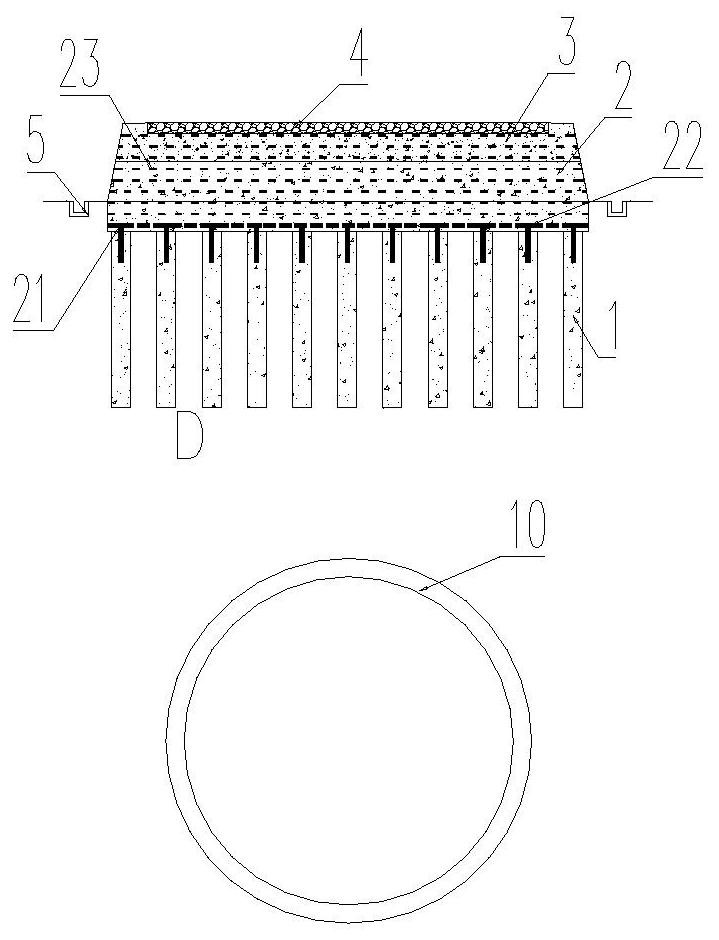

Lightweight subgrade structure, design and construction method of underpassing bridges in operation

ActiveCN111395061BLow densityAvoid crackingGeometric CADSewerage structuresEcological environmentArchitectural engineering

The invention discloses the structure, design and construction method of the light subgrade of the bridge under the operation. Long piles, double rows of long piles are arranged longitudinally along the line and close to the bridge foundation relative to the short piles. The quality trough is set on the top of the light body, and the U-shaped light trough is filled with soil filler. The upper part of the long pile and the short pile is anchored into the connecting steel bar. Structure, the reinforcement layer is fixedly connected with the connection reinforcement. Lightweight soil materials have low density, strong compressive capacity, and upright appearance. This method can achieve the purpose of building subgrades under bridges, ensure the normal use of bridge structures, and ensure the safe operation of various vehicles on the bridge. Local economic construction saves land and can also reduce ecological environment damage.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Evacuation treatment method of concrete face rockfill dam

ActiveCN110185004BIncreased durabilityIncrease elasticityEarth-fill damsRock-fill damsSound waveGround-penetrating radar

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

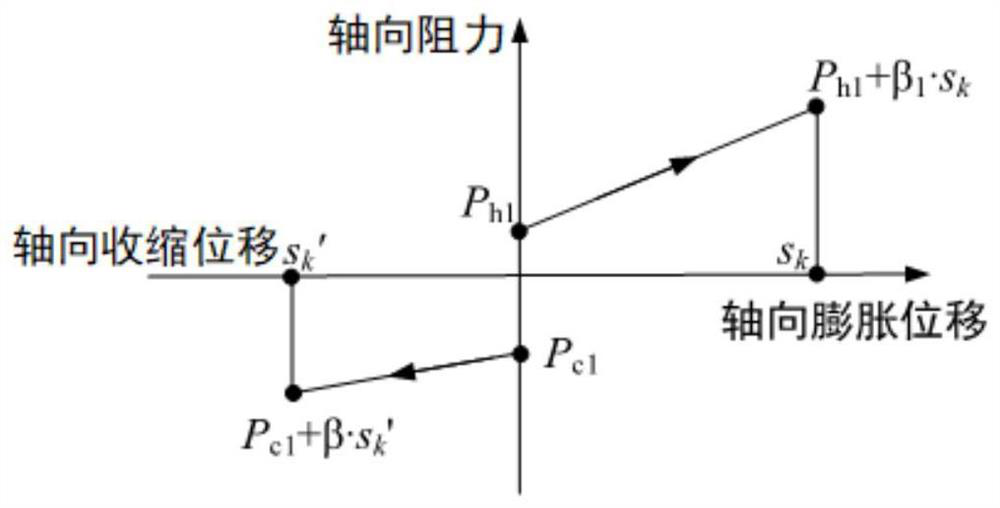

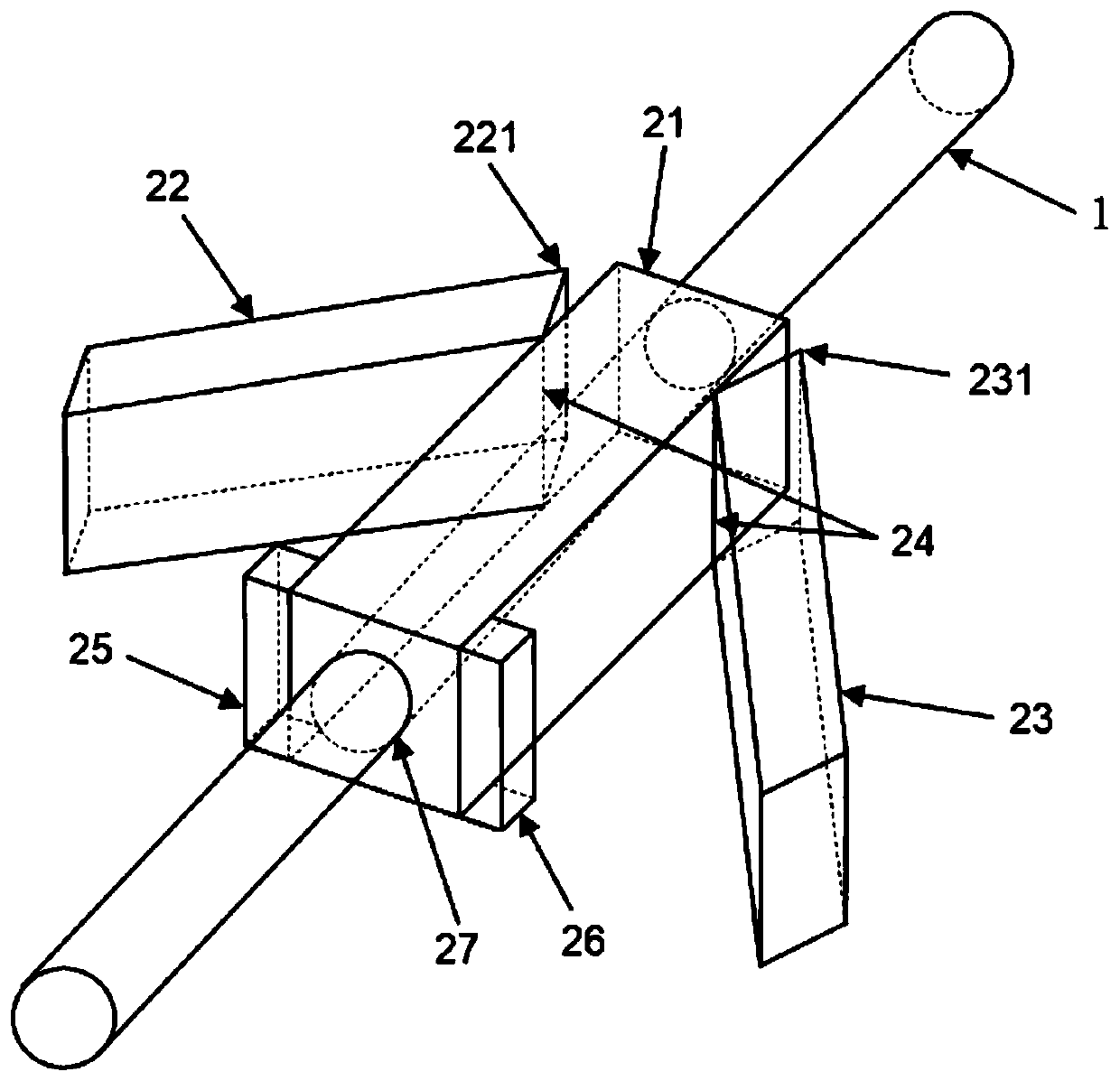

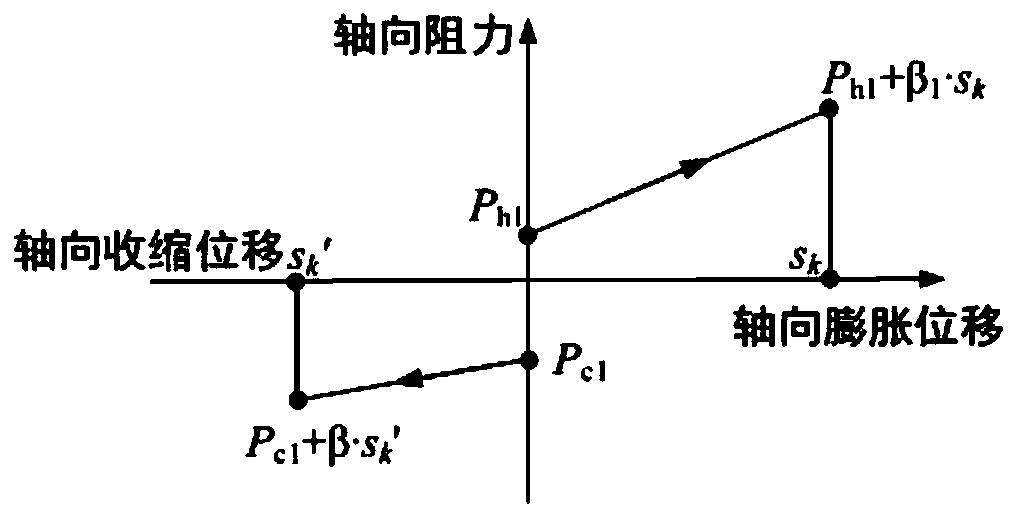

An active low additional force pipeline effect protection method

ActiveCN111561606BAdditional load is smallTo achieve the effect of treating both symptoms and root causesPipe laying and repairAxial displacementEngineering

The invention discloses an active low additional force protection method for pipeline routing effect: (1) calculate the pipeline routing value that will be generated by the pipeline when no protective measures are taken; (2) according to the structural bearing capacity of the area where the pipeline is located, Calculate the maximum pipeline displacement that can be tolerated as the target value of the pipeline control; (3) Based on the target value of the pipeline control, apply variable axial resistance to the end of the pipeline, and calculate the actual displacement of the pipeline under the action of the variable axial resistance. Pipeline value; repeatedly adjust the function of the change of the resistance value with the axial displacement, so that the actual pipe routing value is less than the pipe routing control target value; (4) Design the additional structure at the end of the pipe so that the additional structure slides along the axial direction of the pipe When , the additional structure can generate axial resistance to the pipeline according to the change function of the resistance value with the axial displacement. The invention achieves the purpose of controlling and eliminating the pipe routing effect of deep-sea pipelines by interfering with and inhibiting the fundamental mechanism of the pipe routing.

Owner:TIANJIN UNIV

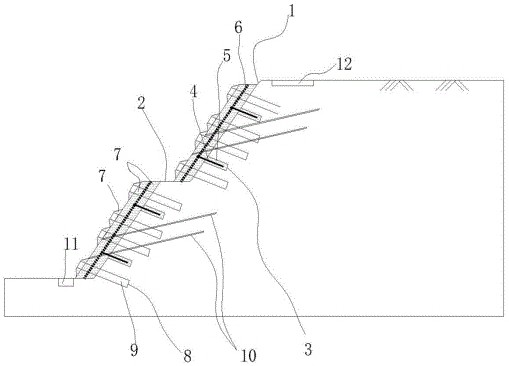

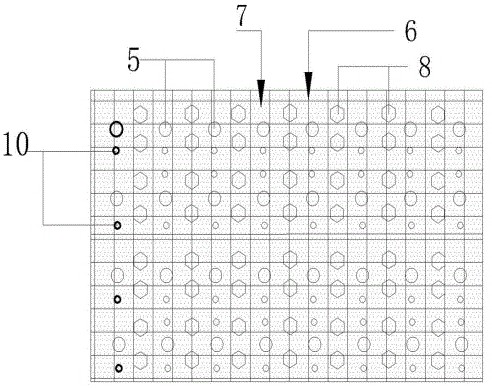

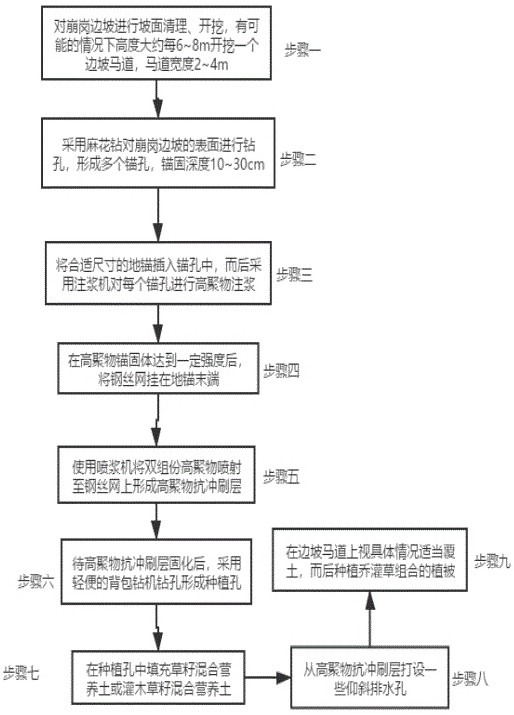

Construction method of fast-setting polymer grouting for rapid control of collapsed hills

ActiveCN113529753BEffective squeezeIncrease anchoring forceHops/wine cultivationTurf growingEnvironmental resource managementEcological environment

The invention relates to a construction method for fast-setting polymer grouting to quickly control collapsed hillocks. The scheme includes the following construction steps: excavating at least one side slope horse track on the collapsed hillside slope; drilling a plurality of anchor holes on the collapsed hillside slope ; Insert the ground anchor into each anchor hole and perform polymer grouting to form a polymer anchor; Lay the steel mesh on the surface of the collapsed hillside slope and connect and fix it with the end of each ground anchor, and the steel mesh is connected to the There are several spacers between the surface of the collapsed hillside slope; two-component intumescent polymer grouting material is sprayed on the steel wire mesh to form a high polymer anti-scour layer; drills are drilled on the collapsed hillside slope through the mesh of the steel mesh. Take a plurality of planting holes; fill each planting hole with mixed nutrient soil of grass seeds; set a plurality of inclined drainage holes inwardly and upwardly from the high polymer anti-scour layer, this method has the advantages of short construction period, ecological environment protection and convenient construction And the advantages of high strength and strong erosion resistance.

Owner:FUJIAN GEOLOGICAL ENG SURVEY INST

Rapid construction wharf structure on soft soil foundation and its construction method

The invention discloses a novel wharf structure quickly constructed on a soft foundation, and belongs to the field of wharf engineering. The novel wharf structure comprises two rows of long piles and two rows of short pile plates which are symmetrically arranged, the two rows of short pipe plates are respectively arranged inside the two rows of long piles in an opposite direction, a short plate pile is arranged between two adjacent long piles in each row of long piles, and a joint between every adjacent short plate piles is covered by the long pile arranged outside the short plate pipes; geotechnical cloths are paved in the opposite sides of the two rows of short pile plates, an area for filling is formed between the geotechnical cloths at the two sides and internally and vertically provided with grouting pipes in an equal interval way, and rubble complexes are filled in the area. The invention further discloses a construction method of the wharf. By adopting the long piles and short pile plates, the wharf structure is simple, and the stability of the wharf can be improved; furthermore, the structure has the characteristics of being light in weight and smaller in additional load to the foundation; meanwhile, the construction method of the wharf structure is simple to operate and low in cost, and is likely to popularize and apply.

Owner:YUSHUN ECOLOGICAL CONSTR +1

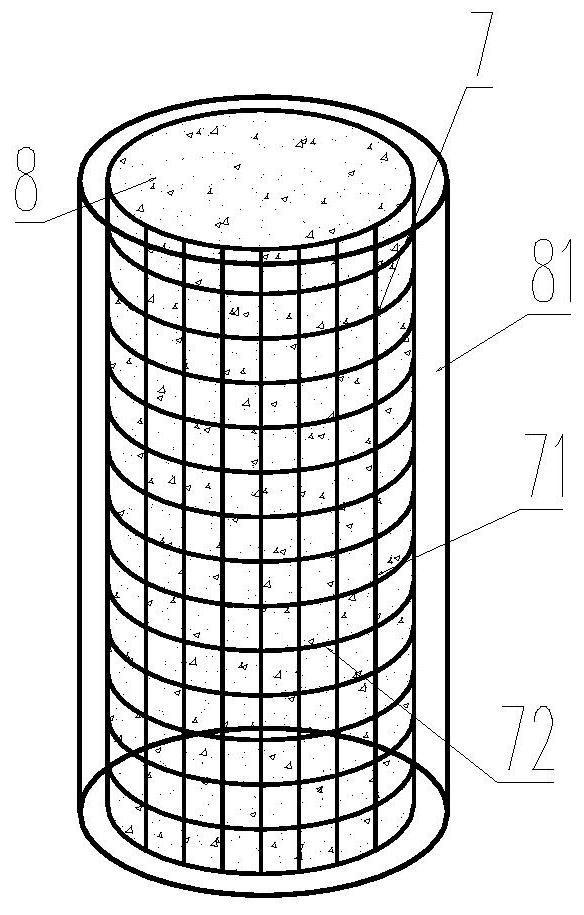

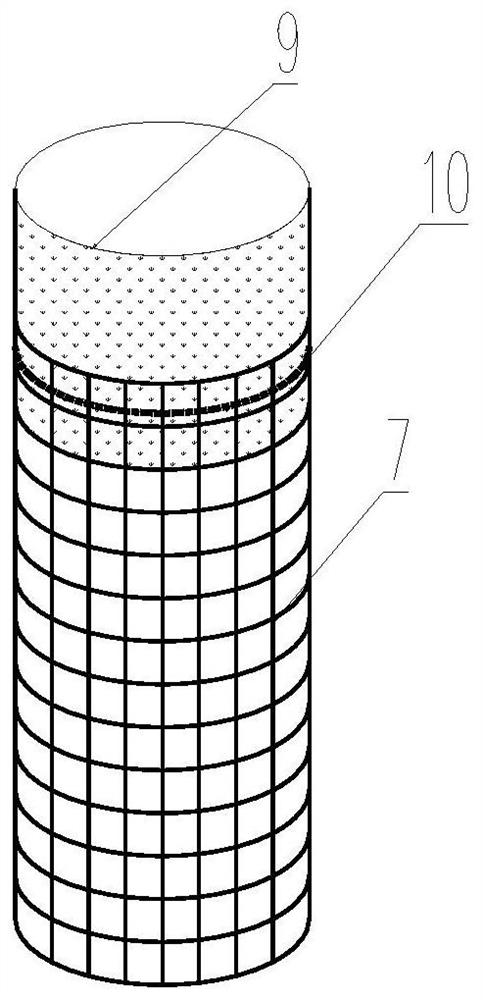

Lightweight subgrade structure, design and construction methods above operating tunnels

ActiveCN111395082BAdditional load is smallGuaranteed functionGeometric CADGround-workEcological environmentArchitectural engineering

The invention discloses a lightweight subgrade structure, design and construction method above the operating tunnel, including composite lightweight piles, lightweight bodies, U-shaped lightweight grooves and drainage ditches, and the composite lightweight piles are arranged in rows at intervals along the longitudinal direction of the line. In the rock and soil foundation above the state tunnel, the composite lightweight pile includes a piled lightweight body, the light body is set on the top of the composite lightweight pile, the U-shaped light groove is set on the top of the light body, and the top of the U-shaped light groove is filled It is built with soil filling, and the drainage ditch is located at both ends of the lightweight body. Combining the characteristics of low density, high compression resistance and upright appearance of lightweight soil materials, based on the hoop effect of composite reinforced cage and the reinforcement effect of vertical geogrid and annular geogrid, an equal-load replacement method is proposed. Lightweight subgrade structure. It can achieve the purpose of building the subgrade above the operating tunnel, and the additional load of the subgrade is small, which can ensure the normal use function of the tunnel structure and the safe operation of the vehicles in the tunnel. The structure saves construction land, reduces damage to the ecological environment, and has remarkable social, economic, and environmental benefits.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Self-forming roadway mining method without coal pillars suitable for fully mechanized top coal caving in thick coal seams

ActiveCN110206542BConducive to collapseIncrease stressDisloding machinesUnderground miningMining engineeringCoal pillar

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Underpinning Method of Pile Foundation Adjacent to Deep Foundation Pit of Building

ActiveCN104179204BAdditional load is smallImprove securityFoundation repairArchitectural engineeringShear resistance

The invention relates to the technical field of civil foundation reinforcement for industrial and civil construction projects. Step 1, investigation and design: investigate the existing buildings, select the type of foundation underpinning piles according to the size of the foundation of the building, the depth of embedding, the distance between the foundation of the building and the deep foundation pit, and the depth of the deep foundation pit. Force calculation to determine the length of the required foundation underpinning piles, the number of foundation underpinning piles, the depth of the foundation underpinning piles exceeding the bottom of the deep foundation pit, and finally complete the design of the ring beam; step 2, building foundation side pressure piles; step 3, building Pile foundation underpinning construction of material foundation. The invention enables the building foundation to meet the requirements of bending resistance, punching resistance and shear resistance through pile foundation underpinning, and converts the natural foundation bearing capacity of the building foundation into pile foundation bearing, greatly reducing the additional load of the building foundation on the deep foundation pit. load, solve the settlement and horizontal displacement of the foundation of the building near the deep foundation pit, and ensure the safety of the factory building.

Owner:山西钢铁建设(集团)有限公司

Active low-additional-force pipeline moving effect protection method

ActiveCN111561606AAdditional load is smallTo achieve the effect of treating both symptoms and root causesPipe laying and repairAxial displacementClassical mechanics

The invention discloses an active low-additional-force pipeline moving effect protection method. The method comprises the following steps that (1) the pipeline moving value produced for a pipeline when no protection measures are adopted is calculated; (2) the maximum tolerable pipeline moving displacement is calculated according to the tolerance capacity of a structure in the area where the pipeline is located and serves as the pipeline moving control target value; (3) variable axial resistance is applied to the end of the pipeline based on the pipeline moving control target value, the pipeline moving value actually produced for the pipeline under the effect of the variable axial resistance is calculated, and a variance function in which the resistance value varies as the axial displacement varies is repeatedly adjusted, so that the pipeline moving value actually produced is smaller than the pipeline moving control target value; and (4) an additional structure at the end of the pipeline is designed, so that the additional structure can produce an axial resistance, with the resistance value varying according to the variation function in which the resistance value varies as the axialdisplacement varies, on the pipeline when sliding in the axis direction of the pipeline. According to the protection method provided by the invention, the purpose that the deep sea pipeline moving effect is controlled and eliminated is achieved through a fundamental mechanism for interfering with and inhibiting pipeline moving.

Owner:TIANJIN UNIV

A Deployment Method of Fusion Video Live Channel in Mobile Cloud Computing Environment

ActiveCN110069342BImprove carrying capacityIncrease the number of usersResource allocationTransmissionLoad SheddingCpu load

The invention provides a deployment method of a fused video channel for balancing channel resources and coordinating cloud delay and local loads in a self-adaptive manner for a video application witha shared interactive load characteristic. The method comprises the following steps: firstly, a shared interactive system with a fused video live broadcast function is realized based on WebRTC and OpenCV; on the basis of the system, the three processes of application dissociation and independence are subjected to experiments, and a shared interactive resource-load model is obtained. On the basis,the channel resource load is estimated on the basis of the model, an admission control strategy is realized through a greedy heuristic algorithm based on a utility ratio, an admission priority sequence of the channel is generated, and a basis is provided for maximizing the system bearing capacity. In the deployment stage, firstly, a server for the channel is selected according to the principle ofminimum total delay for initial placement. Adaptive load balancing is carried out, and the load-delay model of the server is combined; a part of CPU load is released to the terminal so as to realize load-delay balancing between the terminal and the cloud end.

Owner:XI AN JIAOTONG UNIV +1

Concrete overpass bridge protection device and anti-collision reinforcing method thereof

PendingCN114293479AReduce breakageAvoid breakingBridge erection/assemblyBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a concrete overpass bridge protection device and an anti-collision reinforcing method thereof. The concrete overpass bridge protection device structurally comprises studs and an anti-collision layer. The studs are fixed to the side faces and the bottom face of the concrete overpass bridge in a steel bar planting mode, and the studs are connected with the anti-collision layer and the concrete overpass bridge. The anti-collision reinforcing method is simple and convenient in process, damage to the overpass bridge is small, the original bearing capacity of the overpass bridge is prevented from being affected, work can be carried out under the condition that under-bridge traffic is not closed, and construction is rapid; and the anti-collision layer and the overpass bridge can be prevented from being disengaged, and under the condition of the same strength, the anti-collision layer is smaller in thickness and lighter in self weight, and the load amplification on the overpass bridge is very small. When collision occurs, the ultra-high performance concrete anti-collision layer is firstly collided, dissipation of impact kinetic energy can be increased, impact force can be effectively buffered, even under extreme collision, it can be guaranteed that a damaged part does not fall off, the overpass bridge does not collapse, and secondary accidents are avoided.

Owner:四川苏博特新材料有限公司 +2

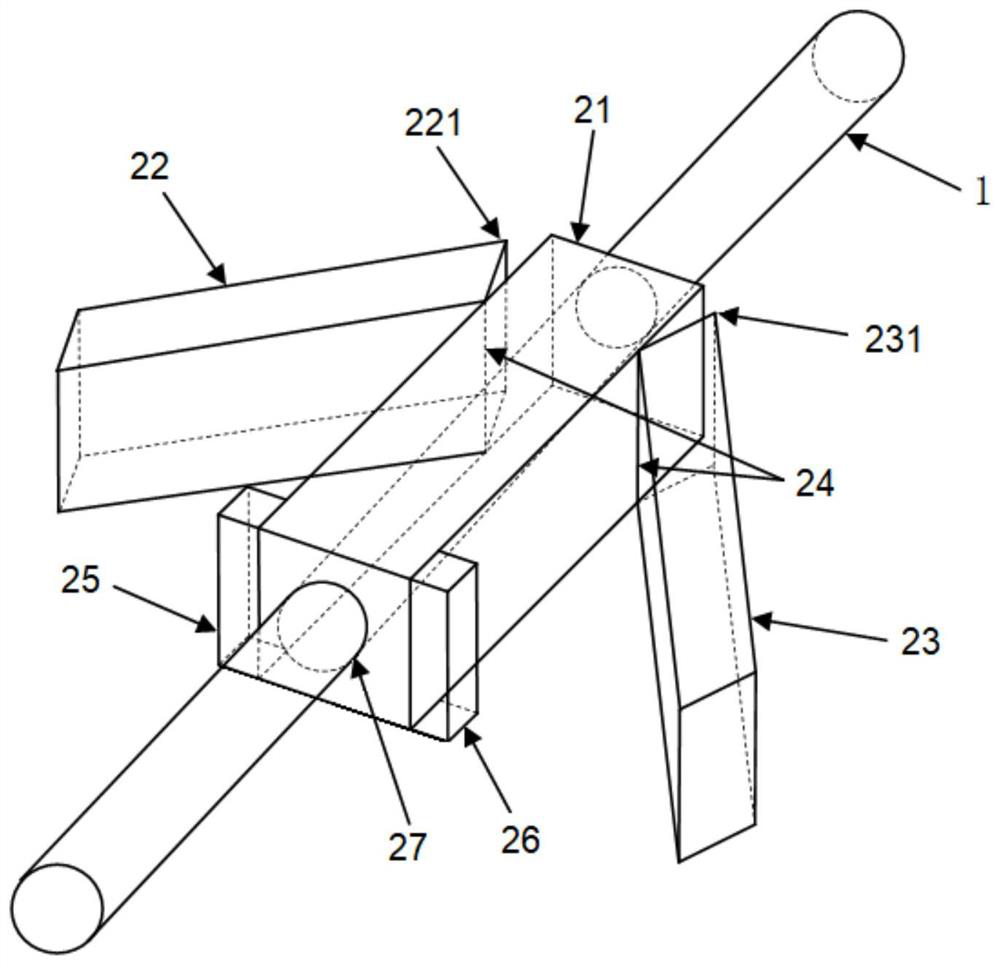

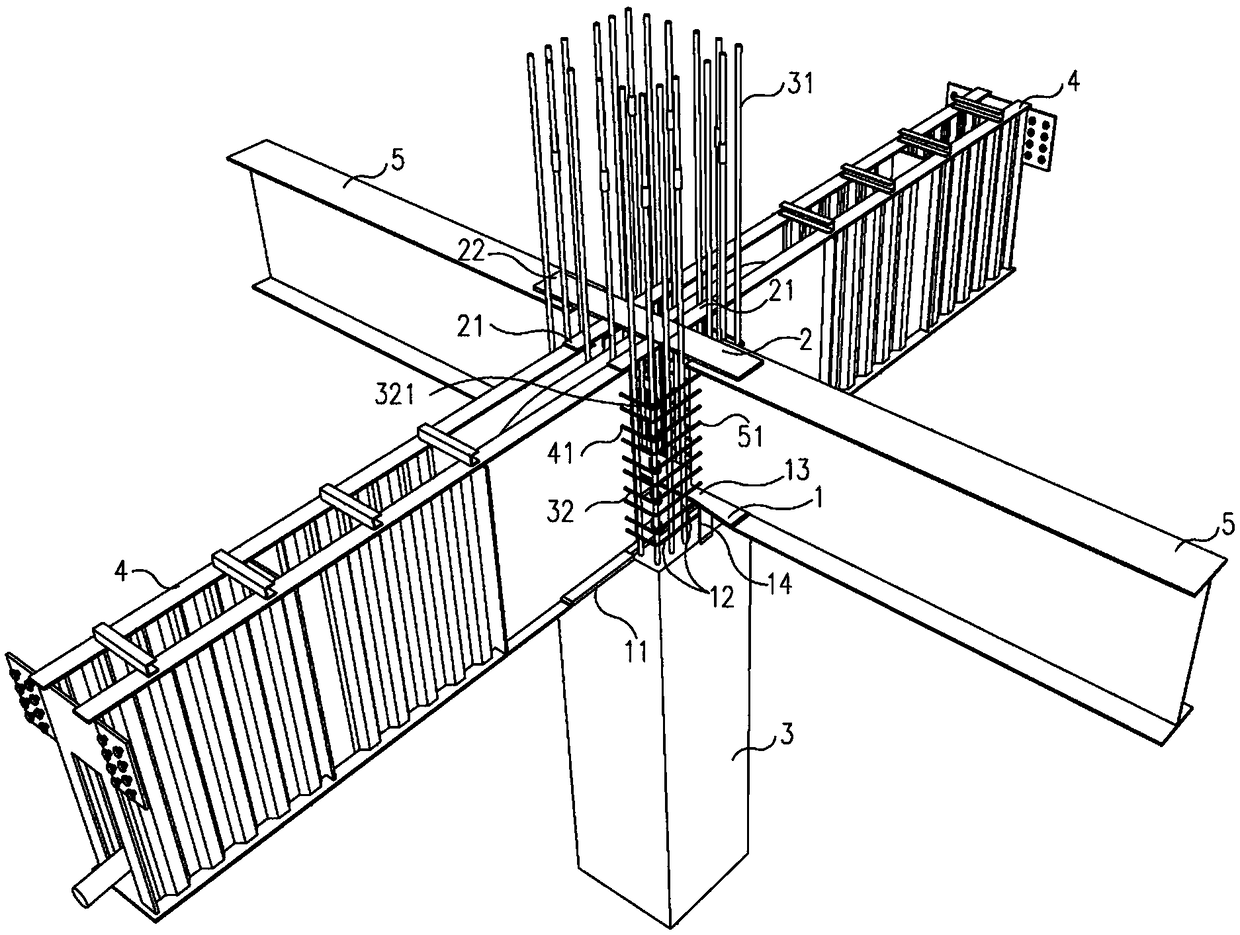

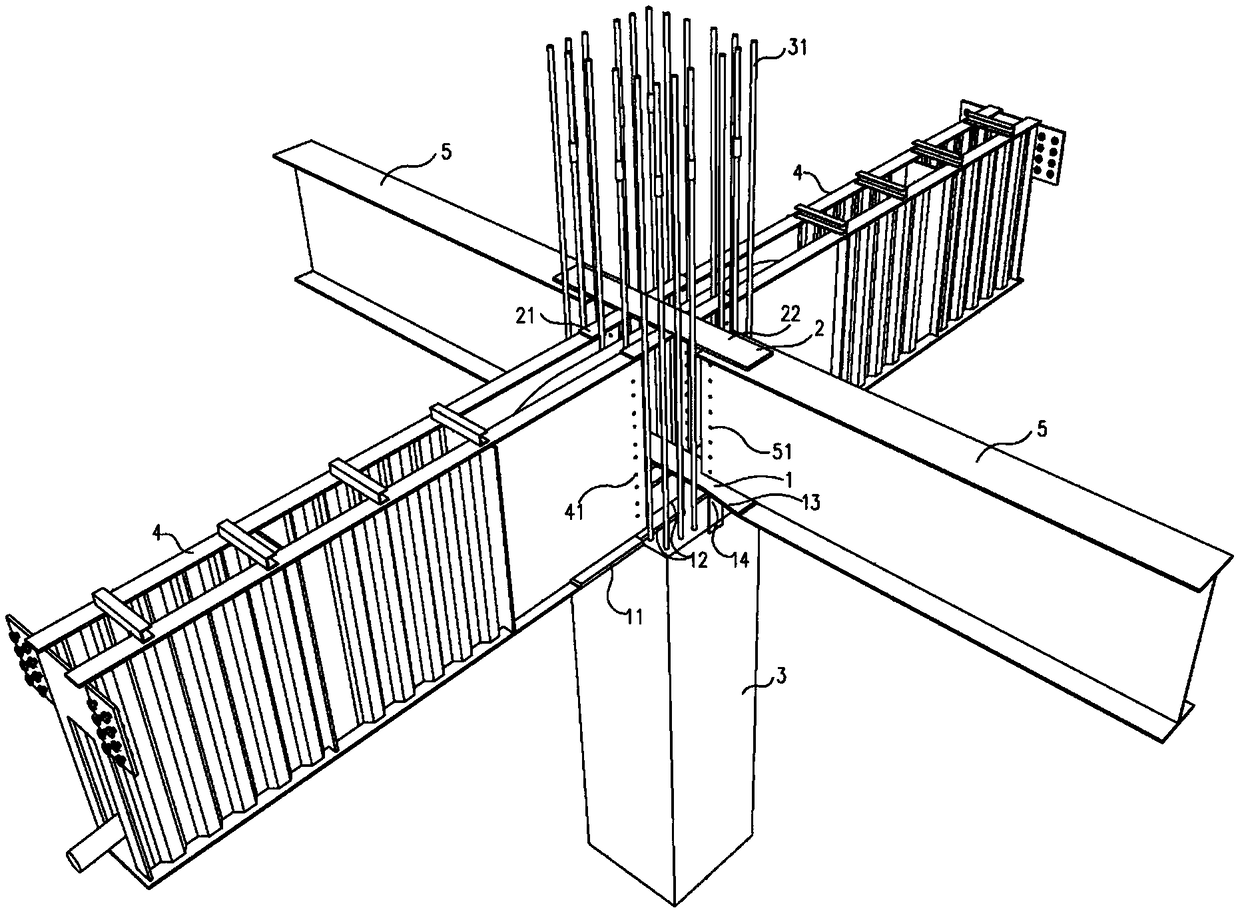

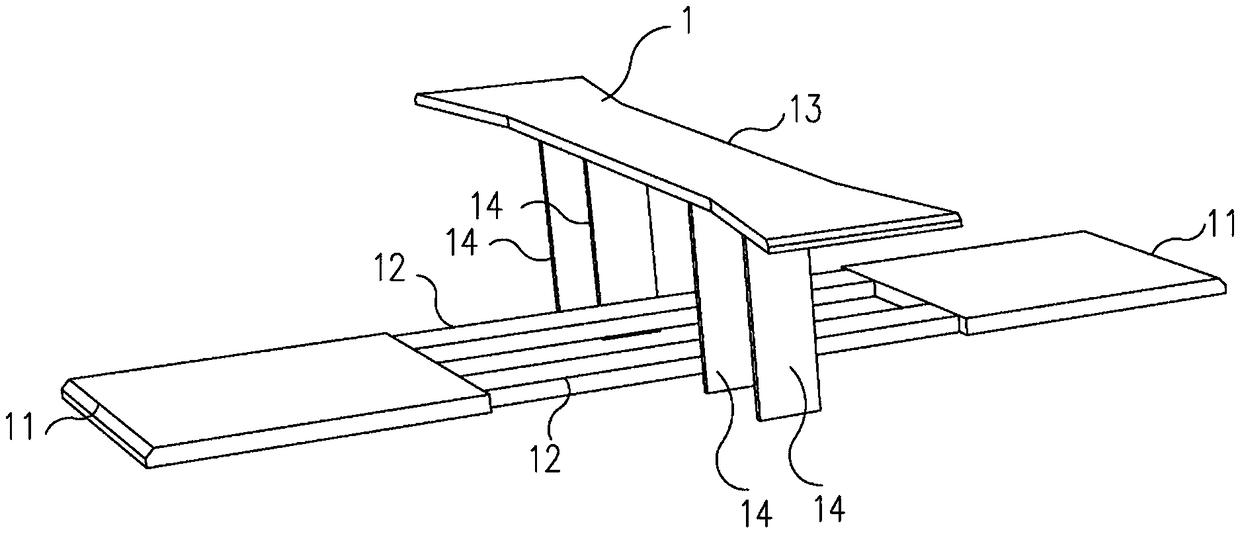

Joint adaptor for connecting reinforced concrete column and steel beams and connecting structure of reinforced concrete column and steel beams

PendingCN109322398AAdditional load is smallPrecise positioningBuilding constructionsReinforced concrete columnHooping

The invention provides a joint adaptor for connecting a reinforced concrete column and steel beams. The joint adaptor for connecting the reinforced concrete column and the steel beams comprises optimal joint lower flanges and optimal joint upper flanges; and the optimal joint lower flanges are located below the optimal joint upper flanges. When the joint adaptor is connected with the steel beams,the lower flanges are not arranged at the ends of the steel beams within a certain range from the side of the column, webs are placed on lower flange plates corresponding to optimal joints during hoisting, the webs extend into the edge of the concrete column for a certain distance, the webs are field welded to the optimal joint lower flanges, and the lower flanges of the steel beams are equally welded to the lower flanges of the optimal joints; the upper flanges of the steel beams are equally welded to the upper flanges of the optimal joints; and openings are reserved in corresponding positions of the webs of the steel beams and column hooping and used for hooping penetrating and binding at site, 135 degrees inclined hook or 90 degrees straight hook welding can be adopted, peripheral closed hooping is formed, and binding hooping can be used in internal hooping.

Owner:SHANGHAI OPEN STEEL JOIST

Inerter type multidirectional tuning energy absorption and vibration reduction device

PendingCN113982137ARealize multi-directional vibration damping controlImprove the efficiency of vibration damping and energy consumptionProtective buildings/sheltersShock proofingEnergy absorptionInerter

The invention belongs to the technical field of engineering structure vibration reduction, and particularly relates to a multidirectional tuning energy absorption and vibration reduction device. The inerter type multidirectional tuning energy absorption and vibration reduction device comprises an inerter device and a mass tuning device which are installed in a main body frame. The mass tuning device is connected with the inerter device; and the inerter device and the mass tuning device are connected with the main body frame through elastic elements. The inerter effect is achieved by changing the structural form of the mass block, the mass tuning mode of the damping device is improved, and the energy absorption and energy consumption efficiency of the damping device is improved.

Owner:SICHUAN UNIV

A top membrane water retaining method for underwater maintenance of channel lining

InactiveCN105040645BLess investmentSimple structureArtificial water canalsMarine site engineeringMarine engineeringWater block

The invention relates to a top film water-retaining method for underwater canal lining overhaul. The top film water-retaining method comprises the following construction process steps: additionally installing a sealing layer on an edge needing to be sealed and a downstream face of a flexible waterproof film respectively, and additionally installing a counter weight on an upstream face; sinking downwards the downstream face of the flexible waterproof film into water, laying the flexible waterproof film on the surface of a canal lining in an area to be overhauled, and exposing the unsealed edge of the flexible waterproof film above the water level of water edge. The waterproof film in the top film water-retaining method disclosed by the invention is low in investment, simple in structure, environment-friendly in material selection, good in water-stopping effect, low in additional load, free from damages to the canal lining, convenient and fast to transport, install and transfer in water, capable of being supported by a floating crane, a movable maintenance cabin and a maintenance gallery, and the like to provide a flexible working space for lining maintenance on the provided working base surface, and also capable of being used as a rush emergency water-retaining curtain for preventing a slide area from expansion.

Owner:贾永奕

Liquid fly ash material for road abutment back backfilling and preparation process of liquid fly ash material

PendingCN112745070AImprove liquidityImprove compactnessCement mixing apparatusSold ingredients supply apparatusSoil scienceEnvironmental engineering

The invention discloses a liquid fly ash material for road abutment back backfilling and a preparation process of the material. The liquid fly ash material comprises cement, fly ash, water and an additive, the mixing ratio of the cement to the fly ash to the water to the additive is (10-20): (80-90): (30-40): (0.1-0.2), and the content of the additive is 1% of the content of the cement; when the liquid fly ash material is prepared, the cement, the water, the fly ash and the additive are weighed according to the proportion; the cement, fly ash, water and additive are mixed to obtain a fly ash-water-cement mixture; the fly ash-water-cement mixture is stirred to prepare a liquid fly ash material; by presetting the falling speed and position of the raw materials, the powder can be quickly and uniformly mixed with water, the subsequent stirring and mixing time is shortened, and the preparation speed of the liquid fly ash material is increased.

Owner:中电建路桥集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com