Novel diversion drainage structure of post-cast strip and construction method of novel diversion drainage structure of post-cast strip

A technology of drainage structure and post-casting belt, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve problems such as hidden safety hazards, changes in the elevation displacement of the independent foundation of the platform, and arching, etc., to eliminate buoyancy and avoid the bottom plate. Cracks, avoid the effect of arching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

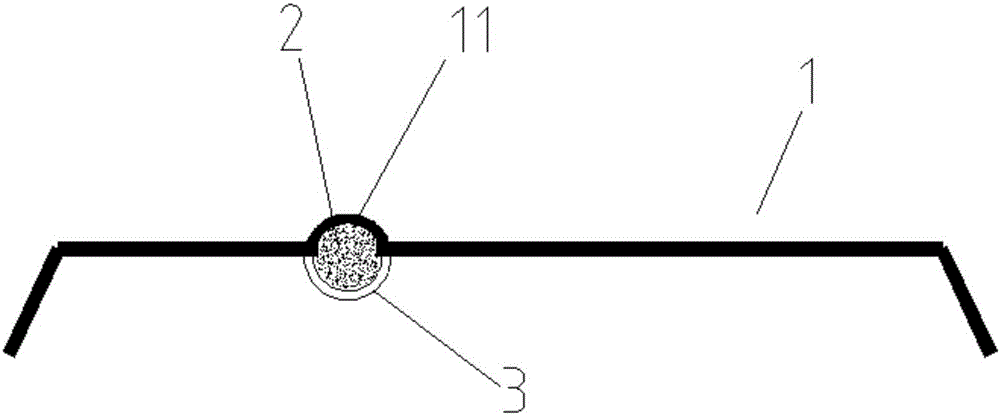

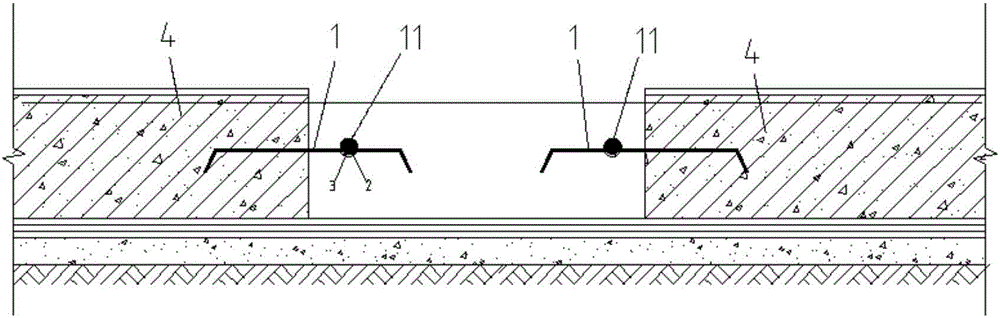

[0025] refer to figure 1 and figure 2 , this embodiment provides a new type of drainage and drainage structure for the post-casting belt, including the processed water-stop steel plate 1 and the belt-shaped medium sand 2 filled inside, the water-stop steel plates 1 are arranged side by side in sequence, and the main body of the water-stop steel plate 1 is set on the bottom plate In the main structure 4, the space of "Ω" arc-shaped groove 11 is filled with belt-shaped medium sand 2 wrapped by geotextiles, and the outer surface of the bagged geotextiles is coated with cement slurry, while ensuring the porosity of the joints, When pouring concrete, ensure that no large amount of cement slurry enters the joints and blocks the joints. And fix the back cover by spot welding with fast and easy closing net 3 every 500mm with water-stop steel plate 1, and process two water-stop steel plates 1 in parallel and sequentially butt.

[0026] The construction method of the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com