Anti-floating system and construction method of sandbar sewage pipe, well

A technology for sewage pipes and sandbars, applied in infrastructure engineering, soil protection, protection devices, etc., can solve problems such as damage and leakage, and achieve the effect of stabilizing pipelines, increasing investment, and increasing fixed foundations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

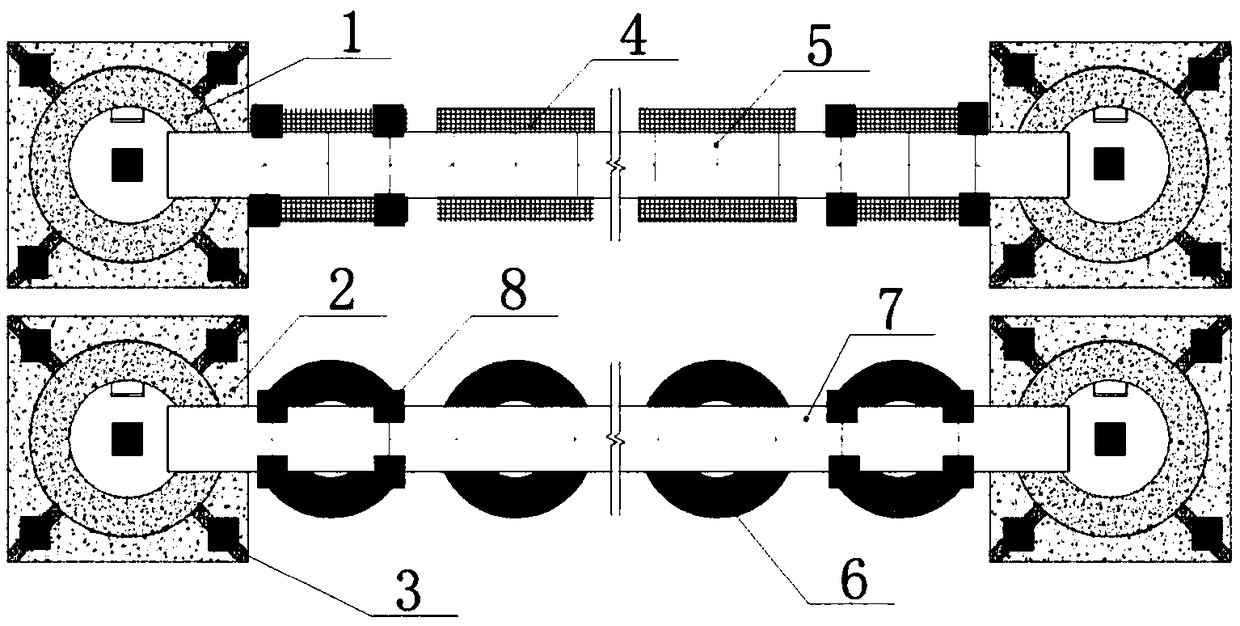

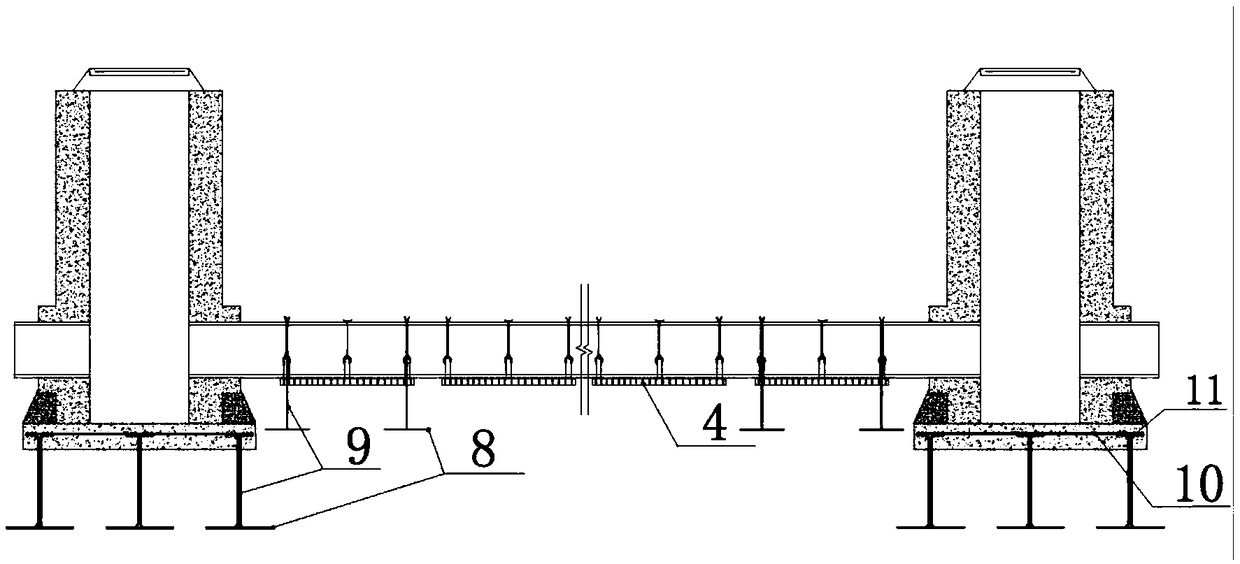

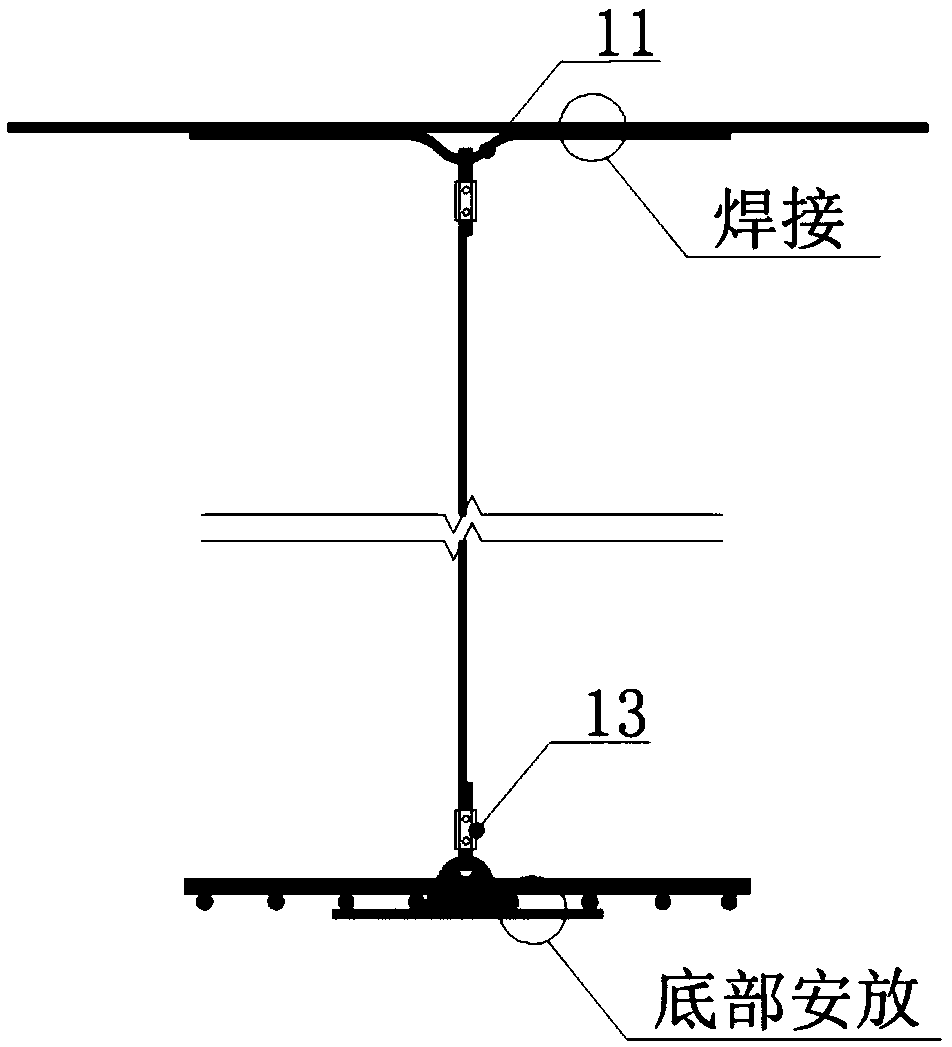

[0056] as attached Figures 1 to 11 Shown, a sandbar sewage pipe, well anti-floating system, including anti-floating plate, bundle wire 5, wire rib 12, steel mesh 8, U groove bar 11, steel plate buckle 14, staple 13, wire rope 9, The anti-floating plate is set at the bottom of the pipe and bound together with the pipe through the bundle wire. The wire ribs are inserted inside the wire bundle to increase the binding surface with the pipe. The steel mesh is set under the pipe and the sewage well, and the steel mesh 8 is welded with U groove bars 11 or steel plate buckles 14, and the U groove bars 11 are not only welded with the mesh surface of the steel mesh, but also bound or welded with the foundation steel bars 10 of the well floor; the steel plate buckles 14 are welded on the steel mesh 8 On or from the bottom of the steel mesh sheet 8;

[0057] The bottom slab foundation steel bars 10 are set on the well bottom slab foundation 2. There are two types of well bottom slab fou...

Embodiment 2

[0069] This embodiment provides a construction method for sandbar sewage pipes and well anti-floating systems. The specific steps are: a. supporting precipitation and trench excavation; b. making and placing steel mesh 8; c. binding drawing wire 9 and backfilling of wool and gravel layer 18; d, completion of surface treatment of wool and gravel layer 18; e, placement and fixing of anti-floating boards; f, laying of pipes and binding and fixing; g, binding and installation of drainage well steel bars; h, drawing wire rope 9 Bind the U groove bar 11, and bind or weld the U groove bar 11 and the foundation steel bar; i, formwork pouring of the drainage well; j, backfilling of the fine sand layer 20 of the pipeline; k, backfilling of the remaining soil layer of the pipeline; l, demoulding of the drainage well , Well wall 1 backfill soil backfill.

[0070] Specifically, the detailed steps of a sandbar sewage pipe and well anti-floating system construction method are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com