Maintenance platform for ship body

A maintenance platform and hull technology, applied in slipway, dry dock, ship parts, etc., can solve the problems of ship wreck, paint peeling, no fishing boat maintenance device, etc., to achieve high bearing capacity, stable side frame structure, safety and Stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

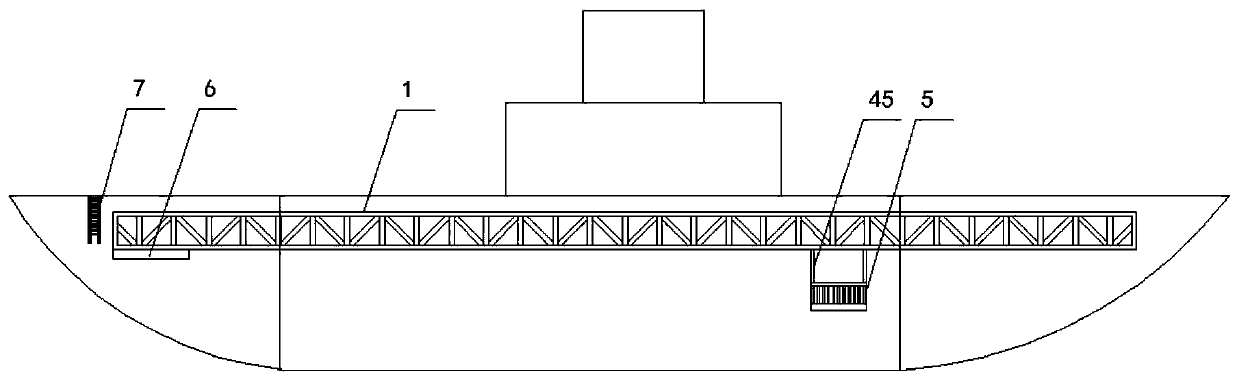

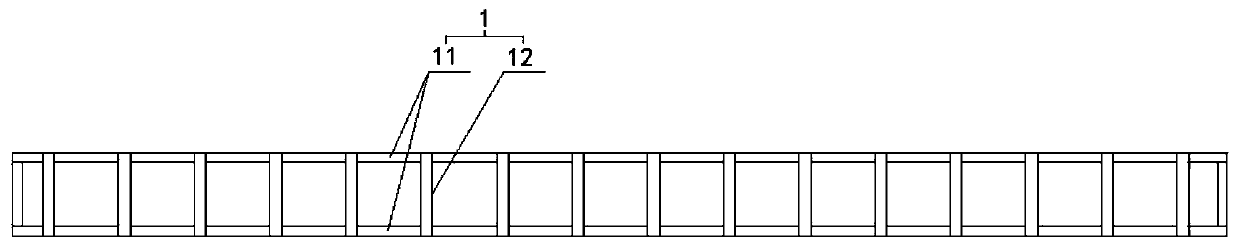

[0030] As shown in the figure, a maintenance platform for the hull is characterized in that it includes an n-shaped fixed frame fixed on the top of the side of the hull on one side; a pair of opposite sliding rails are fixed on both sides inside the fixed frame ;

[0031] One side of the sliding track is fixedly connected to the fixed frame, and the other side is provided with a sliding groove with a square cross section, and a sliding trolley is slidably connected to the sliding track, and the sliding trolley includes a square frame and at least two rollers , at least two driving motors, the driving motors are symmetrically fixed on both sides of the top of the square frame, the driving motors are connected to a roller respectively, and the bottom of the roller is fitted in the sliding groove of the sliding track Inside, the driving motor drives the rollers to roll inside the sliding groove to realize the sliding connection between the sliding trolley and the sliding track; ...

Embodiment 2

[0040] Compared with Embodiment 1, the present embodiment differs in that:

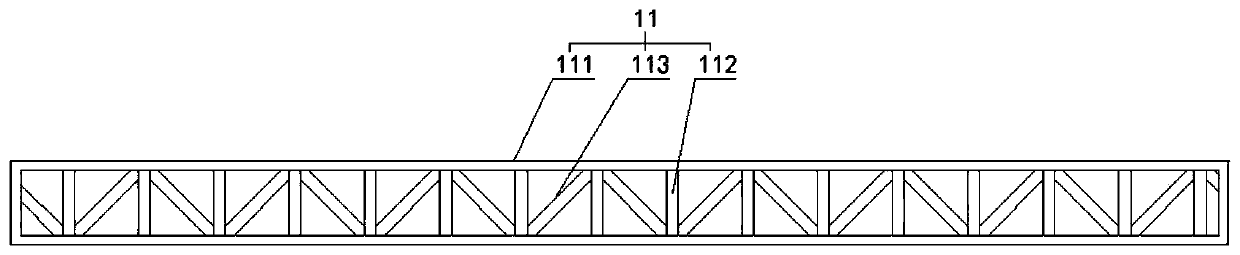

[0041] The side frame is an integrated structure, including a rectangular frame body, inside the rectangular frame body, several vertically arranged support columns and several horizontal reinforcement columns are uniformly distributed, and the horizontal reinforcement columns are horizontally arranged. Two transverse reinforcement columns are evenly distributed from top to bottom between adjacent support columns.

[0042] The winding device includes a winding motor, a winding driving roller and a winding driven roller; two steel cables on the winding driven roller are respectively fixedly arranged on both sides of the maintenance platform.

[0043] The use process of the present invention is as follows:

[0044] 1. The maintenance personnel enter the placement platform from the hanging ladder, open the switch door of the maintenance platform and enter the maintenance platform.

[0045] 2. When not in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com