A breathable combined filling box formed by metal sheet

A technology of thin metal plates and filling boxes, which is applied to floors, building components, buildings, etc., can solve the problems of high buoyancy, high transportation costs, and low rigidity of filling materials, and achieve the effects of improved transportation efficiency, reduced volume, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is realized in the following manner:

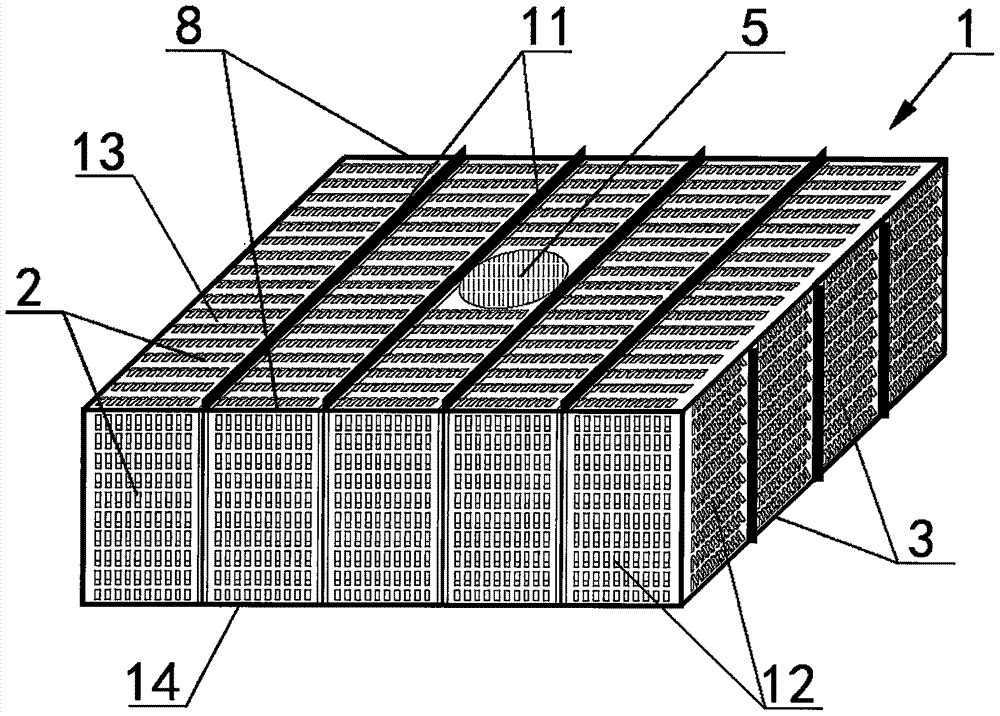

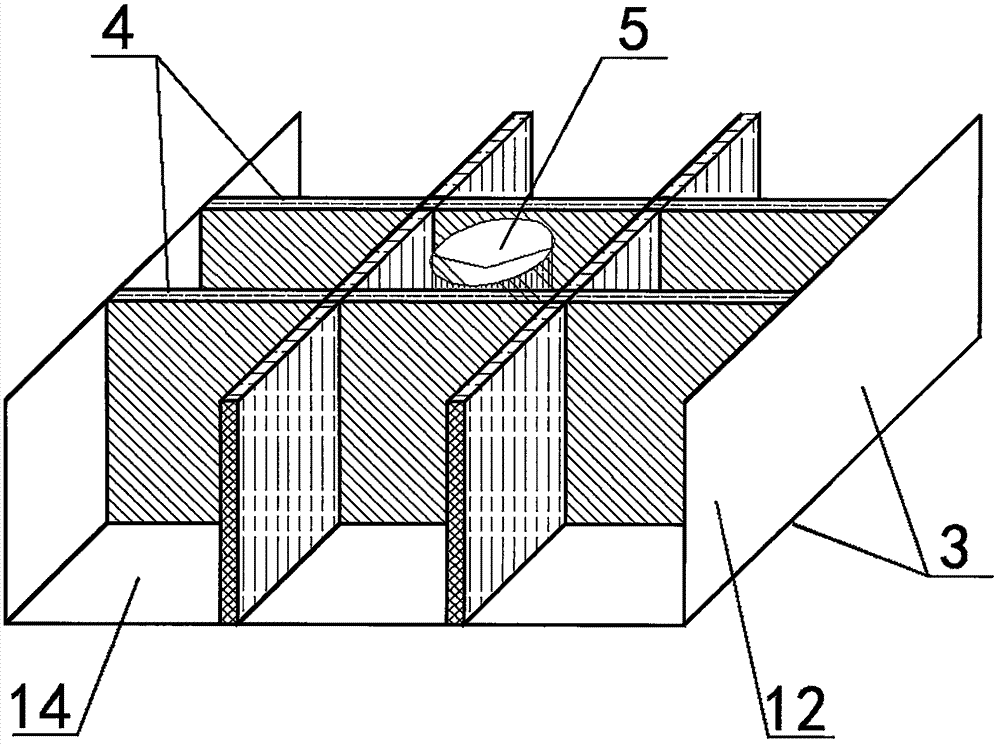

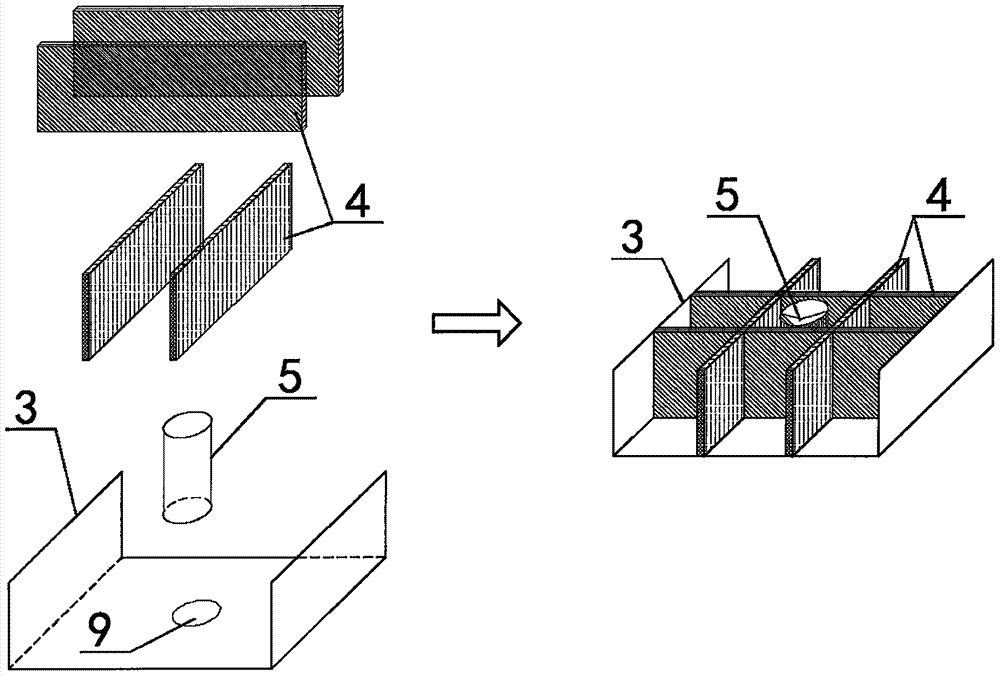

[0036] exist Figure 1-Figure 5 In the shown embodiment, a gas-permeable combined filling box formed by thin metal plates, the filling box (1) includes an upper assembly (2), a lower assembly (3), a stiffener (4), and a leakage cylinder (5) , forming a dense mesh (7) on a strip metal sheet (6) with a thickness of less than 1mm by die-cutting, there are 2 bending lines (8) on each sheet metal sheet, and 2 lines of bending lines (8) on the sheet metal sheet A slurry leakage hole (9) with a size ≥ 50 mm and ≤ 150 mm is opened between the bending lines and in the center of the width range of the metal sheet, and the two ends of the metal sheet are bent 90° in the same direction along the bending line to form a three-dimensional The U-shaped upper and lower components of the two-sided structure are installed in the upper and lower components with leaking tubes and at least 2 stiffeners in each direction. The posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com