Horizontally adjustable stiff support of lattice framed structure

A grid structure and support technology, which is applied to the arch structure, the structure of the dome, the building components, etc., can solve the problems such as the work performance needs to be improved, the theoretical calculation and the actual construction error, the rigidity deviation of the horizontal support and other problems can be solved. , to achieve the effect of improving stress performance, increasing ductility and elastic energy absorption, and improving stress performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

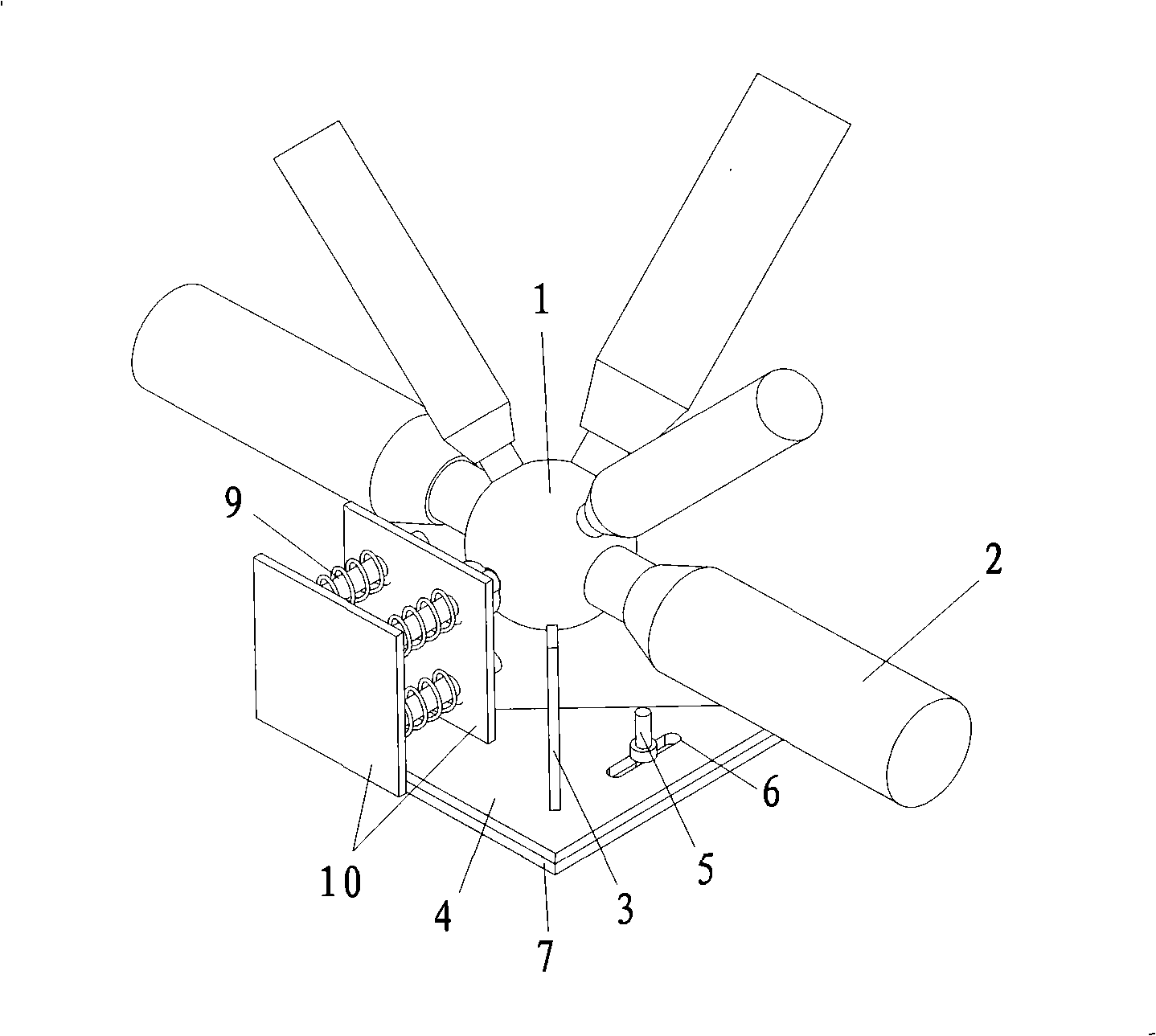

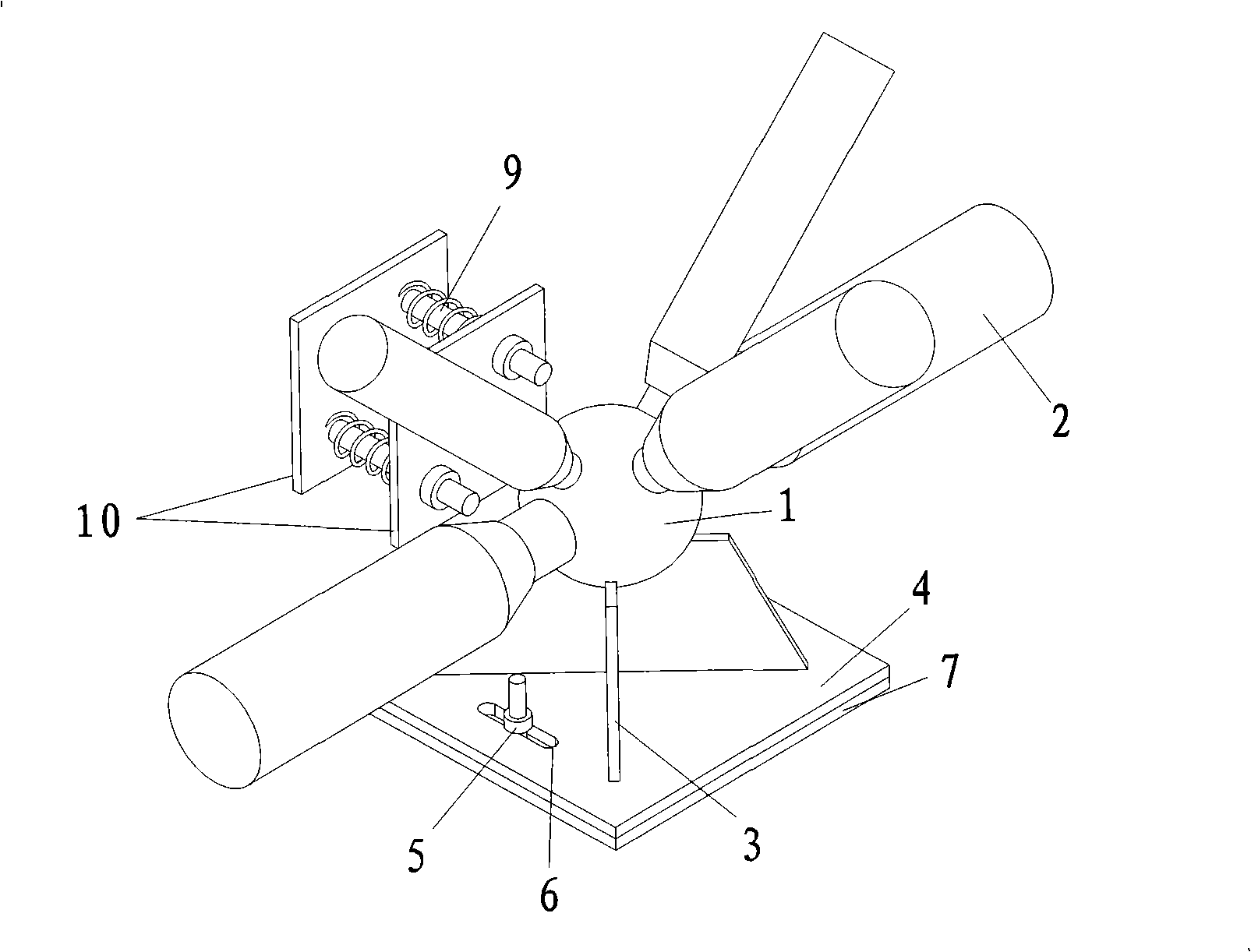

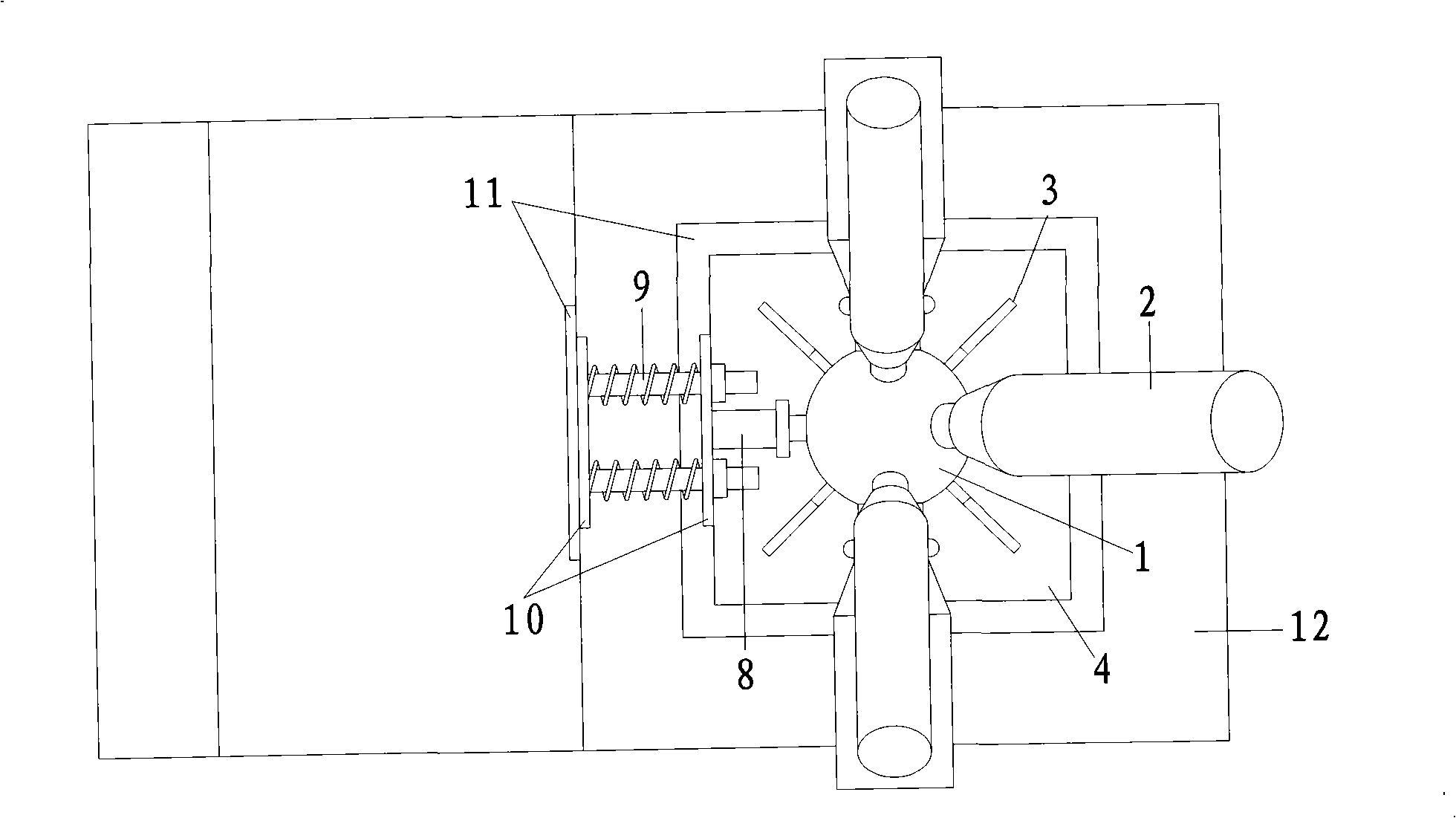

[0024] The horizontally adjustable stiffness support of the grid structure includes bearing ball joints 1, grid members 2, cross-shaped ribs 3, support bottom plates 4, anchor bolts 5, chute 6, slide plates 7, support steel pipes, and sealing plates and connecting bolts 8, pre-embedded steel plates 11, and substructure 12. The pre-embedded steel plates 11 are provided with steel plates 10, slide plates 7, and support base plates 4 in sequence. Cross-shaped ribs 3 and cross-shaped ribs are arranged on the support base 4. 3 is provided with a support ball joint 1, and a plurality of grid members 2 are provided on the support ball joint 1, and a support steel pipe, a sealing plate and a connecting bolt 8 are provided in the horizontal direction passing through the ball center of the support ball joint 1 , the other end of the support steel pipe, the sealing plate and the connecting bolt 8 is connected with the stiffness adjustment device, the stiffness adjustment device is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com