An active low additional force pipeline effect protection method

An active, additional force technology, used in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the problems of high additional force anchoring structure, high cost, poor protection effect, and large uncertainty. , to control and eliminate the effect of pipe-running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

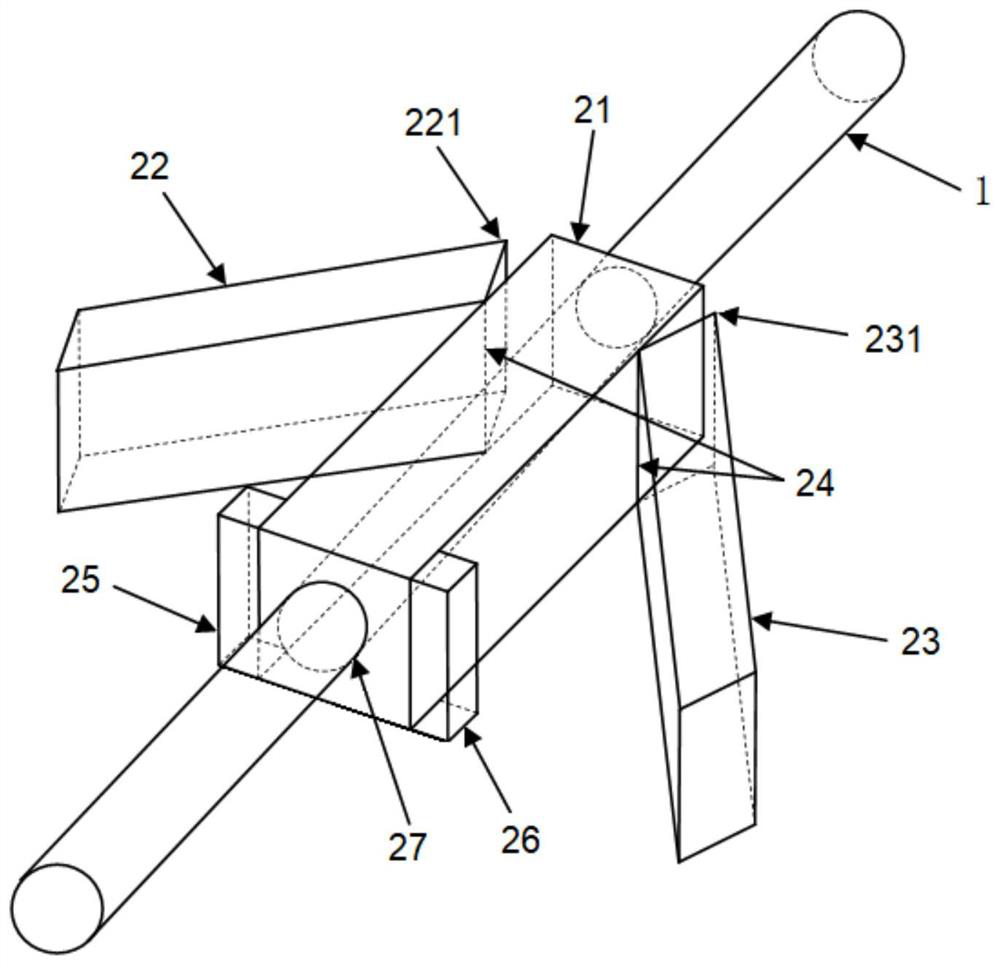

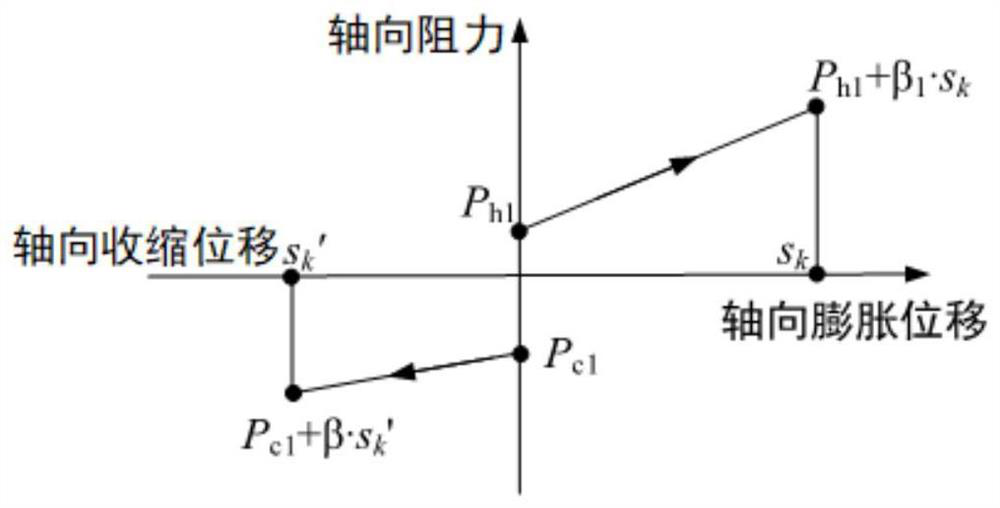

[0080] An engineering calculation example is used to show the implementation effect of the method of the present invention. It is laid on a certain submarine pipeline with an inclination angle of 5° and a length of 1km. The pipe running value is 0.56m, which is too large and seriously threatens the safety of the pipeline system. (2) According to the bearing capacity of the rest of the structure where the pipeline is located, the calculated maximum displacement of the pipeline must be less than 0.1m. (3) Based on the target value, the active low additional force pipeline effect protection method is used for control, and the variable resistance pipe end structure is installed at the end of the pipeline at the top of the slope to control the change curve of axial resistance with displacement Carry out the analysis of the control effect of the pipeline. After multiple adjustments, when the resistance growth coefficient at the end of the pipeline is 43kN / m, the axial pipe running ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com