Method for grouting polymers for tunnel protection

A high polymer and tunnel technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve the effects of no disturbance in the lining, strong pertinence, and small additional loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

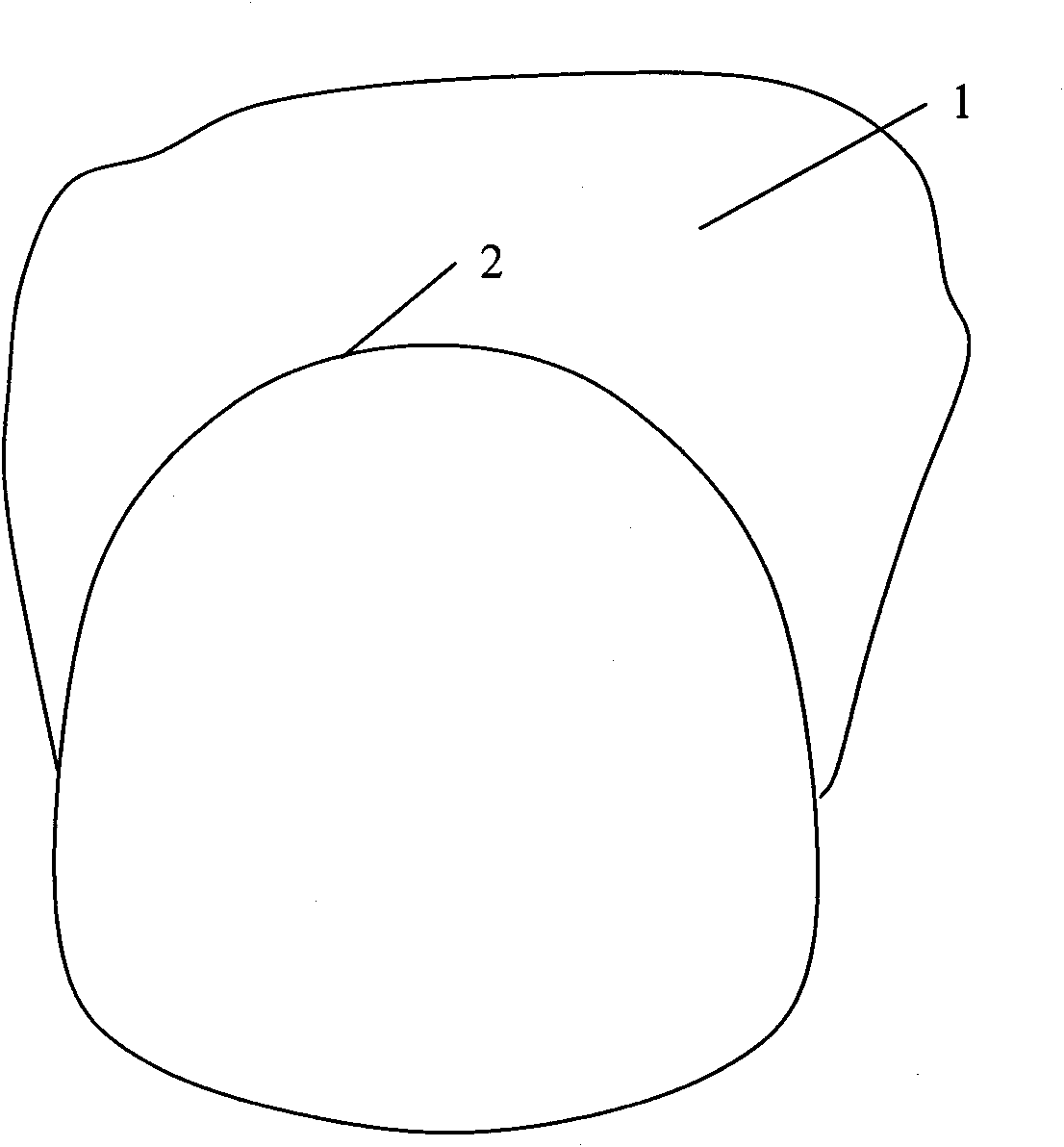

[0022] (1) According to the condition of the cavity 1 at the top of the tunnel and the condition of the tunnel lining structure 2, determine the tunnel section that needs protective treatment, such as figure 1 shown;

[0023] (2) Determine the thickness of the polymer buffer layer according to the size and height of the cavity 1 at the top of the tunnel, possible rockfall conditions, and the bearing capacity of the lining structure 2, such as figure 1 shown;

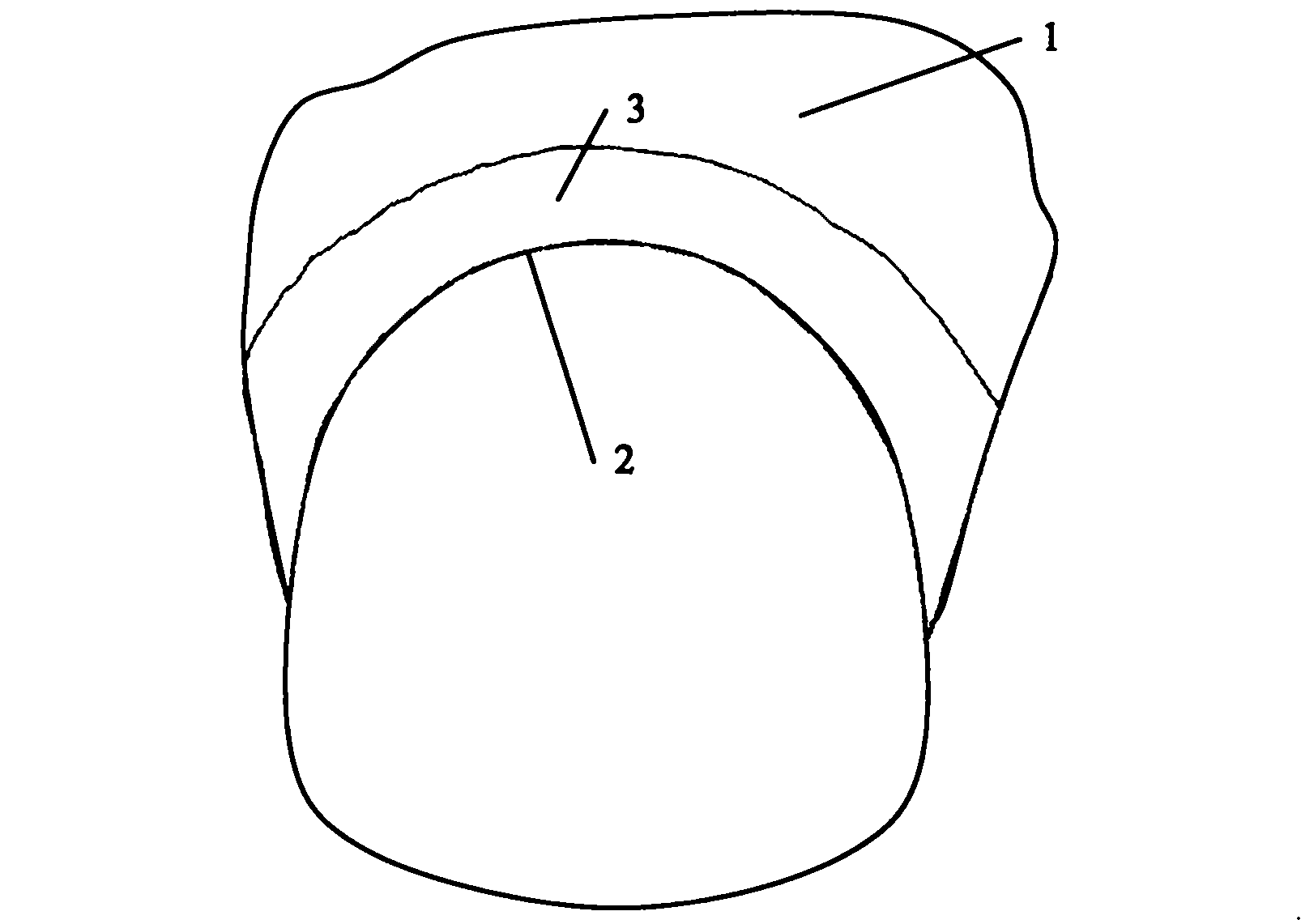

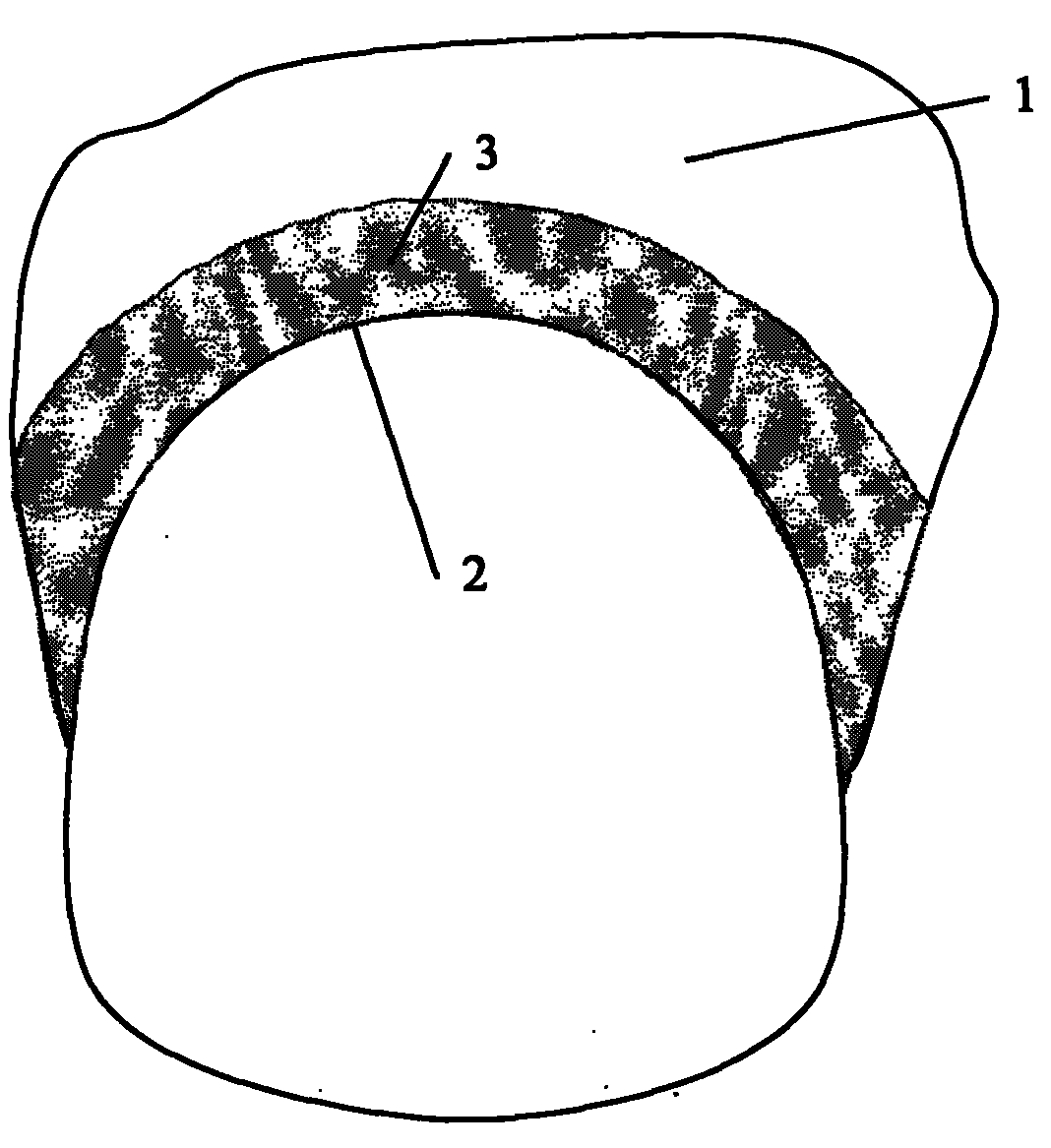

[0024] (3) Polymer grouting technology is used to directly inject high polymer material to the periphery of the lining structure 2 . The material expands rapidly after a chemical reaction to form a polymer buffer layer3, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com