Method of purifying molten steel in tundish by gas vortex and molten steel purification device

A purification device and tundish technology, applied in the field of tundish metallurgical process and its devices, can solve the problems of high electric energy, erosion, etc., and achieve the effects of enhancing efficiency, low equipment investment cost, and avoiding molten steel erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention are described in detail as follows:

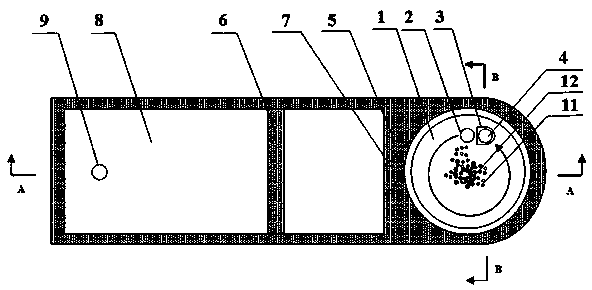

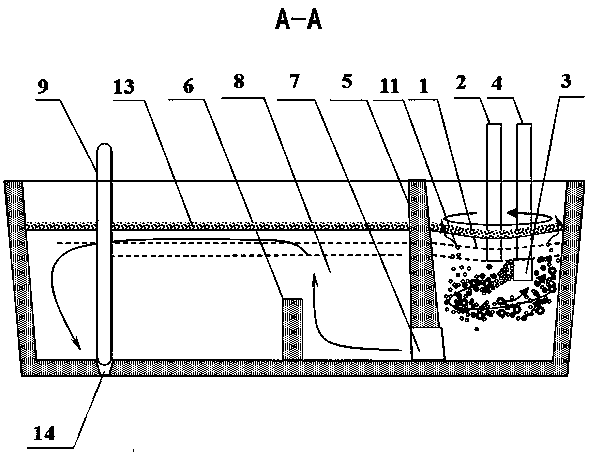

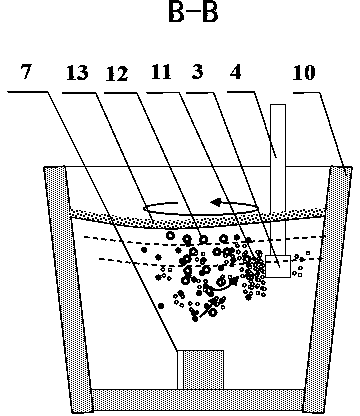

[0031] In this example, see Figure 1 ~ Figure 3, in the present embodiment, the molten steel purifying device of the method for purifying molten steel in the tundish by gas swirl flow, the space for accommodating molten steel in the tundish 10 is composed of the molten steel swirl chamber 1 and the molten steel distribution chamber 8, and the molten steel distribution chamber 8 There is a nozzle 14 at the bottom, and the molten steel in the molten steel distribution chamber 8 is injected into the casting container by controlling the opening of the nozzle 14. The molten steel swirl chamber 1 is in the shape of a truncated cone, and the inner diameter of the lower bottom of the molten steel swirl chamber 1 is 0.5 m, the inner diameter ratio of the upper and lower bottoms of the molten steel swirl chamber 1 is 1.2, the height of the molten steel swirl chamber 1 is 0.8m, the ladle nozzle 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com