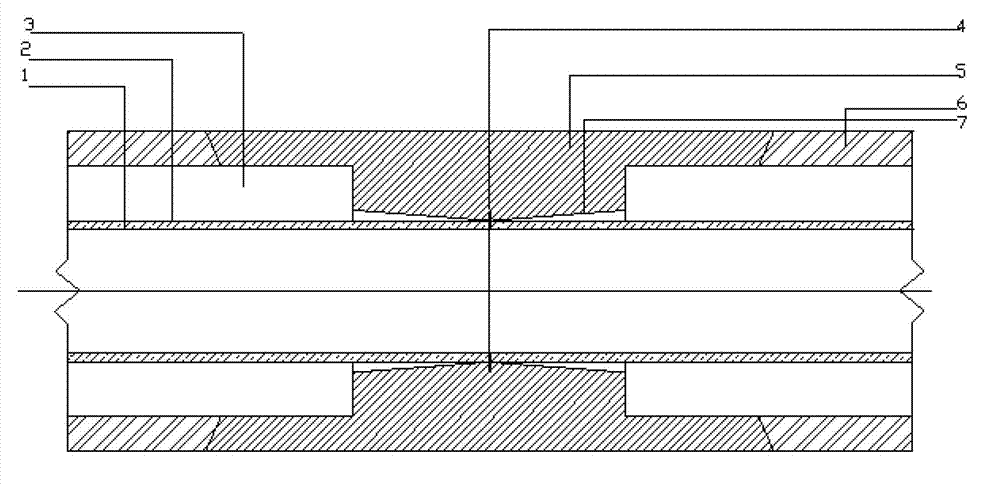

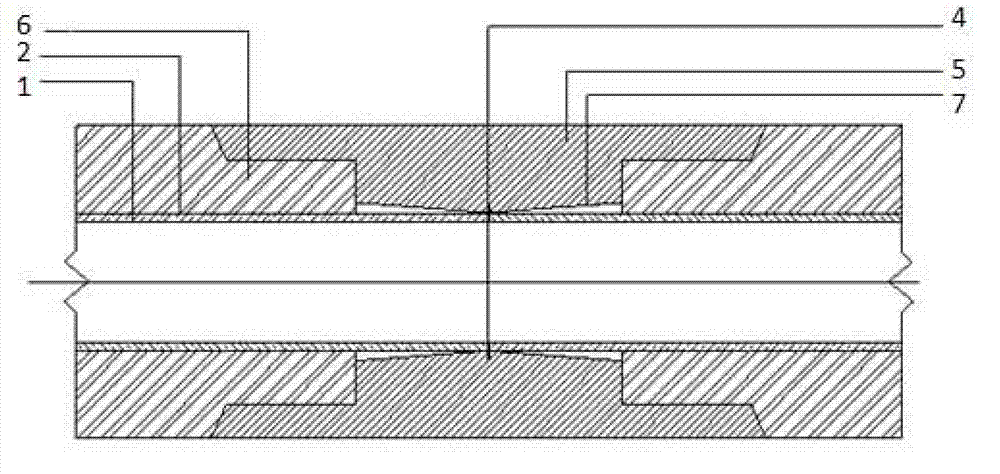

All-water perforated hard polyurethane foam for submarine pipeline joints

A technology of hard polyurethane and water boiling, applied in the field of polyurethane foam, can solve the problems of mastic anti-corrosion layer damage, low compressive strength, large raw material footprint, etc., to achieve shortened laying construction time, high compressive strength, The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of amido grafted polyether polyol, comprises the steps:

[0033] Use 15 parts of glycerin as the initiator, 15 parts of sucrose as the initiator, 10 parts of ethylene oxide, 70 parts of propylene oxide as the polymer monomer, and 0.7 parts of potassium hydroxide as the catalyst at 100 ° C and 0.4 MPa pressure Carry out ring opening and keep warm for 3 hours to obtain the basic polyether. On this basis, add 3 parts of amide-based monomer (N, N-dimethylacrylamide) and 0.2 parts of azobisisobutylcyanide as the initiator at 70 ° C And under the protection of nitrogen, it is formed by free radical grafting polymerization, and then undergoes neutralization and refining steps to obtain amido grafted polyether polyol.

Embodiment 2

[0035] A preparation method of full water open-cell rigid polyurethane foam, comprising the steps of:

[0036] Preparation of component A: Take 70 parts of amide-based grafted polyether polyols prepared in Example 1, 1 part of rigid polyether polyols with sorbitol as the initiator and a hydroxyl value between 400 and 600 mgKOH / g, 29 parts of rigid polyether polyol with a hydroxyl value of 250-500 mgKOH / g, 0.5 part of N, N-dimethylcyclohexylamine, N, N, N', N', N 0.1 part of ″-pentamethyldiethylenetriamine, 0.25 part of N,N-dimethylbenzylamine, and 0.2 part of water were added in order, and stirred for 30 minutes to make the system uniformly mixed to obtain component A;

[0037] After mixing component A and component B polymethylene polyphenyl polyisocyanate at 25°C in a weight ratio of A:B=1:1.10,

[0038] That is, the full water open-cell rigid polyurethane foam of the present invention is obtained.

[0039] Response performance: Milk white time 15s, gel time 65s

[0040] ...

Embodiment 3

[0042] A preparation method of full water open-cell rigid polyurethane foam, comprising the steps of:

[0043] Preparation of component A: Take 50 parts of the amido-grafted polyether polyol prepared in Example 1, 10 parts of rigid polyether polyol with sorbitol as the initiator and a hydroxyl value between 400 and 600 mgKOH / g, 40 parts of rigid polyether polyol with a hydroxyl value between 250 and 500 mgKOH / g, 0.5 part of N, N-dimethylcyclohexylamine, and 0.1 part of N, N-dimethylbenzylamine with propylene glycol as the initiator , 0.2 parts of water are added in order, and stirred for 30 minutes to make the system mix until uniform, and obtain component A;

[0044] After mixing component A and component B polymethylene polyphenyl polyisocyanate at 25°C in a weight ratio of A:B=1:1.20, the full water open-cell rigid polyurethane foam of the present invention can be obtained.

[0045] Response performance: milk white time 30s, gel time 100s.

[0046] Foam performance: free ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com