Elastic member for pushbutton switch

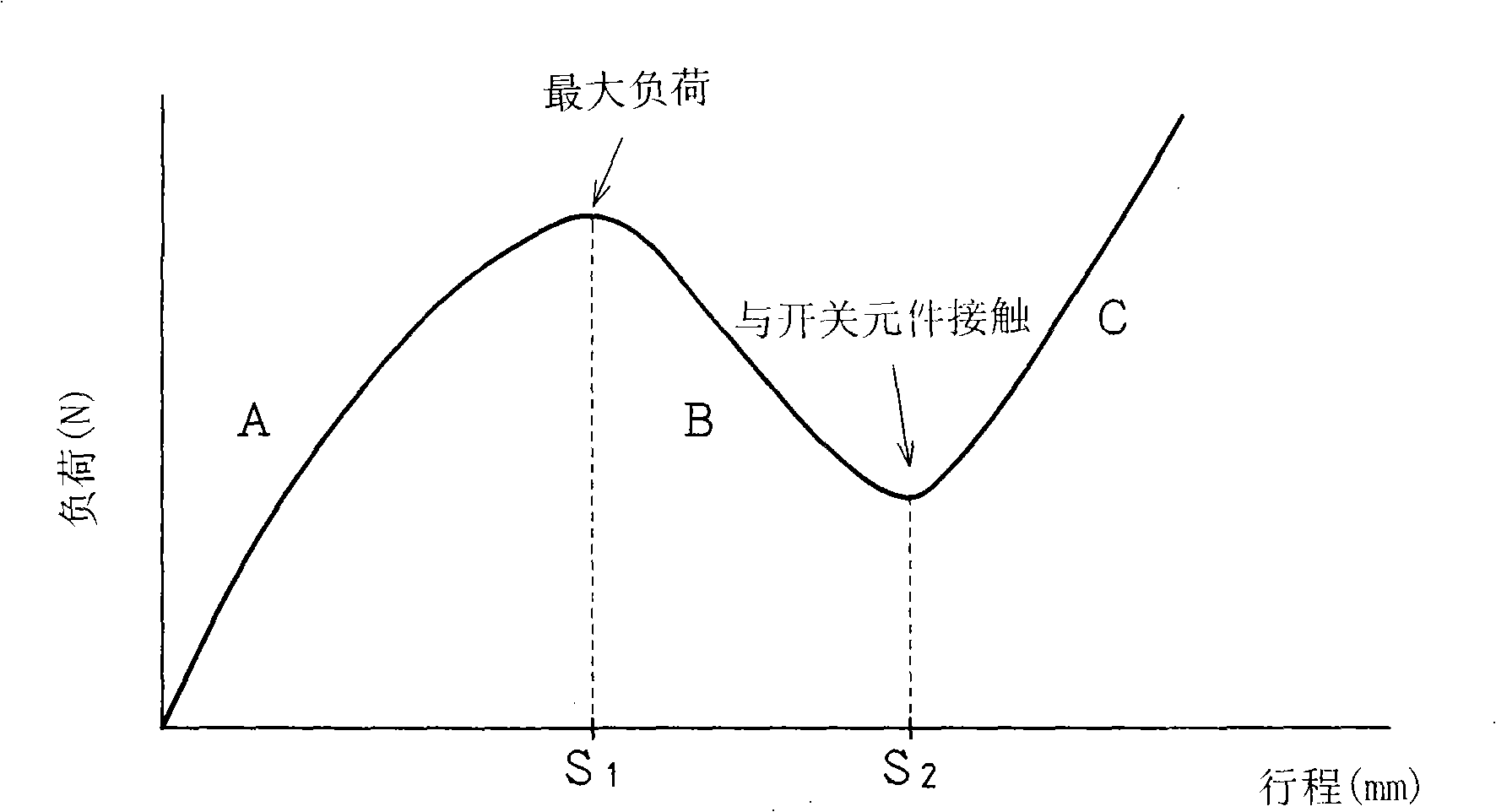

A technology of elastic parts and switches, which is applied to electric switches, electrical components, key modules, etc., can solve the problems that elastic parts cannot have a stroke S1, it is difficult to adjust the peak stroke, and the pressing part cannot maintain the shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

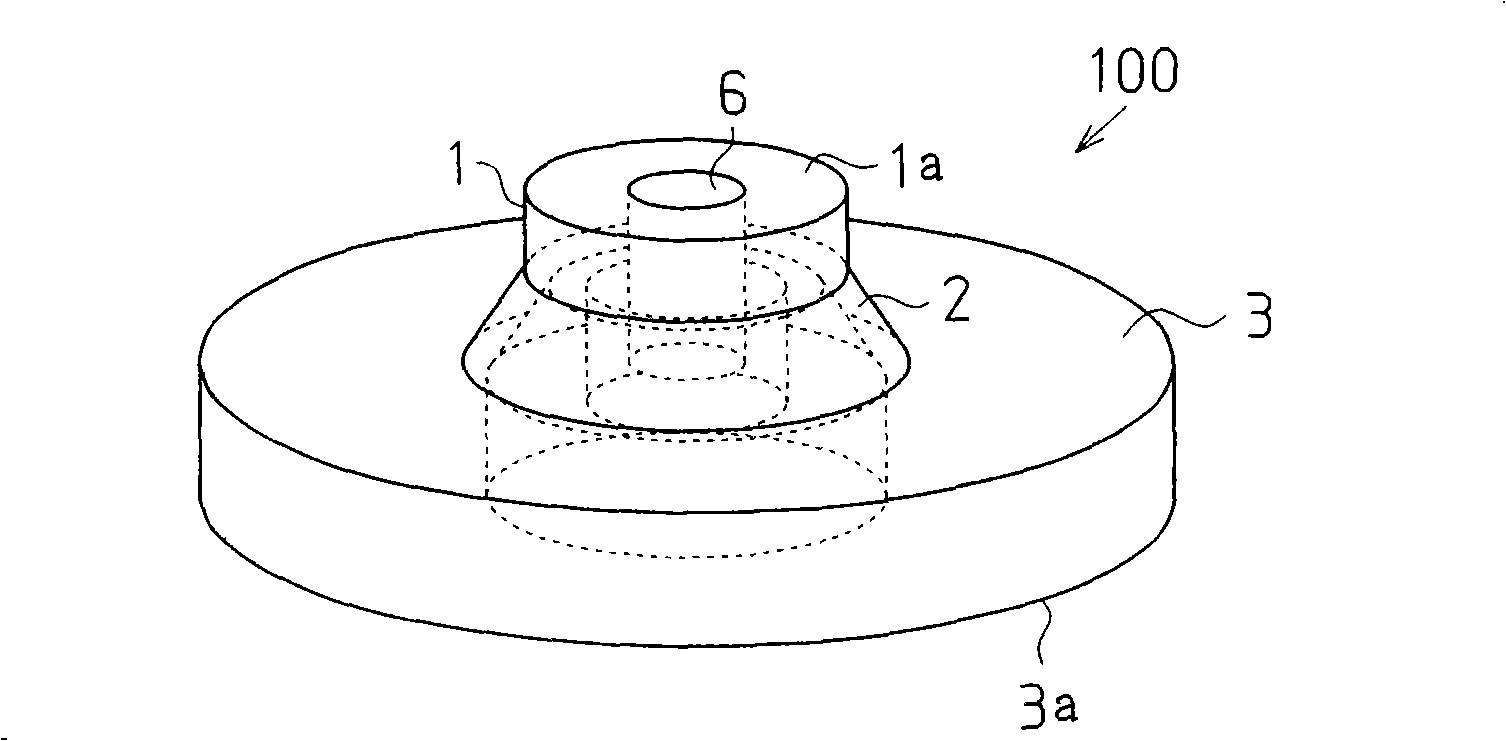

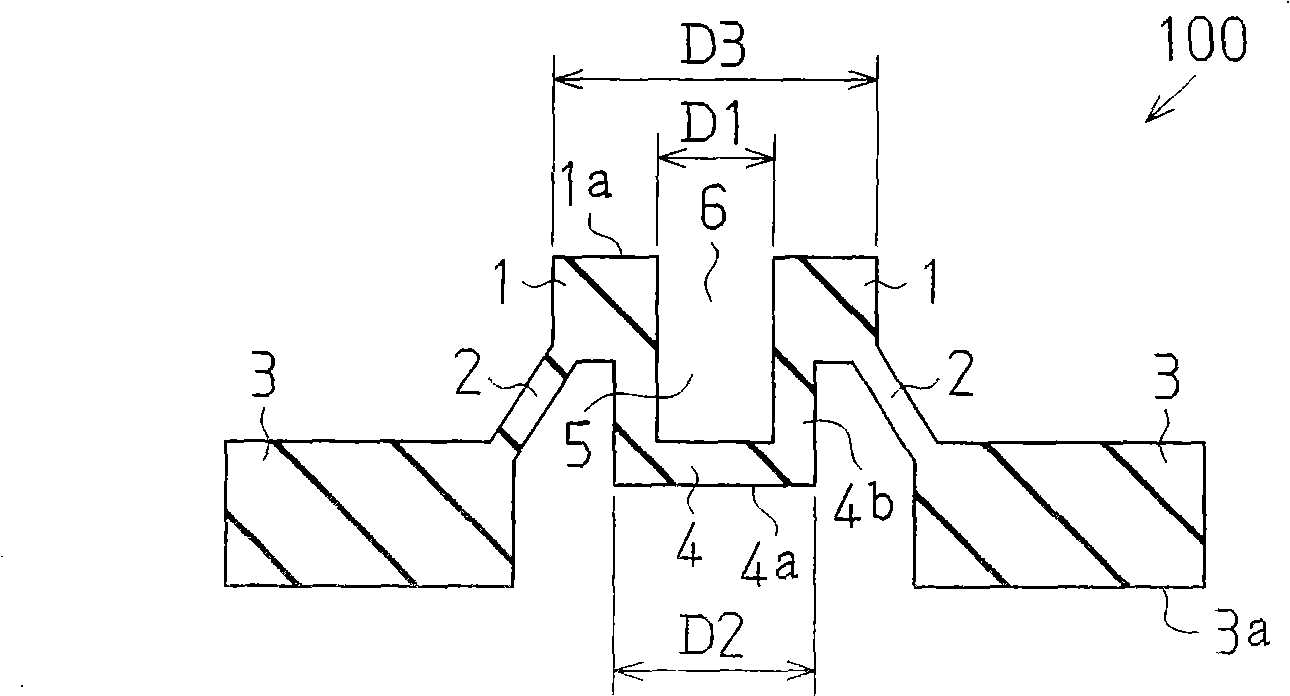

[0033] figure 2 and image 3 are a perspective view and a longitudinal sectional view respectively showing the elastic member 100 according to the first embodiment of the present invention.

[0034] The elastic member 100 has an annular flat base 3 , a thin connecting portion 2 extending obliquely upward from the inner circumference of the base 3 , and a substantially disk-shaped pressing portion 1 supported by the connecting portion 2 above the base 3 . According to this embodiment, if figure 2 As shown, the connecting portion 2 is shaped like an inverted funnel (truncated cone) and converges upwards. The pressing part 1 has a protrusion protruding downward from the lower surface of the pressing part 1 , that is, a push rod 4 . The lower surface 4 a of the push rod 4 is located above the lower surface 3 a of the base 3 . A hollow portion 5 is created inside the push rod 4 , and an opening portion 6 continuing from the hollow portion 5 of the push rod 4 is generated insi...

no. 2 example

[0047] Figure 7 is a perspective view showing an elastic member 200 according to a second embodiment of the present invention.

[0048] The elastic member 200 has a pair of prism-shaped bases 3 spaced apart from each other, thin-plate-shaped connecting parts 2 extending obliquely upward from opposite upper ends of the two bases 3 , and a rectangular plate supported by the connecting part 2 above the bases 3 shaped pressing part 1. The pressing part 1 has a substantially prismatic push rod 4 protruding downward from the lower surface of the pressing part 1 . The lower surface 4 a of the push rod 4 is located above the lower surface 3 a of the base 3 . A hollow portion 5 having openings on both sides of the push rod 4 is formed in the push rod 4 .

no. 3 example

[0050] Figure 8 is a perspective view showing an elastic member 300 according to a third embodiment of the present invention.

[0051] The elastic member 300 has the same structure as the elastic member 200 except that an opening 6 continuing from the hollow portion 5 of the push rod 4 is formed on the upper surface 1 a of the pressing portion 1 . The hollow part 5 of the push rod 4 and the opening part 6 of the pressing part 1 have the same side cross-sectional shape. Such as Figure 8 As shown, the opening 6 of the pressing part 1 and the hollow part 5 of the push rod 4 make the pressing part 1 and the push rod 4 form a U shape as a whole.

[0052] When the elastic member 200 or 300 is assembled in the structure of the button switch and used, when the pressing part 1 of the elastic member 200 or 300 is pressed, the connecting part 2 is elastically deformed and bent, so that the lower surface 4a of the push rod 4 is in contact with the The switching element (not shown) on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com